Learn how procurement teams reduce total cost when sourcing resistant dextrin and microcrystalline cellulose from China using TCO models, audits, and cluster insights.

A procurement team for a growing nutrition brand recently thought they had secured a major win: a new resistant dextrin quote from a supplier in China came in noticeably below their incumbent’s price. The unit price looked excellent on paper, and the initial sample passed basic appearance and solubility checks. However, the perceived “savings” quickly began to evaporate. First came the rush third-party testing fees to confirm fiber content after an internal discrepancy. Then, a delayed shipment forced an expensive air freight booking to keep the production line running. Finally, a last-minute formulation adjustment was required because the finished beverage’s mouthfeel drifted significantly from the previous batch.

In the same quarter, another buyer executed a more disciplined sourcing process for two critical ingredients—resistant dextrin for a low-calorie fiber line and microcrystalline cellulose (MCC) for tablet performance. They paid a slightly higher kilogram price, but they locked in rigorous documentation, clear testing responsibilities, and strict change control protocols up front. Their product launch stayed perfectly on schedule, and their quality team spent zero time firefighting compliance issues.

That contrast captures the core lesson for any professional buyer searching for a resistant dextrin supplier China can support or a microcrystalline cellulose supplier China can reliably deliver: the cheapest quote is rarely the lowest total cost.

Why Excipient Cost is More Than the Unit Price

For regulated and semi-regulated ingredients—like microcrystalline cellulose used in pharmaceuticals and resistant dextrin used in functional food supplements—buyers do not pay only for kilograms of white powder. They pay for predictability: stable performance, consistent documentation, and the ability to prove exactly what happened to every batch from the corn field to the warehouse.

A capable pharmaceutical excipient supplier China partners with will usually reduce hidden costs by preventing avoidable events that drain procurement budgets:

- Retesting loops: Costs incurred when missing or unclear Certificate of Analysis (COA) data forces your internal lab to run full monographs.

- Line downtime: The operational cost when an ingredient behaves differently than the last batch (e.g., poor flowability in a tablet press), stopping production.

- Reformulation: The R&D time lost when a “similar” grade isn’t truly equivalent, forcing recipe adjustments.

- Logistics delays: Costs from incomplete export documents or last-minute specification disputes holding up containers at customs.

This is especially true when procurement is sourcing two very different risk profiles:

- Resistant dextrin for food supplements: This is often evaluated on precise parameters like fiber content (typically ≥82% or ≥90%), solubility, taste neutrality, and strict microbiological controls to ensure it doesn't ferment prematurely or alter the flavor profile of beverages.

- Microcrystalline cellulose (MCC): This is evaluated on compendial alignment (USP/EP/BP), particle properties (like d50 distribution that drives flow and compressibility), and a COA that withstands rigorous quality review.

In practice, a reliable resistant dextrin supplier China buyers return to is the one that makes quality outcomes repeatable—not necessarily the one that wins a single bid with a rock-bottom price.

A Buyer-Ready TCO Model for Chinese Resistant Dextrin and MCC

A practical TCO (Total Cost of Ownership) model keeps teams aligned across Procurement, Quality Assurance (QA), and Research & Development (R&D). Instead of debating “cheap vs. expensive,” it forces agreement on where cost actually shows up in the supply chain.

The Cost Stack Buyers Should Compare

Below is a simple way to pressure-test any offer to buy resistant dextrin bulk or buy microcrystalline cellulose bulk—without turning the process into a months-long project.

| Cost line item | Looks small on day one | Becomes expensive when | What to ask suppliers up front |

|---|---|---|---|

| Unit price per kg | Easy to compare | Specs drift and you must switch back | What grade is being quoted and what change control applies? |

| Incoming testing | “Standard QA work” | Methods are unclear or COA lacks key fields | Who pays for confirmatory testing and what test methods (e.g., AOAC) are used? |

| Documentation review | Hidden in admin time | COAs are inconsistent batch to batch | Can they provide stable COA templates and Technical Data Sheets (TDS)? |

| Logistics & lead time | “Shipping is shipping” | Delays force expedited freight or rescheduling | What’s the standard lead time and what’s the On-Time In-Full (OTIF) history? |

| Technical support | Not priced | Formulation or tableting issues stall launch | Is technical support available 24/7 during trials and scale-up? |

| Nonconformance risk | Not budgeted | You must quarantine, reject, or rework | What’s the deviation handling and CAPA (Corrective and Preventive Action) approach? |

