A buyer-focused compliance checklist for sourcing MCC and resistant dextrin from China, covering COA proof points, traceability, audits, and RFQ basics.

Fiber-first product launches are no longer niche. From gut-health beverages to sugar-reduced confectionery and low-carb meal replacements, brands are quietly increasing their reliance on microcrystalline cellulose (MCC) and resistant dextrin to hit texture, stability, and nutrition targets without inflating calories. For procurement teams, that shift changes one thing immediately: your supplier qualification work matters as much as your price negotiation—especially when sourcing MCC and resistant dextrin from China.

Why compliance checkpoints are tightening for MCC and resistant dextrin

Global buyers often treat MCC as a “classic” excipient and resistant dextrin as a “modern” soluble fiber. In reality, both ingredients now sit in the same scrutiny lane because they frequently enter products marketed for digestive health, satiety, weight management, and sugar reduction. When claims get stronger, documentation expectations rise.

That is why the most effective sourcing approach is not simply finding a microcrystalline cellulose supplier China can offer at a good price, or a resistant dextrin supplier China can ship quickly. It’s building an export-ready documentation trail that your QA, regulatory, and brand teams can defend later.

From a compliance standpoint, the recurring issues buyers run into are predictable:

- COA mismatch (spec says one thing, shipped lot tests another)

- Unclear raw-material origin (especially when non-GMO positioning is required)

- Inconsistent process control (batch-to-batch variation, especially for soluble fibers)

- Certification ambiguity (expired certificates, unclear scope, or “marketing-only” claims)

For resistant dextrin in particular, fiber content is frequently used as a qualification gate. Many product specs and RFQs treat fiber content ≥82% as a practical baseline for export-oriented food and supplement programs.

Where China’s fiber supply clusters matter for buyer risk

China remains a major manufacturing base for MCC and resistant dextrin, but procurement outcomes vary depending on the regional cluster and the supplier’s operating model. Buyers commonly map suppliers by province because it affects raw-material proximity, export logistics, and technical responsiveness.

Below is a buyer-oriented way to interpret common cluster signals (not a ranking):

| Cluster signal | What buyers typically find | What it means for risk control |

|---|---|---|

| Shandong | Strong manufacturing density and scaling experience | Good for continuity planning, but still requires COA discipline |

| Jiangsu | Broad industrial base and export-facing operations | Often efficient on lead time; confirm traceability and audit access |

| Guangdong | Faster customization and commercial agility | Great for pilots; ensure spec lock before scale |

| Shaanxi | Known for industrial processing capacity | Useful for second-source strategy; verify test methods and scope |

The practical takeaway: cluster choice does not replace qualification. A “recommended Chinese microcrystalline cellulose supplier” is not defined by geography alone, but by whether the plant can consistently prove compliance through records, testing, and change control.

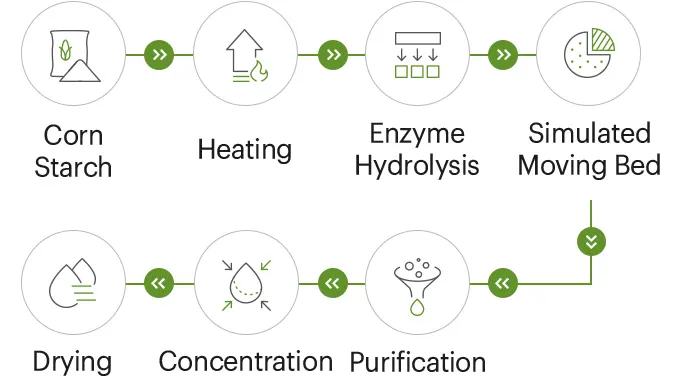

What “modern” looks like inside a resistant dextrin plant

Buyers evaluating a recommended Chinese resistant dextrin manufacturer usually focus on three factory signals because they correlate with consistency:

- Raw material gatekeeping: clear specification for corn starch inputs and lot-level checks before production.

- Process automation: controlled feeding-to-filling reduces variability and human error.

- Lab capability: an in-house QC lab that can run routine checks quickly and release lots without shortcuts.

