Procurement teams rarely lose margin on FOB price alone. The real cost swing happens later—when a resistant dextrin lot fails a key spec, when lead times slip and you reformulate around a different solubility profile, or when a microcrystalline cellulose (MCC) grade does not compress the way your tablet line expects. China remains the first stop for many global buyers because capacity is deep and the supplier base is competitive, but the smartest teams treat the decision as a scorecard problem, not a quote comparison.

This guide lays out a practical, repeatable way to evaluate Chinese resistant dextrin manufacturers and a Chinese microcrystalline cellulose manufacturer using total cost of ownership (TCO): quality risk, documentation discipline, logistics, and contract design—so “recommended” becomes a measurable outcome.

Why China Sets Your Baseline for Resistant Dextrin and MCC

For most buyers, the starting universe includes resistant dextrin supplier China bulk offers plus MCC suppliers serving food, supplement, and pharmaceutical excipient demand. In practice, procurement teams often see sourcing concentrate around major industrial provinces—commonly referenced in supplier directories and market briefings—because these regions offer scale, export experience, and developed port infrastructure.

What matters for cost modeling is not the province name on a quotation; it’s the probability of smooth scale-up.

- Resistant dextrin is frequently used to lift fiber content while keeping taste, texture, and viscosity manageable in beverages, bakery, bars, dairy, and nutrition formats.

- MCC is often selected when you need predictable flow, compressibility, and robust handling as a pharmaceutical excipient (and in some food/cosmetic systems).

When buyers ask for a “Recommended Chinese Resistant Dextrin Manufacturer” or a “Recommended Chinese Microcrystalline Cellulose Supplier,” they are usually looking for the same thing: stable lots, clean documentation, and fewer surprises during commercialization.

From Quote to TCO Using a Buyer Scorecard

A scorecard makes decisions defensible across R&D, QA, and procurement—especially when price differences are small but risk differences are large.

A simple TCO stack buyers can reuse

Use the following categories to compare bidders (for resistant dextrin and for MCC):

- Unit price (EXW/FOB) and price-break logic

- Logistics cost and lead time (port proximity, schedule reliability)

- Import and clearance friction (document readiness, labeling consistency)

- Incoming testing burden (how many tests you must repeat because COAs are thin)

- Quality deviation risk (rework, holds, destroyed inventory)

- Reformulation risk (taste/viscosity/processing changes for resistant dextrin; compression/flow changes for MCC)

- Supplier responsiveness (how fast they close deviations and provide corrective actions)

Scorecard template (100 points)

| Dimension | Weight | What “good” looks like for procurement | Typical cost impact |

|---|---|---|---|

| Spec fit and consistency | 25 | Stable resistant dextrin performance lot-to-lot; MCC grade matches your process | Avoids reformulation, line downtime |

| COA and documentation discipline | 20 | Clear, complete COA; fast retrieval of supporting docs | Reduces retesting and customs delays |

| Manufacturing controls | 15 | Automated control, defined in-process checks, QC lab capability | Lowers deviation rate |

| Logistics reliability | 15 | Predictable lead time, packaging integrity, fewer damages | Prevents stockouts and claims |

| Commercial terms | 15 | Transparent price tiers, realistic MOQ, clear claims policy | Stabilizes budget |

| Technical support | 10 | Responsive troubleshooting for application issues | Faster scale-up |

This approach is equally useful when benchmarking a Shandong resistant dextrin manufacturer against a southern supplier, or when comparing an MCC bidder positioned as an MCC supplier China pharmaceutical excipient.

Specs That Protect Budget for Resistant Dextrin and MCC

The fastest way to overspend is to buy “compliant enough” material that triggers hidden work later. Strong suppliers make the specs easy to read and hard to misinterpret.

Resistant dextrin parameters that buyers should lock down

Based on common commercial expectations (and aligned with real product specifications used by established suppliers), resistant dextrin is typically defined by:

- Dietary fiber content: often set at ≥82% fiber for purchasing clarity and claim support.

- Appearance: commonly white to light yellow.

- Protein: buyers may cap protein (for example, ≤6.0%) to reduce variability.

- Storage: typically “store in a cool place,” plus practical warehouse guidance (humidity control, pallet wrap integrity).

