A buyer-focused guide to selecting a recommended Chinese resistant dextrin manufacturer and microcrystalline cellulose supplier using 2026 demand signals and practical spec checks.

2026 demand signals that should change how you shortlist suppliers

Two 2026 signals are especially relevant for procurement teams building new briefs.

First, fiber is no longer a niche wellness claim. A recent 2026 trend article notes that 54% of consumers associate fiber with digestive health, and 20% report increasing intake of fiber-rich foods over the past year. That kind of demand pressure tends to show up quickly in product development pipelines: fiber-forward bars, shakes, and even coffees become mainstream, which pushes stable supply of resistant dextrin.

Second, delivery formats are converging. Many brands launch powders, gummies, and tablets as a connected line. In practice, that means a fiber ingredient like resistant dextrin may be used in powders and functional foods, while microcrystalline cellulose (MCC) stays essential behind the scenes for tablets and capsules—especially where flow, compressibility, and robustness matter.

For a buyer, the implication is simple: treat resistant dextrin and microcrystalline cellulose as two different risk profiles. Resistant dextrin is “food system + labeling + sensory,” while microcrystalline cellulose is “dosage form + pharmacopeia + process control.”

Resistant dextrin is the “quiet” workhorse fiber buyers keep reordering

In sourcing discussions, resistant dextrin often gets described as a soluble fiber that is easy to formulate with. What that really means in procurement terms is that resistant dextrin is typically valued for a combination of high fiber contribution, neutral taste, and workable viscosity across multiple applications.

On supplier specification tables, one recurring threshold is fiber content ≥82% for resistant dextrin. That number is not just a marketing point—buyers use it as a practical signal that the resistant dextrin is positioned for fiber-forward formulations where a little variance can force recipe changes.

