Sourcing microcrystalline cellulose (MCC) and resistant dextrin from China often appears straightforward on paper: obtain three quotes, select the lowest FOB, and book the freight. However, seasoned procurement professionals know that most budget overruns occur after the purchase order is issued. These hidden costs manifest when a "cheap" lot triggers additional testing, reveals documentation gaps, or requires reworking because the specification was interpreted differently. For procurement teams, the ultimate goal is not merely to chase the lowest quote, but to stabilize the MCC price per kg and resistant dextrin bulk price through a repeatable, audit-ready cost model.

This sourcing playbook covers essential strategies for buyers:

- How to distinguish between the "cheapest FOB" and the true landed cost for pharmaceutical grade microcrystalline cellulose and dietary fibers.

- A functional template to benchmark MCC price per kg and resistant dextrin bulk price accurately.

- Understanding China's regional dynamics (Shandong, Guangdong, Jiangsu) and how they influence lead time, consistency, and cost.

- A practical dual-sourcing approach aligned with MCC USP EP compliance and rigorous fiber specifications.

Why FOB-Only Buying Breaks Budgets

A quote from a microcrystalline cellulose supplier China can look attractive when it bundles little more than the raw goods and standard export packaging. Yet, procurement success is measured by what lands in QA-released inventory—ready for production, with documentation that passes both internal and customer audits.

For MCC, particularly pharmaceutical grade microcrystalline cellulose, the "missing costs" frequently emerge as additional qualification testing (identity, loss on drying, microbial limits), expensive supplier audits, change-control administration, and schedule slippage if the initial shipment is quarantined. Similarly, for a resistant dextrin supplier China, the pain points usually involve specification drift—such as fiber content expectations versus actual test methods—and application performance issues that necessitate costly reformulation trials.

A stable MCC price per kg and resistant dextrin bulk price are invariably the outcomes of process discipline rather than negotiation alone.

What Actually Drives MCC Price per kg and Resistant Dextrin Bulk Price

Buyers searching for current market rates often encounter wide price ranges. This spread is expected because MCC and resistant dextrin are not monolithic commodities; they represent families of grades, specifications, and compliance levels.

The Core Cost Drivers to Price Against

- Grade and Intended Use: A functional filler for general food applications is priced distinctly from pharmaceutical grade microcrystalline cellulose engineered for strict excipient requirements.

- Compliance Scope: While standards like BP/USP/FCC/JP appear on many listings, the real cost driver is a supplier's ability to support routine documentation and change control associated with MCC USP EP compliance.

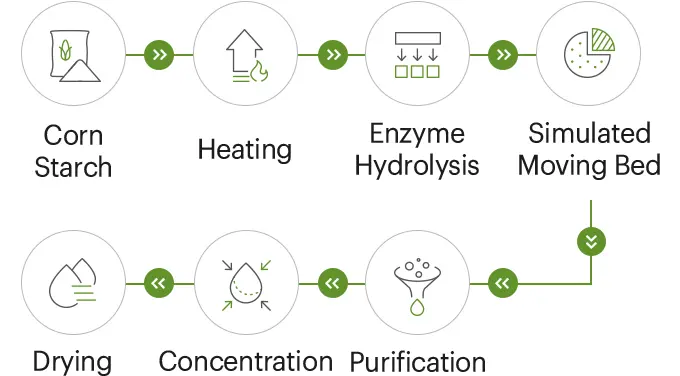

- Raw Material Discipline: Suppliers highlighting NON-GMO corn starch sourcing often position themselves for consistent fiber production and superior traceability.

- Process and Control: The use of imported enzymes, automated production lines, and in-house QC labs typically reduces variability. While this may raise the FOB slightly, it frequently lowers the total cost of ownership by preventing batch rejections.

For resistant dextrin, buyers comparing the resistant dextrin bulk price must treat fiber content (≥82%) and the supplier’s test method discipline as non-negotiable. Without this alignment, "cheap" fiber can quickly become an expensive liability.

China Regional Sourcing Patterns That Change Landed Cost

When procurement teams refer to "China," they are often referencing diverse supply realities. A microcrystalline cellulose supplier China based near one export hub may deliver faster and more predictably than another, even if their FOB prices are identical.

Shandong: Scale and Predictability

Shandong is frequently associated with high-volume functional ingredients and established exporters. For buyers, the practical benefit extends beyond scale to the ability to accurately plan landed costs due to mature routes and documentation workflows. Many Shandong producers also position themselves around NON-GMO starch inputs, imported enzymes, and automated control concepts, which tends to stabilize the MCC price per kg and reduce surprises in resistant dextrin bulk price comparisons.

Guangdong: Speed and Customization

Guangdong sourcing can be attractive for programs requiring heavy changes: fast packaging revisions, private-label workflows, or short lead times. The tradeoff is that "speed" can sometimes increase inland logistics or packaging costs, reinforcing why FOB benchmarking should always be paired with a landed-cost worksheet.

Jiangsu: Process Focus

Jiangsu is often perceived as process- and manufacturing-intensive. For buyers prioritizing compliance systems—such as document control, traceability, and audit readiness—Jiangsu-based options can be robust. However, qualification still demands proof rather than assumptions.

Across all three regions, a "Recommended Chinese Microcrystalline Cellulose Supplier" profile usually includes GMP-style workshops, a fully equipped QC lab, and traceability discipline. A "Recommended Chinese Resistant Dextrin Manufacturer" profile often adds NON-GMO starch sourcing and process automation to that list.

