A buyer-focused playbook to control total landed cost when sourcing MCC and resistant dextrin from China, using clear specs, audits, and quote normalization.

China remains a preferred sourcing hub for two very different—but often co-purchased—ingredients: microcrystalline cellulose (MCC) and resistant dextrin. Yet many procurement teams still treat a supplier quote as a budget, only to discover later that specification gaps, documentation delays, or hidden logistics and testing costs erase the apparent savings. This guide shows how buyers convert a microcrystalline cellulose supplier China offer and a resistant dextrin manufacturer China quote into predictable total landed cost by tightening specifications, standardizing RFQs, and using a repeatable supplier checklist.

Why FOB Prices Fail for MCC and Resistant Dextrin

A competitive headline price from a microcrystalline cellulose supplier China or a resistant dextrin manufacturer China is only a starting point. The true cost is usually driven by three factors that show up after the quote:

- Specification drift: the shipped grade does not match the functional need (tablet compression, beverage clarity, low viscosity, etc.), triggering reformulation or re-testing.

- Compliance friction: missing or incomplete documentation slows qualification—particularly when the purchase requires pharma grade microcrystalline cellulose GMP evidence.

- Landed-cost creep: port choices, packaging formats, moisture risk, and destination testing add cost that never appears on the FOB line.

In practice, procurement stability comes from treating every quote as a structured data set—spec, documentation, and logistics—rather than a single number.

How Costs Are Built Up for MCC Versus Resistant Dextrin

MCC and resistant dextrin behave differently in manufacturing, in applications, and in how their costs accumulate. Buyers who separate the cost logic of each ingredient compare suppliers more accurately.

MCC cost logic buyers should isolate

For MCC, the quote from a Chinese microcrystalline cellulose supplier is often shaped by:

- Grade and compliance tier: food-grade versus pharma-grade; tighter limits and pharmacopeia alignment typically increase quality-system burden.

- Physical performance requirements: particle-size distribution, bulk density, flowability, and compressibility can force extra milling and tighter in-process control.

- Quality system overhead: when the purchase requires pharma grade microcrystalline cellulose GMP, the real cost is as much about documentation and batch traceability as the powder itself.

Resistant dextrin cost logic buyers should isolate

For resistant dextrin, a dietary fiber resistant dextrin supplier is commonly priced on:

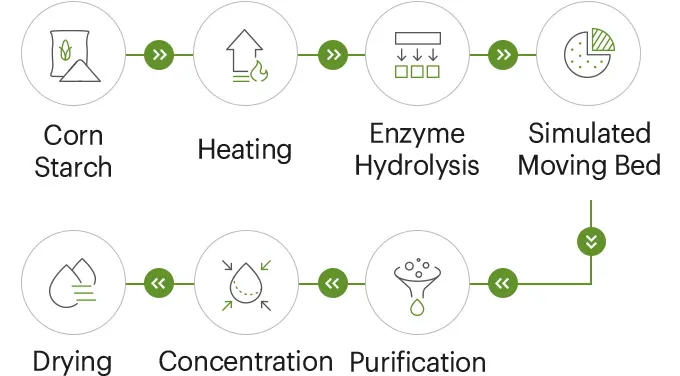

- Starch origin and supply stability: many commercial grades use corn starch; some lines also offer tapioca-based options.

- Process intensity: enzyme and heat-treatment choices influence fiber content, solubility, and taste neutrality.

- Fiber tier: procurement must distinguish between “high fiber” marketing language and a stated fiber-content requirement (for example, ≥82%).

A practical reference point is the widely purchased “nutritional dietary fiber” grade of resistant dextrin at ≥82% fiber, which is offered by manufacturers such as Shine Health (see its nutritional dietary fiber page for an example spec format buyers can mirror in RFQs).

A simple cost-driver map procurement teams can reuse

| Cost driver | MCC impact | Resistant dextrin impact | What to ask in the RFQ |

|---|---|---|---|

| Grade tier | High (food vs pharma) | Medium (food-focused, but tiered) | “State exact grade and intended application” |

| Tight micro limits | High for regulated uses | Medium to high for beverages/nutrition | “List microbial limits and test methods” |

| Process tech | Milling/drying controls | Enzymes + heat-treatment controls | “Describe process controls and QC checkpoints” |

| Documentation | Critical for pharma | Critical for export consistency | “Provide COA panel + traceability statement” |

| Packaging and moisture control | Medium | High (flow, caking risk) | “Confirm moisture-proof packaging options” |

Spec Decisions That Change Your Budget Fast

Specification is the most controllable lever in total cost—and the most common source of hidden cost.

