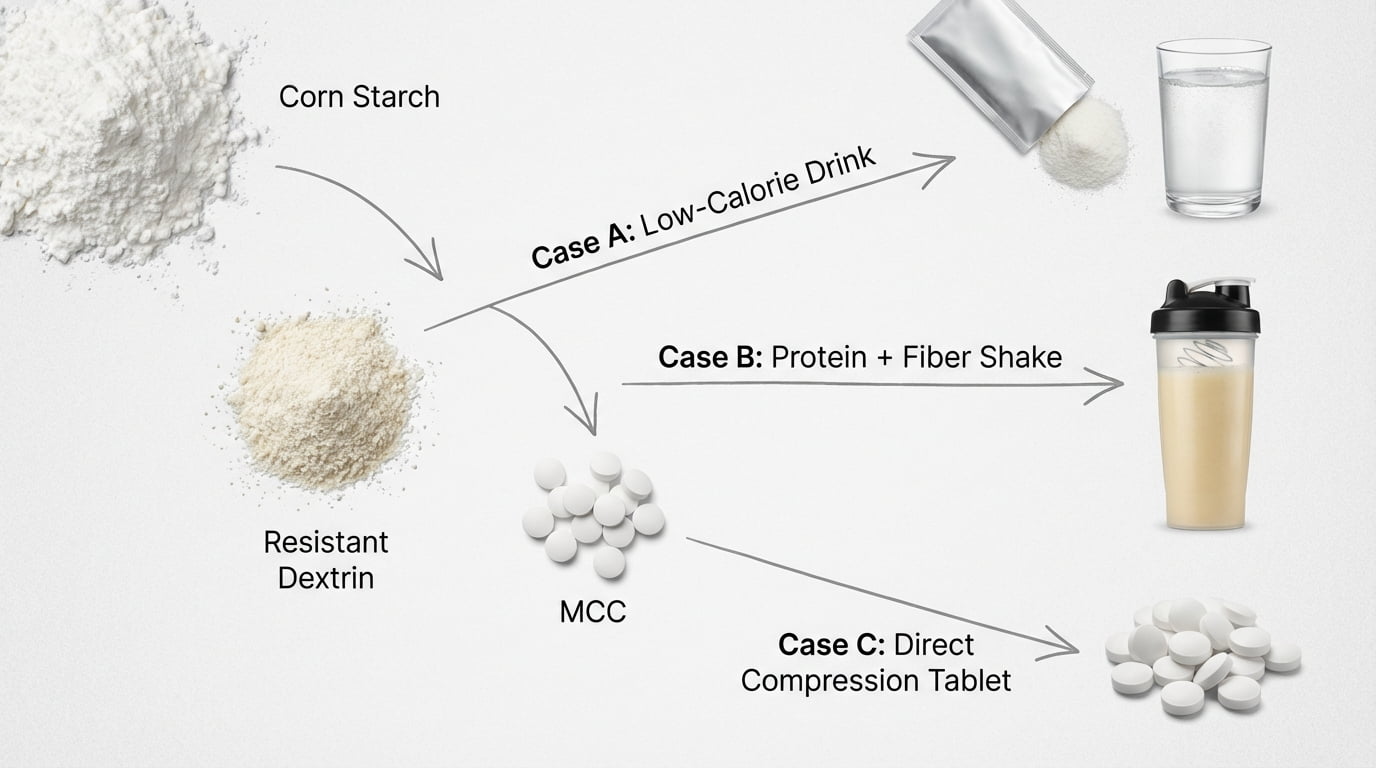

Discover why resistant dextrin and MCC are essential for 2026 product launches. Expert insights on sourcing specs for fiber drinks, GLP-1 shakes, and direct-compression tablets.

Fiber-first product briefs are evolving rapidly. As we approach 2026, buyers are no longer satisfied with generic ingredient lists; they demand measurable fiber delivery, impeccable clean taste in beverages, and repeatable tablet performance. The days of tolerating surprise reformulations during scale-up are fading. In practice, the most successful commercial launches are increasingly relying on two workhorse ingredients: resistant dextrin as a versatile, soluble prebiotic fiber for foods and drinks, and microcrystalline cellulose (MCC) as the critical excipient for direct compression tableting.