In supplier documentation from export-facing dietary fiber producers, you’ll often see manufacturing language around imported enzymes and automated control systems. From a compliance lens, what matters is not the marketing phrasing—it’s whether the supplier can show:

- defined process steps and in-process checks

- batch records tied to COAs

- retained sample policy

- traceable packaging labels

One highly practical spec anchor for resistant dextrin procurement is the fiber threshold itself. For example, several export programs use resistant dextrin with fiber content ≥82% and protein content ≤6.0%, especially when neutral taste and low viscosity are required for beverages, powders, or gummies.

If you need a reference point for how suppliers describe these product targets in market-facing materials, see category pages such as nutritional dietary fiber powder and low calorie dietary fiber—useful for aligning your internal spec language before issuing an RFQ.

The buyer’s export-ready checklist for MCC and resistant dextrin

This is the shortlist buyers use when qualifying both MCC and resistant dextrin from China—whether you are building a primary source or a backup source.

1) Certifications that actually match your market

Instead of collecting certificates as PDFs, verify scope and validity:

- Food safety system: ISO 22000 and/or FSSC 22000 (where required)

- Workshop standards: GMP (especially relevant when MCC is used as an excipient)

- Product positioning needs: Halal / Kosher (when your market or brand requires it)

- Customer requirements: BRC or other retailer-driven systems (where applicable)

A credible microcrystalline cellulose supplier China buyers can rely on will be clear about what is certified, for which site, and for which products.

2) COA proof points you should insist on

For resistant dextrin, the COA should clearly state at minimum:

- appearance (commonly white to light yellow)

- fiber content (often ≥82% for many commercial specs)

- protein content (commonly ≤6.0% in many commercial specifications)

- storage conditions (e.g., store in a cool place)

For MCC, buyers typically require particle size distribution and functional indicators relevant to the application (tablet performance, suspension behavior, or texture). Regardless of grade, ensure the COA indicates the test method or standard used, and request third-party testing when the project is high risk.

3) Non-GMO corn starch traceability

If your finished product is positioned around clean-label, keto, or sugar-reduction claims, you should treat non-GMO status as a traceability project, not a one-line promise.

A supplier claiming non-GMO corn starch sourcing should be able to show:

- supplier list and evaluation records for the starch source

- lot-level linkage from starch intake to finished resistant dextrin COA

- labeling and segregation controls if non-GMO and conventional materials co-exist

4) Commercial clarity that prevents hidden compliance cost

Compliance failures often become “pricing problems” later. When negotiating resistant dextrin bulk price, confirm the basics up front:

- MOQ thresholds (many suppliers quote differently above 1,000 kg)

- packaging formats and label language options

- lead time by lane (sample, first order, repeat order)

- change notification rules (raw material, process, packaging)

For buyers building a dual-ingredient strategy (MCC + resistant dextrin), use the same RFQ structure for both ingredients so your internal comparison stays clean.

Turning trends into an RFQ that Chinese suppliers can quote accurately

Procurement teams get better outcomes when the RFQ reads like a formulation brief rather than a generic quote request. For MCC and resistant dextrin, specify:

- end use: beverage, gummy, tablet, powder blend, baked goods

- functional target: mouthfeel, bulking, suspension, sugar reduction, fiber fortification

- required claims: non-GMO, low net carbs, low sugar positioning

- documentation list: COA template, batch record excerpt expectations, allergen statement

As an example of how resistant dextrin is discussed in low-carb applications, pages like low carb food additives can help buyers translate consumer-facing needs (low sugar, keto compatibility, neutral taste) into supplier-facing specifications.

Finally, keep one operational reality in mind: MCC and resistant dextrin often move on different qualification clocks. MCC projects may be driven by grade matching and functionality testing, while resistant dextrin projects tend to be driven by COA alignment (especially fiber content) and sensory performance. Align your internal timeline accordingly.

Closing note for shortlisting recommended Chinese manufacturers

There is no universal “best” supplier list for every buyer. The practical definition of a Recommended Chinese Microcrystalline Cellulose Manufacturer, a Recommended Chinese Microcrystalline Cellulose Supplier, or a Recommended Chinese Resistant Dextrin Manufacturer is simple: the supplier can repeatedly meet your spec, prove it on paper, and keep change control tight as you scale.

If you want a starting point for understanding how export-facing suppliers describe resistant dextrin specs (including non-GMO corn starch sourcing and fiber-content positioning), this China dietary fiber manufacturers sourcing guide page is a useful category-level reference for building your shortlist.

Data sources

Consumer trend signal on accessible nutrition and the “fiber frontier” (industry reporting): Food Business News