In 2026, “accessible nutrition” is no longer just a brand slogan—it is rapidly becoming a hard procurement requirement. Buyers are increasingly tasked with delivering everyday formats—powders, RTD drinks, gummies, and tablets—that are easier to use, easier to digest, and easier to trust. Two ingredients appear repeatedly on procurement shortlists when teams aim to hit those targets: resistant dextrin for fiber-forward nutrition and microcrystalline cellulose (MCC) for structural integrity, processing reliability, and pharmaceutical-grade performance.

Why Resistant Dextrin and MCC Are Being Specified Together

Historically, procurement teams have treated dietary fiber and excipients as separate workstreams. However, 2026 product briefs are pushing them together into a unified sourcing strategy. The drivers are practical:

- Fiber claims and gut-health positioning increasingly require a soluble fiber that is stable, high in content, and easy to formulate without altering texture.

- Format accessibility (smooth RTDs, low-grit powders, swallow-friendly tablets/capsules) demands consistent processing aids that ensure uniformity.

Consequently, many buyers now look to shortlist a resistant dextrin manufacturer in China that can supply at scale and, in parallel, a microcrystalline cellulose supplier that can support solid dosage or texture control. Sourcing them from regions with mature supply chains allows for better cost control and quality assurance.

A quick comparison buyers can use

| What buyers need | Resistant dextrin (soluble fiber) | Microcrystalline cellulose (MCC) |

|---|---|---|

| Typical role | Raise fiber content without heavy viscosity | Improve structure, flow, compression, and stability |

| Common categories | Beverages, nutrition powders, bars, gummies, prebiotic blends | Tablets, capsules, some foods/cosmetics textures |

| Buyer focus | Fiber assay method, taste neutrality, clarity, microbiology | Particle size, flow, loss on drying, compressibility |

| Risk if mis-specified | Cloudiness, off-taste, weak fiber claim | Poor tablet hardness/disintegration, segregation, dusting |

Resistant Dextrin Fundamentals for Fiber Forward Formulations

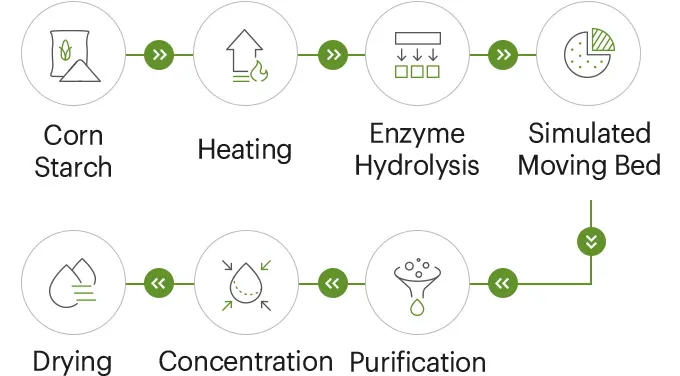

Resistant dextrin is a soluble dietary fiber typically derived from starch—commonly non-GMO corn starch or tapioca starch—through a process of controlled heating and enzymatic hydrolysis. This processing method is critical: it rearranges the starch molecules to become resistant to digestion in the small intestine, allowing them to reach the large intestine where they act as a prebiotic.

