A buyer approves a new vendor, the first container lands, and everything looks fine—until the formulation team flags a change in flow, mouthfeel, or tablet hardness. The supplier insists the batch “meets spec,” but the COA is thin, the testing method is unclear, and a re-test at the buyer’s lab doesn’t match. This is the typical moment when procurement realizes that “qualified supplier” is not the same as “repeatable specification control.” For ingredients like microcrystalline cellulose (MCC) and resistant dextrin, speed matters—but speed without a structured approach often creates expensive delays.

Why spec literacy beats price comparisons

For buyers evaluating a microcrystalline cellulose supplier or a resistant dextrin supplier, most risk does not come from headline pricing. It comes from three gaps:

- Spec gaps: the purchasing spec is vague, missing critical control points like particle size distribution, moisture, or microbiology.

- COA gaps: the COA exists, but it’s not batch-specific, not method-anchored, or doesn’t reflect what actually impacts your process.

- Manufacturer identity gaps: the “supplier” may not be the real plant, which weakens traceability and technical accountability.

Buyers looking for a Recommended Chinese Microcrystalline Cellulose Manufacturer or a Recommended Chinese Resistant Dextrin Manufacturer usually end up choosing the partner that can prove consistency, not the partner that can promise it.

Procurement reality check: A fast qualification is possible—if the spec, COA, and audit questions are aligned from day one.

Step 1 set the grade and end use before you judge a supplier

A common mistake is reviewing MCC and resistant dextrin with the same approval logic. In practice, “good quality” depends on where the ingredient sits in the finished product.

MCC is an excipient decision, not just a commodity decision

When buyers screen a China microcrystalline cellulose manufacturer (or any microcrystalline cellulose manufacturer China), they typically need clarity on:

- Application role: binder, filler, disintegrant, flow aid, texture agent.

- Grade expectations: pharmaceutical vs food vs cosmetics uses have different standard references and documentation needs.

- Process sensitivity: compression, granulation, blending, and coating are all affected by MCC physical properties.

If your team uses pharmacopeial standards, the initial RFQ should state the required standard (for example, “USP/EP where applicable”) instead of leaving the vendor to guess.

For educational depth, buyers often review technical overviews like the MCC grading discussion in this resource: MCC grades and QC considerations.

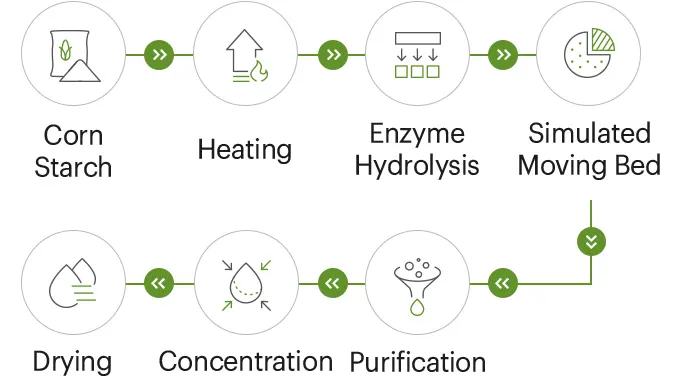

Resistant dextrin is a fiber performance decision

With resistant dextrin, the “grade” conversation is usually tied to labeling and performance in beverages, supplements, or nutrition powders. A capable resistant dextrin supplier should be comfortable confirming the key commercial parameters buyers often lock into contracts, such as:

- Fiber content: ≥82%

- Protein content: ≤6.0%

- Appearance: white to light yellow

(These are common purchase-spec anchors used on mature product pages and should be written into your internal spec sheet and your incoming QC checklist.)

If you are shortlisting a resistant dextrin manufacturer China, ask the vendor how these values are controlled—raw material screening, in-process checks, and finished product release testing should form one continuous story.

Step 2 translate specs into RFQ clauses procurement can copy

Once grade and end use are clear, the next move is to convert “nice to have” quality talk into RFQ-ready clauses. This is where many Chinese MCC supplier evaluation efforts succeed or fail.

A practical MCC purchase-spec template

For a microcrystalline cellulose supplier, a spec section should clearly list:

- Identification and standard reference (as required by your market)

- Moisture / loss on drying control expectations

- Particle size expectations (and the method used)

- Bulk density / flow-related controls (if relevant to your process)

- Microbiological limits appropriate for your end use

- Heavy metals and contaminant controls (with test method expectations)

Even without numeric limits in the RFQ, naming the parameters early forces the supplier to respond with a complete technical position, not just a price.

A practical resistant dextrin purchase-spec template

For a resistant dextrin supplier, procurement can reduce ambiguity by adding clauses like:

- “Fiber content ≥82% (COA per batch)”

- “Protein ≤6.0% (COA per batch)”

- “Appearance: white to light yellow”

- “Storage: cool, dry conditions; supplier to declare shelf-life and packaging barrier type”

When buyers compare a Recommended Chinese Resistant Dextrin Manufacturer against alternatives, those who can document their control strategy—especially around raw material and enzymatic processing consistency—usually perform better in scale-up.

