In 2026, the landscape of "accessible nutrition" and the fiber-forward product pipeline is fundamentally reshaping procurement priorities. Buyers who historically treated fiber as a secondary optional add-on are now constructing core SKUs around it. Simultaneously, pharmaceutical and supplement teams continue to rely on microcrystalline cellulose (MCC) as the indispensable workhorse excipient of solid dosage forms. This dual shift creates a simple but expensive trap: comparing a microcrystalline cellulose supplier China quote and a resistant dextrin manufacturer China quote solely on the FOB price. A lower unit price often disguises a significantly higher total cost of ownership (TCO) once yield loss, rework risk, testing bottlenecks, release delays, and inventory carrying costs are factored in. This analysis provides a practical, two-track cost framework—one for MCC (pharma excipient), one for resistant dextrin (soluble fiber)—enabling buyers to build quote comparisons that accurately predict landed, usable costs.

Why 2026 Buyers Are Rethinking the Price-Per-Ton Mindset

Two significant market forces are converging to disrupt traditional procurement models. First, fiber is aggressively moving into mainstream formats—bars, ready-to-drink shakes, coffees, and functional gummies. In these applications, fiber specifications impact not only the validity of label claims but also critical sensory attributes like taste, solubility, and shelf stability. Second, excipient risk visibility is increasing. Compliance teams are tightening supplier oversight as batch-to-batch variability becomes a production schedule issue, not merely a Quality Control (QC) hurdle.

For procurement professionals, the implication is distinct: the decision metric is no longer "cheapest per ton," but "lowest cost per compliant batch." This distinction is particularly acute when purchasing from a China microcrystalline cellulose manufacturer or a resistant dextrin manufacturer China, where production capabilities and technical consistency can vary widely between facilities.

Track 1: MCC Cost Drivers Buyers Actually Pay For

When sourcing from a microcrystalline cellulose supplier China or any pharmaceutical grade MCC manufacturer, the line item visible on a commercial quote is merely the entry point. The actual costs incurred downstream usually trace back to specific technical and operational variables that affect manufacturing efficiency.

The MCC Specification Points That Hit Your Budget

Buyers typically compare bulk MCC powder PH-101 PH-102 and other common grades by referencing supplier Certificates of Analysis (COAs) against internal performance data. However, even when technical data sheets appear identical, the commercial impact on the production floor can differ substantially.

Key MCC technical checks to tie directly to cost include:

- Particle Size & Grade Selection (e.g., PH-101 vs. PH-102): This impacts flowability, blending uniformity, and compression behavior. Inconsistent particle size distribution can lead to tablet weight variation, triggering machine stops and high rejection rates.

- Moisture Content: This critical parameter affects flowability, compaction profiles, and the risk of caking during storage. High moisture variability often requires frequent recalibration of tablet presses.

- Bulk Density & Compressibility: directly affects tablet weight consistency and packaging efficiency. Variations here can lead to packaging line errors where bottles are under- or over-filled by weight.

- Microbial Limits & Control Strategy: This affects release risk, especially for pharmaceutical and stringent nutraceutical applications. High bioburden risks total batch loss.

These are the "quiet" drivers behind MCC particle size moisture microbial limits—and they influence how often a batch runs cleanly versus needing adjustment, extra screening, or Root Cause Analysis (RCA) investigations.

Why "Cost of MCC Per Ton China" Is a Moving Target

The cost of MCC per ton China can fluctuate with energy tariffs, capacity utilization, and logistics conditions. Yet, the larger financial swing for many buyers comes from internal usage costs:

- Excess Overage: Production teams adding extra material to buffer against weight variability.

- Line Stoppages: Downtime caused by poor flow or segregation in the hopper.

- Enhanced QC Testing: The labor and lab costs required to confirm borderline lots.

- Safety Stock Inflation: Holding more inventory to compensate for inconsistent lead times.

If two supplier offers differ by a small margin on paper, the cheaper quote may actually be more expensive per finished dose once these operational inefficiencies are calculated.