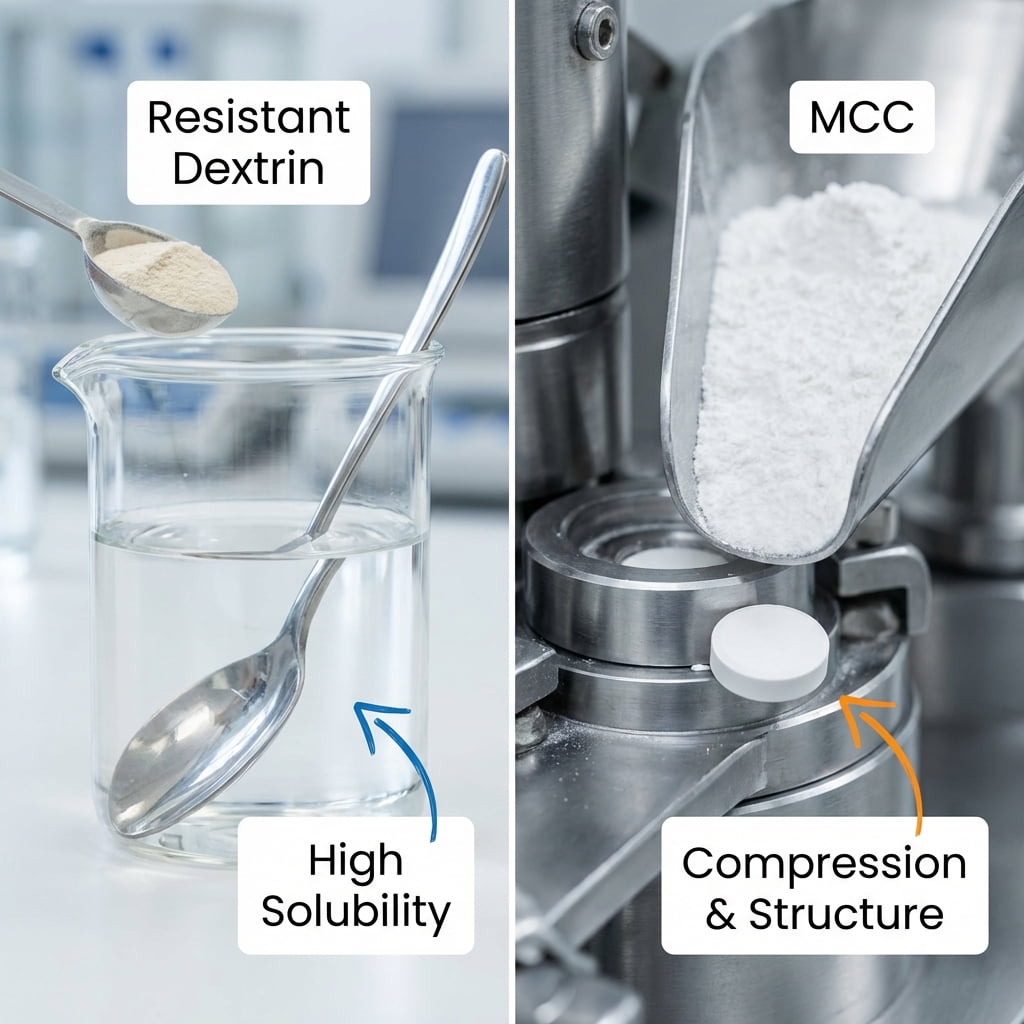

The procurement-relevant takeaway is simple: a high-quality resistant dextrin offers high solubility, low viscosity, and a neutral taste. These traits help formulation teams raise fiber content significantly without making products gritty, cloudy, or overly thick.

For sourcing from China, a widely used commercial benchmark is resistant dextrin fiber ≥82%. This “≥82%” grade appears frequently in RFQs because it balances claim strength, formulation stability, and cost control for mainstream applications like beverages and nutritional powders.

What typically appears on spec sheets

Based on product information commonly provided by established suppliers, a robust resistant dextrin specification often covers:

- Appearance: White to light yellow powder.

- Raw material: Frequently non-GMO corn starch sourced from reputable producers to ensure consistent supply and safety.

- Fiber content: Commonly ≥82% (and up to 90%) for high-fiber grades.

- Protein: Controlled levels (e.g., ≤6.0%) to ensure purity and reduce allergen risks.

- Storage: Cool, dry conditions to protect flowability and prevent caking.

To see how suppliers describe these points in a buyer-readable way, reference product pages such as nutritional dietary fiber or the broader resistant dextrin category.

Functional traits that matter in real products

Buyers typically choose resistant dextrin when they need one or more of the following:

- Clear solubility and neutral flavor: Essential for beverage-friendly claims where “grit” is unacceptable.

- Heat and pH stability: Ensures the fiber survives pasteurization or acidic environments in RTDs and gummies.

- Low viscosity: Avoids the “fiber-thick” mouthfeel at practical serving sizes, maintaining a pleasant consumer experience.

- Health Benefits: Supports blood sugar control (low glycemic index), weight management (satiety), and digestive health (prebiotic effect).

Microcrystalline Cellulose Essentials for Pharma Grade and Beyond

Microcrystalline cellulose (MCC) is purified, partially depolymerized cellulose widely used as an excipient—especially in tablets and capsules. While often associated with pharmaceuticals, it also appears in functional foods and cosmetics where texture, suspension behavior, or “feel” are important.

For many procurement teams, MCC selection starts with MCC pharma grade specifications—because pharma-style documentation and lot-to-lot consistency are often the strictest benchmark, even when the end-use is dietary supplements. A supplier capable of meeting pharma standards typically offers higher reliability for food-grade applications as well.

What changes from grade to grade

When reviewing a Chinese microcrystalline cellulose manufacturer’s portfolio, buyers will usually see MCC grades differentiated by:

- Particle size distribution: Impacts flow, blending uniformity, mouthfeel, and compressibility.

- Bulk density and tapped density: Affects hopper performance, tablet weight control, and packaging volume.

- Moisture / loss on drying: Critical for stability and compression behavior; excess moisture can lead to microbial issues or tablet defects.

- Compressibility and binding performance: Determines suitability for direct compression versus wet granulation.