The "Quiet Victors" of Procurement Reviews

In rigorous procurement reviews, resistant dextrin and microcrystalline cellulose tend to win quietly because they preemptively solve problems that become prohibitively expensive to fix later in the production cycle. Unlike flashy, trend-driven ingredients that often fail stability testing, these two components provide the structural and functional backbone required for modern formulations.

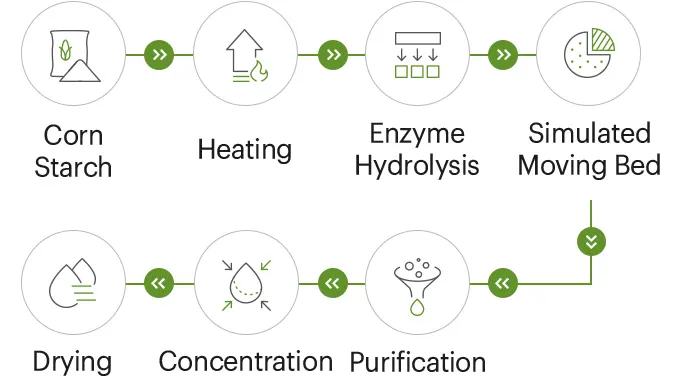

Resistant dextrin has become the gold standard for fiber fortification because it offers a neutral sensory profile. It possesses strong compatibility with high-intensity sweeteners and delicate flavor systems, maintaining performance across diverse formats including powders, ready-to-mix (RTM) beverages, and nutrition foods. Commercial specifications are increasingly standardizing on a fiber content of ≥82% with specific corn-starch sourcing to ensure consistency.

On the solid dose side, Microcrystalline cellulose (MCC) is the automatic choice when engineering teams opt for direct compression or robust continuous manufacturing approaches. The selection of the specific MCC grade directly influences critical parameters: flowability, compressibility, tablet hardness, friability, and disintegration time.

For procurement officers and R&D managers searching for reliable supply partners, the determining factor is rarely the label on the bag—it is whether the supplier can consistently meet a repeatable, application-specific specification.

Case Study A: Low-Calorie Powdered Drink Formulations

Use Case: A low-calorie powdered drink positioned for weight-conscious consumers seeking fiber supplementation without the dreaded "sugar crash."

The Target Brief

- Claims Direction: Low sugar, low-calorie, fiber-fortified, gut-friendly.

- Format: Instant powder (sachet or tub).

- Primary Pain Points at Scale: Cloudiness in solution, flavor off-notes, caking in the hopper, and inconsistent sweetness release.

Why Resistant Dextrin Fits the Job

A well-specified resistant dextrin acts as a functional beverage fiber ingredient rather than merely a nutritional add-on. Its role is multifaceted:

- Fortification: It adds significant dietary fiber while keeping the formula aligned with strict low-carb positioning.

- Texture Modulation: It helps restore body and mouthfeel in reduced-sugar systems where bulk is often lost.

- Flavor Neutrality: It integrates cleanly with delicate fruit flavors and high-intensity sweeteners without masking them.

For a practical reference point on how this ingredient fits into low-carb strategies, examine the applications for low carb food additives.

Buyer-Ready Spec Lines (RFQ Checklist)

When the base formula is simple, the fiber specification must do the heavy lifting. Experienced buyers commonly lock in the following parameters:

- Identity and Source: Resistant dextrin / soluble dietary fiber sourced from corn starch (often specified as NON-GMO).

- Core Composition Targets: Fiber content ≥82%; Appearance must be white to light yellow.

- Powder Handling: Moisture window must be suitable for powdered drink processing to ensure shelf-life stability and prevent caking.

- Micro Limits: Microbial limits must be appropriate for beverage powders, aligned with the destination market's regulations.

Processing Notes for Procurement

While resistant dextrin is standard in powder systems, procurement should confirm instantization and spray drying compatibility. Furthermore, understanding its behavior in acidic environments (citric/malic acids) is crucial, especially if the product is an electrolyte or "sports-style" drink.

