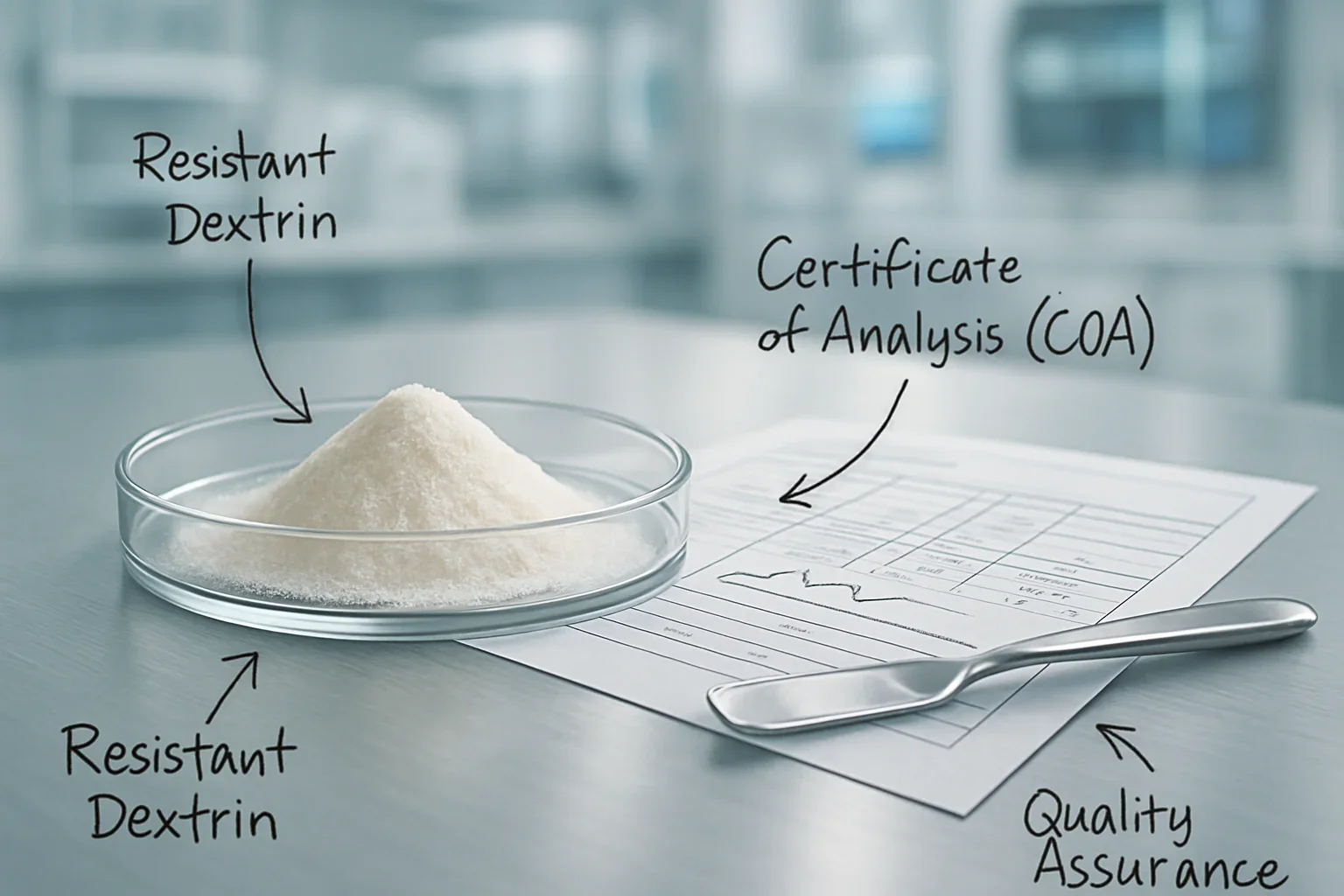

Resistant dextrin has transitioned from a niche dietary fiber to a strategic line item for many global procurement teams. As consumer demand surges for weight management, gut health, and blood sugar support products, the pressure is on buyers to secure high-quality ingredients that perform consistently. For procurement professionals, the challenge is rarely about finding offers online; rather, it is about translating the science of resistant dextrin into specifications that behave predictably in manufacturing and Certificate of Analysis (COA) parameters that prevent supply chain surprises. The goal of this guide is practical: to help you compare resistant dextrin supplier China options side by side, read resistant dextrin COAs correctly, and align your purchasing strategy with your formulation needs—whether you are developing a clear RTD beverage, a keto-friendly powder, or a functional bakery item.