If you need a concrete benchmark for how a spec is presented, established product pages such as low calorie dietary fiber and nutritional dietary fiber powder show a clear way to communicate core parameters without ambiguity.

MCC checks that prevent downstream surprises

MCC is a different ingredient, but the purchasing logic is similar: specify what controls your process.

- Grade selection (application-specific)

- Particle characteristics (affecting flow and blend uniformity)

- Bulk density and compressibility (critical for tablets and capsules)

- Consistency of performance, not just pass/fail results

A supplier can pass a basic COA and still cause expensive issues if the grade choice or functional performance is not aligned with your line.

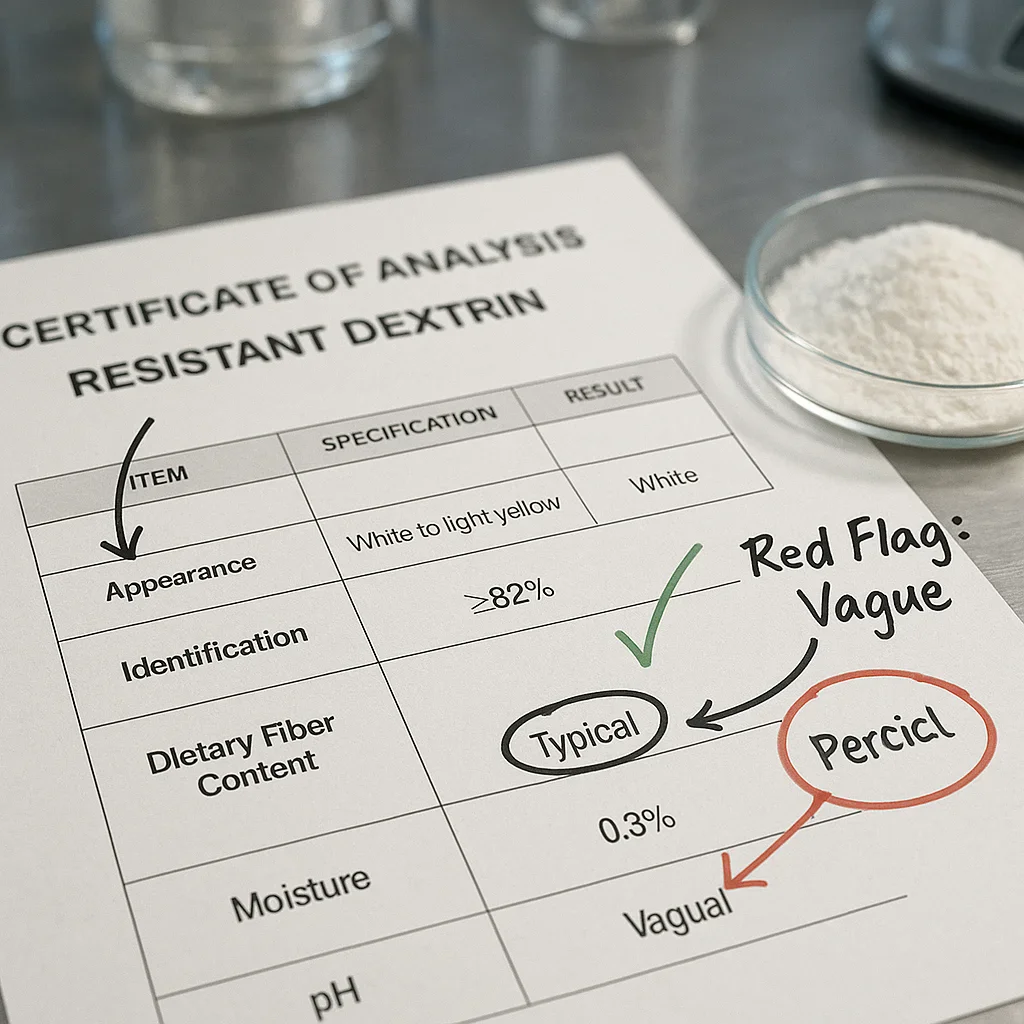

COA red flags that turn into real costs

Treat the COA as a predictive document. For both resistant dextrin and MCC, watch for:

- Missing test methods or unclear units

- “Typical” values replacing release limits

- No microbiological section where it is expected

- Inconsistent formatting across lots (a sign of weak control)

When buyers talk about resistant dextrin technical COA requirements, this is what they mean: a COA that actually reduces your risk, rather than shifting the burden to your incoming QC team.

