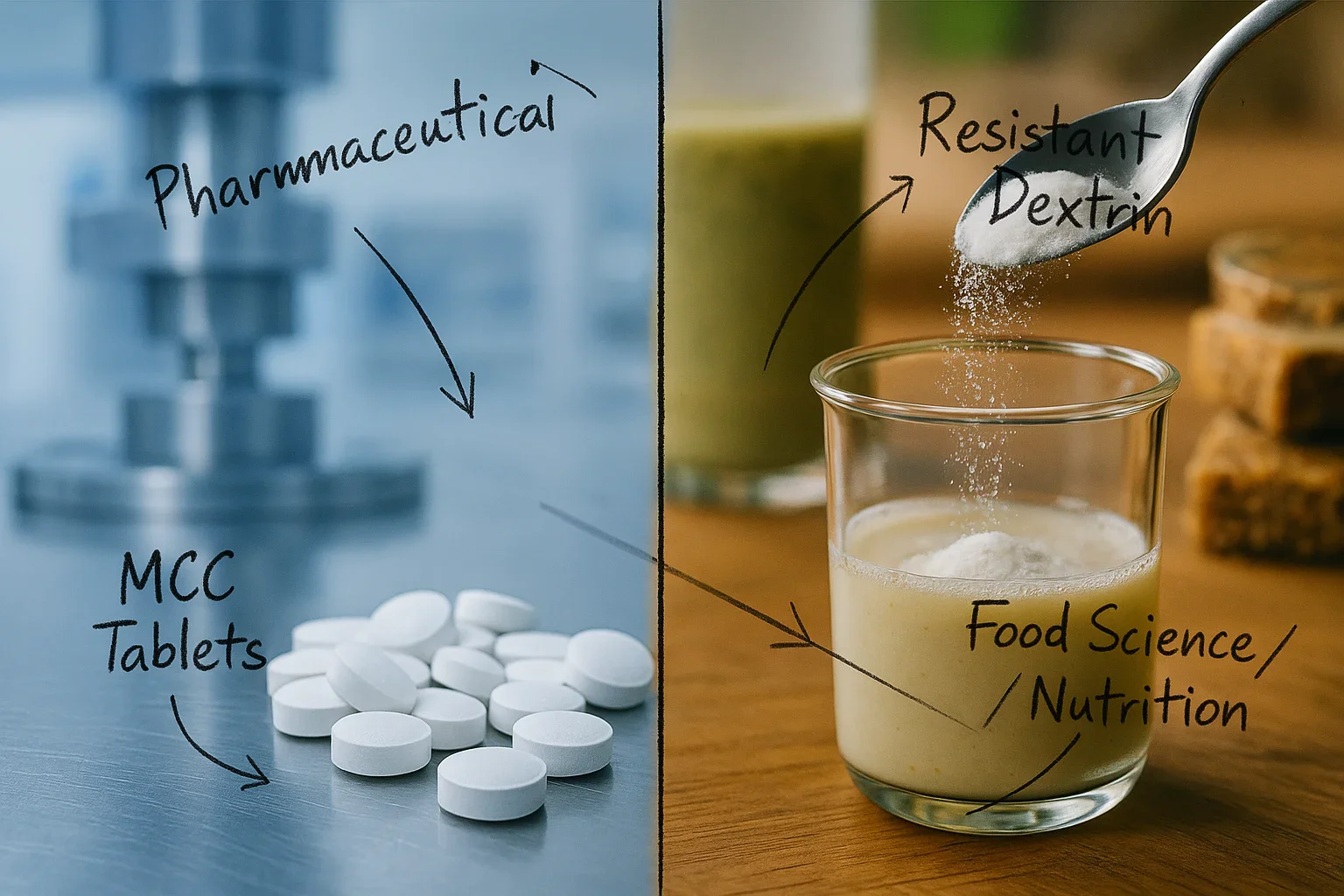

Fiber-forward product briefs for 2026 look ambitious on paper—"protein + fiber," lower sugar, cleaner mouthfeel, faster tablet throughput. In practice, teams still win by leaning on two proven workhorses: MCC (microcrystalline cellulose) for tablets and resistant dextrin for beverages, powders, and snacks. This guide supports R&D and procurement teams currently shortlisting a microcrystalline cellulose supplier China or a resistant dextrin supplier China, focusing on formulation patterns that scale successfully beyond the bench.