Deciphering the Specs: What Resistant Dextrin Is and Why Grades Matter

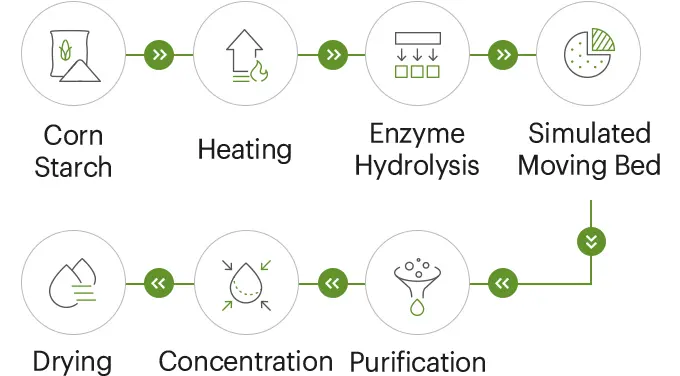

At a technical level, resistant dextrin (often referred to as resistant maltodextrin or soluble corn fiber) is a soluble dietary fiber produced from starch—commonly non-GMO corn starch—through a process of controlled enzymatic hydrolysis and refining. This processing creates glucose bonds that are resistant to digestion in the human small intestine. Because it resists digestion, it reaches the large intestine intact, where it acts as a substrate for fermentation, which is why it is frequently positioned for prebiotic support.

For buyers, understanding the nuance of "grades" is critical. "Resistant dextrin" is a family of products, and specifications can vary significantly based on processing conditions and target applications. Procurement teams must anchor their decisions in measurable parameters rather than marketing terms.

The Fiber Content Nuance: As-is vs. Dry Basis

Many manufacturers, particularly those in the major production hubs of China, offer resistant dextrin derived from non-GMO corn starch. In supplier documentation, you will typically encounter two main fiber content specifications:

- Standard Grade: Often listed as Fiber Content ≥82%.

- High-Fiber Grade: Often listed as Total fiber content (on dry basis) ≥90.0%.

In practice, the safest approach for a buyer is to treat fiber content as a range and, more importantly, to verify the exact reporting method on the COA. When comparing quotes from different suppliers, do not compare "fiber %" without confirming whether the figure is reported on a dry basis or as-is basis. A quote that looks cheaper might be referencing a lower specification or a different testing standard.

Translating Clinical Evidence into Procurement Specs

Human studies and pooled analyses often describe resistant dextrin as producing modest but meaningful changes in health outcomes. These include weight management support, improved glycemic control, and enhanced mineral absorption. While buyers do not need to be clinical experts, they must connect "what the study suggests" to "what the finished product must deliver."

Here is a procurement-oriented interpretation of how application goals dictate specification needs:

- For Weight Management: If the product positioning relies on satiety or caloric reduction, buyers should prioritize high fiber content (≥90% dry basis) and neutral taste. This allows for higher inclusion levels without ruining the flavor profile of a meal replacement shake or bar.

- For Blood Sugar Support: Formulation stability is key. You need a spec that guarantees predictable viscosity and low glycemic response. The COA should support consistent dosing to meet functional claims.

- For Prebiotic Support: Focus on solubility and the absence of off-notes. Batch-to-batch process consistency is vital here to avoid customer complaints about texture changes in probiotic drinks or powders.

Buyer Checkpoints for Verification

To ensure the ingredient matches the intended function, procurement teams should standardize their verification checklist:

- Fiber Content Target: Confirm if you are buying the ≥82% standard or the ≥90% high-fiber variant.

