In today's "functional fiber" cycle, resistant dextrin has moved from a niche label claim to a high-volume formulation tool—especially in powders, beverages, nutrition snacks, and sugar-reduction concepts. At the same time, microcrystalline cellulose (MCC) remains one of the most relied-on excipients for solid dosage forms. For procurement teams, these two categories increasingly share the same challenge: pricing and qualifying China supply without relying on FOB comparisons alone.

Why resistant dextrin and MCC get priced wrong so often

A typical buying cycle for resistant dextrin starts with a target fiber claim, a sensory constraint (neutral taste, low viscosity), and a tight cost cap. MCC sourcing, by contrast, is driven by tableting performance, pharmacopoeial alignment, and batch-to-batch consistency. Yet both ingredients are frequently priced "too early" based on a short spec sheet.

That approach often breaks down because the true cost is determined by what happens *after* the first shipment:

- Does resistant dextrin stay clear in an acidic RTD? Does it remain stable across hot-fill or UHT-like conditions?

- Does MCC keep flow and compressibility consistent across lots, or does a particle-size shift force rework?

- How much third-party testing is needed to trust each COA—and how often does it uncover surprises?

If a procurement team wants a reliable supply partner, the pricing model has to include quality and qualification risk as first-class inputs.

China supply reality that affects cost structure

China remains a strategic production base for resistant dextrin and MCC, and supply is often discussed in terms of regional clusters (commonly referenced in provinces such as Shandong, Jiangsu, and Guangdong). For buyers, the more actionable point is not the province name—it's the plant profile behind the quotation.

In practice, the price band for resistant dextrin and MCC is shaped by whether a supplier demonstrates:

- GMP-standard workshops and controlled production environments.

- A functioning QC laboratory with routine testing, not just a template COA.

- High automation (e.g., "central control" production from feeding to filling).

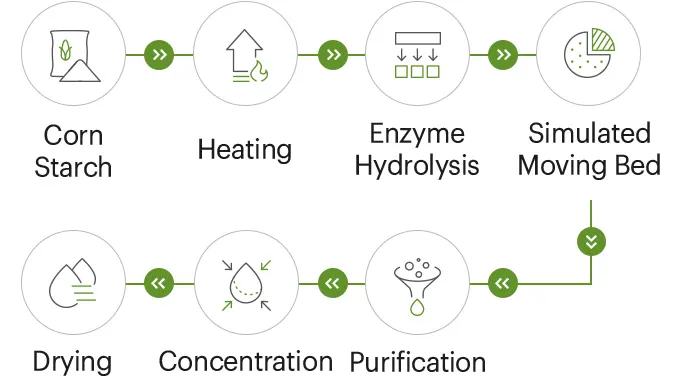

- Consistent raw material strategy (e.g., NON-GMO corn starch as a stable feedstock).

These signals matter because they change failure rates, investigation time, and ultimately total landed cost.

Key terms buyers see on specs and COAs

- Resistant dextrin: A soluble dietary fiber made by processing starch so it resists digestion in the small intestine. Commonly used to raise fiber while keeping taste neutral.

- Soluble dietary fiber: Fiber that dissolves in water; often preferred for beverages and powders due to smoother mouthfeel.

- Fiber content ≥82%: A commonly stated benchmark for resistant dextrin specifications in trade channels and product pages.

- MCC (microcrystalline cellulose): A widely used excipient in tablets/capsules; performance depends on grade, particle size, and flow.

Demand drivers that stabilize pricing in 2026

Two demand streams are keeping resistant dextrin procurement active:

- Accessible nutrition and the "fiber frontier." Brands are pushing fiber into everyday formats (bars, shakes, coffees). That keeps baseline pull stronger than one-off "diet" cycles.

- Sugar reduction and texture engineering. Resistant dextrin is increasingly treated as a multi-function ingredient: fiber claim + body + reduced net carbs positioning (in some product concepts).

Meanwhile, MCC demand remains anchored by pharmaceutical throughput and the need for predictable processing. When procurement teams source both categories from China, they often evaluate them under a shared supplier governance model—even though they land in different cost centers.

For buyers monitoring market direction, it helps to keep internal learning loops tight by using a stable technical reference for MCC grades and testing expectations, such as MCC grades formulation and QC.

The TCO framework that makes resistant dextrin pricing "real"

FOB is a number. Total cost of ownership (TCO) is a decision.

A workable TCO model for resistant dextrin (and similarly for MCC) typically includes five layers.

1) Specification risk cost

For resistant dextrin, buyers usually underestimate how many "small" specs affect final application cost:

- Solubility and clarity (especially for beverages).