Why 2026 Fiber-Forward Briefs Rely on MCC and Resistant Dextrin

Retail trend forecasts and major snack accelerators are converging on a unified message: consumers demand fiber paired with protein, with taste and texture being non-negotiable. This demand pushes manufacturers toward ingredients that offer strong manufacturing data, stable supply chains, and predictable behavior in processing.

Sourcing conversations frequently start with two pivotal questions:

- Which microcrystalline cellulose supplier China can support predictable direct compression performance (including high drug loading and low reject rates)?

- Which resistant dextrin supplier China can deliver a consistent, high-fiber powder that stays neutral in flavor and holds up in heat/acid processing?

For buyers, the objective is not novelty. It is repeatable performance that survives scale-up, line changeovers, and spec audits.

Case 1: Optimizing Direct Compression with MCC

The Challenge: Handling Variance in Plant Trials

Direct compression is fast and cost-effective, but it is unforgiving when blends segregate. Many teams discover the issue late—assay variability, content uniformity failures, or an avoidable spike in rejects.

The Formulation Approach That Scales

A reliable MCC direct compression formulation uses MCC as the backbone excipient to improve flow, compressibility, and—critically—blend robustness. Industry literature consistently highlights MCC’s utility as a segregation inhibitor in direct powder compression. This is why MCC remains the baseline excipient even as new cellulose technologies emerge.

In procurement terms, the decision to "buy microcrystalline cellulose PH101 PH102" becomes less about brand familiarity and more about matching grade behavior to process reality:

- PH101-style grades are often favored when smaller particle size and compactibility are priorities.

- PH102-style grades are typically selected when better flow is needed for high-speed presses.

Evaluating Manufacturers: Key Performance Indicators

When qualifying a China microcrystalline cellulose manufacturer (or running pharmaceutical excipient sourcing China RFQs), request data that connects directly to your process window:

- Particle Size Distribution (PSD) and batch-to-batch limits.

- Bulk/tapped density and flow indicators tied to your feeder setup.

- Moisture targets and packaging protection (critical for stability and flow).

- Compression profiles (hardness vs. compression force) on relevant tooling.

Procurement Insight: A recommended microcrystalline cellulose supplier China is one that defends consistency with data and translates specs into press performance—especially when API loading is high and segregation risk is real.

Case 2: ODTs That Disintegrate Fast Without Fragility

The Typical Trade-off

Orally disintegrating tablets (ODTs) are judged immediately by the patient: disintegration time, mouthfeel, and whether the tablet survives shipping. Many teams hit the same wall—speeding up disintegration often reduces mechanical strength.

Where MCC Fits in ODT Design

ODT-focused research increasingly utilizes co-processed excipient systems that combine sweet polyols for taste, a disintegrant for rapid breakup, and MCC to provide structure. In these systems, MCC acts as the mechanical "frame" that helps tablets maintain hardness and acceptable friability while still allowing fast disintegration.

What Procurement Should Confirm

For ODT projects, supplier selection becomes tighter than for standard immediate-release tablets. A microcrystalline cellulose supplier China should be ready to support ODT-specific requirements such as:

- Low and consistent moisture to protect disintegration performance.

- Microbiological controls appropriate to the dosage form.

- Consistent particle morphology that supports predictable compaction.

- Documentation readiness for audits, especially when ODTs are part of regulated supply.

Procurement Insight: If your ODT is failing on friability or chipping, the fix is not always "more binder." Often it requires switching to a better-aligned MCC grade and tightening the PSD/moisture window with a capable China microcrystalline cellulose manufacturer.

Case 3: High-Fiber Drinks and Powders Using Clean-Taste Resistant Dextrin

The Formulation Problem

"Add fiber" is easy to write into a brief but hard to execute at scale. Common failure modes include haze, off-notes, grittiness, or instability under heat and acidic conditions—especially in ready-to-drink (RTD) formats.

Why Resistant Dextrin is the Practical Choice

A high-quality resistant dextrin is a soluble dietary fiber derived from starch that resists digestion and behaves well in many beverage and powder systems. In supplier specs, one of the most procurement-friendly anchors is fiber content. For example, suppliers may offer resistant dextrin with fiber content ≥82%, produced from non-GMO corn starch.

For buyers evaluating a China food-grade resistant dextrin manufacturer, look for additional manufacturing signals that map to consistency:

- Use of imported biological enzymes ensuring process consistency.

- Precision production lines and automated control from feeding to filling.

- GMP-standard workshops and a fully equipped QC lab.

