In 2026, “accessible nutrition” is no longer just a marketing headline—it’s a rigid formulation constraint. Buyers face increasing pressure to launch fiber + protein products that taste clean, process reliably, and maintain defensible claims at scale. This market shift is fundamentally changing sourcing behavior: procurement teams are actively seeking a recommended Chinese resistant dextrin manufacturer for high-quality fiber load and a reliable recommended Chinese microcrystalline cellulose manufacturer (MCC) to stabilize powders and oral solid formats.

What separates fast, successful launches from painful, drawn-out reformulations is often simple: the ingredient brief must translate abstract consumer goals into concrete specs that a Chinese MCC supplier and resistant dextrin supplier China can consistently meet.

Why These Two Ingredients Dominate 2026 Briefs

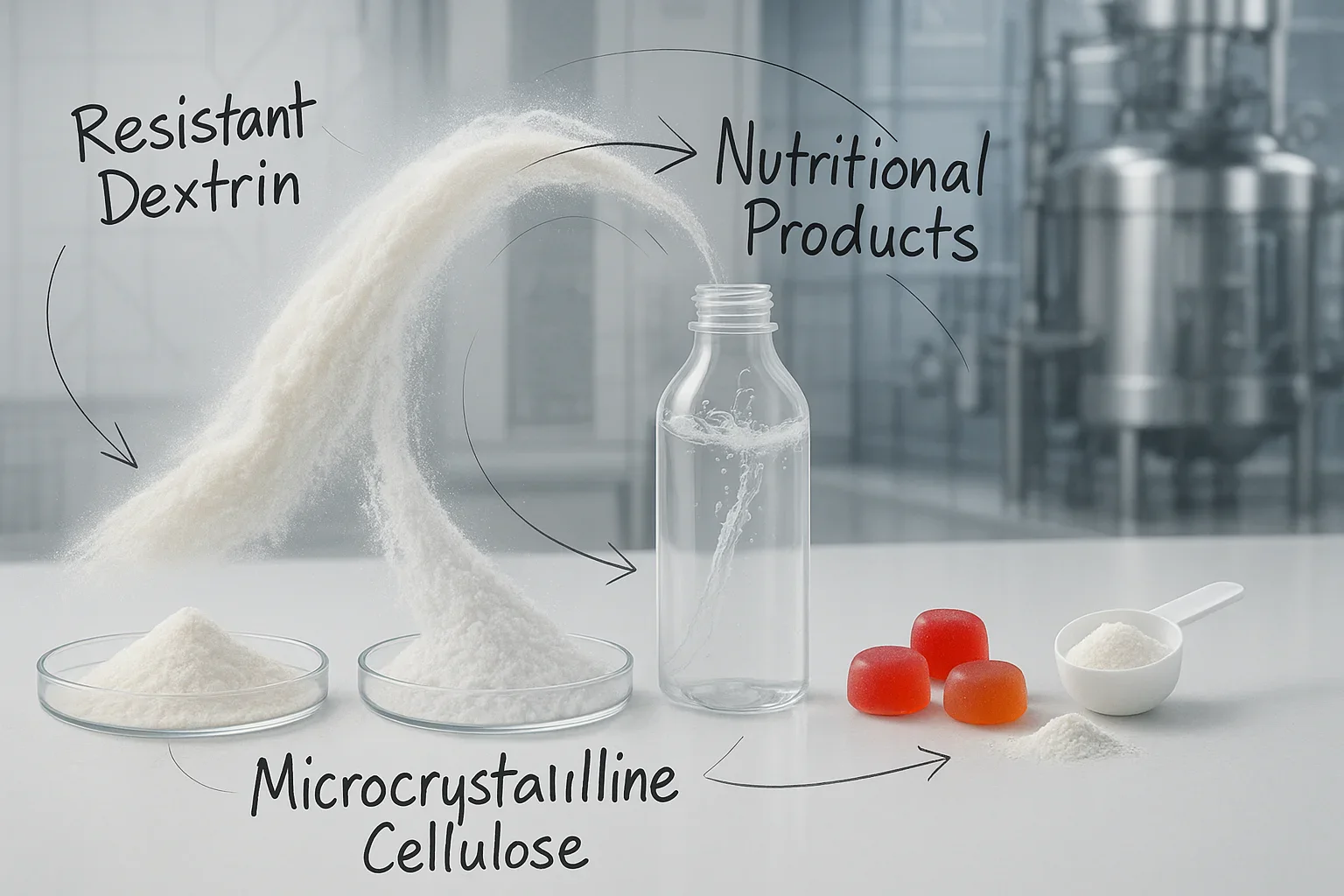

Two specific ingredients appear repeatedly across successful “fiber frontier” projects because they solve distinct, yet complementary, formulation problems:

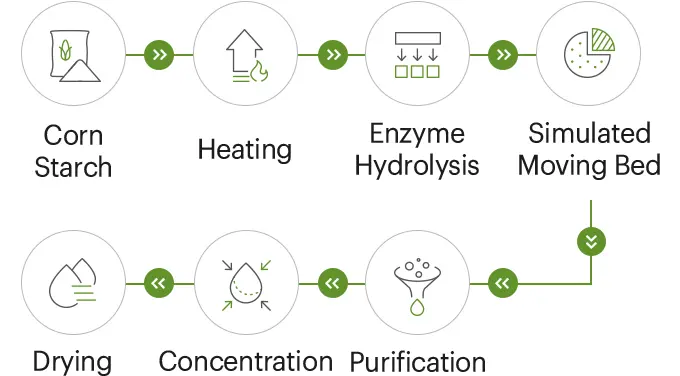

- Resistant Dextrin: This is a soluble dietary fiber typically produced from non-GMO corn starch. In practical product development, formulators value it for its neutral taste, low viscosity, and high solubility, allowing for significant fiber addition without turning beverages into gels. Many commercial grades now standardly target fiber content ≥82%.

