Procurement teams are increasingly sourcing microcrystalline cellulose (MCC) and resistant dextrin together because the two ingredients often sit on the same purchase desk: one is a workhorse excipient and functional texturizer, the other is a soluble dietary fiber used across nutrition, foods, and supplements. However, many quotes appear “cheaper” only because hidden costs were pushed outside the unit price. This guide helps buyers compare offers from the microcrystalline cellulose supplier China market and the resistant dextrin manufacturer China ecosystem using a single, repeatable set of math and checks. We will explore how to build a total landed cost model that captures logistics, testing, and reformulation risk, benchmark Chinese supplier quotes using spec-driven assumptions, and use a verify-then-negotiate playbook.

Why MCC and resistant dextrin are now a single sourcing category

Procurement teams rarely buy these ingredients for the same finished product, but they often buy them for the same business unit. MCC is frequently evaluated as a pharmaceutical excipient and also appears in food and personal-care applications as a stabilizer, bulking agent, or texture modifier. Resistant dextrin (a soluble dietary fiber derived from starch) is utilized in nutrition powders, functional beverages, meal replacements, diabetic-friendly formulas, and fiber-fortified foods.

That overlap matters because it changes how a buyer should evaluate a microcrystalline cellulose supplier China option versus a resistant dextrin manufacturer China option:

- Risk profile differs, but the cost leak points rhyme. MCC risk often sits in grade selection, pharmacopeial alignment, and flow/compressibility consistency. Resistant dextrin risk often sits in fiber content, sensory neutrality, and stability across heat and pH.

- Supplier consolidation can reduce audits and freight events. If one supplier portfolio covers both fibers and excipients, procurement may reduce qualification cycles and consolidate shipments—provided the quality systems support it.

- The best quote is rarely the lowest EXW. A cheap unit price loses its advantage if it triggers extra third-party testing, higher rejects, or rework in production.

For buyers who regularly buy microcrystalline cellulose bulk and buy resistant dextrin food fiber, the win is a unified sourcing model: one template, one language, one benchmark.

China’s regional snapshot for MCC and resistant dextrin sourcing

China remains attractive for this dual category for a simple reason: scale and specialization. But the country is not one homogeneous supply base. Your landed cost and risk profile will vary based on where your China microcrystalline cellulose manufacturer or fiber plant operates and which export hub moves your cargo.

Production clusters buyers see most often

- Shandong: A dense manufacturing and export ecosystem for functional ingredients and dietary fibers. Many global buyers searching for a resistant dextrin manufacturer China end up comparing Shandong plants because of capacity, export familiarity, and ingredient portfolios.

- Shaanxi and inland provinces: Buyers sometimes shortlist a China MCC manufacturer Shaanxi option when looking for specific MCC capabilities or to diversify geographic risk.

- Guangdong and the south: A Guangdong resistant dextrin supplier may offer advantages for lead times to southern ports and certain downstream packaging ecosystems.

Export hubs that shape landed cost

Even when two factories quote the same EXW price, freight and handling differences can change the outcome.

- Shanghai MCC export logistics are often favored when buyers want frequent sailings and strong documentation support through a major port.

- Coastal hubs like Ningbo or other ports can be equally viable, but the right choice depends on sailing schedules, your forwarder network, and inland trucking distance.

Strategic Insight: When benchmarking a microcrystalline cellulose supplier China quote against another, do not compare prices unless the export hub assumption is the same (or explicitly modeled).

The total cost model buyers actually need

If you only compare unit price, you are not sourcing—you are guessing. A practical total cost model for MCC and resistant dextrin should treat quality and logistics as cost drivers, not background noise.

Step 1 Map the cost stack from EXW to your receiving dock

A baseline landed-cost model typically includes:

- EXW / FOB price (grade and spec dependent)

- Packaging format (e.g., standard 25 kg bags vs. reinforced liners, pallets, or custom packaging)

- Inland trucking from plant to port

- Export documentation and handling

- Ocean/air freight (mode depends on lead time and shelf-life strategy)

- Insurance

- Customs clearance and duties in destination market

- Domestic delivery to your warehouse or contract manufacturer

For teams that routinely buy microcrystalline cellulose bulk, packaging and moisture control can move the needle more than expected—especially when long transit or humid climates amplify caking risk.