MCC: avoid ambiguous grade language

When comparing a microcrystalline cellulose supplier China quote, avoid open-ended wording such as “pharma available” or “USP optional.” A buyer-ready RFQ should specify:

- Intended use (tablet direct compression, granulation, food bulking, etc.)

- Target physical properties (particle size range, bulk density, flow)

- Regulatory positioning (if relevant): alignment expectations and evidence for pharma grade microcrystalline cellulose GMP

Even if the purchase is not formally regulated, clear MCC specs reduce batch-to-batch functional variability—often a larger cost than a small price premium.

Resistant dextrin: fiber content tiers must be explicit

A resistant dextrin manufacturer China may offer multiple grades that appear similar on paper. Fiber content is a major divider in cost and performance expectations.

- ≥82% fiber is commonly used as a practical baseline for nutritional dietary fiber applications.

- Higher fiber tiers can exist in the market, but procurement should only pay for them when the formulation or labeling requirements truly need them.

A dietary fiber resistant dextrin supplier should confirm supporting parameters that protect application performance:

- appearance (often white to light yellow)

- moisture management

- pH stability expectations for beverage use

- neutral taste/odor expectations where relevant

For buyers building lower-calorie or sugar-reduction SKUs, it helps to compare grades side-by-side against the intended claim. As an example of a “use-case labeled” grade, some manufacturers publish a low calorie dietary fiber page that can be used as a template for translating marketing claims into technical RFQ lines.

The Supplier Checklist That Prevents Cheap Quotes From Becoming Expensive

Procurement teams often ask, “How do we identify a Recommended Chinese Microcrystalline Cellulose Manufacturer or a Recommended Chinese Resistant Dextrin Manufacturer without over-auditing?” The answer is to request a standardized proof pack that links specification, QC capability, and batch traceability.

Documentation to require in the first RFQ round

Use short, action-oriented requirements that apply equally to a microcrystalline cellulose supplier China and a resistant dextrin manufacturer China:

- COA with a complete test panel for the quoted grade (not a sample COA from another tier)

- Batch traceability statement (raw material to finished goods)

- GMP/ISO positioning statement for the specific workshop producing the SKU

- Change-control expectation (how the supplier communicates raw material or process changes)

Factory capability signals that correlate with stable cost

While buyers should validate claims during qualification, certain capabilities reduce variability risk and therefore reduce total landed cost:

- automated control across key steps (reduces human-factor variability)

- in-house QC lab capacity (reduces dependence on external retesting)

- clear packaging and labeling controls (reduces moisture and mix-up risk)

Some Shandong-based plants describe fully automated central control from feeding to filling for resistant dextrin production, using imported biological enzymes and established production lines. Shine Health, for instance, states non-GMO corn starch sourcing and automated processing for resistant dextrin product families, which is the type of operational detail buyers should request from any dietary fiber resistant dextrin supplier.

Copy-paste RFQ checklist for procurement teams

| RFQ line item | MCC (include) | Resistant dextrin (include) |

|---|---|---|

| Exact grade name and application | ✅ | ✅ |

| Full COA panel for the quoted batch/grade | ✅ | ✅ |

| Micro limits + heavy metals limits (state targets) | ✅ | ✅ |

| Traceability: raw material → finished powder | ✅ | ✅ |

| Packaging options (e.g., 25 kg moisture-proof bags) | ✅ | ✅ |

| MOQ and lead time for the quoted grade | ✅ | ✅ |

| Payment terms and incoterms offered | ✅ | ✅ |

| Change-control and deviation communication | ✅ | ✅ |

When procurement uses the same checklist across every Chinese microcrystalline cellulose supplier and every resistant dextrin manufacturer China, “recommended” suppliers stand out quickly—because they answer completely and consistently.