- Viscosity impact at use level.

- Stated fiber content (often listed as ≥82% in commercial specs).

- Basic microbiological and stability indicators.

For MCC, the parallel is grade selection: particle size and flow drive machine uptime and yield.

2) Documentation and verification cost

A price that looks attractive can become expensive if COA depth is thin.

Buyers pricing resistant dextrin should factor:

- Whether lot traceability is clear.

- Whether the COA includes repeatable core items (appearance, key content, microbiology).

- How much third-party testing is required per shipment at intake.

If the supplier routinely exports, it should also be able to support certification stacks often requested by global buyers (commonly referenced in this category: ISO systems, HACCP, Kosher, Halal; some suppliers also list BRC for food-facing operations).

3) Production maturity cost (the hidden driver)

A mature plant can lower the "soft costs" that never appear on a quotation.

In many resistant dextrin product lines, production maturity is signaled by:

- Automated central control operation from feeding to filling.

- The use of imported biological enzymes.

- Precision equipment and standardized processing.

Those choices typically aim to reduce variability—less re-testing, fewer deviations, fewer reformulation loops.

4) Logistics and packaging cost

Even when resistant dextrin is stable, packaging quality drives real risk:

- Moisture management and caking prevention.

- Label/lot readability.

- Pallet integrity and container loading practices.

This is where a supplier's standard export packaging discipline becomes a pricing lever, not a "nice to have."

5) Failure cost and reformulation cost

This is the layer most teams skip—until a launch is delayed.

For resistant dextrin, reformulation cost can appear as:

- Unexpected haze in beverages.

- Texture drift in powders.

- A need to reduce dosage and lose the intended fiber claim.

For MCC, it can show up as poor compressibility or changed flow leading to tablet defects or throughput loss.

A "cheap" lot that forces a retest cycle, extra blending time, or a spec waiver is no longer cheap.

A buyer-friendly comparison table for internal alignment

Procurement decisions move faster when stakeholders agree on what each ingredient is expected to do.

| Attribute | Resistant dextrin | MCC | Where it matters most |

|---|---|---|---|

| Primary role | Soluble dietary fiber, formulation support | Excipient for solid dosage | Food & beverage vs pharma |

| Typical buyer focus | Fiber content, solubility, viscosity, taste neutrality | Grade, particle size, flow, compaction | QC and performance |

| Common risk | Sensory and application mismatch | Processing variability | Pilot-to-scale stability |

| Value of deeper COA | High (application outcomes depend on consistency) | High (machine performance depends on consistency) | Intake testing and audits |

Negotiation levers that keep pricing stable without boxing you in

When sourcing microcrystalline cellulose China and resistant dextrin from China, procurement teams often get better outcomes with "structured flexibility":

- Lock the performance-critical specs, not every nice-to-have. For resistant dextrin, protect solubility/clarity and fiber content; for MCC, protect the grade and flow profile.

- Use a two-stage qualification before volume pricing. Request a small verification lot, then negotiate volume tiers.

- Build a COA template that matches your end-use. A beverage buyer and a tablet buyer need different emphasis.

- Agree on deviation handling upfront. Define what triggers re-testing, replacement, or discount.

- Keep a second-source pathway warm. Risk management improves when alternatives are pre-qualified.

Where to look for supplier signals without turning the article into an ad

Industry buyers frequently shortlist suppliers by looking for evidence of integrated functional ingredient capability (not just trading). One practical way is to check whether a company can clearly explain its resistant dextrin family and related soluble fiber lines.

As an example of how mature suppliers present these portfolios, buyers can review category pages such as resistant dextrin and dietary fiber. For teams that handle multiple applications (food, supplements, and sometimes personal care), it can also be useful to see how MCC is discussed beyond pharma, such as microcrystalline cellulose in cosmetics.

Closing checklist for a short, defensible shortlist

A procurement-ready shortlist for resistant dextrin and MCC from China usually becomes straightforward when the decision is reframed as "price + proof."

Before signing a long-term price, confirm:

- Resistant dextrin core specs match the application (and are stable across lots).

- COA depth and traceability are adequate for your internal QA expectations.

- The supplier's workshop/QC profile supports consistency (automation + lab capability).

- Packaging and shipping discipline are verified (not assumed).

- The quote holds up under TCO logic—not just per-kg comparison.

When these elements are in place, finding a reliable partner for ingredients like resistant dextrin stops being a gamble and becomes a repeatable sourcing outcome. For more details on qualified suppliers, you can visit www.sdshinehealth.com.