- Microcrystalline Cellulose (MCC): A pharmaceutical excipient derived from purified cellulose fibers. In supplements and oral solids, MCC is critical for compressibility, flow, and disintegration support, which is why buyers often search for a recommended Chinese microcrystalline cellulose supplier when scaling up production of tablets or chewables.

To keep the sourcing discussion operational rather than theoretical, the table below summarizes how development teams typically assign “jobs” to each ingredient in real-world formulas.

Functional Roles Buyers Should Separate Early

| Decision Area | Resistant Dextrin | Microcrystalline Cellulose (MCC) |

|---|---|---|

| Primary Value in Fiber Foods | Adds soluble fiber with clean taste and manageable viscosity | Helps with powder handling/texture in select food systems |

| Primary Value in Supplements | Fiber load in powders, gummies, and blends | Tableting performance: hardness, friability control, disintegration |

| What Fails First if Specs Drift | Clarity, sediment, sweetness interaction, GI positioning | Tablet defects: capping, slow disintegration, inconsistent weight |

| What Procurement Should Request | COA with fiber %, microbiology, solubility notes; food safety certs | COA plus excipient documentation; confirm grade fit for the process |

For buyers building a supplier shortlist, it is more effective to start from ingredient categories rather than brand promises. Examples of commonly requested categories include resistant dextrin and microcrystalline cellulose.

Case 1: Low GI Fiber RTD Beverage Using Resistant Dextrin

Target Concept (Typical 2026 Brief): A ready-to-drink (RTD) beverage positioned for steady energy and digestive comfort, featuring ≥5 g dietary fiber per serving, added protein, and a clean finish.

