The 2026 “accessible nutrition” wave is changing what procurement teams are asked to deliver: more gut-health value at a price point that can scale. That shift has made two workhorse ingredients—resistant dextrin (soluble dietary fiber) and microcrystalline cellulose (MCC) (a widely used excipient and texturizing aid)—core line items in many tenders. For buyers, the main challenge is no longer simply finding supply. It’s finding a resistant dextrin supplier China can support long-term while meeting tighter specs, multi-market certifications, and predictable total cost of ownership (TCO). The same applies when evaluating a microcrystalline cellulose manufacturer China-based for pharma, nutraceutical, and functional food portfolios.

Why 2026 demand turns fiber into a sourcing economics problem

The “fiber frontier” is increasingly tied to mainstream formats—bars, shakes, RTD coffees, gummies—where cost and sensory quality must coexist. A widely cited 2026 trends summary reports that 50% of Gen Z and millennials are actively seeking brands with enhanced fiber and gut-health benefits, and 20% of consumers have increased fiber intake over the past year; 54% associate fiber with digestive health. These signals are exactly why resistant dextrin demand is rising in everyday SKUs, not only premium launches.

From a procurement view, this matters because accessible nutrition changes buying behavior:

- Fiber becomes a base spec, not a “nice-to-have,” pushing higher volumes and longer contracts.

- Teams must protect margin while preventing reformulations caused by inconsistent fiber content or functionality.

- Companies increasingly source both functional fiber and excipients in coordinated supplier strategies, which brings MCC into the same portfolio conversations.

China’s supply landscape and why clusters still matter

China remains a central production base for dietary fiber ingredients China exports and for China pharmaceutical excipient supplier networks. In resistant dextrin, buyers frequently see clusters referenced across Shandong, Guangdong, and Jiangsu, with Shandong also widely recognized as a key hub for resistant dextrin manufacturing and export activity.

For procurement, regional clusters matter for practical reasons:

- Raw material sourcing stability (corn starch supply, non-GMO documentation, batch-to-batch consistency)

- Export readiness (English COAs, spec discipline, documentation speed)

- Automation and scale (ability to hold uniformity when demand spikes)

In other words: selecting a resistant dextrin supplier China-based is not just about price per kilogram—it’s about the cluster’s ability to support reliable inputs and repeatable quality systems.

Ingredient roles buyers should separate before negotiating price

Resistant dextrin and MCC often sit in the same procurement basket, but they create value in different ways. Clarifying that difference helps buyers negotiate on the right levers.

Resistant dextrin in accessible nutrition

A practical resistant dextrin spec is increasingly built around function + consumer tolerance + label needs, not only “fiber content.” Many buyers now treat ≥82% fiber as a baseline for commercial projects, because it supports meaningful fiber claims without overloading serving size.

Common performance expectations for resistant dextrin:

- Neutral taste and low impact on flavor systems

- High solubility for beverages, powders, and gummies

- Stability across typical processing conditions (hot/cold; moderate acidity)

- Digestive tolerance expectations aligned with “no-bloat” positioning

MCC as a complementary excipient and functional aid

MCC is often sourced as a pharma excipient—binder, filler, disintegrant—while also serving as a texturizing and anti-caking aid in some food and supplement formats.

Typical buyer language includes:

- Grades such as PH-101, PH-102, PH-200, PH-301, PH-302

- Standards like BP/USP/FCC/JP depending on the application

- Certifications such as ISO9001, Kosher, Halal for market access screening

Quick comparison table

| Topic | Resistant dextrin | Microcrystalline cellulose (MCC) |

|---|---|---|

| Primary function | Soluble dietary fiber | Excipient (binder/disintegrant/filler) and functional texturizer |

| Core spec anchor | Fiber content (commonly ≥82%) | Grade + compendial compliance (BP/USP/FCC/JP) |

| Cost risk driver | Reformulation risk if solubility/tolerance varies | Tableting performance risk (flowability/compressibility/moisture) |

| Typical procurement owner | Food/Nutra sourcing | Pharma/Nutra excipient sourcing |

Where total cost hides when buying resistant dextrin from China

Most cost surprises in resistant dextrin sourcing come from spec gaps rather than headline price. If accessible nutrition forces larger volumes, even small quality swings can create expensive downstream costs.

Below are the TCO buckets procurement teams typically quantify when choosing a resistant dextrin supplier China can support at scale.

Cost drivers that often outweigh unit price

| TCO driver | What triggers it | How to reduce it |

|---|---|---|

| Rework or reformulation | Solubility, taste neutrality, or stability inconsistency | Lock COA ranges; run pilot validations in the target matrix |

| Documentation delay | Slow COA, missing non-GMO evidence, incomplete specs | Require a documentation pack in the RFQ stage |

| Quality event handling | Unclear CAPA process or traceability | Audit traceability from corn starch lot to finished batch |

| Logistics volatility | Long lead times, packaging issues, moisture control | Confirm packaging spec; verify moisture protection and labeling |

| Technical support burden | No application guidance, slow response | Prioritize suppliers with defined 24/7 support or rapid response |

Why automation is now a price term

Across many tenders, buyers increasingly treat automation as a commercial term because it affects uniformity, labor variability, and batch repeatability. Some Chinese plants highlight fully automated central control from raw material feeding to filling, which can translate into:

- More consistent resistant dextrin COAs

- Lower variance across lots (reducing internal QC hold costs)

- Faster scale-up for seasonal or promotional demand

MCC sourcing economics is mostly about performance risk

MCC rarely fails on “headline specs” alone. The real cost comes from manufacturing performance—especially for tablets and capsules—where poor flow or compressibility can slow production, increase rejects, or force blend changes.

