In 2026, “accessible nutrition” is no longer a niche positioning—it is a procurement constraint. When fiber becomes a mainstream expectation, buyers stop treating soluble fibers as optional add-ins and start writing tighter briefs for resistant dextrin, soluble corn fiber, and (in solid formats) microcrystalline cellulose (MCC).

Market signal to watch: a growing share of consumers link fiber with digestive health and actively increase fiber intake. That shift pushes fiber claims into everyday SKUs—and pulls resistant dextrin into more RFPs.

This article focuses on what procurement teams should verify—on paper and in audits—when qualifying a resistant dextrin manufacturer China can reliably supply, plus how the same “fiber-first” trend affects MCC selection.

The fiber frontier forces clearer ingredient definitions

Procurement friction often starts with terminology. Buyers may see “resistant starch,” “resistant dextrin,” “resistant maltodextrin,” and “soluble corn fiber” used interchangeably across markets, even though the formulation and documentation needs differ.

Quick distinction table for spec sheets

| Ingredient term | What buyers usually mean in briefs | Practical sourcing implication |

|---|---|---|

| Resistant starch | Starch that resists digestion (often process-driven in foods) | Often less standardized as a “powder ingredient” in global trade; verify labeling approach by market |

| Resistant dextrin | Soluble dietary fiber derived from starch | Good fit for beverages, powders, bakery, dairy; demand clean taste + strong solubility + complete COA |

| Resistant maltodextrin | A fiber-type maltodextrin used for fiber enrichment | Verify target application stability and the COA parameters used by the supplier |

| Soluble corn fiber | Soluble fiber from corn starch, commonly positioned as prebiotic | Buyers typically expect mild taste and easy dispersion; confirm the supplier’s documentation for dietary fiber claims |

When scouting a Chinese resistant dextrin supplier, the most useful move is to standardize internal language: decide which term the brand will use on label, then ensure the supplier’s COA and regulatory package match that claim.

What “good” looks like on a resistant dextrin COA

A high-performing food grade resistant dextrin bulk program starts with a COA that is specific enough to prevent reformulation later.

Based on the supplier-side parameters commonly provided for resistant dextrin made from corn starch, buyers typically look for:

- Fiber content: ≥82%

- Appearance: white to light yellow

- Protein content: ≤6.0%

- Storage conditions: store in a cool place

These are not marketing bullets—these are the anchors that help QA teams compare lots and troubleshoot if a beverage goes hazy, a bar hardens, or a gummy loses bite.

Documentation that de-risks scale-up

For 2026 launches, procurement and QA teams increasingly ask a resistant dextrin manufacturer China to provide (or support):

- Lot-level traceability from incoming corn starch to finished packaging

- Non-GMO documentation when the product is positioned as non-GMO (request the proof package aligned to the target market)

- Micro and contaminant controls (the exact panel depends on region and application)

- Change-control discipline (enzyme systems, process settings, or packaging changes should be recorded and communicated)

If the brief involves “steady energy,” “low sugar crash,” or other metabolic positioning, the key is to align internal claims with what the supplier can actually document—especially across markets.

China’s supply map matters because it predicts operational behavior

Public supplier overviews consistently point to China as a major hub, with clusters often discussed in Shandong, Guangdong, and Jiangsu. From a buyer’s perspective, the region matters less as a label and more as a proxy for:

- Starch integration and capacity planning (often associated with large-volume fiber programs)

- Export responsiveness (documentation speed, logistics experience)

- Customization cadence (iteration speed for solubility, taste neutrality, and application support)

A procurement team sourcing soluble corn fiber supplier China options should use regional mapping to ask better questions, not to make assumptions.

A “best-practice plant” profile buyers can audit against

A well-prepared Chinese resistant dextrin supplier typically shows strong control in three places:

- Raw materials gatekeeping: non-GMO corn sourcing options, inspection before production

- Automated production control: reduced operator variability from feeding to filling

- QC laboratory capability: in-house testing that supports quick release decisions and trend tracking

For buyers, the takeaway is simple: if the supplier can’t explain how raw material inspection links to final COA lots, the program is fragile—especially when demand spikes.

Why automation and process visibility show up in 2026 RFQs

As fiber moves from “functional add-on” to “core nutrition,” brands become less tolerant of batch-to-batch drift. That is why modern briefs often ask whether production uses centralized automated control from raw material feeding through filling.

