Fiber-first launches in 2026 are pushing new expectations for resistant dextrin. Learn formulation-ready specs and how to vet a resistant dextrin supplier China buyers can trust.

Fiber is rapidly evolving from a secondary label claim to a primary driver of purchase intent. For procurement teams and R&D formulators, this shift fundamentally changes how resistant dextrin is evaluated—particularly for low-calorie beverages, functional waters, and protein-forward powders where taste neutrality, solubility, and clean label claims must align perfectly.

In the current market landscape, success rewards brands that can deliver robust resistant dextrin-backed fiber claims without sacrificing clarity, sweetness control, or production throughput. More importantly, it rewards buyers who can qualify a resistant dextrin supplier China partners with confidence—securing supply chain resilience before market demand tightens lead times.

Why 2026 Will Be a Pivotal Year for Fiber Ingredients

Two distinct signals are converging to reshape the fiber market: evolving consumer expectations and aggressive portfolio strategies.

Industry trend forecasts have highlighted "fibermaxxing"—a consumer movement pushing for maximum fiber density per calorie—suggesting fiber could challenge protein as the top health driver for 2026. Simultaneously, reports on "accessible nutrition" indicate that 54% of global consumers associate fiber with digestive health, and 20% actively attempted to increase fiber intake in the prior year.

For buyers, this data matters because fiber is no longer restricted to niche digestive aid SKUs. Mainstream RTD beverages, meal replacement powders, and snackable formats are being reformulated around fiber-forward claims. Resistant dextrin has emerged as the backbone for these reformulations due to its unique ability to provide high fiber content without the viscosity or texture issues associated with traditional fibers like inulin or psyllium.

The Technical Case: Why Resistant Dextrin Dominates Briefs

Not all fibers behave consistently in complex beverage and protein systems. When product development teams specify resistant dextrin, they are typically solving a bundle of formulation constraints simultaneously:

- Caloric Density Control: Fiber addition must not pull calories upward like digestible carbohydrates. Resistant dextrin offers a lower caloric value, essential for "light" or "diet" positioning.

- Neutral Taste Profile: Modern consumers reject off-notes. Manufacturers need an ingredient with minimal sweetness and no lingering aftertaste to allow delicate flavor systems (like fruit or botanical extracts) to shine.

- Process Stability: Beverage lines often include high-temperature steps (pasteurization or UHT). Many functional drinks also exist in mildly acidic pH ranges. Resistant dextrin demonstrates superior stability under these stress conditions compared to other soluble fibers.

- Texture and Mouthfeel: In powders, the ingredient must flow freely and blend instantly; in RTDs, it must avoid the "chalky" mouthfeel that kills repeat purchase rates.

Resistant dextrin from reputable Chinese manufacturers is commonly specified at fiber content ≥82% with protein ≤6.0% (per typical supplier parameter tables). These numbers are not mere label details—they are procurement anchors for consistency. A protein content above that threshold can lead to unwanted Maillard browning or flavor degradation over time, while fiber content below the standard risks regulatory non-compliance for label claims.

Spec Reality Check for Buyers

Supplier technical sheets often describe solubility in vague terms, such as "dissolves easily under normal use." Rather than debating wording, buyers should convert these claims into a standardized qualification test. We recommend dissolving the resistant dextrin sample at the target dosage within your specific matrix, then validating clarity, viscosity, and stability after heat and shelf-life simulation. This practical approach cuts through marketing language and reveals the true quality of the raw material.

Market Application Snapshot: Briefing R&D and Procurement

To help align procurement with R&D goals, here are two high-frequency 2026 product briefs where resistant dextrin is selected for risk reduction and functional performance.

Snapshot A: Upgrading an RTD Drink Without "Fiber Penalties"

Typical Brief: A 250 mL Ready-to-Drink (RTD) beverage delivering 5–8 g of fiber per serving, with low calorie positioning, zero gritty mouthfeel, and crystal-clear appearance.

Why Resistant Dextrin Fits:

- Low Sweetness Impact: It helps keep flavor systems stable when sugar is already reduced, preventing the product from becoming cloying.

- High Solubility: This supports faster batch preparation in the factory and eliminates the risk of sediment formation at the bottom of the can or bottle.

- Acid Stability: With stability often cited around pH 4–5, it supports the acidity required for shelf-stable functional beverages.

Validation Steps for Buyers:

- Order of Addition: Confirm whether the resistant dextrin disperses best before or after acids and flavors are added to the tank.

- Heat Tolerance: Validate the ingredient after pasteurization or UHT-equivalent conditions to ensure no degradation occurs.

- Clarity vs. Claims: If "clear" is a marketing claim, specify a turbidity window and test in the actual packaging to account for interaction effects.

Procurement Takeaway: If the brief demands significant fiber loading, purchase decisions should not be made on "fiber %" alone. Batch-to-batch solubility and strict microbiological limits (backed by COA evidence) are often more decisive for line stability than a marginal price difference.

Snapshot B: Protein Plus Fiber Powders for Satiety

Retailers and brand portfolios are increasingly built around multi-benefit claims. Pairing protein with fiber is a dominant pattern for 2026, and resistant dextrin is frequently chosen to avoid the heavy viscosity and flavor masking costs associated with gums or less soluble fibers.

