Discover how to qualify Chinese suppliers for resistant dextrin and microcrystalline cellulose using an evidence-based approach, focusing on automation, hub selection, and verifiable QC data.

Why Automation is the New Quality Baseline

In previous sourcing cycles, many buyers viewed ingredients like resistant dextrin and microcrystalline cellulose as standard commodities where price was the primary differentiator. Today, the risk profile has evolved, and the cost of inconsistency is far higher than the savings from a cheaper initial quote.

Consider the operational impact of variability:

- A minor fluctuation in resistant dextrin fiber content or moisture levels can drastically alter sweetness perception, viscosity, and shelf stability in finished beverages or functional foods.

- For microcrystalline cellulose, inconsistent particle size distribution or bulk density can lead to tablet capping, poor flow in hoppers, and compressibility issues—resulting in costly production downtime and rework.

Consequently, astute buyers now use automation as a proxy for repeatability. When a manufacturing plant demonstrates centralized control systems—managing everything from raw material feeding to final packaging—alongside robust in-house QC testing, it signals that the operation is engineered to minimize human error and reduce batch-to-batch variation. This level of process control is becoming the standard for export-grade ingredients.

China’s Production Hubs: Where to Look

China’s production capacity for functional ingredients is not evenly distributed; it is concentrated in specific industrial clusters. For overseas buyers, the choice of hub influences not just price, but also lead times, logistics resilience, and the supplier's ability to provide credible export documentation quickly.

Hub Snapshot for Resistant Dextrin and MCC Sourcing

| Province / Cluster | Typical Strengths Buyers See | Why It Matters for Exports |

|---|---|---|

| Shandong | Dominant presence in dietary fiber, corn starch derivatives, and functional ingredients; highly experienced export operations. | Proximity to raw material sources (corn) ensures consistent supply; mature shipping routes support reliable delivery schedules. |

| Jiangsu | A strong mix of food ingredients and pharmaceutical excipient capabilities; close to major international ports. | Facilitates easier coordination for third-party audits, sampling, and container consolidation for multi-ingredient orders. |

| Guangdong / Coastal South | Robust trading infrastructure and deep export experience; diverse ingredient ecosystems. | Offers faster market feedback and easier procurement of complex, multi-ingredient formulations. |

Strategic Insight: If your formulation relies heavily on high-performance fiber (specifically resistant dextrin at higher purity grades), Shandong-based producers are often the logical starting point. The region is the heart of China’s corn processing industry, providing a secure supply chain for corn-starch-derived fibers.