Step 2 Add quality-driven costs that procurement often forgets

A true total cost model also needs the costs that appear only when something goes wrong:

- Third-party testing: identity, microbiology, heavy metals, and method-to-method verification when switching suppliers.

- Audit costs: remote document review, on-site visits, and follow-up CAPA verification.

- Trial batches and reformulation: especially relevant for resistant dextrin where sensory neutrality and solubility matter in finished products.

- Rejects and rework: disposal, return freight, or re-blending.

- Change control overhead: updating specs, labels, and internal approvals.

These costs are why a higher-quality food grade microcrystalline cellulose supplier (or higher-control fiber plant) may be cheaper over 12 months even if the unit price is higher.

Step 3 Use scenarios instead of “one number”

Below is a simple way to benchmark offers from a microcrystalline cellulose supplier China group and a resistant dextrin manufacturer China shortlist without pretending you can forecast every variable.

| Scenario | Unit price signal | Added testing & audit cost | Reject/rework risk | Best fit |

|---|---|---|---|---|

| A: Lowest price, minimal documentation | Low | High | Medium–High | Short-term spot buys, non-critical applications |

| B: Mid price, strong COA package | Medium | Medium–Low | Low–Medium | Most food/nutrition programs scaling volume |

| C: Premium price, tight change control | High | Low | Low | Regulated or high-consequence formulations |

Strategic Insight: If your business must buy resistant dextrin food fiber with consistent performance, Scenario B often wins on total cost. If you are qualifying MCC for excipient use, Scenario C is frequently the safer long-run target—especially when a pharmaceutical excipient microcrystalline cellulose specification is required.

Specs and COA items that move price and reduce surprises

Most quote variance traces back to one thing: the spec sheet. Tight specs raise price, but they also cut failure probability. The goal is not “tightest possible,” it is “tight where it matters.”

MCC spec items that change your real cost

When buyers compare a China microcrystalline cellulose manufacturer to another, MCC pricing often shifts based on:

- Grade alignment: food, industrial, and pharmacopeial grades are not interchangeable.

- Pharmacopeial compliance expectations: when a procurement team needs pharmacopeial alignment (commonly USP/EP/ChP expectations), the supplier’s documentation and testing discipline becomes part of the price.

- Physical performance parameters: particle size distribution, bulk density, flowability, and moisture-related measures can influence tableting, blending, and stability.

- Safety limits: microbiological limits and heavy metals expectations affect test frequency and process controls.

If your program requires a pharmaceutical excipient microcrystalline cellulose profile, treat COA completeness and traceability as part of the bid—because every gap turns into your cost later.

Resistant dextrin spec items that buyers should anchor on

Resistant dextrin is often marketed with broad claims. Procurement should pin the quote to measurable, consistent targets.

From supplier documentation used in commercial practice, common specification anchors include:

- Fiber content: ≥82% is a frequently used procurement benchmark for resistant dextrin used as nutritional dietary fiber.

- Protein content: ≤6.0% is commonly referenced for the same product family.

- Appearance: white to light yellow powder (important for applications where color carryover matters).

- Storage conditions: “store in a cool place” is typical wording, but buyers should still request a shelf-life statement and handling recommendations.

A buyer evaluating a resistant dextrin manufacturer China option should also ask how the plant controls consistency in enzymatic processing and drying—because those controls often explain why one supplier’s dextrin stays neutral in taste while another introduces off-notes.

