Fiber has evolved from a label luxury to a formulation necessity. By 2026, industry forecasts suggest that many product briefs will begin with fiber targets first, subsequently working backward into sweetness profiles, mouthfeel, process conditions, and packaging stability. For procurement teams, this shift creates a practical challenge: while finding a resistant dextrin supplier China offers is straightforward, translating marketing language like "gut health," "weight management," and "clean taste" into measurable specifications that a manufacturing plant can consistently meet is far more complex.

This guide bridges that gap by outlining three repeatable, buyer-ready case patterns. Each pattern demonstrates how resistant dextrin and microcrystalline cellulose (MCC) integrate into real-world products, identifying exactly what to request on a Certificate of Analysis (COA), and how buyers can effectively compare offers from a soluble dietary fiber manufacturer China or a pharma grade MCC supplier China without necessitating costly reformulation later.

From Fiber Headlines to Plant-Floor Decisions

Many 2026 product briefs reflect identical consumer expectations: the combination of fiber + protein, significant sugar reduction, and daily-use formats that feel "normal," such as RTD drinks, gummies, and tablets. The operational reality, however, is that increasing fiber content impacts far more than just the nutrition panel. It can fundamentally alter viscosity, sweetness perception, water activity, and even tablet compression dynamics.

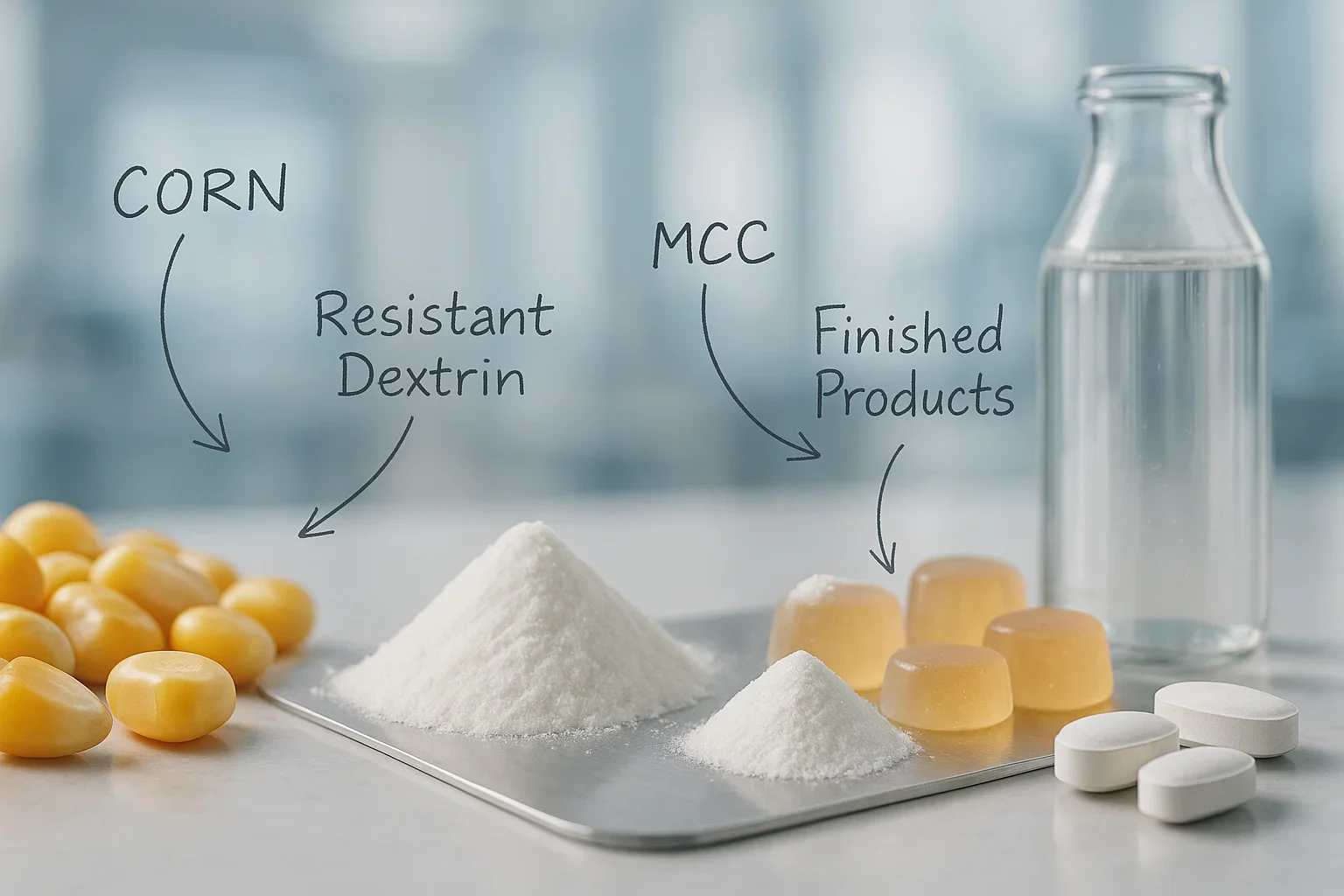

Two ingredients appear repeatedly in these forward-looking briefs:

- Resistant dextrin (a soluble dietary fiber) for low-calorie fiber build, neutral taste, and exceptional process stability.

