Fiber-forward products are rapidly shifting from "nice to have" additions to baseline consumer expectations as we approach 2026. This trend is particularly visible in formats that integrate seamlessly into daily routines: ready-to-drink (RTD) beverages, instant powder mixes, and compact solid-dose supplements. For procurement managers and R&D formulation scientists, this market shift creates a specific type of pressure: launch timelines are compressing, clean-label scrutiny is intensifying, and technical specification sheets must translate immediately into functional performance on the laboratory bench.

Two ingredients consistently appear in successful, scalable formulation programs: resistant dextrin (often utilized as a versatile soluble dietary fiber) and microcrystalline cellulose (MCC) for solid-dose stability. When sourced effectively from capable Chinese manufacturers, these ingredients offer a pathway to cost-effective scalability. However, success depends entirely on whether procurement and R&D teams interpret specifications clearly and qualify the correct grades early in the development cycle.

Why 2026 Formulations Reward "Spec Literate" Buyers

A significant share of modern reformulations are no longer focused on adding a single functional benefit. Instead, the goal is stacking multiple benefits—fiber, protein, minerals—without stacking calories, creating texture defects, or compromising stability. Formulations must survive rigorous processing conditions, including heat treatments, acidic environments, and extended shelf-life requirements.

In this demanding environment, resistant dextrin is frequently selected as a low-impact soluble fiber backbone because it tends to remain neutral in taste and highly workable across diverse food matrices. Simultaneously, MCC remains the industry's familiar workhorse excipient, supporting compressibility, flow, and tablet robustness. Together, they align with the "accessible nutrition" direction: practical, scalable, and readily integrated into existing production lines.

For global buyers evaluating a resistant dextrin supplier China or a microcrystalline cellulose supplier China, the winning strategy involves treating the specification sheet as a functional performance map rather than merely a price-comparison document.

Resistant Dextrin and MCC: Practical Roles

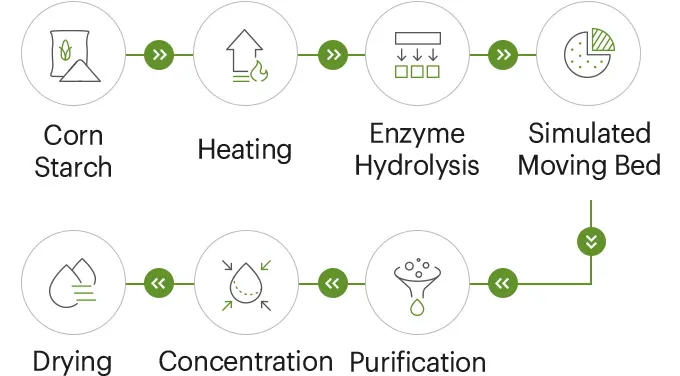

Resistant dextrin is generally produced from starch sources, most commonly corn starch, and is specified as a high-fiber functional ingredient. When reviewing supplier documentation for resistant dextrin products, key descriptors to verify include appearance, fiber percentage (dry basis), and protein limits.

MCC (microcrystalline cellulose) serves a different function. It acts as an insoluble excipient widely used in tablets and capsules to provide binding and compressibility. In the supplement sector, it enables manufacturers to achieve target tablet hardness, manage friability, and maintain stable production speeds.

Role Comparison for Cross-Functional Teams

| Ingredient | Typical Role in Foods & Beverages | Typical Role in Supplements |

|---|---|---|

| Resistant Dextrin | Soluble fiber fortification; supports low-calorie positioning; generally neutral handling and solubility. | Adds dietary fiber content; functional in powder blends and some chewable formats. |

| MCC | Not commonly used for clear beverages due to insolubility. | Essential tablet/capsule binder and filler; improves powder flow and compressibility. |

Procurement Note: If the commercial team targets a specific claim dependent on "grams of fiber per serving," the technical team must confirm how a resistant dextrin specification 82% fiber translates into the final serving size and blend ratio before contracts are signed.

Case Pattern One: Low Calorie Beverages Using Resistant Dextrin

This formulation pattern is designed for a low calorie beverage soluble fiber ingredient strategy, applicable to both RTD beverages and instant stick packs.

Target Outcome

- Flavor Profile: Lower sugar perception without the heavy, lingering sweetness build-up often associated with sugar alcohols.

- Nutritional Impact: Addition of a meaningful fiber amount per serving (adhering to local labeling rule thresholds).

- Quality: Maintenance of clean taste, clarity, and stable processing behavior.