Where resistant dextrin tends to win in formulations

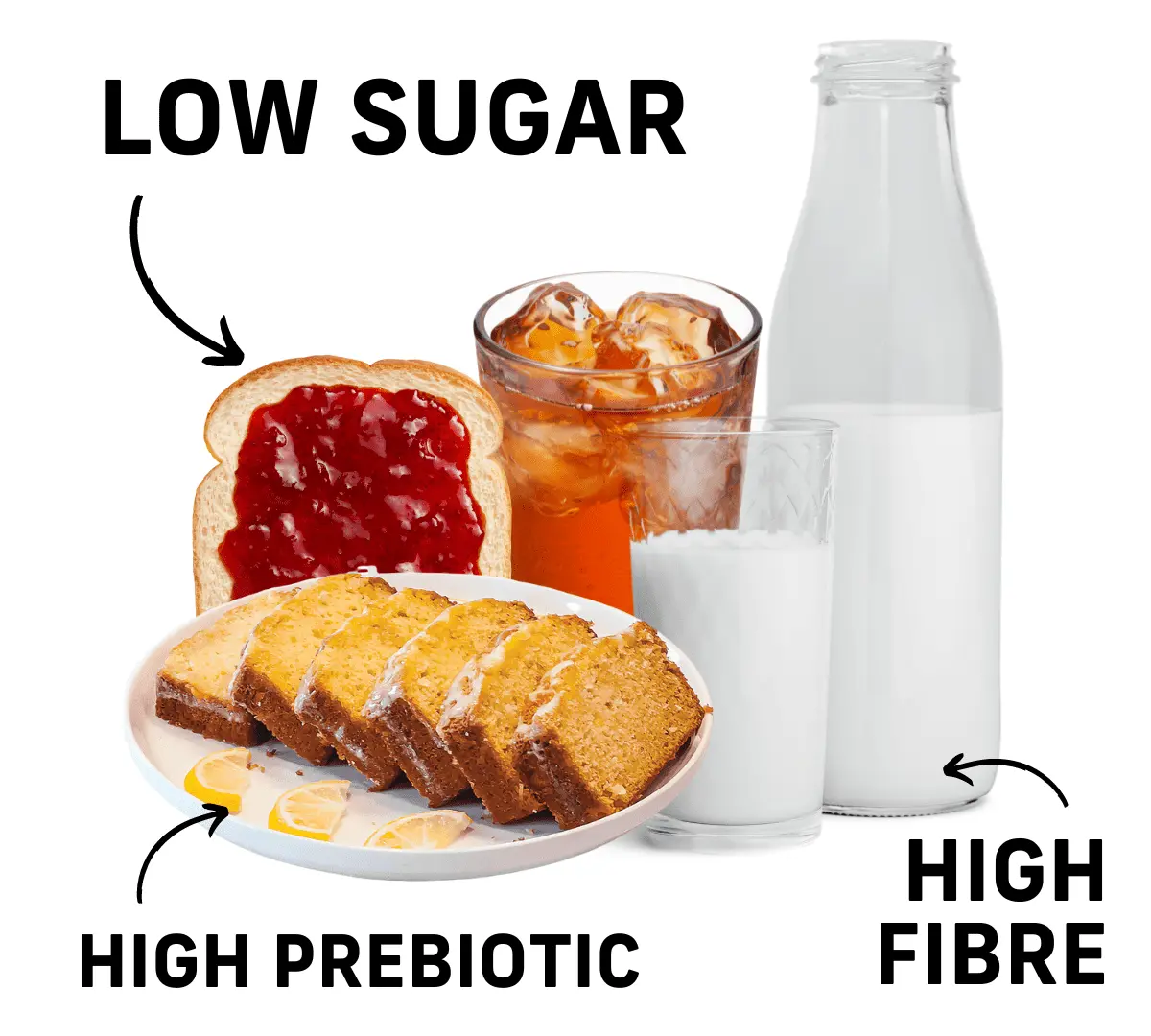

Resistant dextrin is frequently chosen when the product team wants to add fiber without creating a strong flavor signature or gritty mouthfeel. In market reality, that can look like:

- High-fiber confectionery and gummies where texture and sweetness balance are sensitive

- Low-sugar or “low calorie dietary fiber” positioning in powders and premixes

- Keto-style and reduced-net-carb recipes where resistant dextrin supports fiber targets

For buyers needing a quick orientation on commercial formats, it helps to review how suppliers position resistant dextrin across finished applications. One example category view is available here: resistant dextrin portfolios and formats.

A buyer-ready checklist for resistant dextrin specs

When qualifying resistant dextrin, many teams focus on the fiber number and forget the “operating specs” that prevent production surprises. A practical resistant dextrin checklist usually includes:

- Fiber content: ≥82% (as stated on many resistant dextrin spec tables)

- Appearance: white to light yellow (helps QA set visual acceptance)

- Protein: typically listed as ≤6.0% on common spec sheets

- Storage conditions: “store in a cool place” is basic, but confirm shelf-life and humidity precautions

- Food safety signals: evidence of controlled workshops and QC testing (more on what to look for below)

If your sourcing brief includes “cleaner” positioning, it’s also reasonable to request a non-GMO statement for resistant dextrin and confirm the starch origin described by the supplier.

A quick comparison buyers can share internally

| Decision question | Resistant dextrin (food & nutrition) | Microcrystalline cellulose (solid dose) |

|---|---|---|

| What does it protect? | Label fiber targets, taste neutrality, texture | Tablet robustness, flow, compression behavior |

| Common “must-have” documentation | COA, non-GMO statement (if needed), food safety certificates | COA aligned to pharmacopeia expectations, GMP evidence |

| Main failure mode | Reformulation due to sensory/solubility variability | Compression issues, friability, variability in particle properties |

This is why procurement teams often end up dual-sourcing: resistant dextrin supply continuity protects launches, while microcrystalline cellulose supply continuity protects manufacturing schedules.

Microcrystalline cellulose remains the excipient buyers can’t “innovate away”

Microcrystalline cellulose is widely used as an excipient, and buyers typically evaluate it with a different mindset than resistant dextrin. You’re not buying microcrystalline cellulose for a consumer-facing claim—you’re buying microcrystalline cellulose to keep a dosage form manufacturable and stable.

Even when the commercial project is a nutrition product, microcrystalline cellulose is often part of the enabling system: it supports tablet binding, helps manage flow, and contributes to consistent compression performance.

What to verify when you need pharmaceutical grade MCC from China

When a sourcing request says “pharmaceutical grade MCC China,” it usually implies the buyer will check:

- Alignment with relevant pharmacopeia expectations (often referenced as USP/EP in buyer language)

- Evidence of controlled production conditions (GMP language frequently appears in qualification)

- Clear grade communication and repeatable QC methods

A useful, buyer-facing primer that many teams share across QA and formulation is a grades-and-QC overview like this: MCC grades formulation guide. Even if you source from multiple partners, having a shared grade vocabulary reduces back-and-forth during tech transfer.