If MCC is being considered for cosmetics, an overview like Microcrystalline Cellulose in Cosmetics can help non-pharma teams align grade language with application needs.

Reading and Comparing COAs From Chinese Suppliers

A Certificate of Analysis (COA) should not be treated as a mere “pass/fail PDF.” In the context of China sourcing, it is a comparability tool—helping you verify that two lots (or two suppliers) are truly equivalent for your process. Understanding the nuance in these documents is key to avoiding production headaches.

Key numbers to check on a resistant dextrin COA

For resistant dextrin, buyers typically prioritize:

- Dietary fiber result and test method: Always ask the supplier to state the method used (e.g., AOAC 2001.03) to ensure the ≥82% claim is accurate and comparable.

- Moisture content: Low moisture signals better stability and lower caking risk during storage.

- Protein and ash: Lower values generally indicate higher purity and better refining processes.

- Microbiological limits: Crucial for ready-to-mix powders and supplement applications where the ingredient is not further processed.

- Sensory-relevant notes: Check for descriptors like “white to light yellow” and “neutral taste” to ensure batch consistency.

Key numbers to check on an MCC COA

For MCC, the COA is often more “processing-critical” than “nutrition-critical.” Core checkpoints include:

- Identification and grade name: Confirm it matches the specific grade requested (e.g., PH101 vs. PH102).

- Particle size / sieve analysis: Verify the distribution matches your equipment’s flow requirements.

- Loss on drying: Ensures the moisture level is within the specific range for your formulation’s stability.

- Residue on ignition: A measure of purity.

- Bulk density / tapped density: Essential for calculating fill weights in capsules or die fill in tableting.

A practical way to build internal literacy is to use a supplier’s educational grade guide—see MCC Grades Formulation and QC Guide for an example of how grade differences are typically framed.

How Buyers Use Resistant Dextrin and MCC Together in Accessible Nutrition

Many “accessible nutrition” formats benefit from pairing a soluble fiber with a dependable structuring excipient. This combination allows brands to deliver health benefits in convenient forms:

- Nutrition powders and stick packs: Resistant dextrin supports fiber claims and mixability, while MCC can help with flow and uniform dosing when tablets or compressed formats are part of the line extension.

- Chewable tablets or fiber tablets: Resistant dextrin brings the fiber value and prebiotic benefits; MCC supports direct compression, ensuring the tablet holds together while remaining chewable.

- Hybrid supplement lines: One brand may sell an RTD beverage plus a daily tablet. Sourcing both ingredients from a supplier with strong documentation can reduce variability across formats and simplify the supply chain.

The guiding principle is straightforward: resistant dextrin delivers the fiber message, while MCC protects the manufacturing outcome.

Procurement Signals That Separate Reliable Chinese Suppliers From Risky Ones

If the goal is to build a shortlist that can survive scale-up, audits, and recurring orders, buyers can use a few supplier signals that are easy to validate before a site visit:

- Clear raw material story: Look for transparency regarding origin, such as non-GMO corn starch for resistant dextrin. This impacts both safety and labeling.

- Documented quality systems: Reliable suppliers often reference GMP guidelines, ISO systems, and HACCP for workshop control. Certifications like Halal and Kosher are also standard indicators of a serious exporter.

- Automated or controlled production flow: Advanced factories use automated central control from raw material feeding to product filling. This drastically improves lot-to-lot consistency, which is vital for fiber assay stability.

- Responsive COA support: The ability to explain test methods, provide recent lot samples, and answer technical queries promptly is a strong sign of a capable partner.

In practice, these criteria are what people mean when they search for a Recommended Chinese Resistant Dextrin Manufacturer or a Recommended Chinese Microcrystalline Cellulose Supplier—they are looking for consistency, not just the lowest quote.

A useful benchmarking approach is to compare supplier documentation against established product pages and technical notes. For example, reviewing pages on variants like indigestible maltodextrin and organic resistant dextrin fiber can help teams align “what to ask for” before issuing a formal RFQ.

Turning Ingredient Knowledge Into Faster Approvals

Most delays in fiber-forward launches are not caused by “bad ingredients.” They are caused by unclear specifications and inconsistent COA interpretation across teams. When procurement and R&D are not aligned on what “high quality” looks like on paper, the sampling process drags on.

If procurement teams align early on two anchors—resistant dextrin fiber ≥82% for the nutrition target and fit-for-purpose MCC pharma grade specifications for the format target—supplier conversations in China become shorter, sampling becomes more meaningful, and scale-up surprises drop significantly.

For buyers who want real spec examples and category context without locking into a single grade too early, it is helpful to start with neutral, documentation-rich supplier resources. Exploring the resistant dextrin category at www.sdshinehealth.com provides a solid baseline for building an internal checklist that matches your specific application needs.