Accessible nutrition is no longer just a consumer slogan—it has become a procurement filter. Brands want cost-effective, label-friendly products that still deliver texture, stability, satiety, and digestive comfort. That shift is moving more tenders toward China, where scale and export readiness are strong for both microcrystalline cellulose (MCC) and resistant dextrin.

Accessible nutrition is changing ingredient shortlists

For buyers, the practical question is not whether China can supply. It is whether a microcrystalline cellulose supplier China can consistently meet pharmacopoeia expectations, and whether a resistant dextrin supplier China can deliver fiber performance (often ≥82% fiber) without creating taste, viscosity, or tolerance issues in finished products.

Market coverage highlights China’s central role in global MCC supply, especially as pharmaceutical and food applications grow in parallel. A procurement team building “accessible” SKUs—fiber-fortified beverages, meal replacement powders, gummies, or simplified supplement stacks—typically needs ingredients that do three things at once:

- Keep formulations stable at scale and across shipping conditions.

- Protect taste and mouthfeel (no chalkiness, minimal off-notes).

- Support modern positioning: low sugar, lower calories, clean label, and digestive comfort.

This creates a divergence in sourcing strategies:

- MCC is sourced for structure and processing reliability (tablet performance, flow, texture control).

- Resistant dextrin is sourced for fiber delivery with a neutral sensory profile.

When buyers run a global RFP, a microcrystalline cellulose supplier China and a resistant dextrin supplier China are frequently evaluated side by side because many reformulations combine both: MCC for processing/texture and resistant dextrin for fiber claims.

What buyers expect from MCC and functional fibers in 2026 reformulation

Across categories, 2026 reformulation briefs keep repeating the same themes:

- Cleaner labels without losing performance

- Fewer “unknown” additives.

- More reliance on functional ingredients that can justify their presence.

- Low-calorie fiber that behaves well in real products

Resistant dextrin is often selected because it is designed to resist digestion in the small intestine and be fermented in the large intestine, supporting gut-health positioning without adding meaningful net carbs.

- Consistent specs with faster technical support

Product development cycles are shorter; buyers increasingly treat responsiveness as part of supplier qualification.

- Export-ready documentation

A capable China microcrystalline cellulose exporter is expected to support COA, MSDS, and relevant grade alignment (e.g., USP/EP for pharma applications).

For resistant dextrin, the buying language is often less pharmacopoeia-driven and more application-driven: resistant dextrin food grade, clear solubility behavior, and reliable performance in beverages, powders, or confectionery.

China’s supply landscape for MCC and resistant dextrin

Sourcing teams often talk about “China” as a single origin, but supplier capability clusters are regional. The practical advantage is that geography can help buyers predict strengths.

Shandong as a volume and export hub

Shandong is widely recognized among buyers as a high-volume manufacturing base for both functional ingredients and excipients. For procurement, this often translates into:

- Competitive scale for routine replenishment

- Established export experience

- A strong pool of manufacturers that can support stable supply contracts

If the goal is steady throughput for mainstream SKUs, Shandong frequently sits near the top of the shortlist when screening a microcrystalline cellulose supplier China and a resistant dextrin supplier China.

Jiangsu and the broader Yangtze River Delta for specialization

Buyers often associate Jiangsu and nearby areas with stronger specialization—technical services, application guidance, and product development support. This can matter when MCC is being used beyond a “standard” binder role or when fibers are being pushed into sensitive matrices.

Guangdong for beverage-forward fiber use cases

Guangdong is frequently discussed as an ingredient export and customization zone, particularly when the application is beverage-oriented—RTDs, mixes, and functional drinks. For resistant dextrin, that can mean stronger familiarity with clarity, stability, and sensory requirements.

Some global brands run dual sourcing: MCC from one regional cluster and fiber from another—especially when the beverage and supplement businesses operate under separate technical teams.

Turning specs into performance for weight management and daily nutrition

Procurement success depends on translating specs into outcomes. Below is a practical comparison buyers use when aligning MCC and resistant dextrin to “accessible nutrition” formats.

Buyer checkpoints for MCC vs resistant dextrin

| Checkpoint | MCC (typical buyer focus) | Resistant dextrin (typical buyer focus) |

|---|---|---|

| Primary role in formulation | Flow, compression support, texture/structure | Soluble fiber delivery, digestive/gut positioning |

| Grade language | Pharma/food grade; USP/EP alignment often requested | resistant dextrin food grade; fiber performance metrics |

| COA review emphasis | Identification, loss on drying, particle properties, microbiology | Fiber content (often ≥82%), appearance, protein limits, microbiology |

| Sensory risk | Chalky texture if misapplied | Off-notes/viscosity if grade is mismatched |

| Typical bulk packaging | Commonly requested in bulk sacks (e.g., 25 kg) | Bulk sacks (often 25 kg) plus customized packing options |

| Where it wins in accessible nutrition | Tablets, powdered blends, texture control in bars | RTDs, powders, gummies, sugar-reduction systems |

In weight management lines, resistant dextrin is often positioned as a neutral, low-calorie fiber that blends smoothly. This is why buyers searching for a resistant dextrin supplier China increasingly cross-check fiber specs and process stability rather than just price.