Track 2: Resistant Dextrin Cost Drivers Buyers Overlook

Resistant dextrin is often procured to increase fiber content without compromising the taste and viscosity of the final product. In the extensive China supply base, many procurement teams focus heavily on origin and basic certifications, often missing how a few key parameters translate directly into formula economics.

The Resistant Dextrin Spec That Protects Label Claims

A central commercial specification is fiber content. In high-quality manufacturing contexts, resistant dextrin is typically defined by:

- Fiber Content: ≥82% (on a dry basis)

- Protein Content: ≤6.0%

- Appearance: White to light yellow powder

- Raw Material Source: NON-GMO corn starch

For brands building "fiber-forward" positioning, the ≥82% fiber requirement is not academic. If a supplier's fiber content drifts lower, R&D must increase the inclusion rate to hit the target label claim. This raises the cost per serving and can inadvertently alter the sensory performance of the product, such as increasing viscosity or affecting mouthfeel.

What Buyers Should Connect to TCO

For a food grade resistant dextrin manufacturer or resistant dextrin manufacturer China, buyers should link specification and plant capability to a handful of specific cost outcomes:

- Inclusion Rate Efficiency: Driven by consistent fiber content.

- Rework Risk: Driven by solubility speed, taste neutrality, and batch-to-batch consistency.

- Stability Under Processing: Driven by strict processing controls (pH and heat stability).

- Supply Chain Velocity: Driven by QC readiness, documentation accuracy, and export experience.

China-Specific Cost Levers That Affect Price Stability and Risk

China’s ingredient supply landscape is not a uniform cost curve. For both MCC and resistant dextrin, procurement outcomes often improve significantly when buyers understand what drives stability behind the factory gates.

What to Watch in a China Microcrystalline Cellulose Manufacturer

When assessing a China microcrystalline cellulose manufacturer or pharmaceutical grade MCC manufacturer, look beyond the spec sheet and interrogate the systems that reduce variability:

- Structured QC Workflows: Evidence of documented release protocols that prevent out-of-spec material from leaving the warehouse.

- In-Process Monitoring: Consistency of raw material control and real-time monitoring during hydrolysis and spray drying.

- Export Readiness: Documentation discipline matters as much as lab capability; missing paperwork causes port delays.

In practice, a microcrystalline cellulose supplier China that can demonstrate stable historical lots and disciplined change control procedures often produces a lower long-run TCO than one that wins contracts solely on spot price.

What to Watch in a Resistant Dextrin Manufacturer China

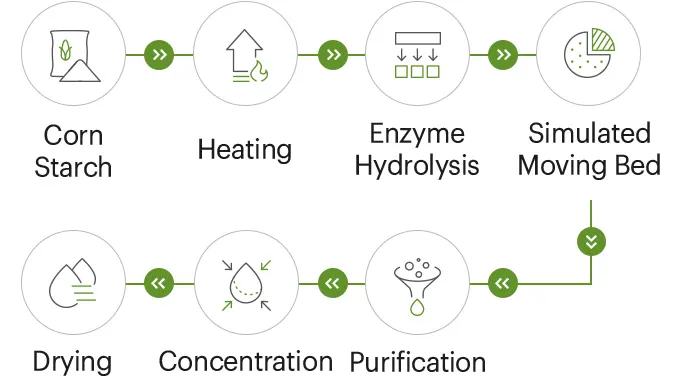

Sophisticated production setups for resistant dextrin often involve specific high-tech investments. Look for manufacturers utilizing:

- Fully Automated Central Control Operations: From raw material feeding to product filling, automation reduces human error.

- Imported Biological Enzymes: High-quality enzymes ensure consistent hydrolysis and fiber generation.

- German-Origin Precision Production Lines: Equipment quality directly correlates to particle uniformity.

- Fully Equipped QC Laboratories: The ability to test every batch internally before shipment.

For buyers, these signals matter because automation and tight process control tend to reduce batch variance. Reduced variance means less retesting, lower complaint risk, and reduced need for safety stock. This is a practical advantage when evaluating any resistant dextrin manufacturer China.