- Protein Limits: Common high-quality supplier targets include Protein ≤6.0%. Lower protein content often correlates with better taste neutrality and solution clarity.

- Sensory Evaluation: While specs say "tasteless/neutral," always request a pre-shipment sample. "Neutral" can vary between suppliers based on their refining process.

- Stability Data: For acidic beverages or baked goods, request application notes confirming heat and acid resistance.

Practical Application Mapping for Product Teams

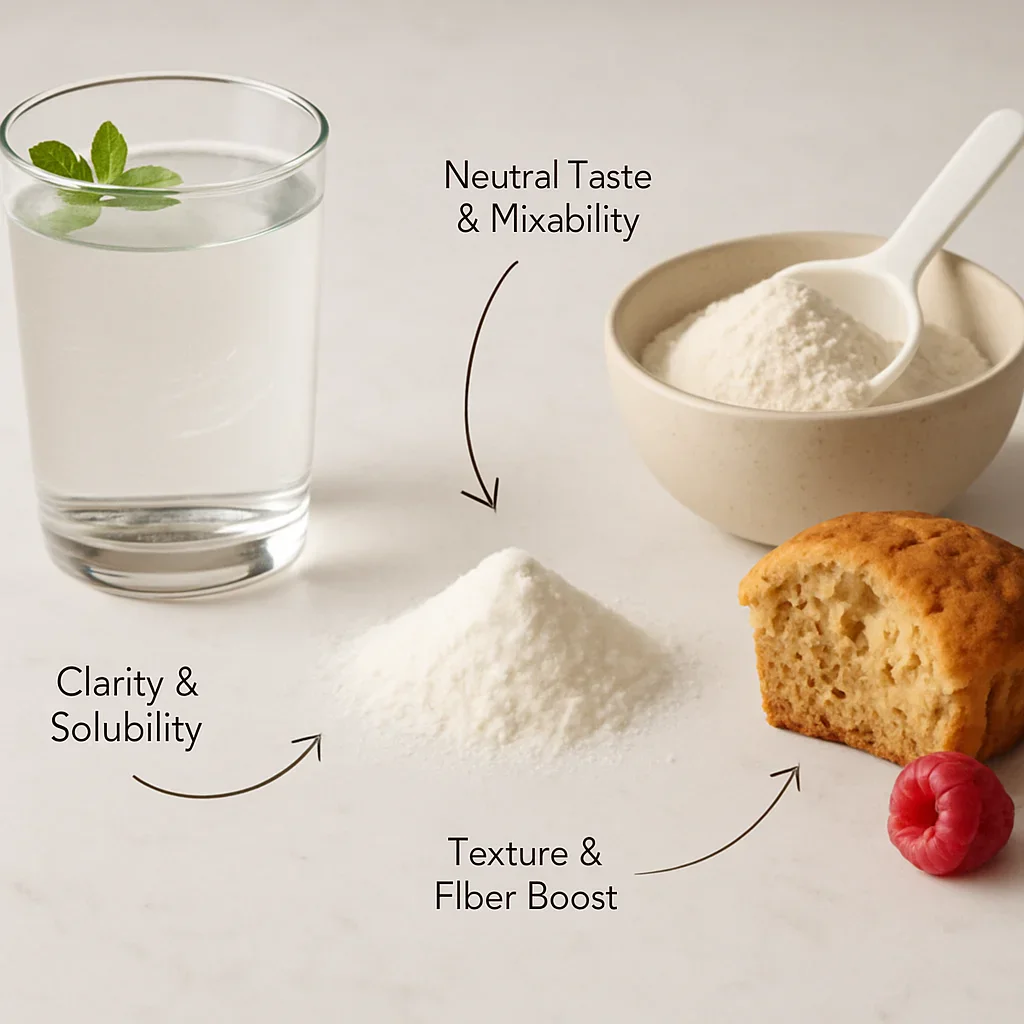

A resistant dextrin that looks perfect on a specification sheet can still fail in a real production environment if it clouds a clear beverage, creates unexpected sweetness, or cakes during storage. When teams buy resistant dextrin bulk, these functional properties tend to drive the success of the final product.

