For many procurement teams and product developers, the success of weight-management and “better-for-you” launches hinges on a single, critical question: does the fiber behave the same in the factory as it does on a spec sheet? The fastest route to predictable performance often involves piloting a Chinese resistant dextrin manufacturer grade in real formulations—then locking the winning parameters into the purchase specification. This guide breaks down three practical case patterns (RTD beverages, gummies, and nutrition powders) and demonstrates how to translate resistant dextrin specs into finished-product outcomes, while also clarifying where microcrystalline cellulose (MCC) fits into the equation.

Why “Application-First” Sourcing Wins for Resistant Dextrin

In the competitive landscapes of beverages, confectionery, and nutrition powders, resistant dextrin is frequently selected for its soluble fiber contribution, neutral taste, and exceptional formulation flexibility. However, experienced procurement teams understand the inherent risk: purchasing based on “fiber %” alone can lead to significant production issues.

Common pitfalls include:

- Haze or sediment in low-sugar drinks when solubility and moisture metrics are not aligned with the processing method.

- Sticky, weeping gummies when the resistant dextrin grade carries more moisture than the recipe can tolerate.

- Dusting, poor dispersion, or clumping in powders when particle behavior and packaging barriers are overlooked.

Consequently, many teams initiate the process with a pilot from a recommended Chinese resistant dextrin manufacturer, treating the first production run as a qualification test rather than a simple commodity purchase.

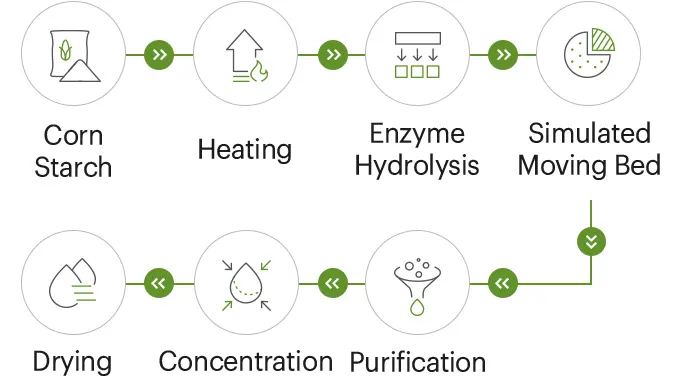

To ground this discussion, a useful benchmark used by many buyers is Shine Health’s food-grade resistant dextrin, produced from non-GMO corn starch with a fiber content listed as ≥82%. Their documentation highlights practical manufacturing signals that are crucial during scale-up—such as automated central control from feeding to filling, the use of imported enzymes, and a dedicated QC laboratory.

Turning Chinese Resistant Dextrin Specs into Real Performance

Most buyers encounter similar grade “bands” across the Chinese market—commonly marketed as 82% / 90% / 95% fiber tiers. In practice, selecting the right tier depends less on the label and more on the specific demands of the application: clarity, sweetness profile, tolerance to heat or acid, and strict water activity control.

The table below provides an application-facing perspective on resistant dextrin grades (illustrative of common market positioning):

| Typical grade positioning | Where it usually fits best | What the buyer should stress-test | Why it matters |

|---|---|---|---|

| ~82% fiber (entry export grade) | RTD drinks, powdered drink mixes, general foods | Solubility, color, moisture, micro limits | Stable dispersion and clean flavor at scale |

| ~90% fiber (higher purity positioning) | Nutrition powders, “fiber-forward” claims | Flowability, bulk density, moisture, micro | Better dosing flexibility, fewer off-notes |

| ~95% fiber (premium claim positioning) | Specialized formulas | Compatibility with sweeteners/acids, processing robustness | Helps when claim space is tight |

For many projects, starting with a stable ≥82% resistant dextrin grade is a pragmatic first step, particularly for beverage and powder platforms.

The COA Mindset Buyers Use

Instead of treating the Certificate of Analysis (COA) as mere paperwork, astute teams utilize it as a performance predictor. A buyer screening a Chinese resistant dextrin manufacturer typically requests a COA package that connects directly to potential risk points:

- Fiber content: Grade confirmation.

- Moisture: Predicts clumping, gummy texture drift, and shelf-life sensitivity.

- pH range: Helps predict behavior in acidic beverages.

- Microbiology: Aerobic plate count, yeast & mold; plus pathogen statements where required.

- Heavy metals: To align with internal specs and destination-market expectations.

- Appearance/color: Critical for clear or lightly flavored drinks.

Case Pattern 1: Clear Low Sugar Drinks and Instant Beverage Powders

Target outcome: Add soluble fiber while keeping a clean taste and stable appearance.

In beverage development, resistant dextrin is usually chosen when the team requires fiber without the heavy viscosity associated with many hydrocolloids. In low-sugar systems, the role of resistant dextrin is often less about sweetness and more about body, balance, and label-friendly fiber delivery.

What tends to work well when piloting resistant dextrin for beverages:

- RTD (ready-to-drink) formulas: Focus on solubility and visual stability—particularly if the beverage is lightly colored or marketed as “clear.”

- Powdered drink mixes: Focus on instant dispersion and moisture management to reduce caking.