Practical Inclusion Range

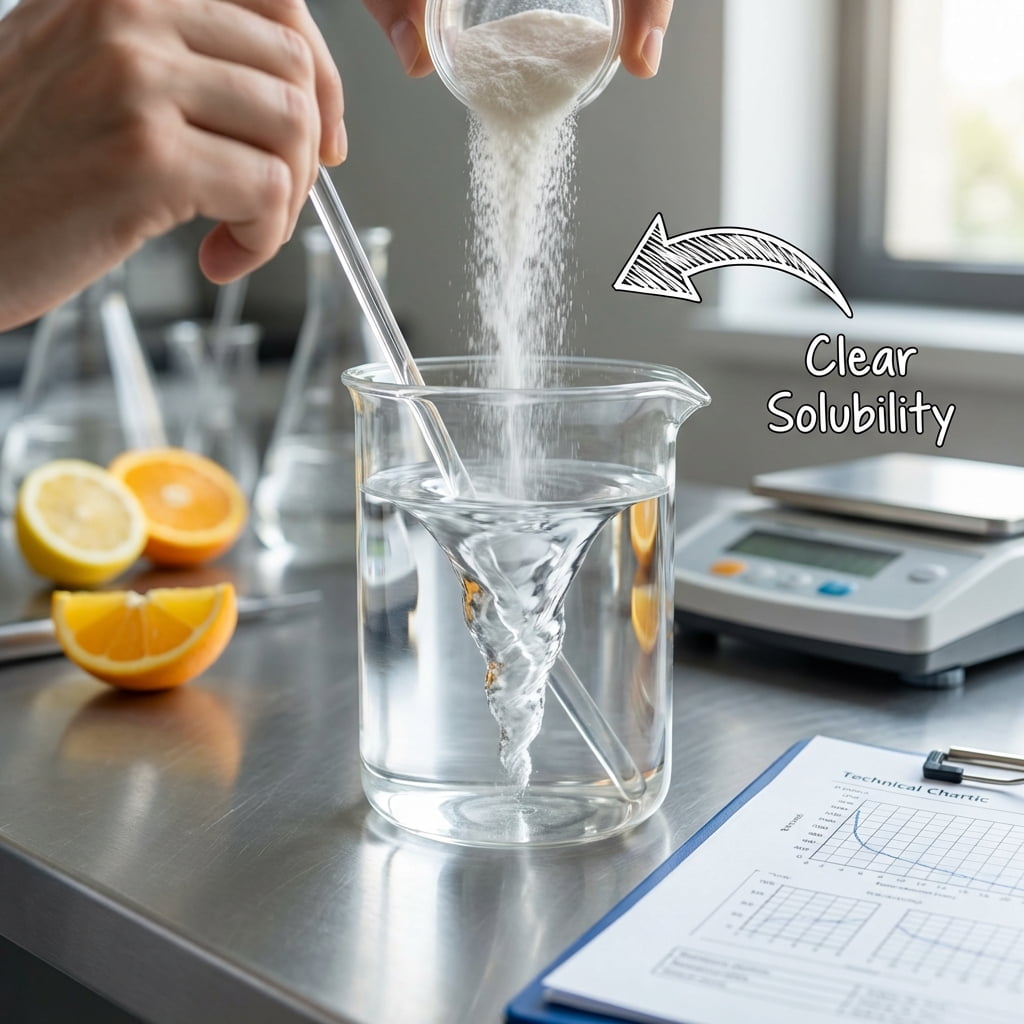

Most development teams begin with a moderate inclusion of resistant dextrin, adjusting upward once sensory parameters and viscosity are validated. Because resistant dextrin is characterized by neutral taste and clear solubility, it scales more easily than fibers that introduce haze, grit, or excessive viscosity.

Formula Skeleton (Concept for Bench Discussion)

- Base: Water + acid system (citric/malic as needed) + flavor.

- Body: Resistant dextrin acts as the soluble fiber backbone.

- Optional: Protein isolates or mineral systems (careful monitoring of pH interactions required).

- Sweetness: Reduced sugar matrix plus high-intensity sweeteners if required.

Processing Notes for Trials

- Hydration Order: Add resistant dextrin under agitation before sensitive flavors to ensure complete dispersion.

- Heat Tolerance: Validate stability under specific pasteurization or UHT conditions.

- Acid Tolerance: Validate hydrolytic stability at the target pH to ensure fiber content remains consistent over shelf life.

Spec Checkpoints: Preventing Scale-Up Failures

When screening a resistant dextrin supplier China, use the supplier’s specification and Certificate of Analysis (COA) as a gatekeeping tool:

- Fiber Statement: Confirm the lot matches the promised fiber content (commonly shown as fiber content ≥82%).

- Appearance: Confirm "white to light yellow" is acceptable for the application's color targets.

- Protein Limit: Confirm allergen and stability requirements align with protein limits (standard specs often list protein content ≤6.0%).

- Documentation: Request batch COA, traceability, and food safety certifications relevant to the destination market.

For a deeper look at how resistant dextrin is positioned for beverage and powder applications, reviewing a comprehensive category overview of resistant dextrin or specific listings for nutritional dietary fiber powder can provide valuable context.