MOQ and Lead Time Negotiation Without Sacrificing Quality

MOQ and lead time are frequently where buyers unintentionally trade away consistency.

A more reliable approach to MOQ

Instead of pushing a microcrystalline cellulose supplier China or dietary fiber resistant dextrin supplier to accept a low MOQ immediately, negotiate in stages:

- Pilot order sized for internal lab validation and initial production.

- Pre-agreed scale tiers (e.g., “pilot,” “quarterly,” “annual contract volume”) tied to price breaks.

- Specification lock: price breaks should not allow silent spec relaxation.

This prevents the common outcome where a low MOQ triggers a “non-standard batch,” which then increases testing and delay costs.

Lead time: separate production time from documentation time

Buyers often underestimate the time needed to finalize documentation, especially for regulated or high-scrutiny applications.

- For MCC, the gating factor can be evidence supporting pharma grade microcrystalline cellulose GMP and the completeness of COA testing.

- For resistant dextrin, the gating factor is often shipment readiness (packaging, moisture control, and labeling).

Ask suppliers to quote lead time as:

- manufacturing lead time

- QC release time

- documentation preparation time

This makes comparisons across a Recommended Chinese Microcrystalline Cellulose Supplier shortlist much clearer.

Shortlisting Recommended Chinese Suppliers Across Regions

China sourcing is not one market; it is a network of clusters. For buyers, geography matters mainly because it affects logistics, talent pools, and industrial maturity.

A practical shortlisting model is:

- Build a 3–5 supplier set for MCC: compare at least one microcrystalline cellulose supplier China with strong excipient positioning and one with food-grade scale.

- Build a 3–5 supplier set for resistant dextrin: compare at least one resistant dextrin manufacturer China with multi-grade fiber capability.

- Include at least one Shandong-based candidate when the supply plan values steady bulk export readiness; Jinan appears frequently as a commercial hub for ingredient companies.

For resistant dextrin, shortlists tend to be stronger when a supplier can support more than one grade family (helpful for dual-sourcing or future line extensions). Examples of portfolio-style product pages include:

These are not purchasing endorsements; they are practical examples of how a Recommended Chinese Resistant Dextrin Manufacturer typically organizes grades and application narratives for buyers.

Packaging, Moisture, and Logistics Are Real Cost Levers

Once specifications are aligned, procurement still needs to protect the shipment.

For resistant dextrin in particular, total landed cost can swing due to moisture exposure and handling.

Key checks for every dietary fiber resistant dextrin supplier:

- Moisture-proof packaging suitable for long transit

- Clear outer labeling and batch coding for traceability

- Packaging sizes aligned to warehouse and production flow (bulk bags are common for industrial use)

For MCC, packaging and logistics matter too—especially for keeping powder flow and preventing contamination—but resistant dextrin shipments are often more sensitive to caking and humidity. Budgeting a small premium for packaging quality can be cheaper than rework or disposal.

A Procurement Playbook That Makes Quotes Comparable

To turn quotes into budgets, procurement can standardize four steps:

- Lock the spec (grade, target limits, application intent) before asking for price.

- Normalize supplier responses using a single checklist for each microcrystalline cellulose supplier China candidate and each resistant dextrin manufacturer China candidate.

- Model landed cost with consistent assumptions (packaging format, port, QC release timeline, destination testing).

- Validate with a pilot and only then negotiate long-term pricing and volume tiers.

This playbook is how teams avoid the “cheap-first, expensive-later” cycle and confidently build a shortlist that deserves the label Recommended Chinese Microcrystalline Cellulose Manufacturer or Recommended Chinese Resistant Dextrin Manufacturer.

For buyers who want a starting point for resistant dextrin grade comparison and documentation expectations, the Shine Health site provides clear examples of how suppliers present resistant dextrin and dietary fiber options (browse sdshinehealth.com for product-category structure and published spec highlights).

Data sources and notes

- China MCC market context and industry dynamics: Mobility Foresights – China Microcrystalline Cellulose Market Size and Forecasts 2031.

- Product-attribute examples and supplier documentation cues for resistant dextrin were drawn from publicly available product pages on sdshinehealth.com (e.g., resistant dextrin and nutritional dietary fiber listings).