A practical reference point for product developers is Shine Health’s beverage-oriented positioning around dietary fiber and its use for "high dietary fiber in drinks,” with the core ingredient being resistant dextrin.

What usually goes wrong (and how specs prevent it):

- Light haze after heat treatment: Tighten solubility/appearance criteria; confirm the grade is intended for beverage use.

- Powder clumping in humid storage: Set a moisture ceiling in the purchase spec and require moisture-barrier packaging.

- Flavor drift in delicate profiles: Specify appearance (white to light yellow) and request retention samples for comparison.

If the line includes low-calorie positioning, many buyers cross-check how resistant dextrin is described in applications such as low calorie dietary fiber to ensure the functional expectations match the formulation goal.

Case Pattern 2: Fiber Gummies That Hold Chew and Shelf Life

Target outcome: Reduce sugar and add fiber without stickiness, weeping, or texture collapse.

Gummies are where “specs become texture.” Resistant dextrin can help replace part of the bulk normally delivered by sugar syrups while supporting fiber claims. The catch is that gummies are highly sensitive to water activity and small moisture shifts.

Procurement teams piloting resistant dextrin in gummies typically pay special attention to:

- Moisture: As-received and stability across storage.

- Micro limits: Gummies can be more forgiving than beverages, but shelf life still depends on tight controls.

- Batch-to-batch consistency: Because the same cooking curve can produce different chew properties if solids vary.

A useful visual reference for confectionery applications is the "FIBER-FUL Confectionery” concept built around resistant dextrin.

Common gummy failure modes tied to sourcing:

- Sticky surface or “wet” bite: Moisture spec too loose or packaging not moisture-proof.

- Texture inconsistency across lots: Fiber content varies outside tolerance, changing solids and water binding.

- Crystallization-like defects in reduced-sugar designs: Grade mismatch (buyers sometimes use a resistant dextrin intended for other formats).

For low-carb or sugar-reduction lines, buyers also compare how resistant dextrin is positioned in applications such as low carb food additives, then back-solve the purchase spec from the process requirements.

Case Pattern 3: Nutrition Powders for Weight Management Lines

Target outcome: Neutral taste, easy mixing, stable powder flow, and predictable dosing.

Nutrition powders (meal replacements, fiber blends, and weight-management mixes) are often where a Chinese resistant dextrin manufacturer can add significant value—because powder performance is as much about production discipline as it is about chemistry.

Buyers designing a powder platform with resistant dextrin usually prioritize:

- Dispersibility: In shaker bottles and instant beverages.

- Neutral sensory profile: To avoid masking costs.

- Powder handling: Flow, dusting, and bulk density for automated filling.

- Packaging fit: Multi-layer bags and moisture barriers if shipping to humid regions.

Shine Health’s nutritional dietary fiber powder page is a helpful example of how resistant dextrin is positioned for powder-format nutrition, including the same baseline specification cues buyers often request (appearance, fiber content ≥82%, and storage in a cool place).

Where MCC Complements Resistant Dextrin in Finished Dosage Forms

Resistant dextrin is a soluble fiber; microcrystalline cellulose (MCC) is typically an insoluble structuring excipient. Buyers searching for a recommended Chinese microcrystalline cellulose manufacturer or recommended Chinese microcrystalline cellulose supplier are often trying to solve different problems than they are with resistant dextrin:

- Tablet hardness and compressibility.

- Flow and content uniformity.

- Structural support in chewables.

In practice, MCC can complement resistant dextrin when a product needs both a fiber story (resistant dextrin) and a predictable mechanical structure (MCC).

For teams building tablets, chewables, or layered formats, it helps to align MCC grade selection with the chosen resistant dextrin grade early in development. Two practical resources for understanding this synergy are:

- MCC Grades Formulation and QC Guide

- Microcrystalline Cellulose in Cosmetics (useful for understanding broader performance language buyers may encounter across industries)

An Application-Driven Sourcing Checklist Buyers Can Reuse

When shortlisting a Chinese resistant dextrin manufacturer, use the three case patterns above to convert formulation needs into a clean procurement brief.

For resistant dextrin (beverages, gummies, powders):

- Confirm starch origin: Commonly non-GMO corn; some supply chains also offer tapioca-based options.

- Specify fiber content tier: Set tolerances, not just a minimum.

- Require a complete package: Ask for the full resistant dextrin COA, including microbiology and heavy metals, before the first shipment.

- Define moisture limits based on the format:

- Strict for gummies and humid-market powders.

- Still important for beverages, especially powder drink mixes.

- Ask for retention samples: And a lot-to-lot consistency plan.

For MCC (when structure matters):

- Match the MCC grade to the dosage form (tablet vs. chewable vs. core systems).

- Request flow/compressibility-related data that ties directly to your process window.

Pilot rule that reduces surprises:

Run a pilot with at least one ≥82% resistant dextrin grade in the exact process conditions you plan to commercialize (heat treatment for RTD, cooking curve for gummies, filling conditions for powders). Then lock the winning COA parameters into the contract.

For buyers who want a concrete benchmark while screening the market, a Shandong-based producer like Shine Health can be used as a reference set for export-facing production discipline and documentation. You can review their capabilities and product details directly at www.sdshinehealth.com.