Case Study B: Protein Plus Prebiotic Fiber Shake (GLP-1 Companion)

Use Case: A ready-to-mix (RTM) shake designed for consumers prioritizing satiety and nutrient density. This format is seeing a surge in interest as GLP-1 usage increases, driving retailers to lean into "protein + fiber" combinations that support digestive health and sustained fullness.

The Target Brief

- Format: RTM powder.

- Nutrition Direction: High protein content paired with meaningful fiber per serving.

- Practical Constraints: Viscosity control, clean finish (no grit), high digestive tolerance, and consistent reconstitution.

Ingredient Strategy: The Quiet Stabilizer

This is where resistant dextrin becomes the "quiet stabilizer" in the formula architecture. It provides prebiotic soluble fiber without aggressively altering the flavor profile or creating the "sludge" effect common with other fibers. It pairs exceptionally well with dairy proteins (whey/casein) and plant proteins, keeping the shake drinkable and smooth.

If the product positioning leans explicitly into digestive support, buyers often evaluate prebiotic soluble corn fiber as a close functional reference.

Buyer-Ready Spec Lines for the Shake Brief

- Functional Goal Definition: Define fiber grams per serving first, then back-calculate the required inclusion rate.

- Standardized Parameters: Ensure the raw material is corn starch (often NON-GMO), appearance is consistent, and fiber content is ≥82%.

- Sensory Performance: The ingredient must have a neutral taste (no bitterness or burnt notes) and dissolve cleanly with minimal sedimentation under typical consumer mixing conditions (e.g., shaker bottle).

Case Study C: Direct-Compression Tablets & MCC Selection

Use Case: A daily tablet combining vitamins, minerals, and botanicals. The manufacturing team requires consistent hardness and low friability without the complexity and cost of wet granulation processes.

Why MCC is Central in Direct Compression

In direct compression, Microcrystalline Cellulose (MCC) is not merely a filler; it is a functional performance driver. It serves as:

- A compression aid that ensures tablet strength and integrity.

- A flow and processing excipient that stabilizes high-speed manufacturing.

Different MCC grades exhibit distinct behaviors regarding flow, bulk density, moisture sensitivity, and compaction. Consequently, buyers must treat the excipient decision as a technical procurement strategy rather than a generic catalog choice. Aligning R&D language with supplier documentation is vital; a useful starting point is the MCC Grades Formulation and QC Guide.

Buyer Questions to Prevent Production Failures

To avoid the "works in pilot, fails in production" scenario, buyers should ask potential suppliers:

- Grade Rationale: Which specific MCC grade is recommended for direct compression versus granulation?

- QC Correlation: What in-house tests are performed batch-to-batch that correlate with tableting outcomes (e.g., flow indices, moisture windows)?

- Process-Fit Evidence: Can the supplier share application guidance for continuous or high-throughput manufacturing environments?

- Change Control: How are raw material shifts and process changes managed, documented, and communicated to the buyer?

Manufacturing Transparency: Reducing Buyer Risk

For global buyers, particularly those evaluating manufacturers in major supply hubs like China, risk reduction comes from transparency. When a supplier can clearly articulate their production controls and QC checkpoints, confidence increases. In supplier audits, savvy buyers look for:

- Automated Operations: From feeding to filling, automation reduces human error and variability.

- In-House QC: A fully equipped laboratory capable of routine release testing without relying solely on third parties.

- Traceability: Clear documentation of raw material screening and batch history.

Turning Insights into Sourcing Strategy

The overarching lesson for 2026 procurement is that "resistant dextrin" and "MCC" should never be purchased as generic commodities. They must be bought against format-specific specifications that align with the final product's promise.

A Neutral Path to Shortlisting Suppliers

Buyers looking for reliable partners typically achieve better results by validating three pillars early in the conversation:

- Consistency Controls: Verify the level of automation and how batch-to-batch variation is prevented.

- QC Depth: Understand exactly what is tested in-house versus what is outsourced.

- Application Support: Determine if the technical guidance provided is tailored to beverages, powders, or tablet processes specifically.

For procurement teams seeking to compare product pages, technical notes, and supplier capabilities in one centralized location, exploring the resistant dextrin category hub and related soluble fiber resources is a recommended next step. You can review detailed specifications and supplier capabilities at www.sdshinehealth.com.