A COA quick-checklist you can paste into RFQs

Use this checklist to standardize quote comparison when you buy microcrystalline cellulose bulk or buy resistant dextrin food fiber:

For MCC (RFQ/COA checks)

- Declared grade and intended use (food vs. excipient vs. industrial)

- Test methods stated (not just results)

- Moisture-related control items disclosed

- Microbiological limits disclosed

- Heavy metals limits disclosed

- Lot traceability and retention sample policy

For resistant dextrin (RFQ/COA checks)

- Fiber content target stated (e.g., ≥82%)

- Protein limit stated (e.g., ≤6.0%)

- Appearance and solubility notes

- Microbiological limits disclosed

- Change control process for enzymes and raw material lots

- Packaging and moisture protection statement

Strategic Insight: These checks make it easier to benchmark a microcrystalline cellulose supplier China quote against another without “spec drift” hiding inside the offer.

How to benchmark Chinese quotes without overpaying

Procurement teams often swing between two extremes: trusting a low quote too quickly, or over-specifying and overpaying. A better approach is to benchmark with structured evidence.

1) Normalize Incoterms and logistics assumptions

Before you compare any Shanghai MCC export logistics route versus another port option, force every quote into the same terms:

- Same Incoterm (FOB Shanghai, for example)

- Same packaging basis (bag type, pallets, container utilization)

- Same lead time assumptions (production + booking + sailing)

This is the fastest way to turn “apples vs. oranges” quotes into comparable numbers for your team.

2) Treat documentation as a priced component

A reliable food grade microcrystalline cellulose supplier or fiber plant is selling more than powder. They are selling risk reduction:

- predictable COA packages,

- clear lot traceability,

- and stable change control.

If a resistant dextrin manufacturer China candidate cannot provide a consistent COA format or avoids method disclosure, you should model the added verification costs explicitly rather than hoping they won’t appear.

3) Score suppliers using a two-lane matrix

Use two lanes—price lane and quality lane—and do not let one lane erase the other.

- Price lane: normalized landed price, payment terms, MOQ flexibility, responsiveness on delivery windows.

- Quality lane: COA completeness, audit readiness, lab capability, and evidence of process control.

This approach helps buyers avoid the common trap where a microcrystalline cellulose supplier China looks inexpensive until your QA team adds urgent testing and your plant adds rework.

A practical procurement playbook for MCC and resistant dextrin in China

To keep sourcing disciplined, apply a consistent three-step playbook across both ingredient families.

Step 1 Shortlist suppliers with “audit-ready signals”

A credible shortlist for a China microcrystalline cellulose manufacturer or a resistant dextrin manufacturer China candidate usually includes:

- Clear product positioning: the supplier can state which grades serve food vs. pharmaceutical excipient programs.

- Traceability narrative: raw material origin and incoming QA checks are described without evasiveness.

- Process control evidence: automation, controlled feeding-to-filling workflow, and documented QC checkpoints.

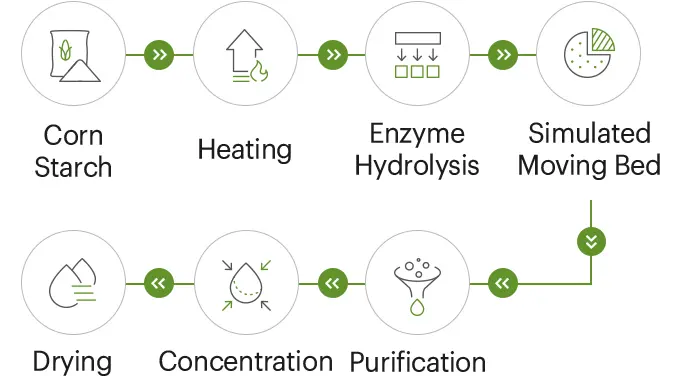

In supplier materials commonly used for resistant dextrin, examples of capabilities that may justify a moderate premium include non-GMO corn starch inputs, imported biological enzymes, and precision production lines built for stable output.

Step 2 Verify with documents first, then a pilot order

Verification does not have to be slow, but it has to be real.

- Start with a document pack: specs, COA templates, allergen statements where relevant, and change control description.

- Use third-party testing strategically: confirm identity and a few high-risk items before scaling.

- Run a pilot order: evaluate blend behavior, sensory neutrality (for dextrin), and manufacturing performance (for MCC applications).