A Buyer’s Worksheet to Compare Quotes Using TCO

To move from a simple "FOB comparison" to a sophisticated "usable cost comparison," procurement teams should capture the line items below for both MCC and resistant dextrin.

Quote Comparison Worksheet

| Cost Element | What to Collect | Why It Changes TCO |

|---|---|---|

| Unit Price | EXW/FOB price per ton | Only the starting point of the negotiation. |

| Expected Overage | % added for process stability | Drives the real material usage cost per batch. |

| Quality Testing | COA + your incoming testing plan | Adds time delays and external lab costs. |

| Audit/Qualification | Remote/on-site audit, sampling | Upfront cost that dramatically reduces downstream risk. |

| Freight + Insurance | Route, carrier, Incoterms | Determines landed cost volatility and risk transfer. |

| Duties/Clearance | HS code, brokerage fees | Can exceed small unit-price gaps in international trade. |

| Lead Time + OTD | Supplier history and buffer needs | Determines the capital tied up in safety stock. |

| Packaging Performance | Caking risk, moisture protection | Impacts yield losses and potential material returns. |

Translating Specs Into Money: Two Scenarios

These examples illustrate how small technical differences become real financial costs on the balance sheet.

1. MCC Example (Flow and Moisture-Driven Losses)

* Quote A from a microcrystalline cellulose supplier China is slightly cheaper per kg.

* Quote B is slightly higher but demonstrates tighter control in moisture content and smoother flow characteristics in trial use.

If Quote A forces production to add even 0.5–1.0% more overage to protect tablet weight and reduce line stops, the "cheaper" option becomes more expensive per million tablets—especially when operator labor and machine downtime are included in the calculation.

2. Resistant Dextrin Example (Fiber Content and Inclusion Rate)

If a batch trends closer to the minimum ≥82% fiber and you need to increase inclusion to keep a label claim intact, your cost per serving rises. Furthermore, you may need to re-validate taste and viscosity profiles. A food grade resistant dextrin manufacturer that holds fiber content consistently high can eliminate this hidden variable cost.

Practical Sourcing Playbook for Dual-Ingredient Buying

Many procurement teams now manage MCC and soluble fiber categories in parallel. While the suppliers do not necessarily need to be the same, the evaluation methodology should be consistent.

Pre-RFQ Checklist

For MCC (Pharma Excipient):

* Define target compendial expectations (USP/EP/BP) and internal performance needs.

* Specify the grade strategy you are comparing (common examples include bulk MCC powder PH-101 PH-102).

* Require disclosure of MCC particle size moisture microbial limits on the COA.

For Resistant Dextrin (Soluble Fiber):

* Confirm raw material source (e.g., NON-GMO corn starch).

* Confirm Fiber Content ≥82% and protein limit expectations.

* Align storage and packaging requirements to your specific climate and shipping duration.

Audit Focus Points That Prevent "Cheap Quote" Surprises

During audits or technical reviews, prioritize the indicators that predict stability:

- Traceability: Full visibility from raw material intake to finished packaging.

- Automation: Evidence of automated control systems (DCS/PLC) and in-process checks.

- Documentation Quality: Batch records, COA consistency, and deviation handling procedures.

Some modern Chinese ingredient suppliers publicly share process and product documentation cues through their digital presence. For example, the production approach, parameter ranges, and facility details described on sdshinehealth.com illustrate what "audit-friendly by design" looks like for resistant dextrin and functional fibers.

Closing Guidance for Buyers Building 2026 Contracts

In a fiber-forward market, procurement teams gain leverage by upgrading their comparison method rather than simply renegotiating the unit price. Whether the target is a pharmaceutical grade MCC manufacturer or a resistant dextrin manufacturer China, the winners are usually the buyers who tie specifications to measurable manufacturing outcomes, track quote differences through a rigorous TCO worksheet, and qualify suppliers for consistency rather than just minimum compliance. That strategic shift turns sourcing from a price contest into a predictable cost advantage—exactly what 2026 product roadmaps demand.

If you are looking for a supplier that meets these rigorous standards for resistant dextrin and soluble fibers, consider exploring the capabilities at Shine Health.