China sourcing reality for resistant dextrin and MCC is regional and capability-driven

For global buyers, the conversation about a microcrystalline cellulose supplier China or a resistant dextrin supplier China is rarely about “China” as a single market. It’s about clusters and plant capabilities.

Across B2B sourcing guides, the most commonly cited production hubs for resistant dextrin include Shandong, Jiangsu, and Guangdong. In practice, these regions often support export-oriented production with established logistics and documentation workflows.

What procurement teams should look for on supplier pages is not broad claims, but operational specifics that indicate repeatability for resistant dextrin and microcrystalline cellulose, such as:

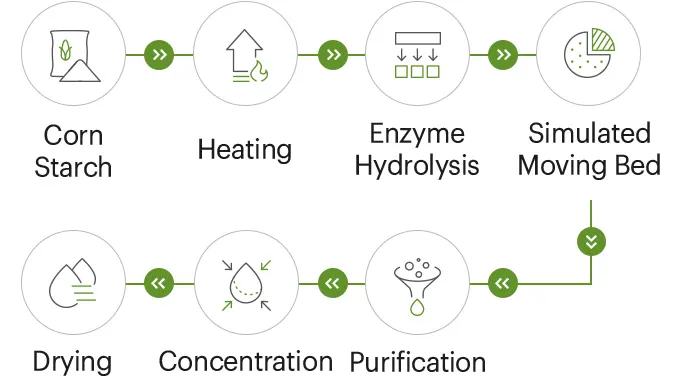

- Non-GMO corn starch positioning for resistant dextrin inputs (when required by your market)

- Mentions of imported enzymes and controlled processing (relevant for resistant dextrin consistency)

- Signs of GMP-standard workshops and QC laboratory testing capability

- Process transparency: a clear sequence from raw material feeding to finished filling

These are the signals that separate a “listed exporter” from a recommended Chinese microcrystalline cellulose manufacturer or recommended Chinese resistant dextrin manufacturer in real-world procurement.

The documentation pack that makes a supplier “recommended” in buyer terms

A recommended supplier is not just the cheapest bulk offer. For resistant dextrin and microcrystalline cellulose, “recommended” usually means the supplier can support qualification without friction.

For resistant dextrin supplier qualification

Ask for a COA that clearly lists (at minimum) the items buyers already use as quick gates:

- Resistant dextrin fiber content (commonly ≥82%)

- Appearance

- Protein

- Storage guidance

If your product positioning depends on it, add a non-GMO statement and allergen statement for resistant dextrin. The goal is speed: you want QA to approve resistant dextrin once, and production to reorder resistant dextrin without re-opening questions.

Buyers comparing multiple fiber types often start from an application-oriented page and then move into specs. A concise starting point for categories such as low-sugar or keto-friendly resistant dextrin is: keto-friendly resistant dextrin options.

For microcrystalline cellulose supplier qualification

For microcrystalline cellulose, procurement usually benefits from pre-alignment between QA and manufacturing:

- Confirm which microcrystalline cellulose grade language the supplier uses

- Validate whether the supplier provides consistent testing methods for those grades

- Ensure change control expectations are clear (grade changes create major downstream risk)

This is why microcrystalline cellulose sourcing often begins with a grades guide and only then moves to pricing.

A practical shortlisting workflow that saves time in 2026

Procurement teams often lose weeks comparing resistant dextrin suppliers or microcrystalline cellulose suppliers on non-comparable data. A faster workflow is:

- Screen for fit: resistant dextrin (fiber threshold and application suitability) vs microcrystalline cellulose (grade and excipient intent)

- Screen for proof: QC lab language, workshop standards, production transparency

- Screen for documents: COA clarity, consistency, and response speed

- Pilot the logistics: one sample + one small commercial lot to validate repeat orders

This approach tends to produce a more defensible shortlist of a recommended Chinese microcrystalline cellulose supplier and a recommended Chinese resistant dextrin manufacturer—without forcing you to bet on the lowest offer.

Closing note for buyers building a “recommended supplier” list

In 2026, resistant dextrin demand is rising with fiber-forward consumer trends, and microcrystalline cellulose remains central to tablets and many supplement formats. The winning procurement strategy is rarely complicated: write two separate briefs, qualify resistant dextrin and microcrystalline cellulose with the right documentation, and prioritize suppliers who show repeatable production and transparent specs.

For buyers who want to benchmark what export-facing resistant dextrin documentation and formats often look like, a neutral starting point is the category page here: resistant dextrin supplier portfolio.