If you routinely buy resistant dextrin food fiber for beverages or powders, a pilot should include solubility and taste checks across your real process conditions (heat, pH, shear). If you buy microcrystalline cellulose bulk for excipient use, a pilot should check processing consistency in your tableting or blending environment.

Step 3 Negotiate what prevents future cost spikes

Negotiation is not only a unit price discussion. For a microcrystalline cellulose supplier China relationship or a fiber contract, negotiation should lock the risk controls that protect your total cost.

Include:

- Incoterms and freight clarity (who books, who insures, who owns delays)

- COA format and timing (sent before shipment, not after arrival)

- Change control clause (raw material changes, enzyme changes, process changes)

- Dispute handling (how nonconforming material is managed)

- Technical support expectation (response times during trials and scale-up)

This is how procurement keeps a China microcrystalline cellulose manufacturer offer “cheap” in practice, not just in a spreadsheet.

Mini case showing how total cost drops after consolidation

The following scenario is fictionalized but reflects what many procurement teams observe when moving from multi-supplier spot buying to a more controlled approach.

Case example

A mid-sized nutrition brand had been sourcing MCC and soluble fiber from separate suppliers. On paper, the lowest-priced vendors were winning each quarter. In reality, QA costs kept climbing: repeated COA clarifications, extra third-party tests, and frequent pilot runs when lots behaved differently.

The team rebuilt their model using a consistent checklist and shifted toward a supplier portfolio that could support dietary fiber and excipient-grade materials under documented QC systems. The unit price increased modestly, but the business reduced testing frequency, cut rework events, and simplified audit scheduling. Over two purchasing cycles, total landed cost decreased because the “hidden” costs stopped leaking.

For buyers who want a real-world example of an integrated ingredient portfolio (dietary fibers such as resistant dextrin, plus pharmaceutical excipients), one manufacturer reference point in Shandong is available at https://www.sdshinehealth.com/. Use it as a benchmark for what “audit-ready” product pages and documentation structure can look like—then apply the same standards across your full shortlist.

What a recommended supplier profile looks like in 2026

When procurement teams search “Recommended Chinese Microcrystalline Cellulose Manufacturer” or “Recommended Chinese Resistant Dextrin Manufacturer,” they are rarely looking for hype. They are looking for a supplier profile that reduces operational friction.

A “recommended” profile for a microcrystalline cellulose supplier China market typically includes:

- Clear grade boundaries (food vs. excipient vs. industrial)

- Stable documentation and traceability

- Defined QC testing routines and a consistent COA template

- Export experience through major hubs (including Shanghai MCC export logistics where relevant)

A “recommended” profile for a resistant dextrin manufacturer China market typically includes:

- Transparent raw material story (commonly non-GMO corn starch for many programs)

- Process control discipline for enzymatic treatment and drying

- A stable fiber target (often ≥82% fiber) and disclosed protein limits (often ≤6.0% for the same family)

- Packaging designed to preserve flow and prevent moisture pickup

These are also the traits that help a food grade microcrystalline cellulose supplier and a fiber plant earn longer-term contracts—because the buyer is paying for predictability.

Closing actions buyers can take this quarter

A better sourcing outcome rarely requires a bigger team. It requires a cleaner method.

- Stop comparing unit prices without normalized logistics assumptions. Your cost model should state the port, terms, and packaging basis—especially when comparing Shanghai MCC export logistics routes.

- Tie every quote to a COA checklist. If two suppliers cannot be compared on the same document standard, they should not be compared on price.

- Model quality as a cost component. For programs that buy resistant dextrin food fiber at scale, include testing and sensory trial costs. For programs that buy microcrystalline cellulose bulk for regulated or performance-critical use, include audit and change-control costs.

When procurement applies this math consistently, a microcrystalline cellulose supplier China shortlist becomes easier to manage, a resistant dextrin manufacturer China comparison becomes less subjective, and “recommended” suppliers rise naturally because they reduce total landed cost—not because they promised the lowest number.