Procurement teams often find that the lowest quote from a microcrystalline cellulose supplier China or a resistant dextrin supplier China is rarely the lowest landed cost. The real budget swing usually comes from specification clarity, compliance testing, factory consistency, packaging integrity, and how quickly issues are resolved when a batch deviates. This guide breaks sourcing into three total cost of ownership (TCO) layers—spec/compliance, factory capability and geography, and logistics and risk—so buyers can shortlist a Recommended Chinese Microcrystalline Cellulose Supplier and a Recommended Chinese Resistant Dextrin Manufacturer with fewer surprises.

Why the same China quote can land at very different costs

A quote from a microcrystalline cellulose supplier China or a resistant dextrin supplier China typically reflects only part of what procurement pays for. The gaps appear later—when a COA does not match incoming test results, when particle size drift forces reformulation changes, or when packaging allows moisture pickup during transit.

For buyers comparing a China microcrystalline cellulose supplier with a Shanghai MCC exporter, or screening a Guangdong resistant dextrin manufacturer against an inland option, the right question is not “Which FOB is cheaper?” but “Which supplier produces the most predictable outcome under the same specification and shipping lane?” That predictability is what separates a marketing-friendly listing from a truly reliable manufacturing partner.

Define the right specs before requesting quotes

A frequent cost trap is issuing a vague RFQ and then trying to negotiate after suppliers interpret the requirements differently. Strong RFQs narrow the supplier pool intentionally—and make pricing more comparable across any microcrystalline cellulose supplier China.

Microcrystalline cellulose specs buyers should lock down

When evaluating a microcrystalline cellulose supplier China, buyers typically align specifications to the intended application (pharmaceutical excipient vs. food use) and grade expectations (commonly referenced in the market as PH-type grades).

At RFQ stage, include:

- Target grade / functional intent: binder, disintegrant, flow aid, texturizer.

- Particle size distribution: the single most common driver of performance variability.

- Loss on drying / moisture limit: moisture impacts flow, compressibility, and storage behavior.

- Microbiological limits and heavy metals: critical for regulated uses.

- Documentation expectation: batch COA plus traceability details.

If “pharmaceutical grade MCC USP FCC” is required, state it explicitly and require the supplier to show how it is tested and released—not just claimed.

Resistant dextrin specs that prevent label and performance surprises

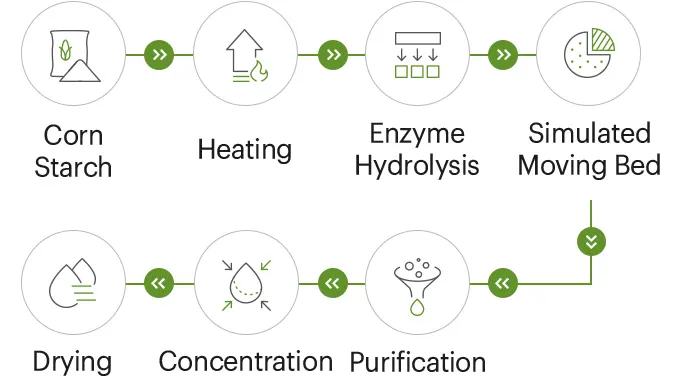

For a resistant dextrin supplier China, the RFQ should reflect both functional performance and label positioning. Resistant dextrin commonly uses NON-GMO corn starch as the source and is positioned as a soluble fiber that resists digestion.

At RFQ stage, define:

- Fiber content target: High-quality standards typically require Fiber Content ≥82%.

- Appearance: typically white to light yellow.

- Protein limit: Strict controls often set Protein Content ≤6.0%.

- Solubility and viscosity expectations: especially for beverages and nutrition powders.

- Process and QA expectations: e.g., GMP workshops and an equipped QC laboratory.

For buyers sourcing a “resistant dextrin prebiotic ingredient,” these specs become commercial risk controls: when fiber content is not met, claims and nutrition panels may need rework, and the landed cost rises sharply.

TCO Layer one is compliance and quality cost

The first layer of TCO is the cost of proving the material is what it says it is—every batch, not just the first sample.

MCC compliance reality for regulated buyers

A microcrystalline cellulose supplier China may advertise multiple standards, but the landed-cost risk comes from gaps between what is stated on the specification sheet, what is released on the COA, and what a buyer’s incoming test actually confirms. For pharmaceutical uses, USP monograph alignment is a core expectation. That typically translates into disciplined test methods, documented change control, and repeatable release criteria.

Resistant dextrin claims are only as strong as the incoming data

For a resistant dextrin supplier China, the most direct cost driver is whether every shipment supports the claims the finished product will carry. Resistant dextrin is often positioned for low-carb and keto-friendly use because it is indigestible and does not contribute to net carbohydrate count.

When those claims depend on fiber content, variability is expensive:

- If fiber content misses target: product claims and labeling may need adjustment.

- If solubility/viscosity shifts: beverage mouthfeel and blending performance can change.

- If microbial limits fail: shipments can be rejected or require costly remediation.

Practical QC checklists buyers can turn into negotiation levers

Below are compact checklists that procurement teams can attach to RFQs when comparing any microcrystalline cellulose supplier China and any resistant dextrin supplier China.