- Microcrystalline cellulose (MCC) for tablet robustness—ensuring flow, compressibility, and consistent disintegration.

For professional buyers, the advantage of utilizing these two tools together is clarity: you can specify exactly what each ingredient must achieve, then shortlist a resistant dextrin supplier China can support and a Chinese microcrystalline cellulose supplier that matches your solid-dose requirements.

What Resistant Dextrin Must Deliver in Modern Formulations

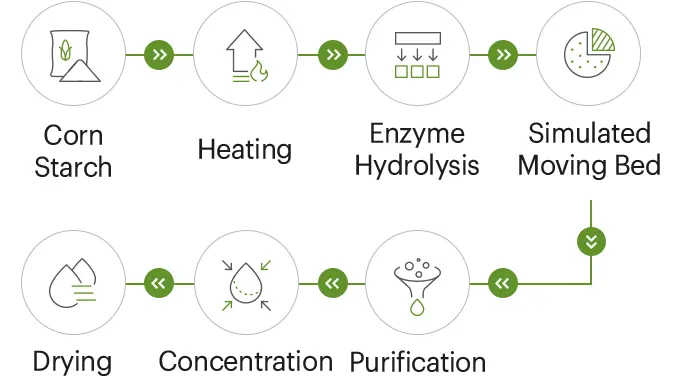

Most procurement officers prioritize resistant dextrin because it is straightforward to formulate and relatively easy to document. As typically shown in supplier specification layouts, resistant dextrin is positioned with specific technical parameters that define its quality:

- Fiber content: Commonly specified at ≥82% to ensure label claim validity.

- Raw material source: Often non-GMO corn starch, though tapioca-based options are increasingly sought after for specific markets.

- Sensory profile: Neutral taste and minimal color impact are non-negotiable.

- Processing tolerance: Stability under heat and across a broad pH range is essential, making resistant dextrin compatible with beverages, baked goods, and supplements.

If a brief begins with the requirement for a "soluble fiber that doesn’t fight the product," resistant dextrin is usually the practical baseline. For context on category-level specs and formats, referencing a supplier-side overview of dietary fiber and the product family page for resistant dextrin can provide a solid benchmarking foundation.

When a tender includes organic requirements, buyers often request a clear specification layout similar to what is published for organic resistant tapioca dextrin.

Quick Comparison for Shortlisting

The table below is not about determining "better vs. worse." Rather, it is about aligning your procurement brief with the source format you are likely to encounter when working with a soluble dietary fiber resistant dextrin manufacturer.

| Resistant dextrin format | Typical sourcing signal | Where buyers see it fit best |

|---|---|---|

| Corn-based resistant dextrin | Broad availability; common non-GMO declarations | RTD drinks, powders, gummies, baked goods |

| Tapioca-based resistant dextrin | Often shortlisted for specific label preferences | Gummies/chews, diet powders, cleaner flavor systems |

| Organic resistant tapioca dextrin | Documentation-driven brief (organic program, traceability) | Premium nutrition powders, "organic" positioned products |

Case Pattern 1: Low Calorie RTD Beverage with Resistant Dextrin

The Target Brief Buyers Actually Write

A beverage brief becomes actionable only when it includes measurable targets. Vague requests lead to vague samples. Effective briefs specify:

- Claim direction: "High fiber" or "source of fiber" positioning (as allowed by your local market regulations).

- Sensory: Clean taste, low grit, and low aftertaste.

- Process: Compatibility with hot-fill or UHT; stable clarity and viscosity over the entire shelf life.

- Nutrition: Sugar reduction and low-calorie positioning.

In practice, formulators commonly start resistant dextrin at low single-digit percentages in RTD systems and adjust based on fiber-per-serving targets and mouthfeel. What matters for procurement is not the exact recipe—it is whether the resistant dextrin behaves predictably at your specific pH, temperature, and fill method.

What to Request on the COA for Beverages

When evaluating what a *resistant dextrin supplier China* can provide, beverage buyers typically prioritize specific data points:

- Fiber content (e.g., ≥82%) for claim consistency.

- Solubility / clarity notes, especially critical for clear drinks.

- Microbiology limits aligned with strict beverage QA requirements.

- Appearance (white to light yellow) for color-sensitive SKUs.

- Storage conditions and shelf-life statements for warehousing planning.

A useful habit for buyers is to ask the supplier to confirm the resistant dextrin performance window for your specific process (hot fill vs. UHT) and the final product pH range. That single email exchange often prevents weeks of reformulation.

Sourcing Note for China-Focused Procurement

Many beverage teams shortlist producers in established ingredient hubs (such as Shandong) because they can typically support:

- Scale for bulk shipments.

- Documented QC routines.

- Consistent batch-to-batch COAs.