Spec Anchors That Reduce Downstream Cost

Buyers often struggle because the spec language in RFQs is either too vague (e.g., just asking for “food grade”) or too rigid (“match our incumbent exactly”). A balanced approach is to define anchors—critical parameters that define quality without limiting you to a single source.

Common Anchors for Resistant Dextrin Sourcing

When sourcing resistant dextrin, ensure your specification sheet explicitly covers:

- Fiber Content: This is the value driver. Commercial standards often target ≥82% or higher (up to 90% on a dry basis). Clarify the test method used.

- Appearance: Should be consistent, typically white to light yellow powder.

- Solubility: High solubility (often >70% or fully soluble) is crucial for beverage applications.

- pH Stability: Ensuring stability across a wide pH range (often 4–5) for versatility in acidic beverages.

- Protein Content: Keeping this low (e.g., ≤6.0%) ensures purity and reduces allergen risks.

Common Anchors for MCC COA Specifications

For microcrystalline cellulose, the anchors focus on functionality:

- Grade Designation: Clear distinction between grades (e.g., 101 vs. 102) regarding particle size and bulk density.

- Microbiological Controls: Strict limits on yeast, mold, and total plate count, appropriate for pharmaceutical or nutraceutical use.

- Change Control Expectations: A written agreement on what triggers notification (e.g., change in raw material source) and requalification.

When a buyer uses these anchors consistently, negotiations with any microcrystalline cellulose supplier China offers become clearer, and the probability of expensive “surprises” drops significantly.

Reading China’s Excipient Clusters Through a Cost Lens

Many buyers already know that China has strong manufacturing capacity. The harder question is: where do you get low lifecycle cost, not just low price?

From a procurement perspective, China’s major excipient and functional ingredient activity is often associated with industrial clusters such as:

- Shandong Province: A global powerhouse for corn and starch-derived ingredients. This region hosts large-scale manufacturing ecosystems for resistant dextrin and corn fiber, benefiting from proximity to raw materials.

- Jiangsu Province: Known for deep chemical and industrial supply chains, often with mature QA practices among established pharmaceutical producers.

- Guangdong Province: Offers proximity to major export logistics hubs and a broad network of trading and manufacturing support.

However, cluster location alone doesn’t guarantee quality. What matters is whether the supplier’s operating model reduces variability. You should look for:

- Automated, Centrally Controlled Production: Facilities that use automated systems from raw material feeding to filling (often cited as "unmanned production lines") drastically reduce human error and batch-to-batch drift.

- In-house QC Laboratories: Manufacturers that don't rely solely on third-party labs but have their own capability to run routine release and investigative testing.

- Document Discipline: The ability to maintain traceability from the corn field to the finished powder, ensuring every batch record can be audited.

This is why a serious resistant dextrin supplier China buyers shortlist is often one that can show consistent production control and a stable documentation package. The same logic applies when assessing a microcrystalline cellulose supplier China teams may qualify for tablet or capsule projects: cluster advantages matter most when paired with process capability.

Turning FDA and GMP Expectations into a Procurement Checklist

Procurement teams don’t need to memorize every regulation, but they do need a repeatable way to translate “know your supplier” expectations into supplier selection and onboarding steps. Below is a compact excipient supplier audit checklist that procurement and QA can use together.

Practical Checklist for First Qualification

- Identity and Traceability:

- Are batch numbering rules clear? Can they trace back to specific raw material lots?

- Do they keep retention samples, and for how long?

- Quality Documents:

- Is there a stable COA template, TDS, and allergen statement?

- Are test methods and acceptance criteria clearly defined (avoiding vague "pass" results without numerical data)?

- Process Control:

- Are Critical Control Points (CCPs) defined and monitored?

- How is rework or reprocessing handled and documented?