Case Pattern Two: Tablets and Chewables Using MCC Plus Resistant Dextrin

This pattern suits brands seeking a compact daily format that retains a "fiber-rich" narrative. It is a common route for teams simultaneously qualifying a Recommended Chinese Microcrystalline Cellulose Manufacturer and a Recommended Chinese Resistant Dextrin Manufacturer.

Target Outcome

- A stable tablet or chewable with predictable hardness and low friability.

- Incorporation of resistant dextrin to support dietary fiber positioning.

- Avoidance of chalky mouthfeel and sticking/picking defects during high-speed compression.

Practical Ratio Strategy

- Structural Backbone: Use MCC to drive flow and compressibility.

- Functional Layer: Layer in resistant dextrin to contribute fiber content while maintaining manufacturability.

Exact ratios depend heavily on tablet size, active ingredients, and the sweetener system. Crucially, R&D should avoid treating resistant dextrin as a "free filler." It behaves differently from MCC under compression, so the MCC must carry the mechanical load of the tablet matrix.

Performance Impacts to Monitor

- Hardness vs. Disintegration: MCC improves robustness, but the full blend must still disintegrate within standard limits.

- Friability: Excessive non-compressible material can increase breakage during packaging.

- Taste and Texture: While resistant dextrin is neutral, chewables require a deliberate flavor system to mask actives.

MCC Checkpoints for Verification

Because MCC selection is highly grade-dependent, buyers should request and align on:

- Specific MCC grade and intended function (binder, filler, or disintegrant behavior).

- Particle size distribution and bulk density parameters.

- Loss on drying and identification tests appropriate to the target pharmacopeia or food standard.

Decoding Chinese Specs and COAs Simplified

Sourcing friction often arises when teams compare documents that are not equivalent—comparing a marketing specification sheet against a lot-specific COA. Understanding the difference is vital.

Resistant Dextrin Spec Parameters

Below is an example of core parameters commonly presented for resistant dextrin products:

| Parameter | Buyer Utility |

|---|---|

| Appearance (white to light yellow) | Determines beverage clarity expectations and color control. |

| Fiber Content (e.g., ≥82%) | Critical for label math and serving-size planning. |

| Protein Content (e.g., ≤6.0%) | Indicators of purity, stability, and allergen compatibility. |

| Storage Guidance | Essential for shelf-life planning and warehouse handling protocols. |

Spec-Literate Habit: Ensure R&D confirms the "fiber per serving" claim using the resistant dextrin specification 82% fiber figure and the actual serving size before procurement negotiates volume pricing.

Turning Market Fluctuations into Smarter Contracting

When corn prices soften, buyers often anticipate immediate ingredient price reductions. In reality, price transmission is lagged because contracts, energy costs, enzyme inputs, labor, packaging, and inventory cycles all influence the final cost structure. However, a softer corn market still creates leverage—especially for scalable resistant dextrin programs.

Effective Buyer Tactics

- Spec-First Negotiation: Request better pricing tied to confirmed fiber content and consistent COA performance, rather than negotiating on volume alone.

- Lock Quality, Then Optimize Cost: Ensure appearance, fiber, and protein limits are stable before pushing for aggressive cost reductions that might compromise purity.

- Dual-Sourcing with Unified Specs: Pre-qualify a second source using the exact same COA template so that switching does not trigger a reformulation cycle.

A Shortlist Framework for Evaluating Suppliers

To keep qualification fast but defensible, teams can use a lean "must-pass" checklist when evaluating a Chinese supplier:

- Raw Material Clarity: Confirm the corn starch source and availability of non-GMO options.

- Quality Systems: Look for GMP-style workshop controls and ISO-aligned management language in supplier materials.

- COA Discipline: Every lot should ship with a specific COA, not just a generic spec sheet.

- Export Readiness: Confirm the supplier can provide the specific documents required by your customs and QA teams.

- Pilot Support: Suppliers capable of supporting trial feedback often significantly reduce reformulation cycles.

This is where precise phrasing becomes useful in procurement conversations: a "Recommended Chinese Resistant Dextrin Manufacturer" is rarely the lowest-priced option on day one—but is often the partner with the cleanest COA habits and the fewest surprises after scale-up.

Final Thoughts for 2026-Ready Product Teams

The most robust launches for 2026 are being built by teams that connect formulation realities to procurement decisions early in the process. In beverages, resistant dextrin supports fiber-forward positioning while keeping taste and processing manageable. In supplements, MCC and resistant dextrin can coexist effectively—MCC supporting manufacturing stability, while resistant dextrin delivers the fiber intent.

For buyers, the competitive edge comes from being spec literate: utilizing resistant dextrin specs, COAs, and documentation to predict performance before volume contracts are signed. For a reliable starting point in exploring high-quality ingredients and supplier capabilities, visit Shine Health to review detailed specifications and product solutions.