As a reference point for how beverage-oriented spec pages are presented, reviewing content like "high dietary fiber in drinks" under the resistant dextrin category on sdshinehealth.com can be helpful.

Case Pattern 2: Confectionery or Snack Matrix Using Resistant Dextrin

Confectionery is where resistant dextrin becomes less about "soluble fiber" and more about process control: managing crystallization, chewiness, and water activity while simultaneously adding fiber.

Two Common Confectionery Briefs

1) Fiber-Forward Gummies/Chews

- Raise fiber content while maintaining a familiar chew.

- Avoid gritty texture and keep sweetness balanced.

- Control water activity to protect shelf life.

2) Snack Bars and Baked Formats

- Replace a portion of syrups or sugars.

- Maintain softness without sticky handling issues.

- Manage browning in baked systems.

In both scenarios, buyers lean on resistant dextrin because it is neutral and stable. The critical procurement question becomes: can the resistant dextrin supplier provide the same sensory and hydration behavior batch after batch?

Short Table Buyers Use for Confectionery Selection

| What your confectionery team cares about | What to confirm with the resistant dextrin supplier | Why it matters |

|---|---|---|

| Texture and chew | Typical behavior in gummy or chew systems | Predictable bite across batches |

| Water activity risk | Recommended handling and storage guidance | Shelf-life protection |

| Sweetness perception | Neutral taste confirmation | Avoid "fiber taste" masking costs |

| Processing tolerance | Heat stability and pH tolerance | Fewer surprises during cook and deposit |

For a supplier-side example of how confectionery applications are described, the confectionery-oriented resistant dextrin page at Shine Health provides relevant context.

Case Pattern 3: Tablets Where MCC and Resistant Dextrin Coexist

In the supplements sector, buyers often treat MCC and resistant dextrin as separate purchasing conversations—until the same SKU needs both tablet performance and a label-friendly fiber story.

Where Microcrystalline Cellulose Still Anchors the System

A Chinese microcrystalline cellulose supplier is usually evaluated on how MCC performs as an excipient:

- Flow for consistent die fill.

- Compressibility for robust hardness without capping.

- Disintegration behavior for consistent performance.

In a fiber-positioned tablet, formulators may incorporate resistant dextrin alongside MCC to support fiber content expectations. The key is role clarity:

- MCC stabilizes the tablet build.

- Resistant dextrin contributes soluble fiber positioning.

Buyer-Facing Comparison Table for MCC Roles

| Application | What MCC is expected to do | MCC specs buyers often watch |

|---|---|---|

| Tablets (supplements/pharma-style solids) | Binder/filler supporting compression and flow | Particle size distribution, moisture, microbiology |

| Food powders (secondary use cases) | Texture support and stabilization | Grade consistency and dispersibility notes |

For a deeper orientation on how buyers discuss MCC grade selection and QC checkpoints, resources such as MCC grades and QC guidance are valuable.

Turning These Case Patterns into Supplier Briefs in China

The most efficient way to qualify a resistant dextrin supplier China offers—and to select a pharma grade MCC supplier China can support—is to convert each case pattern into a one-page brief.

A One-Page Brief Template Buyers Reuse

Include the same structure for every Request for Quotation (RFQ):

- End format: RTD, gummy/chew, tablet.

- Process conditions: Temperature, pH, shear, hot-fill/UHT (if applicable).

- Performance targets: Clarity/viscosity (beverages), chew/water activity (confectionery), hardness/disintegration (tablets).

- Quality targets: Fiber content (for resistant dextrin), microbiology, appearance, storage conditions.

- Documentation list: Non-GMO statement if required, batch COA format, traceability statement.

This keeps supplier responses comparable—especially when you are evaluating multiple Chinese functional fiber manufacturers and more than one Chinese microcrystalline cellulose supplier.

What Buyers Typically Expect from Documentation

Without overcomplicating it, China sourcing tends to run smoother when you request the documents that match your category:

- For resistant dextrin used in foods: COA with fiber content and basic quality indicators.

- For microcrystalline cellulose in tablets: Grade clarity, compendial alignment (where required by your market), and particle size/moisture consistency.

If your procurement includes a strict non-GMO requirement, it helps to compare supplier layouts against an example such as non-GMO resistant dextrin.

Closing Notes for Buyers Building a Recommended Supplier Shortlist

A "recommended" supplier list is rarely built from marketing claims. It is built from repeatable briefs and repeatable outcomes.

If you are qualifying a resistant dextrin supplier China for beverages, insist on beverage-relevant COA items and confirm performance under your pH and heat conditions. If you are evaluating a Chinese microcrystalline cellulose supplier for tablets, treat particle size and moisture control as non-negotiable, then benchmark MCC behavior in compression. When an SKU needs both, define roles clearly: MCC for tablet integrity, resistant dextrin for soluble fiber positioning.

For buyers who want to compare specification layouts before launching RFQs, the product category pages on www.sdshinehealth.com provide practical examples of how resistant dextrin and related dietary fiber formats are typically documented.