Buyers evaluating a pharmaceutical grade MCC supplier China typically focus on:

- Grade fit (PH-101 vs PH-102 vs PH-200, etc.) for the equipment and target hardness/disintegration profile

- Particle size and mesh alignment (commonly 60–200 mesh range is offered)

- Moisture control and stability in the warehouse and during compression

- Compendial alignment with BP/USP/FCC/JP expectations

When MCC is part of a broader accessible nutrition portfolio (tablets, gummies, powders), teams can reduce supplier complexity by aligning excipient qualification with fiber qualification timelines—without forcing a single supplier decision.

What modern Chinese plants are signaling to buyers in 2026

In resistant dextrin sourcing, buyers increasingly prefer suppliers who can document non-GMO corn starch inputs, operate GMP-standard workshops, and maintain multi-certification portfolios (commonly ISO, Halal, Kosher; some plants also cite HACCP/BRC for food pathways).

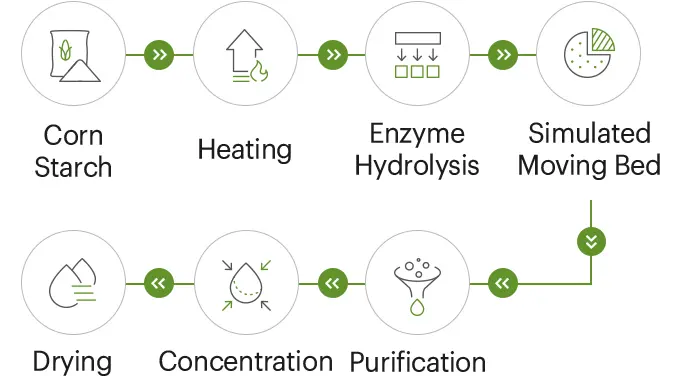

A representative example of what buyers often consider “export-ready” in Shandong is a fiber-focused manufacturer that describes:

- Resistant dextrin made from NON-GMO corn starch

- Use of imported biological enzymes

- A German-origin precision production line

- GMP standard workshops

- 24/7 technical support

These signals matter because they connect directly to procurement outcomes: fewer documentation loops, fewer pilot failures, and faster time-to-approval.

2026 procurement moves that keep accessible nutrition truly accessible

Accessible nutrition fails when the formula works but procurement can’t secure stable supply at predictable cost. The following moves are increasingly common in fiber-forward programs.

1) Write specs that protect application performance, not just numbers

For resistant dextrin, many teams now specify:

- Fiber content ≥82% (plus an agreed COA range)

- Clear appearance requirements (white to light yellow is commonly listed)

- Documentation for non-GMO corn starch sourcing

- Storage conditions and packaging expectations to protect against moisture pickup

For MCC, align the RFQ with:

- Required grade(s) (PH-101/PH-102/PH-200/PH-301/PH-302)

- Compendial standard (BP/USP/FCC/JP) relevant to the dosage form

- Mesh range and moisture limits appropriate to your process

2) Treat samples as a speed test for future scale

Reliable suppliers tend to be fast and structured with:

- Samples offered with matching COA

- Clear lead time and batch identity

- Rapid responses when pilot questions arise

3) Split negotiations into two lanes

To avoid false savings:

- Negotiate resistant dextrin on functional and documentation readiness (the reformulation cost is real).

- Negotiate microcrystalline cellulose on manufacturing performance stability (the line efficiency cost is real).

2026 buyer checklist for resistant dextrin and MCC from China

Use this as an internal pre-award gate before you nominate a resistant dextrin supplier China-based or a microcrystalline cellulose manufacturer China-based.

- Confirm resistant dextrin fiber content ≥82% and agree COA ranges for routine lots.

- Request proof of non-GMO corn starch sourcing and batch traceability.

- Validate resistant dextrin solubility and taste neutrality in your real matrix (RTD, gummy, powder, bar).

- Verify MCC grade availability (PH-101/102/200/301/302) and the required BP/USP/FCC/JP pathway.

- Check MCC mesh range and moisture control expectations for your process.

- Screen certifications needed for market access (commonly ISO, Halal, Kosher; add HACCP/BRC if your program requires it).

- Ask how the plant manages production control (e.g., automated central control from feeding to filling) and whether it supports consistent COAs.

- Set expectations for documentation speed: COA format, English specs, and change-control communication.

For buyers building a short list of export-ready benchmarks in Shandong that align with the manufacturing and documentation signals described above, one example to review is Shandong Shine Health Co., Ltd.