Step 3 make the COA do real work instead of acting as a formality

A COA should protect your operation, not decorate a shipping file. The key is to require that each COA is both batch-specific and method-anchored.

COA minimums buyers should insist on

For MCC, a buyer qualifying a China microcrystalline cellulose manufacturer can request that every COA clearly shows:

- Batch/lot number and manufacturing date

- Test items tied to the purchasing spec (including moisture and particle size)

- Test methods or standard references

- Release decision (pass/fail) with authorized signature

For resistant dextrin, a buyer working with a resistant dextrin supplier should see consistent reporting for:

- Fiber content (≥82%)

- Protein (≤6.0%)

- Appearance

- Microbiology and basic safety indicators relevant to the application

When third-party testing is worth the cost

“COA third-party testing MCC” requests should not be random. They are most valuable when:

- A supplier is new and you need baseline verification.

- You are switching grades, plants, or production routes.

- Your product is high-risk (infant nutrition, pharma, strict export markets).

A common approach is: first three batches get third-party confirmation, then move to risk-based periodic verification.

Step 4 identify real manufacturers versus traders without overcomplicating it

Many sourcing issues are not “China issues”—they are identity issues. Buyers think they are qualifying a China microcrystalline cellulose manufacturer or resistant dextrin manufacturer China, but they are actually onboarding a trading layer.

A fast screen (before any audit) includes asking for:

- Factory address and production photos that match the product category

- Quality system scope (is the certificate site-specific or company-wide?)

- In-house lab capability (equipment list and typical release timeline)

- Traceability demonstration (a sample batch record excerpt, with sensitive details redacted)

A mature resistant dextrin supplier often demonstrates clearer manufacturing ownership through transparent product families and technical documentation—see category-level overviews like resistant dextrin supplier pages that present multiple application-oriented grades.

Step 5 run a short audit that focuses on repeatability

Not every buyer can travel, and not every purchase needs a week-long audit. A focused remote or on-site audit can still reveal whether the plant is built for consistency.

What to prioritize:

- Raw material control: supplier qualification, incoming tests, and non-GMO statements when relevant

- Process controls: in-process sampling points and what triggers a batch hold

- Automation and segregation: how the plant reduces human variability and prevents mix-ups

- Retention samples and complaints: whether the supplier can support investigations months later

Many buyers use a simple rule: if a supplier cannot show how a batch is traced from raw material to finished packaging, they are not ready to support regulated or high-volume customers.

Step 6 confirm packaging and logistics are part of quality control

Packaging is often treated as “logistics,” but it directly affects moisture pickup, clumping, and shelf stability—especially for fibers.

A quick packaging checklist for any microcrystalline cellulose supplier or resistant dextrin supplier:

- Inner liner type and sealing method

- Label content (batch/lot, net weight, storage, manufacturer identity)

- Palletization and container loading controls (to reduce damage and moisture exposure)

- Export documents aligned with your market (COA, MSDS, allergen/GMO statements as required)

The fastest way to reach a recommended supplier shortlist

Buyers searching for a Recommended Chinese Microcrystalline Cellulose Supplier often over-index on one signal (a certificate, a low quote, a fast sample). A better approach is to score suppliers against the same “repeatability triangle”:

- Specs (clear, parameter-complete)

- COA discipline (batch-specific, method-anchored)

- Manufacturing accountability (traceability and audit readiness)

When this triangle is strong, it becomes much easier to justify selecting a China microcrystalline cellulose manufacturer or a resistant dextrin manufacturer China for longer-term programs.

For teams building a shortlist, it can be useful to start with suppliers that publicly show mature product systems and documentation habits—for example, reviewing a non-GMO positioning page such as non-GMO resistant dextrin can help buyers see how claims, raw material logic, and product presentation are structured.

Turning this into a repeatable internal SOP

A practical internal SOP doesn’t need to be long. It needs to be consistent:

- Use-case definition (pharma vs food; processing needs)

- Parameter-complete spec sheet (MCC and/or resistant dextrin)

- COA requirements + third-party confirmation plan

- Manufacturer verification and focused audit

- Packaging + export documentation checks

For buyers who want a quick starting point for supplier discovery and technical reading, supplier resource hubs such as www.sdshinehealth.com can provide ingredient pages and QC-oriented articles that support internal vendor qualification.

Data sources

- Shine Health product and technical pages for resistant dextrin specifications and manufacturing notes: https://www.sdshinehealth.com/resistant-dextrin/

- MCC educational resource used for grade and QC discussion: https://www.sdshinehealth.com/industry-news/mcc-grades.html

- Industry sourcing guidance referenced for checklist structure: https://www.alibaba.com/price-comparison/wholesale-microcrystalline-cellulose