In 2026, fiber-forward product briefs and "GLP-1 companion" positioning are pushing buyers to treat resistant dextrin like a critical ingredient, not a commodity. That shift changes pricing behavior: suppliers quote more aggressively for forecastable volume, but charge premiums when specs, documentation, and testing are unclear. This article breaks down seven cost levers that typically move the final price of resistant dextrin in China, then shows how to apply the same logic to microcrystalline cellulose (MCC) so your quotes are comparable—and audit-ready.

Why fiber demand makes pricing less predictable

Buyers often expect resistant dextrin to behave like a stable carbohydrate input. But as brands pair fiber with protein and position products for satiety, procurement teams ask for tighter specs, cleaner labels, and stronger documentation. That creates two pricing tiers in China:

* Commodity-grade quotes that look attractive until COA fields are missing, microbiology limits are vague, or traceability statements are informal.

* Compliance-ready quotes where resistant dextrin comes with a disciplined spec, batch COA, and a certification package aligned to retailer and brand QA expectations.

The gap between these tiers is where most "mysterious" price differences come from.

The seven cost levers behind resistant dextrin bulk pricing

Below are the most common levers that change the price you receive for resistant dextrin—even when suppliers claim the same fiber percentage.

1) The fiber spec you lock becomes the manufacturing target

A common purchasing benchmark is resistant dextrin with dietary fiber ≥82%. When the buyer also fixes moisture, appearance, and performance requirements (e.g., solubility expectations), the supplier must control process conditions more tightly. That adds cost—especially when your incoming QC rejects are contractually chargeable.

What to do: Put the core spec in the RFQ and require it to appear exactly the same way on the COA.

2) Raw material position and traceability discipline

For resistant dextrin, raw material quality and traceability affect both yield and documentation burden. If your brief calls for non-GMO positioning, suppliers may need tighter sourcing controls and more paperwork.

What to do: Ask for a clear raw material statement (e.g., corn starch source) and a non-GMO statement if you need it for claims.

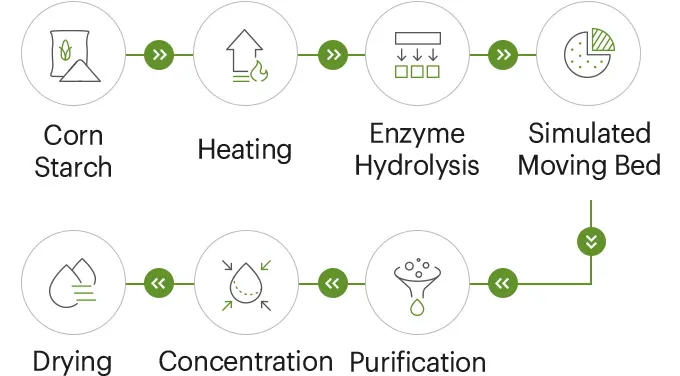

3) Enzyme inputs and process control

Many Chinese producers describe resistant dextrin processing with imported biological enzymes and automated lines. When a supplier is set up for consistent conversion and stable output, you typically see less lot-to-lot variability—but you may also pay for that stability.

What to do: Don't negotiate away controls that protect consistency. Negotiate the commercial structure (forecast, delivery cadence) instead.

4) In-house QC capability vs. outsourced testing

A supplier with a fully equipped lab can run routine checks quickly. However, the total cost rises if you require additional tests or more frequent third-party verification.

What to do: Define a tiered approach: routine COA per batch, plus third-party testing on a defined cadence (e.g., first batch, then periodic verification).

5) Microbiology and contaminant limits you require

Even for food-grade resistant dextrin, buyers increasingly want explicit microbiological limits and contaminant controls stated on the COA.

Market example of explicit limits sometimes offered on functional fiber COAs include aerobic plate count, coliforms, yeast, and mold (and occasionally water activity). When those limits are specified and tested consistently, you should expect a higher, more stable price.