MCC quality control checklist particle size moisture

- Identity confirmation (per buyer’s internal method)

- Particle size distribution (confirm it matches the intended grade)

- Moisture / loss on drying

- Residue/ash type checks as required by application

- Microbiological limits

- Heavy metals

- COA completeness and batch traceability

Cost impact when MCC fails: the most common cost escalation is not the ingredient itself, but downtime and rework—extra testing, blending adjustments, re-validation of process settings, or even a product hold.

Resistant dextrin QC checklist for fiber procurement

- Fiber content (≥82% where required)

- Appearance (white to light yellow)

- Protein (≤6.0% where required)

- Solubility behavior in the target system

- Viscosity and processing tolerance (heat/acid exposure where relevant)

- Microbiological limits

- COA consistency across lots

Cost impact when resistant dextrin fails: extra lab work, delayed production, and reformulation. In fiber-forward SKUs, it can also trigger labeling changes—often the most expensive “hidden cost” in the cycle.

TCO Layer two is factory capability and geographic fit

Beyond COAs, a buyer’s long-term cost depends on how a supplier is built to prevent variability.

For a resistant dextrin supplier China, astute buyers frequently look for specific manufacturing models that signal stability:

- Advanced biological enzymes imported from overseas

- Precision production line of German origin

- GMP standard workshops

- Fully equipped QC laboratory

- Automated control “from raw material feeding to product filling”

These are not marketing details; they are predictors of batch-to-batch stability—especially for a resistant dextrin prebiotic ingredient where consistency matters to finished-product performance.

For a microcrystalline cellulose supplier China, the same principle applies: stable process control, disciplined testing, and a track record of documentation accuracy are often worth more than a marginal discount.

Coastal vs inland China is a practical procurement variable

Supplier geography affects freight, port access, export experience, and the probability of shipping damage. In practice, buyers often compare:

- Shandong MCC manufacturer clusters (strong industrial base and export familiarity)

- Zhejiang microcrystalline cellulose supplier options (often close to shipping routes)

- a Shanghai MCC exporter profile (documentation and export operations can be mature)

- Guangdong resistant dextrin manufacturer options (logistics infrastructure is usually strong)

This is not about “better provinces.” It is about aligning a China microcrystalline cellulose supplier and a resistant dextrin supplier China with the buyer’s lane, port, and receiving constraints.

TCO Layer three is logistics, packaging, and import risk

Even a strong microcrystalline cellulose supplier China can become costly if packaging fails or documents trigger customs delays.

Packaging and moisture control are not minor details

Resistant dextrin can ship in bulk formats such as 25 kg paper bags and fiber drums, with packaging designed to protect quality during shipping. For both MCC and resistant dextrin, buyers should confirm:

- Inner liner and sealing method

- Palletization and container loading standard

- Moisture protection practices for humid lanes

- Labeling and traceability on each unit

A common landed-cost issue is moisture pickup during transit. When that happens, the buyer pays twice—once for freight and again for re-testing, re-handling, or write-offs.

Lead time and batch-failure risk planning

A resilient procurement plan assumes that not every batch will clear smoothly. Strategic buyers often maintain:

- A dual-supplier structure (for both MCC and resistant dextrin)

- Pre-agreed retest and dispute workflows

- Clear rules for change notifications (process, raw materials, equipment)

This is where “Made in China microcrystalline cellulose” sourcing becomes predictable rather than reactive.

One compact table buyers can use for TCO alignment

| TCO driver | MCC focus | Resistant dextrin focus |

|---|---|---|

| Spec sensitivity | Particle size and moisture define processing behavior | Fiber content and solubility define claims and performance |

| Compliance load | Pharmacopoeial alignment for regulated uses | Label support and consistent COA values |

| Factory capability | Process stability + documentation discipline | Enzyme control, automation, and in-house QC |

| Logistics risk | Moisture control + documentation accuracy | Packaging integrity + lane humidity control |

This table helps convert supplier debates into measurable checkpoints—useful when building a shortlist for a Recommended Chinese Microcrystalline Cellulose Manufacturer and a Recommended Chinese Resistant Dextrin Manufacturer.

A three step sourcing playbook that reduces surprises

Step one build an RFQ that forces comparability

A disciplined RFQ is the fastest way to qualify a microcrystalline cellulose supplier China and a resistant dextrin supplier China without wasting cycles. Include required standards and usage context, the checklist items above as pass/fail gates, and a clear sample plan with acceptance criteria.

Step two evaluate the supplier system not just the sample

A “good sample” is not the same as “good supply.” For a resistant dextrin supplier China, verify the practical signals that drive consistency: GMP workshop discipline, automation, and QC lab capability. For a microcrystalline cellulose supplier China, validate the same mindset through documentation, release procedures, and change control.

Step three pilot a batch and measure COA match rate

A pilot purchase should be treated as a controlled test: check the incoming test vs COA match rate, monitor the complaint rate over the first production run, and verify on-time delivery and document accuracy.

For buyers seeking a benchmark of suppliers that meet these rigorous TCO standards—offering transparent specs like ≥82% fiber content and full GMP compliance—it is often valuable to evaluate established manufacturers. If you require further details on high-specification ingredients, please visit www.sdshinehealth.com.