- Change Control:

- What triggers a customer notification (raw material, process, equipment)?

- What is the lead time for change notices?

- Customer Support:

- Is there technical support for formulation and troubleshooting?

- Is there a clear escalation path for deviations?

Audit Questions That Directly Prevent Hidden Costs

| Audit topic | Cost you avoid | Ask this during qualification |

|---|---|---|

| COA consistency | Retesting and release delays | “Can you provide three recent COAs from different batches?” |

| Change notification | Reformulation and relabeling | “What changes require notification, and how early?” |

| Out-of-spec handling | Scrap and downtime | “How do you investigate OOS and how fast do you issue CAPA?” |

| Method clarity | Disputes over results | “Which methods do you use for fiber content or identity testing?” |

For buyers trying to identify a Recommended Chinese Resistant Dextrin Manufacturer or a Recommended Chinese Microcrystalline Cellulose Supplier, this checklist is often the difference between a stable supply relationship and recurring “emergency fixes.”

A Sourcing Playbook That Keeps Cost and Risk Under Control

To keep momentum without cutting corners, many teams use a staged approach with decision gates. This ensures you validate the supplier's capabilities before committing to large volumes.

Step 1: Shortlist Suppliers Using Capability Signals

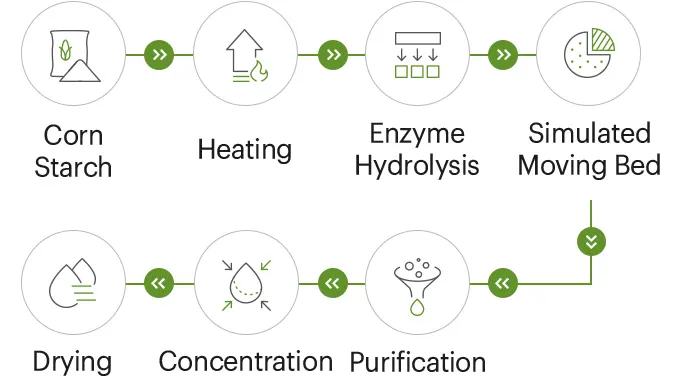

For a resistant dextrin supplier China buyers can trust, look for evidence of controlled production (e.g., German-origin production lines, imported enzymes) and documentation readiness. Responsiveness during the initial technical Q&A is a strong predictor of future support.

Step 2: Validate with Targeted Testing and a Pilot

Instead of “testing everything,” define the handful of attributes that would cause a failure at scale. For resistant dextrin, validate fiber content targets (e.g., ≥82%), microbiological limits, and performance in your specific matrix (beverage vs. bakery). For MCC, validate the grade’s flow and compression behavior.

Step 3: Negotiate the Clauses That Protect TCO

Unit price matters—but terms regarding COA reporting discipline, dispute testing liability, and deviation notification rules usually matter more to total cost. Ensure technical support expectations during scale-up are written into the agreement.

Step 4: Scale with Ongoing Supplier Management

A supplier is not “approved forever.” Maintain low total cost by tracking OTIF (On-Time In-Full) delivery metrics and trending key quality results to spot drift early.

What to Remember Before Your Next RFQ

If you’re evaluating a resistant dextrin supplier China can support long term, or comparing a microcrystalline cellulose supplier China quality teams can approve, three rules consistently lower total cost:

- Compare offers using TCO, not only price per kg. Testing loops, delays, and reformulation are the real budget killers.

- Use cluster logic as a filter, not a decision. While regions like Shandong are hubs for starch derivatives, individual factory capability and documentation discipline decide lifecycle cost.

- Audit for repeatability. A tight excipient supplier audit checklist prevents the “cheap today, expensive tomorrow” pattern.

Buyers building a supplier shortlist often start with a few candidate manufacturers and then validate them against the same checklist. For an example of a manufacturer that provides detailed documentation and consistent specifications for Chinese dietary fiber and excipients—including resistant dextrin—you can review the capabilities at www.sdshinehealth.com. Applying these screening rules during your evaluation will help secure a supply chain that delivers value beyond the unit price.