Decoding Resistant Dextrin Specs Without Guesswork

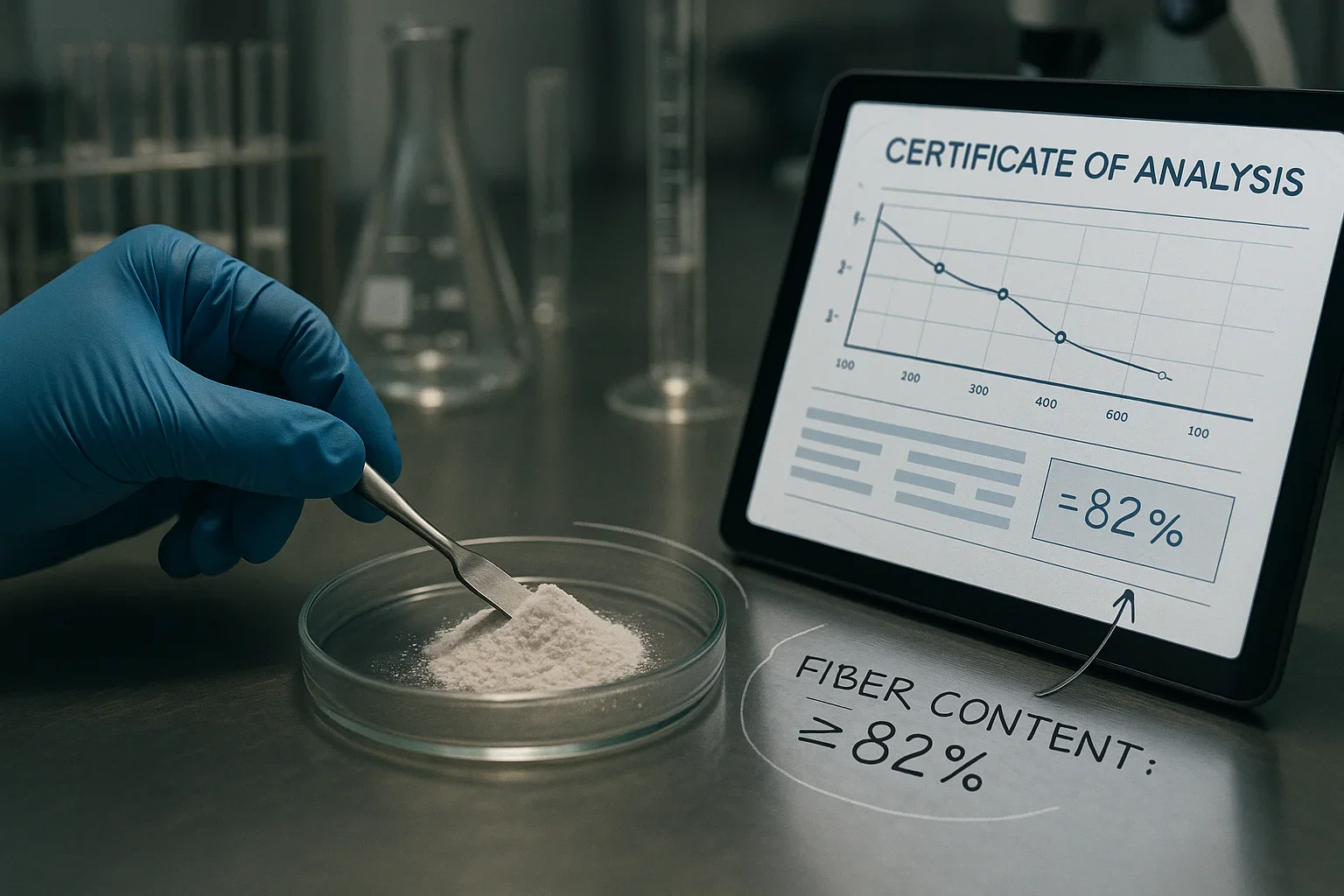

Most sourcing projects begin with a Certificate of Analysis (COA) and a specification sheet. However, effective shortlisting requires a deeper dive: linking specifications to potential risks and verification methods.

Critical Parameters for Resistant Dextrin

When reviewing a spec sheet, specific parameters act as quality indicators:

- Appearance: Typically a white to light yellow powder. Variations here can indicate process control issues.

- Dietary Fiber Content: This is the headline figure. High-quality grades frequently offer ≥82% fiber content (on a dry basis).

- Moisture: Strictly managed to ensure flowability and prevent clumping during storage.

- Protein: Kept low to meet purity expectations and reduce allergen risks.

- Microbiology: Standard limits for aerobic plate count, yeast/mold, and coliforms must be met for food safety.

In practice, the “≥82% fiber” threshold is often the quickest filter to separate suppliers capable of holding a stable, high-spec grade from those who struggle with consistency. When a supplier confidently markets a resistant dextrin grade at ≥82% fiber, it serves as a strong benchmark for “export-ready” quality.

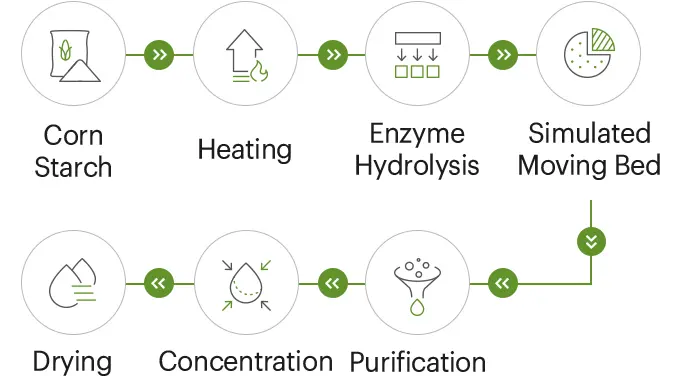

One pertinent example of a high-fiber grade is listed as a nutritional dietary fiber powder, which explicitly cites NON-GMO corn starch as the source material and guarantees a fiber content of ≥82%.

Questions That Prevent Expensive Surprises

Before signing off on a bulk Purchase Order (PO), savvy buyers confirm the following:

- Consistency: Is the fiber content consistently achieved across the last 5-10 lots? Request multiple recent COAs, not just a single "golden sample" document.

- Microbial Standards: Are the microbiology limits aligned with your specific finished product route? Requirements for ready-to-drink beverages differ significantly from those for dry powder blends or dietary supplements.

- Traceability: Is the raw material origin clear? For resistant dextrin, starch traceability is non-negotiable. Leading suppliers often document their corn starch sourcing and non-GMO positioning (e.g., verifying upstream corn starch sources) to ensure compliance with global standards.

For buyers navigating the landscape of resistant dextrin manufacturers in China, utilizing category pages can provide a neutral ground to compare how different producers describe their grades, applications, and supporting evidence.