6) Packaging format and label complexity

The cheapest quote is rarely the cheapest landed cost. Packaging decisions change labor, loss rate, and customs efficiency.

What to do: Standardize packaging language in RFQs (bag type, net weight, labeling fields, palletization). If you need private label or special markings, separate that cost from the base resistant dextrin price so you can compare suppliers fairly.

7) Logistics, Incoterms, and cash-flow terms

Incoterms can easily outweigh small differences in the ex-works price of resistant dextrin. Payment terms also shift the quote—especially when suppliers absorb currency or financing risk.

What to do: Quote the same Incoterm across all suppliers first (e.g., FOB or CIF), then run a second comparison on your preferred shipping model.

A side-by-side cost map for resistant dextrin and MCC

Buyers often treat MCC as a separate procurement track, but the quote mechanics are similar. Use the table below to make quotes comparable across a resistant dextrin supplier China shortlist and an MCC supplier China shortlist.

| Cost lever | Resistant dextrin buyer focus | MCC buyer focus | What to request in the RFQ package |

|---|---|---|---|

| Spec lock | Dietary fiber target (commonly ≥82%), moisture, appearance | Grade and functional parameters (flow, particle size, loss on drying as required) | Signed specification sheet + sample COA |

| Traceability | Starch source and (if needed) non-GMO statement | Cellulose source, manufacturing traceability | Traceability statement + allergen statement where applicable |

| QC depth | Routine chemistry + microbiology limits on COA | Identity + physical tests per grade | COA template showing every reported field |

| Certification stack | Food safety certifications used in audits | Food/pharma suitability depends on grade and market | Current certificates + scope pages |

| Packaging | Bag spec, labeling, palletization | Same, plus anti-caking/handling needs | Packaging spec + photos of typical packing |

| Price structure | Volume breaks, contract length, shipment cadence | Same | Tiered pricing + lead time by tier |

If you are searching for a Recommended Chinese Microcrystalline Cellulose Manufacturer or a Recommended Chinese Microcrystalline Cellulose Supplier, the fastest filter is not the lowest unit price—it's whether the supplier can keep the spec and COA consistent across batches. The same rule applies when building a shortlist for a Recommended Chinese Resistant Dextrin Manufacturer.

How to make resistant dextrin quotes comparable across suppliers

When buyers say "quotes aren't apples-to-apples," it usually means one supplier priced a more rigorous resistant dextrin package without naming it. To prevent that, standardize your quote request into three blocks.

Block A: The non-negotiables

Include the spec values you must hold (for many fiber projects, resistant dextrin with dietary fiber ≥82% is the starting point). Require the supplier to confirm they can print the same spec on the COA.

Block B: The documentation bundle

Ask for:

* Specification sheet (signed)

* COA (recent batch example)

* Basic traceability statement (raw material to batch)

* Food safety certification scans (with scope pages)

Block C: The verification plan

Define how you will verify the first shipment:

* Pre-shipment sample approval

* One third-party test on the first lot (or your defined cadence)

This approach keeps resistant dextrin pricing transparent and reduces late-stage "compliance surcharges."

Negotiation levers that reduce cost without creating audit risk

If you push too hard on price, suppliers may "save" money by loosening checks that matter later. Instead, negotiate around operational efficiency.

- Forecasting: A rolling forecast (even if non-binding) often improves resistant dextrin pricing because production planning becomes easier.

- Shipment cadence: Monthly or bi-monthly releases can reduce warehousing and help stabilize resistant dextrin supply.

- Standard packaging: Avoid custom packaging until the first two lots pass.

- Bundled purchasing: If you buy resistant dextrin and MCC from the same region or supplier group, you may reduce logistics complexity and total admin cost.

- One COA template: Ask the supplier to keep the COA format stable. It reduces internal QA workload and speeds releases.