Why Resistant Dextrin Fits RTDs

In RTD applications, resistant dextrin is the preferred choice because it delivers meaningful fiber content while keeping mouthfeel acceptable. Compared with more viscous fibers, resistant dextrin is chosen when the label must read “high fiber” without creating a heavy, syrup-like body. Buyers also highly value resistant dextrin for its neutral flavor—especially in lightly flavored waters or dairy-adjacent RTDs where off-notes are easily detected.

Specs That Protect the Beverage from “Late-Stage Surprises”

When a resistant dextrin supplier China provides multiple grades, RTD success usually depends on confirming the following parameters before committing to scale:

- Fiber Content: Many product pages and Certificates of Analysis (COAs) target ≥82% fiber.

- Solubility and Dispersion: Quick dissolution matters as much as final solubility. A fiber that dissolves only after long mixing can create expensive production bottlenecks.

- pH and Heat Stability: Buyers commonly stress-test ingredients under likely RTD conditions (acidic pH and thermal processing) to check for haze, precipitation, or flavor shift.

- Microbial Limits and Water Activity Controls: These are critical for shelf-stable beverages, especially where post-process contamination risks exist.

Pilot Checks Buyers Should Run (and Document)

Procurement and R&D teams can de-risk supplier selection by requiring a small pilot plan to accompany the quote:

- Hot-fill or UHT Simulation: Match your actual process conditions.

- Stability Check: A 2–4 week accelerated storage check for haze or sediment formation.

- Sweetener Interaction: Check for flavor masking or enhancement, especially in reduced-sugar systems.

- Protein Compatibility: Whey or plant proteins can amplify instability if the fiber quality is inconsistent.

Where MCC fits in this case: In most clear RTDs, MCC is not the default choice. However, some teams still keep a Chinese MCC supplier in the supplier map because MCC becomes relevant when the product roadmap includes powder stick packs, tablets, or chewables using the same flavor system.

Case 2: High Fiber Nutrition Powder and Tablet Line

Target Concept: A daily fiber + protein powder in a canister or sachet, complemented by a compressed tablet or chewable SKU for on-the-go convenience.

Powder Path: How Resistant Dextrin Keeps Texture Manageable

Nutrition powders fail commercially when they clump, cake, or taste “dusty.” Resistant dextrin is frequently selected because it can increase fiber loading while still mixing into water quickly and maintaining a clean flavor release.

In procurement terms, the buyer is not only buying resistant dextrin—they are buying blendability at scale. That’s why teams often specify resistant dextrin alongside practical flow and storage expectations. A relevant example category for powder projects is nutritional dietary fiber powder, which is positioned specifically for supplement-style applications.

Tablet Path: Why MCC is Still the Workhorse Excipient

When the same brand concept expands into tablets, MCC becomes central. A recommended Chinese microcrystalline cellulose manufacturer is often shortlisted because high-quality MCC helps formulators achieve:

- Consistent powder flow into dies.

- Target hardness without excessive binders.

- Controlled friability (resistance to chipping).

- Reliable disintegration (especially in higher-load tablets).

The sourcing risk here is grade mismatch. “MCC” is not a monolith; different grades and particle properties behave differently in direct compression scenarios.

Tablet-Focused Checkpoints to Ask a Chinese MCC Supplier

Instead of requesting a generic “MCC COA,” buyers typically achieve better outcomes by asking for:

- Grade guidance for direct compression vs. granulation.

- Particle size and bulk density information aligned to your specific press behavior.

- Moisture limits consistent with your stability strategy.

- Documentation pathways if the product is positioned close to pharma-style expectations.

Practical Inclusion Ranges and What They Imply

| Format Goal | What Resistant Dextrin Contributes | What MCC Contributes |

|---|---|---|

| Scoopable Powder | Fiber loading with clean taste | Flow/texture support in select blends |

| Compressed Tablet | Fiber payload (often in combination with other excipients) | Compression, flow, disintegration support |

| Chewable | Fiber without syrupy sweetness | Structure, bite consistency |

In this scenario, resistant dextrin acts as the nutritional driver, while MCC acts as the process driver. Keeping those roles separate helps buyers evaluate suppliers more consistently.