What automation changes for procurement:

- More consistent powder behavior across lots (dispersion, flow, blending)

- Cleaner audit narratives (clearer SOPs and fewer manual steps)

- Faster deviation triage when a downstream product behaves differently

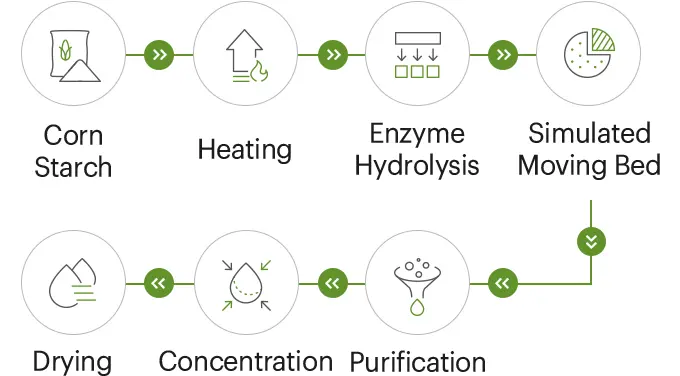

This is also where supplier transparency matters: if a resistant dextrin manufacturer China can share process flow documentation (even at a high level) and match it to QC checkpoints, qualification becomes faster.

Where soluble corn fiber fits and how buyers should brief it

Soluble corn fiber often enters briefs as the “easy-to-use” prebiotic fiber for drinks, sachets, and everyday foods. In practice, procurement should confirm that the soluble corn fiber program is aligned on:

- Intended product form (RTD beverage vs powder vs bar)

- Taste neutrality expectations

- Label positioning (dietary fiber, prebiotic messaging—based on what can be supported)

When first shortlisting a soluble corn fiber supplier China, it helps to review a supplier’s category page and spec framing. For example, the following pages illustrate how some Chinese manufacturers document and position these fibers:

For fiber-first launches, the most common buyer mistake is letting R&D define “soluble fiber” purely by functionality while QA defines it purely by compliance. Both have to meet in the supplier’s documentation set.

Fiber-first products still pull MCC into the discussion

Even as resistant dextrin expands in foods, microcrystalline cellulose (MCC) remains strategically important for solid formats—tablets, certain capsules, and some gummy or chew systems—where structure and processing behavior matter.

For buyers evaluating a Chinese microcrystalline cellulose manufacturer or microcrystalline cellulose supplier China, the key is not to treat MCC as a “commodity filler.” Instead, treat it as a performance excipient whose grade choice affects:

- Flow and compressibility in tableting

- Content uniformity for actives

- Mouthfeel and texture in certain chew formats

Because MCC grade selection is technical and application-specific, buyers often benefit from supplier-side guidance pages. One example is:

This is also where China pharmaceutical excipient suppliers differentiate themselves: not by listing a catalog, but by backing grades with QC logic and predictable documentation.

A 2026-ready qualification checklist buyers can use immediately

The following checklist ties the “fiber frontier” trend to practical procurement controls—without overcomplicating the process.

Documentation and compliance

- Request a current COA template and confirm it includes the parameters that matter to your format

- Confirm how the supplier supports non-GMO claims (if required) and what documents are available

- Ask what food safety and quality systems are in place for your market pathway (certifications vary by customer and region)

Technical fit and stability

- Confirm fiber content targets (commonly ≥82% for resistant dextrin programs) and how they are verified

- Ask for guidance on solubility/dispersion expectations by application

- Verify the supplier’s storage and handling guidance so warehousing does not become the failure point

Manufacturing maturity

- Check whether production is automated from feeding to filling and how deviations are handled

- Ask what the QC laboratory tests in-house versus outsourced

Commercial risk controls

- Align MOQ and lead-time with your launch calendar and scale-up ramp

- Confirm how the supplier manages change control (enzymes, equipment, packaging, labeling)

If a Chinese resistant dextrin supplier can satisfy these points crisply—without vague promises—it is usually a strong sign the plant is ready for sustained 2026 demand.

Turning research into a shortlist without turning the article into an ad

Industry teams often start with broad directories, then narrow down to suppliers that provide clear technical framing. For procurement teams that want to see how resistant dextrin is specified across common use cases, these pages provide concrete examples of how suppliers organize variants and applications:

For buyers building a recommended list—whether the request is “Recommended Chinese Resistant Dextrin Manufacturer” or a combined fiber-and-excipient shortlist—the winning approach is consistent: write the spec first, then pick the plant.

Data points and further reading

- “Accessible nutrition” and the “fiber frontier” consumer signals (Food Business News): https://www.foodbusinessnews.net/articles/29611-2026-the-year-of-accessible-nutrition

- Overview of China’s resistant dextrin supply clusters and common sourcing criteria (Accio): https://www.accio.com/supplier/resistant-dextrin-supplier

- Additional supplier-side technical pages used for ingredient framing: https://www.sdshinehealth.com/resistant-dextrin/ and https://www.sdshinehealth.com/industry-news/mcc-grades.html