Behavior in Powders:

- In dry blends, resistant dextrin supports fiber claims while keeping the overall sweetness profile low.

- The particle size and moisture behavior are critical for flowability and anti-caking performance during high-speed filling.

The Role of Microcrystalline Cellulose (MCC):

When product lines expand into tablets, chewables, or specific dry-format nutrition systems, microcrystalline cellulose (MCC) is often evaluated alongside fiber as a functional excipient for structure and texture management. Consequently, many procurement searches bundle "**microcrystalline cellulose supplier China**" with fiber sourcing. While MCC and resistant dextrin solve different problems, sourcing them from a unified, capable supplier can streamline logistics and quality assurance.

Buyer Note: If your product roadmap includes both powders and compressible formats, plan a dual-qualification track early. This avoids a late-stage scramble to find a compatible supply combination.

Translating Chinese Supplier Capability into Lower Risk

China remains a primary global source region for resistant dextrin. However, the landscape is vast, ranging from trading houses to fully integrated manufacturers. Buyers often narrow the map by focusing on manufacturing hubs and export logistics capabilities. A practical evaluation framework for a resistant dextrin supplier China shortlist includes:

1. Verify Usable Certifications

Marketing materials often list logos, but procurement needs valid documentation. Commonly requested food safety and quality systems include ISO9001, BRC, HALAL, HACCP, and KOSHER. Do not just check for their existence; verify the current certificate scope and expiration date, ensuring they cover the specific production lines for resistant dextrin and match your intended export market requirements.

2. Connect COA Items to Your Process

At a minimum, your Certificate of Analysis (COA) review should reconcile:

- Fiber Content: Verify it meets the ≥82% standard (or your specific requirement).

- Protein Content: Ensure it adheres to the ≤6.0% limit to prevent flavor issues.

- Appearance: Consistent color and texture are proxies for process control.

- Microbiological Limits: These must align with your finished product's safety profile.

If purchasing for a sensitive application like a low-calorie beverage, insist on a pilot shipment. Run the process steps that actually stress the ingredient—mixing shear, heat treatment, and pH adjustment—to identify potential failure points before a full container order.

3. Understand the Plant Story Behind "Consistency"

Many established manufacturers highlight automated, centrally controlled production—from raw material feeding to filling—alongside in-house QC labs. For buyers, the value lies in the implication of these features:

- Automation: Fewer manual handling steps reduce human error and batch variability.

- In-House QC: A real, equipped laboratory speeds up deviation investigations and ensures retention samples are available for trace-back if a consumer complaint arises months later.

A Buyer Checklist for 2026 Resistant Dextrin Tenders

Use this checklist to compare a resistant maltodextrin manufacturer or dietary fiber manufacturer China partner against your needs.

Product and Performance Checklist

- Target fiber grams per serving and serving size defined.

- Target taste profile established (neutral vs. slight sweetness allowed).

- Beverage requirements: clarity, pH window, and heat step tolerance.

- Powder requirements: flowability, caking risk, and instantization needs.

- Packaging format: moisture barrier requirements and shelf-life expectations.

Supplier Checklist

- Documentation: COA template, specification sheet, and allergen statement.

- Certification scope: ISO, BRC, HALAL, HACCP, KOSHER verified.

- Batch consistency approach: retention samples, complaint handling, and change control procedures.

- Pilot-to-scale support: willingness to provide trial quantities and technical input.

MCC Companion Checklist (If Applicable)

- Confirm intended MCC grade for your format (tablet vs. chewable vs. dry blend).

- Ask how MCC is tested and how lot-to-lot variability is managed.

- Ensure both resistant dextrin and MCC are compatible with your processing humidity and compression conditions.

Finding Credible Manufacturers

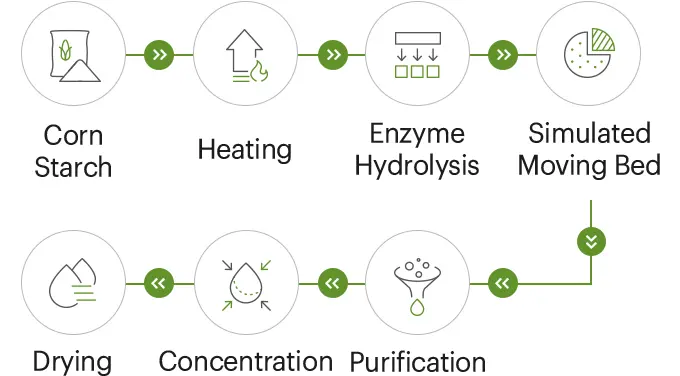

While B2B platforms are useful for building an initial longlist, a "recommended" supplier is ultimately the one that proves consistency through paperwork, transparency, and pilot behavior. Manufacturers that control the entire chain—from non-GMO corn starch sourcing to final powder processing—offer a distinct advantage in traceability and risk management.

As a starting point for your vetting process, reviewing a representative manufacturer's technical data and production philosophy can help set a baseline for what "good" looks like. For detailed specifications on resistant dextrin and insight into automated production standards, you can review the technical resources at Shandong Shine Health Co., Ltd..

This is not a substitute for your own internal qualification, but leveraging established industry players with transparent quality systems can significantly speed up your screening process, ensuring you enter 2026 with a robust and compliant fiber strategy.