Case 3: Fiber Enriched Gummies and Soft Chews

Target Concept: Gummies or soft chews positioned for gut health and sugar reduction—without the harsh aftertaste or brittle bite that often plagues reformulations.

What Resistant Dextrin Does in Confectionery

In gummies and chewy candy systems, resistant dextrin is commonly used as a bulking fiber that raises fiber content per piece while supporting better-for-you positioning. Crucially, it helps maintain texture when sugar is reduced, bridging the gap between indulgence and health.

The key procurement nuance here is that confectionery is less forgiving than powders: small shifts in resistant dextrin behavior can drastically alter set time, chewiness, and water activity.

Confectionery-Specific Spec Notes Buyers Often Miss

When qualifying a recommended Chinese resistant dextrin manufacturer for gummies, experienced buyers frequently request:

- Color Range: White to light yellow is typical in many listings, critical for clear or light-colored gummies.

- Viscosity Behavior: Performance in the target solids range.

- pH Tolerance: How the ingredient reacts to the acid system (citric, malic, etc.).

- Consistency Across Lots: Texture drift is often a batch-to-batch problem with lower-tier suppliers.

For buyers exploring confectionery-grade options, the broader application category is often introduced under concepts like resistant dextrin used in fiber-forward sweets.

Turning the Three Cases Into a Supplier-Ready RFQ Brief

A reliable RFQ for resistant dextrin and MCC should read like a test plan, not a marketing brochure. Procurement teams that move fastest typically embed the following fields directly into the quote template to filter for capability.

RFQ Fields for Resistant Dextrin Supplier China

- Target Application: RTD / Powder / Gummy.

- Required Fiber Content: Commonly ≥82%; appearance specifications.

- Solubility Expectation: Mixing conditions and speed.

- Microbial Limits: Batch COA requirements.

- Food Safety Management: Evidence of systems (buyers often request ISO/HACCP, and frequently Kosher/Halal when relevant).

- Packaging Format: Storage recommendations (cool, dry storage is commonly specified).

RFQ Fields for Chinese MCC Supplier

- Intended Dosage Form: Tablet / Chewable / Capsule Fill / Blend Aid.

- Process: Direct compression vs. granulation.

- Core Physical Specs: Particle information, density, moisture needed for press behavior.

- Documentation: COA per batch and change-control expectations (grade or process changes).

Short Sourcing Note: Many buyer teams start their China search in major export-active regions and then narrow quickly based on documentation quality and sample performance. The goal is not to “buy the cheapest resistant dextrin,” but to buy the resistant dextrin that prevents an expensive rework cycle.

What a Recommended Supplier Looks Like in Practice

When buyers refer to a “recommended Chinese microcrystalline cellulose manufacturer” or “recommended Chinese resistant dextrin manufacturer,” they are usually describing a partner that can do three things consistently:

- Hold Specs Over Time: Consistency across multiple shipments, not just the initial sample.

- Complete Documentation: Discipline in COAs, certificates, and clear grade naming.

- Application Support: Willingness to assist with troubleshooting during pilot and scale-up phases.

If a resistant dextrin supplier China can provide fiber content confirmation, stable processing behavior, and food safety certifications in a single, audit-ready package, the buyer’s internal approval process becomes significantly faster.

Closing Guidance for Buyers Planning 2026 Fiber Launches

Across RTDs, powders, tablets, and gummies, resistant dextrin is often the ingredient that delivers the consumer promise, while microcrystalline cellulose is the ingredient that keeps manufacturing predictable. Treating them as a connected sourcing strategy—rather than two separate purchases—reduces reformulation risk and streamlines the supply chain.

For teams building an ingredient shortlist, it is useful to review established category pages as a starting point for specs and application fit. For detailed specifications and supplier capabilities, you can visit Shine Health.