A Practical TCO Template Buyers Can Use Immediately

The following table provides a procurement-friendly structure to stabilize cost analysis, avoiding "market price claims" to focus on where cost is created.

Landed Cost Checklist Table (MCC and Resistant Dextrin)

| Cost Line Item | Low-spec MCC (Example) | Fully Compliant MCC (Example) | Resistant Dextrin (Example) |

|---|---|---|---|

| Supplier Quote Basis | FOB | FOB / FCA | FOB |

| Product Spec Risk | Higher | Lower | Medium (depends on fiber test method) |

| Documentation Workload | Low | High (CoA + controlled docs) | Medium |

| Incoming QC Tests | Standard ID/basic | Expanded (method alignment) | Fiber content + micro + application checks |

| Third-party Inspection | Optional | Common | Optional-to-common |

| Supplier Audit Cost | Often skipped | Often required | Common for key accounts |

| Lead-time Buffer | Larger | Smaller | Medium |

| Nonconformance Risk | Higher | Lower | Medium |

How to Apply This:

- Start with the FOB quote from each microcrystalline cellulose supplier China and each resistant dextrin supplier China.

- Add "program costs" your organization actually incurs: audits, third-party testing, and inventory buffers.

- Convert everything into a comparable "landed and released" cost per kg to benchmark MCC price per kg and resistant dextrin bulk price effectively.

Specification Traps That Inflate Cost

A significant cost trap occurs when a specification is "technically acceptable" but misaligned with the specific application or QA release process. For procurement, these traps distort MCC price per kg and resistant dextrin bulk price comparisons.

For MCC (Pharmaceutical Programs)

- Unclear Compliance Wording: "USP/BP/JP" listed on a spec sheet is not equivalent to routine support for MCC USP EP compliance expectations.

- Grade Confusion: Buyers may qualify one MCC type and receive another. Common grades include PH-101, PH-102, PH-103, PH-105, PH-112, PH-113, PH-200, PH-301, and PH-302.

- Packaging Mismatches: Bulk packing might suffice for trial lots but fail downstream handling requirements.

For Resistant Dextrin and Soluble Fibers

- Fiber Content Expectations: Many buyer briefs call for fiber content ≥82%; misalignment here can trigger rejection or labeling issues.

- Method Alignment: The supplier’s testing approach must align with buyer expectations to ensure "pass" results translate accurately.

- Performance Assumptions: Resistant dextrin is often selected for neutral taste, solubility, and processing stability. If these characteristics are not verified in a trial, scale-up costs rise.

When the category involves weight-management or low-carb products, resistant dextrin is frequently positioned as a low-impact carbohydrate fiber. Buyers can review commercial specifications, such as low calorie dietary fiber, to align internal terminology and purchasing language.

Supplier Audit Checklist for Buyer Teams

A reliable manufacturer is defined by verifiable systems, not marketing language. The checklist below is designed to be included in an RFQ and used during supplier qualification.

MCC Supplier Audit Checklist

- Traceability: Do batch records link raw material → production → packaging → shipment?

- Quality System: Is there a controlled CoA format, retention samples, and deviation handling?

- Change Control: Are there notification rules for process, packaging, or method changes?

- Lab Capability: Does the supplier have an in-house QC lab with routine release testing?

Resistant Dextrin Supplier Audit Checklist

- Raw Material Discipline: Is NON-GMO corn starch sourcing available when required?

- Process Control: Is there evidence of enzymatic process control and automation discipline?

- Core Spec Control: Are fiber content (commonly ≥82%) and test methods clearly defined?

- Application Support: Can the supplier support beverages, tablets, gummies, or other formats?

For buyers writing internal standards, referencing a category page like resistant dextrin can help keep naming conventions consistent across procurement, R&D, and QA teams.

A Dual-Sourcing Plan That Protects Cost and Compliance

A dual-sourcing strategy works best when designed around total cost and qualification effort—not merely around having a "backup."

Step-by-Step Dual-Sourcing Roadmap:

- Define Priorities: Distinguish between "must-haves" (e.g., specific documentation for MCC) and "nice-to-haves."

- Split Suppliers by Role: One supplier can serve as a "compliance anchor," while another offers "capacity and flexibility."

- Keep Specs Consistent: Stable specifications keep the MCC price per kg and resistant dextrin bulk price comparable over time.

- Use Trial Lots: A 2–3 lot mini-program is often more cost-effective than an annual contract that fails at scale.

If a buyer can qualify both MCC excipients and soluble fibers with one export-ready partner, the savings often materialize in fewer audits, fewer method transfers, and simplified vendor onboarding.

Practical Next Moves to Stabilize Your Next China RFQ

Procurement teams aiming to improve MCC price per kg and resistant dextrin bulk price can implement these steps in their next sourcing cycle:

- Rebuild RFQs Around "Landed and Released" Cost: Require suppliers to quote Incoterms clearly and budget for the testing and audit work the program actually needs.

- Insist on Spec-Method Alignment Early: For resistant dextrin supplier China comparisons, align fiber content expectations and test methods before price negotiation.

- Shortlist by Capability Signals: A microcrystalline cellulose supplier China that supports stable documentation and quality control often delivers a better long-run value.

- Use Public Product Pages as References: Procurement can use neutral, publicly available catalogs such as microcrystalline cellulose excipient and nutritional dietary fiber powder to standardize naming and spec language across teams.

For teams that want to compare product families and quality-system signals across suppliers, reviewing manufacturing catalogs and capability notes at www.sdshinehealth.com offers a robust starting point to translate requirements into actionable RFQs.