A 2026-ready sourcing brief for procurement teams evaluating a resistant dextrin manufacturer China and microcrystalline cellulose manufacturer China, with verification steps, hub insights, and COA checkpoints.

Accessible nutrition is quickly turning into a procurement reality: shoppers want everyday products that feel “better-for-you,” and brands are responding by adding fiber while keeping taste and cost under control. For global buyers, this shift elevates two ingredients that solve different problems in the same formulation pipeline—resistant dextrin for soluble fiber and label-friendly nutrition, and microcrystalline cellulose (MCC) for texture and tablet performance.

That combination is why requests for a resistant dextrin manufacturer China and a microcrystalline cellulose manufacturer China are showing up earlier in RFP cycles. The question is no longer “Can China supply it?” but “Which China supplier can hold spec, documentation, and delivery when volumes scale?”

The 2026 shift that is reshaping fiber and MCC demand

The “accessible nutrition” wave matters for sourcing because it changes what buyers prioritize:

- Fiber becomes a default upgrade, not a niche feature. Brands want fiber in bars, RTD beverages, coffees, powders, and gummies—often without changing taste or viscosity.

- Formulation teams want cleaner functionality: soluble fiber that blends easily (resistant dextrin) and a proven structuring excipient (microcrystalline cellulose).

- Procurement needs repeatability, not just a low FOB quote—especially when fiber claims, digestive positioning, and shelf-life expectations collide.

In this environment, procurement teams commonly shortlist a dietary fiber supplier China alongside a microcrystalline cellulose manufacturer China to cover both nutrition and processing performance.

What buyers now ask a resistant dextrin manufacturer in China to prove

When buyers search “China resistant dextrin manufacturers,” many suppliers appear similar on paper. In practice, qualification tends to hinge on a few measurable outcomes.

1) Can the supplier meet the target fiber specification consistently?

Across market listings, a widely requested benchmark is fiber content ≥82% for resistant dextrin used in mainstream food and supplement applications. Some product lines in the market also position higher total fiber content (for example, certain grades specify ≥90% on a dry basis), but buyers should treat that as grade-specific, not assumed.

What to verify:

- Fiber content target and method stated in the COA

- Protein limit clarity (commonly controlled at ≤6.0% in several commercial specs)

- Color/appearance and lot-to-lot uniformity (often “white to light yellow”)

2) Can the ingredient support low-sugar, low-net-carb positioning?

Resistant dextrin is frequently selected because it resists digestion in the small intestine and can be used to support low-sugar or low-net-carb concepts. This is where “label strategy” meets “supplier reality.” Buyers need documentation that aligns with their finished-product labeling needs.

If your pipeline includes keto-positioned products, it can be useful to compare multiple resistant dextrin options such as non-GMO grades and resistant maltodextrin styles, then align them with your labeling policy and target markets.

3) Does the quality system match export expectations?

Serious resistant dextrin manufacturer China shortlists often converge on plants that can demonstrate established food safety and export readiness through commonly requested certifications such as:

- ISO9001

- BRC

- HACCP

- HALAL

- KOSHER

Certification alone is not a guarantee, but it is a fast way to filter suppliers before deeper testing.

Why MCC is back in the conversation for 2026

Fiber-forward product roadmaps often revive older challenges: gritty mouthfeel, separation in liquids, or tablet issues when adding functional actives. That is where microcrystalline cellulose returns as a practical tool.

Buyers typically involve a microcrystalline cellulose supplier China for tablets when they need:

- Tablet binding and compression support

- Better flow and consistency in dry blends

- Texture building in certain food systems (depending on formulation design)

For procurement teams, MCC sourcing success is less about discovering “any MCC” and more about qualifying the right grade and making sure documentation supports your dosage form and market requirements. A helpful starting point for internal alignment is an MCC grade and QC overview like this resource: MCC Grades Formulation and QC Guide.

China’s fiber and MCC clusters buyers watch for capacity and specialization

China’s supply base is not uniform. Buyers often map capacity and export maturity by region—especially when building dual sourcing.

Shandong cluster

Shandong is frequently associated with scale and export-oriented ingredient manufacturing. For buyers looking for a Shandong microcrystalline cellulose supplier or a dietary fiber supplier China with stable output, Shandong remains a recurring shortlisting region. Cities such as Jinan and nearby industrial zones often appear in procurement mapping because of logistics access and established ingredient trade lanes.

Jiangsu and Guangdong clusters

For resistant dextrin, sourcing discussions often highlight Jiangsu and Guangdong alongside Shandong. Buyers searching for a “Jiangsu resistant dextrin manufacturer low calorie fiber” are usually trying to balance three constraints: cost targets, clean taste, and documentation reliability.

Coastal logistics nodes

Ports and manufacturing corridors around areas such as Qingdao can simplify lead times and consolidate export workflows, which matters when multiple ingredients ship together (fiber plus excipients, or fiber plus sweeteners).

The key point: when evaluating China microcrystalline cellulose manufacturers and China resistant dextrin manufacturers, location isn’t a quality guarantee—but it often correlates with logistics predictability and the supplier’s export routine.

Marketplace discovery versus direct factory engagement

Most buyers begin their search for a resistant dextrin manufacturer China or microcrystalline cellulose manufacturer China via global B2B directories. That’s useful—if you understand what a listing can and cannot tell you.