Application Specifics

- RTD Beverages & Fiber Waters: Prioritize high solubility (often cited as ~70%) and clarity. The ingredient must dissolve completely without sediment. Heat and acid stability are non-negotiable for pasteurized or low-pH drinks.

- Keto-friendly Powders: Prioritize low hygroscopicity. The powder must remain free-flowing and not clump in the tub once opened by the consumer. A consistent fiber spec is crucial so the nutrition panel remains accurate.

- Baked Goods: Prioritize moisture retention. Resistant dextrin can help keep gluten-free breads soft or reduce the caloric density of cookies without compromising texture.

Evaluating Suppliers in China: The Shandong Advantage

China, and specifically the Shandong province, has emerged as a global hub for the production of starch derivatives and functional ingredients. When searching for a resistant dextrin manufacturer in Shandong, buyers can leverage the region's established supply chain for corn starch and advanced manufacturing infrastructure. However, verification is still essential.

Manufacturing and Quality System Indicators

Regardless of the specific region, a reliable supplier should demonstrate specific capabilities that reduce buyer risk:

- Advanced Equipment: Look for suppliers utilizing precision production lines (often imported from Germany or Japan). This hardware investment usually correlates with tighter particle size distribution and better solubility.

- Enzymatic Technology: The quality of the biological enzymes used in hydrolysis defines the final fiber content and sugar profile. Top-tier suppliers often import specialized enzymes to ensure a cleaner product.

- Automation: Evidence of fully automated central control—from raw material feeding to filling—is a strong indicator of batch-to-batch consistency. It minimizes human error in the complex hydrolysis process.

- QC Laboratories: A supplier must have an in-house, fully equipped QC laboratory capable of running HPLC analysis for fiber content and microbiological testing.

The Standardized Request Template

When evaluating a resistant dextrin supplier, create one standardized request template and apply it to every candidate. Below is a buyer-friendly baseline that aligns with what reputable manufacturers publish:

- Product Name: Resistant Dextrin (or Resistant Maltodextrin)

- Raw Material: Corn starch (Specify Non-GMO if required)

- Appearance: White to light yellow powder

- Fiber Content: ≥82% (Standard) or ≥90% (High Fiber, Dry Basis)

- Protein: ≤6.0%

- Moisture & Water Activity: Low (for shelf life stability)

- Storage: Cool, dry place

Practical Rule: If two suppliers quote the same price, but one provides a more complete COA with clear method notes (e.g., AOAC methods for fiber), that supplier is often the more cost-effective choice in the long run due to reduced qualification time and lower variability risks.

Where Microcrystalline Cellulose Fits

It is worth noting that resistant dextrin and microcrystalline cellulose (MCC) are often sourced together, yet they solve different problems. Resistant dextrin is a soluble fiber for nutritional enhancement, while MCC is typically an insoluble excipient used as a binder or flow aid in tablets and capsules. Buyers often look for suppliers who can handle both to consolidate logistics, but the performance tests differ significantly. For resistant dextrin, you test for dissolution and taste; for MCC, you test for compressibility and flow.

A Neutral Sourcing Note for Buyers

If your sourcing plan includes China, consider running resistant dextrin through a rigorous qualification workflow: initial document review, lab testing, pilot production, and then scale-up. Buyers doing Chinese dietary fiber supplier evaluation typically save time by standardizing their questionnaires and letting the data—COAs, samples, and pilot results—make the decision.

For procurement teams looking to compare suppliers that publish clear specifications—including fiber content ranges, protein limits, and details on automation and QC capabilities—referencing established manufacturers is a good starting point. One example of a manufacturer providing detailed technical documentation and resistant dextrin specifications is www.sdshinehealth.com. Conducting a thorough review of such suppliers' capabilities can help build a resilient and high-quality supply chain for your functional food and beverage products.