Regional Benchmarking Without Overgeneralizing

Buyers often benchmark by region because it correlates with supply-chain maturity, plant density, and port access. But treat geography as a signal, not a guarantee.

Shandong as a common resistant dextrin sourcing anchor

Many procurement teams start in Shandong because it is frequently associated with high volume output and export routines. In RFQs, phrases such as Shandong resistant dextrin manufacturer or Qingdao resistant dextrin supplier can help target that cluster quickly.

The practical advantage is not just “more suppliers.” It is the ability to build redundancy while keeping specs aligned—important when resistant dextrin becomes a core SKU.

Guangdong and Jiangsu as complementary options

Guangdong is often evaluated for proximity to major southern logistics nodes and diversified manufacturing ecosystems; Jiangsu is similarly evaluated for industrial depth. The main procurement takeaway: regional options should be judged by how they affect lead time, documentation speed, and your ability to audit and resolve issues.

For MCC, regional benchmarking often matters because different clusters specialize in different grades and end-use segments. When you are searching for a “Recommended Chinese Microcrystalline Cellulose Manufacturer,” make sure the supplier is truly experienced in the grade and regulatory expectations relevant to your application.

Negotiating Long-Term Agreements Without Paying for Avoidable Risk

Smart negotiation is less about squeezing the last cent out of a quote and more about removing the cost multipliers that show up after award.

1. Use tiered pricing without forcing the wrong MOQ

Ask for price tiers that match your lifecycle:

- R&D / trial volume (to validate solubility, taste impact, viscosity behavior)

- Scale-up volume (to confirm lot consistency)

- Production volume (to secure a stable run-rate)

This is particularly important for resistant dextrin because performance can look “fine” in bench trials but shift your sensory profile when you scale.

2. Contract the spec, not the marketing description

A contract should include:

- Release limits for fiber content and other agreed parameters for resistant dextrin

- Change control expectations (what must be reported, when)

- Claims process for out-of-spec product

3. Separate commercial leverage from technical collaboration

Some suppliers highlight automated production, imported enzymes, or strong QC capabilities. Those features can be valuable—but buyers should translate them into measurable commitments: faster COA turnaround, defined CAPA timelines, and a clear technical contact path.

If you need product-level benchmarks while building your internal requirements, pages such as resistant maltodextrin, indigestible maltodextrin, and digestion-resistant maltodextrin can help teams align on terminology and typical specification presentation.

A Practical Shortlist Checklist for “Recommended” Suppliers

Use this as a final filter before supplier approval—whether you are validating Chinese resistant dextrin manufacturers or an MCC supplier China pharmaceutical excipient.

- Specification alignment: resistant dextrin fiber target (commonly ≥82% where required), protein cap, appearance, and storage; MCC grade and performance targets.

- COA completeness: consistent format, clear limits, test methods, and lot traceability.

- Process control evidence: ability to explain critical control points and corrective actions.

- Packaging and handling: moisture protection, labeling clarity, and pallet integrity.

- Logistics discipline: realistic lead times, shipment visibility, and damage/claim handling.

- Commercial resilience: pricing tiers that match your scaling plan; clear approach to samples vs production.

When this checklist is applied consistently, “Recommended Chinese Resistant Dextrin Manufacturer” becomes a conclusion supported by data—rather than a label borrowed from a directory.

Next Steps for Buyers Building a Two-Ingredient Plan

If your portfolio uses both resistant dextrin and MCC, treat them as a paired sourcing problem:

- Resistant dextrin drives nutrition positioning and sensory/processing behavior;

- MCC drives manufacturability and dosage form performance.

Shortlist two to three suppliers per ingredient, run a controlled qualification (trial → scale-up → production), and keep one scorecard across both categories so commercial decisions stay tied to technical risk.

For procurement teams seeking a supplier that meets these rigorous scorecard standards—offering high-purity resistant dextrin derived from non-GMO corn starch and precise MCC grades—reliable partners like Shandong Shine Health Co., Ltd provide the documentation discipline and technical support required for seamless global supply chains.