What marketplace listings are good for

- Fast supplier discovery and category breadth

- Early screening by certifications, rough capacity claims, and typical MOQ

- Identifying which grades are marketed (food grade, supplement grade, tablet-focused MCC)

What must be validated off-platform

Once you have a shortlist, serious qualification moves to direct engagement:

- Request a recent COA (not a template)

- Ask for microbiology and impurity controls appropriate to your application

- Confirm non-GMO positioning if required, and how it’s documented

- Run a sample trial that reflects your real processing conditions

- Verify packaging integrity and traceability for bulk shipment

In other words, the best buyers treat listings as a directory, then evaluate the supplier like a long-term manufacturing partner.

How to read COAs without slowing down your launch

COAs are where many buyer-supplier relationships either become efficient—or become expensive. The goal is not to “collect documents,” but to ensure the COA matches your application risk.

For resistant dextrin

Common COA checkpoints buyers request from a food grade resistant dextrin manufacturer China include:

- Fiber content (often specified at ≥82% for mainstream grades)

- Protein (commonly controlled at ≤6.0% in commercial specs)

- Appearance, moisture-related handling notes, and storage conditions

- Batch/lot traceability and date coding

If your team is targeting non-GMO positioning, consider shortlisting a non-GMO resistant dextrin China bulk option and validate how the non-GMO statement is supported.

For microcrystalline cellulose

For MCC, buyers often focus on:

- Grade alignment to dosage form (especially tablets)

- Flow/compression indicators and consistency controls

- Documentation that supports regulated end markets

This is where a well-defined incoming inspection plan saves time—because MCC issues tend to appear during scale-up, not the first lab batch.

Innovation signals that matter to procurement teams

Innovation in fibers is not only about new claims; it’s also about reducing formulation trade-offs. Today’s buyers screen China resistant dextrin manufacturers for practical innovation signals such as:

- Ability to supply fibers positioned for low-sugar or low-net-carb concepts

- Stable performance under heat and acid conditions (important for beverages and baking)

- R&D support that can adjust sensory and solubility performance without changing your entire formula

From a procurement view, innovation is valuable when it lowers total project risk: fewer reformulations, fewer consumer complaints about taste, and fewer delays caused by inconsistent lots.

A buyer’s shortlisting checklist for recommended Chinese MCC and fiber partners

If your internal goal is to identify a Recommended Chinese Microcrystalline Cellulose Manufacturer, a Recommended Chinese Microcrystalline Cellulose Supplier, and a Recommended Chinese Resistant Dextrin Manufacturer, a practical shortlisting checklist looks like this:

- Spec fit: resistant dextrin and microcrystalline cellulose grades match your application needs

- COA quality: real batch COAs, clear test methods, consistent limits

- Certifications: ISO9001/BRC/HACCP/HALAL/KOSHER where relevant to your markets

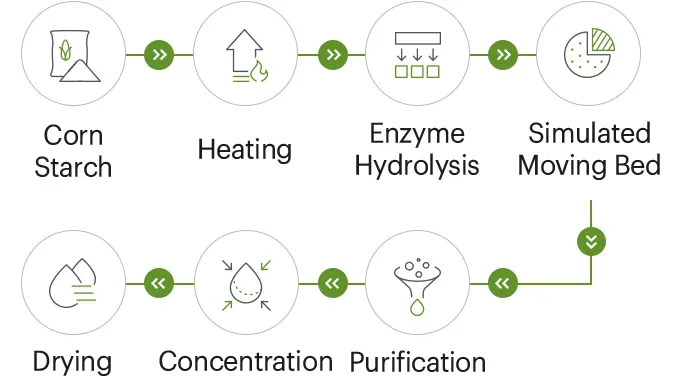

- Manufacturing clarity: automated processing controls and defined QC steps

- Packaging and traceability: bulk packaging suitable for export handling

- Sampling discipline: supplier supports small-lot trials before scaling

A supplier does not need to be “the biggest” to be recommended—but it should be predictable, document-ready, and responsive during technical evaluation.

Where to review market-ready resistant dextrin examples

When procurement teams want to benchmark specs and product formats from a Shandong-based export supplier, it can help to review public product pages that show typical parameters, applications, and documentation expectations.

Relevant starting points include:

- Resistant dextrin category

- Non-GMO resistant dextrin

- Resistant maltodextrin

- Organic resistant tapioca dextrin

- Low calorie dietary fiber

These pages are most useful as a spec and positioning reference—buyers should still rely on their own COA reviews, sampling, and qualification steps before contracting a supplier.

The takeaway for 2026 procurement planning

Accessible nutrition is pushing fiber and excipient sourcing upstream. Buyers who wait until after formulation lock often discover that the “cheapest” resistant dextrin or MCC becomes expensive in rework, inconsistent performance, or documentation gaps.

A disciplined approach—shortlist the right resistant dextrin manufacturer China, validate COAs early, and align MCC grades to dosage forms—turns China’s scale into a competitive advantage instead of a sourcing risk.

Data sources and market reading

- FrieslandCampina Ingredients trend coverage (accessible nutrition and fiber awareness): Food Business News

- Marketplace discovery context for resistant dextrin sourcing: Alibaba supplier directory

- China production hub discussion for resistant dextrin: Foodchem

- Innovation events highlighting targeted functional fibers: Food Ingredients First

- Macro view on China’s self-sufficiency trend and supply chain implications: ICIS