Fiber-forward launches in 2026 are less about simply “adding fiber” and more about building a repeatable supply spec that survives scale-up. Procurement teams are being asked to move faster—yet still prove documentation depth, traceability, and consistent performance across applications. This case-style walkthrough shows how one global brand translated a fiber-first brief into purchase-ready specifications, then narrowed a long list of candidates to a dependable resistant dextrin supplier China could support long-term—while also defining where microcrystalline cellulose belonged in the portfolio and how to evaluate a microcrystalline cellulose supplier China buyers could trust.

From Fiber Trend to Sourcing Reality

Consumer demand is pushing fiber from a niche claim to a mainstream expectation—especially in convenient formats like gummies, powders, and ready-to-mix drinks. For buyers, that shift changes the job: instead of sourcing “a fiber,” teams must source repeatable functionality.

In practice, many projects now specify two ingredients:

- Resistant dextrin for soluble fiber delivery in beverages, powders, and many confectionery systems.

- Microcrystalline cellulose (MCC) for structure, flow, and mechanical strength in tablets, chewables, and certain confectionery architectures.

That dual-ingredient approach helps teams hit label goals without sacrificing manufacturability. It also means supplier qualification can’t be generic. A short questionnaire is not enough when your label promise depends on batch-to-batch consistency.

Case Brief: A Fiber-First Launch with Low Sugar Constraints

A Western brand planned a 2026 launch across two SKUs:

- Low-sugar gummies positioned around gut comfort and daily wellness.

- Drink powder sticks designed for quick mixing and neutral taste.

The non-negotiables were typical of today’s briefs:

- 8–10 g dietary fiber per serving without a gritty mouthfeel.

- Minimal sweetness “spikes”, stable sensory performance, and clean labeling.

- A supplier set that could withstand retailer and internal QA scrutiny.

Early formulation trials revealed predictable pain points. Gummies suffered from texture drift when fiber type or moisture varied. Drink powders that mixed well in the lab clumped at scale. Furthermore, the compliance loop stalled when QA asked for more than a basic COA—especially around identity, microbiology, and raw material statements.

At this stage, the team realized the brief was not only a formulation challenge. It was also a supplier selection challenge.

Ingredient Roles: Why Resistant Dextrin and MCC Solve Different Problems

Resistant Dextrin for Soluble Fiber Without Heavy Viscosity

For the beverage and powder SKU, resistant dextrin was selected because it behaves like a formulation “team player”: it is generally mild in taste, easy to incorporate, and suitable for building fiber content without turning a drink into a gel.

In supplier discussions, the brand treated the following as baseline expectations for resistant dextrin:

- Corn-starch origin

- White to light yellow appearance

- Fiber content ≥82%

- Protein content ≤6.0%

- Controlled storage and moisture management practices

These targets are commonly presented on technical pages from experienced producers of resistant dextrin. As an example of typical specification framing, buyers can review how a verified producer presents resistant dextrin basics and applications on a category page such as resistant dextrin supplier.

Just as importantly, the team put “paperwork readiness” on the scorecard early. For a US-facing project, the brand’s compliance lead explicitly asked for a supplier that understood resistant dextrin GRAS FDA compliance expectations in practice—meaning traceable inputs and documentation discipline, not vague marketing claims.

MCC for Structure and Process Control

MCC was not used to “add fiber” in this project. It was evaluated for the situations where physical performance matters more than nutritional contribution:

- Improving tablet integrity and compressibility in supplement line extensions.

- Acting as a flow aid and structure builder in certain dry blends.

Because MCC is often used in regulated dosage forms, MCC pharma compliance expectations were treated separately from food-grade fiber sourcing. The team’s key learning was simple: a microcrystalline cellulose supplier China that is strong in pharma documentation may not be the same partner who excels in functional fiber for foods.

Turning Consumer Claims into Purchase-Ready Specs

The brand used a “claims-to-spec” worksheet to prevent late-stage reformulation. The worksheet forced every team—R&D, QA, procurement—to agree on what must be true before scale.

For resistant dextrin in particular, procurement requested three layers of evidence:

- Specification targets (fiber %, protein, appearance) and a matching COA format.

- Manufacturing controls that reduce variability (automation, controlled feeding to filling, and defined packaging steps).

- Application fit proven through samples in the brand’s own gummy and powder processes.

The team also avoided a common mistake: over-specifying early. Instead of demanding exotic analytics from day one, they started with essentials that actually predict manufacturing outcomes (fiber %, moisture discipline, microbiology, and lot traceability) and tightened requirements after pilot trials.

Working with Chinese Suppliers: How the Long List Became Two Qualified Partners

China remains an important sourcing base for both fibers and excipients, but the brand did not treat “China” as a single risk bucket. They used two filters: Regional capability clusters (where industrial concentration supports stable supply) and Plant maturity signals (automation level, QC lab capability, and responsiveness).