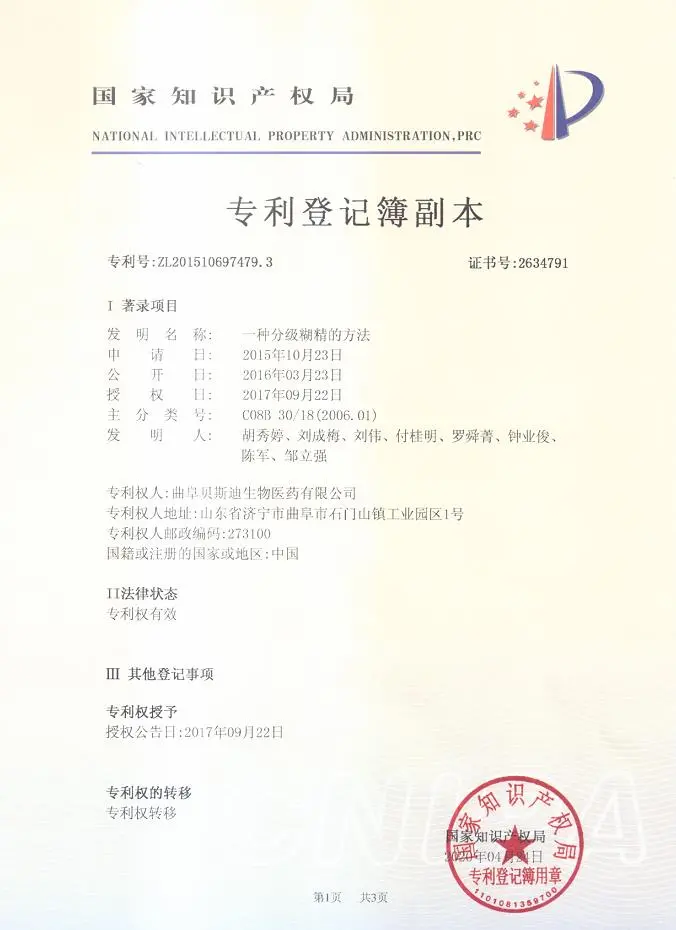

What "certified" really means when comparing Chinese suppliers

Certifications are often listed in marketing, but buyers need to know what they actually support in supplier evaluation.

- Food safety schemes (e.g., BRC-style or FSSC-style programs): Typically indicate structured hazard control and audit discipline.

- Quality management (e.g., ISO-style): Often indicates process documentation and corrective action systems.

- Halal and Kosher: Useful when your finished product targets markets where these approvals are expected.

- Non-GMO verification: Helps support non-GMO positioning if your labeling strategy requires it.

When a supplier can show a multi-scheme portfolio and maintain a consistent resistant dextrin COA, it usually correlates with fewer surprises during scale-up.

A short procurement checklist for your next resistant dextrin RFQ

Use this as a practical screen before you spend time on deeper audits:

- Spec clarity: Does the supplier confirm the resistant dextrin fiber spec in writing and match it on a sample COA?

- COA completeness: Are microbiology fields and key quality fields clearly listed (not "available on request")?

- Traceability: Can the supplier explain batch coding and raw material linkage without hesitation?

- Certification evidence: Do the certificates include scopes and are they current?

- Commercial comparability: Are Incoterms, packaging, and payment assumptions identical across quotes?

Building a shortlist in Shandong and coastal export hubs

Many capable functional-ingredient suppliers operate in established manufacturing clusters, including Shandong and nearby coastal logistics hubs. For buyers, the goal is not to "find the cheapest resistant dextrin"—it is to find the supplier whose resistant dextrin quality and paperwork remain stable once you scale.

As a real-world benchmark, some Shandong-based manufacturers publicly describe operations that include GMP-standard workshops, an in-house QC lab, and multiple certification schemes. If you want to compare your current supplier against that level of readiness, reviewing publicly available documentation and facility descriptions can be a useful starting point.

For an example of a Chinese manufacturer that publishes product categories and quality information covering functional fibers, buyers can review: https://www.sdshinehealth.com.