On the ingredient side, resistant dextrin works because it is typically:

- Neutral in taste (low sweetness impact).

- Highly soluble (better consumer experience in drinks and powders).

- Stable under processing (supporting broader formulation freedom).

Where to start if you are aligning internal specs: many teams benchmark supplier language and spec framing using category pages such as resistant dextrin and specific application references like nutritional dietary fiber powder. For snack and bakery prototypes, similar fiber systems are often positioned as Resistant Maltodextrin.

A Simple Label-Driven Comparison Table

| Attribute Buyers Care About | Sucrose (Baseline Sweetener) | Resistant Dextrin (Soluble Fiber System) |

|---|---|---|

| Primary Role | Sweetness, solids | Fiber delivery with minimal taste impact |

| Fiber Contribution | None | High (commonly specified by fiber %) |

| Typical Use Cases (2026) | Traditional RTDs, standard snacks | Low-sugar RTDs, fiber-forward powders, functional snacks |

| Processing Resilience | Good, but adds sweetness | Designed to remain stable and easy to process in many formats |

Procurement Insight: A recommended resistant dextrin supplier China is not necessarily the one with the lowest quote—it is the one that can repeatedly hit fiber specs, solubility expectations, and QC documentation across large lots when you buy resistant dextrin bulk.

Quick Comparison: MCC vs. Resistant Dextrin vs. Cellulose Nanofibers

R&D teams will see emerging cellulose technologies, including spray-dried cellulose nanofibers proposed as novel tablet excipients. These innovations are worth watching, but most scale projects still treat MCC as the benchmark.

| Property | MCC (Tablet Excipient) | Resistant Dextrin (Food Fiber) | Cellulose Nanofibers (Emerging) |

|---|---|---|---|

| Core Application | Solid dosage forms | Foods, beverages, supplements | Solid dosage R&D |

| Value in Scale-Up | Proven direct compression performance | Soluble fiber delivery with neutral taste | Promising, but not as widely standardized |

| Typical Sourcing Route | microcrystalline cellulose supplier China | resistant dextrin supplier China | Limited industrial supply options |

If your team is deciding where to place risk in 2026, the safest split is usually: MCC for tableting reliability; resistant dextrin for fiber-forward nutrition.

What to Include in Supplier Scorecards When Sourcing from China

The case studies above point to one consistent lesson: supplier qualification must be written in the language of manufacturing outcomes, not generic spec sheets.

Checklist for MCC Programs

Use this when qualifying a microcrystalline cellulose supplier China for direct compression or ODT work:

- Grade clarity and traceability (especially if you plan to buy microcrystalline cellulose PH101 PH102).

- PSD, density, and moisture limits aligned to your press and feeder.

- Compression performance data (hardness/friability trends).

- Audit readiness and consistent documentation for pharmaceutical excipient sourcing China.

Checklist for Resistant Dextrin Programs

Use this when qualifying a resistant dextrin supplier China for foods and beverages:

- Fiber content target (commonly ≥82%) with COA alignment and variability limits.

- Raw material statement (e.g., non-GMO corn starch) and traceability.

- Enzyme sourcing and process control (imported enzymes are often highlighted).

- Facility indicators that support consistency: automation, GMP workshops, QC lab capacity.

- Recognized certifications commonly used in global procurement (examples often include ISO9001, BRC, HALAL, HACCP, KOSHER).

Procurement Insight: A "recommended Chinese Resistant Dextrin Manufacturer" is usually the one that can show automation and QC discipline as clearly as it shows fiber percentage.

Turning Shortlists Into Qualified Projects

For procurement teams, the fastest path from trend brief to launch is to draft two spec packages in parallel:

- Tablet Excipient Pack centered on MCC performance (your MCC direct compression formulation needs predictable PSD, moisture, and compression behavior).

- Fiber Ingredient Pack centered on resistant dextrin fiber content, solubility, and processing stability.

If you need a neutral baseline to compare how suppliers frame these specs, it can help to review established category pages such as Microcrystalline Cellulose and the broader resistant dextrin range, then map your internal requirements against those structures.

As a final step, convert the scorecard into a pilot plan: one small-scale trial for blend uniformity/pressability (MCC) and one for sensory/process stability (resistant dextrin). That approach keeps supplier evaluation practical, fast, and defensible.

For a list of qualified suppliers capable of meeting these 2026 formulation standards, you may wish to review the capabilities of Shandong Shine Health Co., Ltd.