The Stepwise Qualification Path

The process was deliberately staged:

- RFI and documentation screen: COA template, allergen/dietary statements, and basic traceability.

- Sample evaluation: gummy texture stability, powder flow and mixing, sensory neutrality.

- Pilot run: at least one pilot with packaging similar to commercial format.

- Remote or on-site audit: focused on the items that actually cause batch variation.

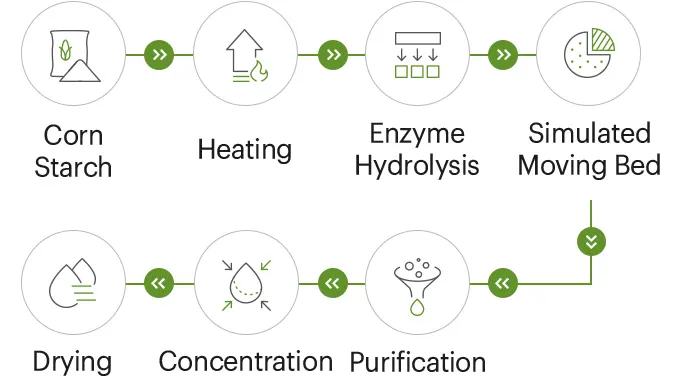

For resistant dextrin, one supplier candidate stood out because it could explain its production controls clearly: non-GMO corn-based inputs, use of imported enzymes, automated central control from feeding through filling, and in-house testing. These traits are frequently associated with mature operations and are also reflected in how established suppliers describe their resistant dextrin manufacturing approach across applications like soluble corn fiber.

Audit Focus Areas That Prevented Surprises

Rather than auditing everything, the brand concentrated on what predicts scale reliability:

- Raw material controls: how incoming corn starch is qualified and released.

- Automation and process stability: where human handling is minimized.

- QC testing discipline: how deviations are handled and documented.

- Packaging and labeling controls: lot traceability, seal integrity, and storage guidance.

This approach helped the team de-risk the relationship without slowing the project to a crawl.

Implementation Results: What Changed After Qualification

Once resistant dextrin specifications and supplier controls were aligned, two practical outcomes followed.

Product Outcomes

- Gummies achieved the targeted fiber claim with more stable chew across trial batches.

- Drink powder sticks mixed more consistently, reducing rework tied to clumping.

Supply Outcomes

- Procurement negotiated clearer lead-time expectations because quality and packaging requirements were already standardized.

- A second-source plan was drafted for both resistant dextrin and MCC, reducing exposure to single-point disruptions.

Most importantly, the compliance team stopped being a late-stage blocker. When suppliers could consistently provide complete documentation sets, regulatory review became routine rather than urgent.

A Buyer Checklist for Resistant Dextrin and MCC Sourcing in China

Use this list as a practical starting point when qualifying a resistant dextrin supplier China teams plan to scale with, and when shortlisting a microcrystalline cellulose supplier China for pharma or supplement programs:

- Lock the application first (gummies, RTD, powder, tablets) before comparing suppliers.

- Require a COA that clearly shows fiber content targets for resistant dextrin (commonly ≥82%) and matches your internal spec fields.

- Confirm raw material statements (e.g., corn-starch origin, non-GMO statement where applicable).

- Ask about variability controls: Look for automation and central control from feeding to filling.

- Verify safety data: Ensure the supplier can provide microbiology and basic safety data consistently, batch by batch.

- Clarify Pharma standards: For MCC, confirm which pharmacopeia expectations apply to your market and align documents accordingly.

- Run a pilot: Execute at least one pilot using production-like packaging and logistics time.

- Document packaging: Include storage conditions in the purchase spec to prevent warehouse-driven failures.

- Evaluate responsiveness: Slow, unclear answers during sampling often become slower at scale.

- Maintain a second source: Essential for both ingredients once the SKU becomes a core product.

For buyers who want to benchmark what a complete resistant dextrin specification and application set can look like, the resistant dextrin category pages at www.sdshinehealth.com provide a helpful reference point—especially for teams building internal spec templates.

Closing Note for 2026 Sourcing Decisions

In 2026, the winners in fiber-forward products won’t be the teams that “find a cheap fiber.” They’ll be the teams that translate a consumer promise into a supplier-ready specification, then qualify manufacturing reality—not just sales claims.

Treat resistant dextrin and microcrystalline cellulose as complementary tools, not substitutes. Source each with the right checklist, the right documents, and the right pilot discipline, and China can remain a reliable supply base—whether you are evaluating a resistant dextrin supplier China buyers trust for foods or a microcrystalline cellulose supplier China partner for regulated dosage forms.