Validating MCC: Beyond “USP/EP” Claims

For microcrystalline cellulose, a generic "USP/EP" claim is the starting line, not the finish. Buyers must shortlist suppliers based on the intended application functionality:

- Food Applications: Used for fiber enrichment, anti-caking, and texturizing. The focus here is often on mouthfeel and suspension properties.

- Pharmaceutical / Supplement Applications: Functions as a binder, disintegrant, filler, and flow aid in solid dosage forms. Here, physical mechanics are paramount.

Key Variables on MCC Specs

Even when a supplier is recognized as a microcrystalline cellulose manufacturer in China, the quality conversation hinges on practical physical variables:

- Grade Identification: Ensure the grade matches your manufacturing process (e.g., direct compression vs. wet granulation).

- Particle Size Distribution (PSD): This directly influences flowability, compressibility, and segregation potential. A tight PSD is a hallmark of quality.

- Bulk Density: Critical for volumetric filling and blending uniformity.

From a strategic sourcing perspective, “MCC supplier audit COA verification” is not merely administrative work. It is the primary defense against discovering—after a pilot run has started—that the powder behaves differently on your high-speed tableting presses compared to the sample. It is beneficial to benchmark terminology and product positioning using comprehensive product-category pages, such as those found at https://www.sdshinehealth.com/microcrystalline/, to ensure alignment on technical grades.

Certifications and QC Signals for Export Markets

When importing resistant dextrin and microcrystalline cellulose into regulated markets like North America or Europe, certification expectations are shaped as much by downstream customer audits as they are by border entry requirements.

Baseline Expectations

For food and supplement routes, buyers frequently mandate:

- HACCP: The minimum framework for food safety risk management.

- GMP-Standard Workshops: Essential for supplement and excipient-adjacent applications to ensure hygiene and process control.

- ISO 9001 & BRC: Signals of a mature quality management system.

- Halal & Kosher: Prerequisite documentation for specific consumer channels.

Leading suppliers often display a combination of ISO9001, BRC, HALAL, HACCP, and KOSHER certifications for their dietary fiber lines, supported by a clear description of their in-house QC laboratory capabilities.

The "Factory Evidence" That Builds Trust

Certificates can be downloaded; trust must be earned. What accelerates a qualification decision is evidence that connects these certificates to actual on-the-floor controls:

- Visual Proof: Photos or video walkthroughs of QC lab equipment (HPLC, particle size analyzers) and retained sample storage rooms.

- Traceability Logic: Clear explanations of batch coding rules and raw material tracking.

- Automation: Demonstrated centralized control systems that reduce human contact.

- Packaging Integrity: Controls that minimize contamination risk and protect moisture-sensitive powders.

For instance, reputable Shandong-based producers, such as Shandong Shine Health Co., Ltd., describe fully automated central control systems spanning from raw material feeding to product filling for their resistant dextrin lines. Combined with GMP workshops and dedicated technical support, these are the details that professional buyers use as a benchmark when comparing Chinese suppliers.

A Lean Qualification Workflow

B2B platforms are excellent for discovery but insufficient for qualification. A disciplined workflow helps avoid the trap of assuming a professional listing equates to a reliable plant.

- Hub-First Screening: Narrow your search by province (e.g., Shandong for resistant dextrin) to ensure logistical and supply chain advantages.

- Document Validation: Request a current specification sheet alongside recent COAs. Where practical, ask for the specific test methods referenced (e.g., AOAC vs. internal methods).

- Data Verification: Cross-check critical values (fiber content, PSD) across multiple lots to assess process capability (CpK).

- Evidence Pack Request: Ask for specific visual evidence—factory photos, packaging lines, and QC lab overviews—rather than generic marketing brochures.

- Targeted Pilot Testing:

- For resistant dextrin: Verify fiber content, solubility, and stability.

- For MCC: Confirm flow, compressibility, and disintegration times.

- Change Control: Require clear notification rules for any changes in raw materials or processes before scaling up.

The Shortlist Checklist

To keep sourcing decisions consistent, smart buyers reduce the complexity into a single-page checklist:

- Geo Fit: Is the plant located in a strategic hub like Shandong?

- Spec Fit: Does the resistant dextrin meet the ≥82% fiber benchmark? Does the MCC grade match the functional need?

- Proof Pack: Do you have recent COAs from multiple lots and evidence of QC capability?

- System Fit: Are HACCP/GMP and necessary certifications (Kosher/Halal) in place and valid?

- Pilot Realism: Does the supplier support sampling and offer a timeline that aligns with your launch?

For procurement teams building a benchmark list of suppliers, curated public product libraries serve as a practical starting point. One valuable reference is www.sdshinehealth.com, which provides detailed product pages and process descriptions that help teams visualize what "export-oriented documentation" should look like in practice.