For product teams building fiber-forward concepts, one practical starting point is reviewing how resistant dextrin is positioned in weight-control applications—see the supplier-facing explanation of best fibre for weight loss. While that page is written from a product standpoint, it mirrors common buyer expectations: neutral taste, easy mixing, hot/cold stability, and low-calorie positioning.

In parallel, sourcing managers still keep MCC on the radar because “accessible” often means high-volume and fewer reformulation cycles. If the finished product is a tablet or a chewable, MCC frequently becomes non-negotiable, which is why screening a microcrystalline cellulose supplier China remains a standard procurement task.

What differentiates a recommended Chinese manufacturer in practice

Buyers often use the phrase “recommended” loosely. In supplier evaluation, it usually means the manufacturer can prove three things under pressure:

- Raw material control and repeatability

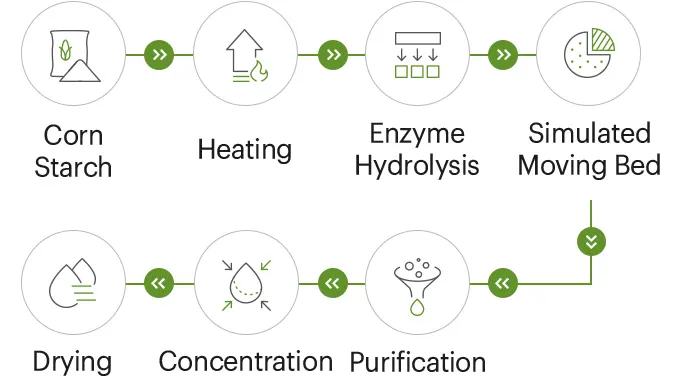

Many resistant dextrin products in China are produced from non-GMO corn starch, with supplier selection and incoming inspection controlling variability.

- Process consistency that supports scale

Automated control—from feeding through filling—reduces batch-to-batch drift.

- Documentation and traceability that match export routines

The expectation is that a China microcrystalline cellulose exporter can provide a predictable documentation package, and a resistant dextrin supplier China can do the same for food-grade needs.

A good example of what buyers look for is a manufacturer that emphasizes controlled raw materials, imported enzyme systems, and structured QC labs for fiber production. These are not “marketing extras”—they are practical signals that support stable COA performance and fewer surprises in application trials.

Risk controls buyers still expect when sourcing from China

Even when China is the preferred supply base, procurement teams still run a familiar risk-control playbook.

Documentation checklist (build this into RFQs)

- COA (batch-linked, with clear test methods)

- MSDS

- Allergen and non-GMO statements (when required for the finished claim)

- Quality system alignment (commonly ISO/HACCP; some suppliers also present broader certifications)

- For MCC used in pharma or dual-use contexts: USP/EP alignment evidence

This is why “MCC COA MSDS USP EP verification checklist” style workflows are increasingly standardized in procurement. A microcrystalline cellulose supplier China that cannot support this quickly tends to stall out early—regardless of price.

Practical execution checks

- Request a pilot batch that matches the intended packaging and shipping route.

- Run third-party testing for critical specs if the application is sensitive.

- Confirm packaging integrity and labeling consistency for bulk supply (many buyers still default to buy microcrystalline cellulose bulk 25kg bags style ordering for operational efficiency).

A sourcing pattern that matches accessible nutrition realities

For 2026 planning, many buyers are moving toward a two-lane strategy:

- Lane 1: Scale and stability

Lock in a dependable microcrystalline cellulose supplier China for the grades that are repeatedly used across SKUs.

- Lane 2: Application-forward fiber

Qualify a resistant dextrin supplier China with proven performance in the target format (RTD, gummy, powder) and a fiber content profile that supports product positioning.

Where possible, buyers also prefer a functional fiber manufacturer China that can support both standard grades and application guidance, because it reduces development friction when a brand needs to reformulate quickly.

For teams comparing suppliers, the resistant dextrin category page at resistant dextrin is a useful reference point for seeing how fiber products are positioned by application and how specs are typically presented. It also provides a practical way to navigate related fiber variants without forcing a single-fiber approach.

A similar “buyer education” signal exists for MCC: a supplier that publishes technical guidance (for example, grade selection and QC topics) usually understands the questions procurement teams and formulators will ask before scaling.

Choosing recommended suppliers without turning the process into a science project

A reliable shortlist does not require endless audits, but it does require consistency in evaluation. Use these three questions to keep supplier screening focused:

- Can the supplier prove consistency, not just capability?

Stable COA trends matter more than a one-time “perfect” sample.

- Does the supplier’s regional cluster match the product’s needs?

Shandong often aligns with volume and routine export; other regions may align better with niche applications.

- Is the documentation workflow fast enough for your launch calendar?

A good resistant dextrin supplier China and microcrystalline cellulose supplier China should treat documents, traceability, and technical response time as part of the product.

If you are building a recommended supplier list and want a practical starting set of product pages and technical reading, explore: