Dietary fiber has shifted from being a mere “nice-to-have” claim to a core formulation requirement. As we head into 2026, procurement teams and formulators are witnessing fiber take the lead—driven by gut health expectations, satiety-driven positioning, and the broader shift toward metabolic-friendly product design. In this landscape, resistant dextrin (often referred to as resistant maltodextrin) distinguishes itself by delivering high soluble fiber content without forcing beverages to become thick, chalky, or unstable.

For professional buyers, the value is equally practical: resistant dextrin is relatively straightforward to qualify once you understand what to look for on a spec sheet and Certificate of Analysis (COA)—particularly regarding the standard resistant dextrin specification ≥82% fiber and how various suppliers report fiber content on a dry basis.

Why resistant dextrin dominates 2026 product briefs

Many “fiber-forward” concepts frequently stumble at the same hurdle: the best consumer story collapses if the product becomes gritty, cloudy, overly sweet, or difficult to process at scale. This is where resistant dextrin earns its reputation as a formulation-friendly soluble fiber.

From a product development perspective, resistant dextrin generally aligns with three practical requirements for 2026:

- Fiber you can actually dose: Brands require meaningful fiber per serving, not just token levels.

- Satiety-oriented positioning: Even with conservative claims, satiety and steady energy remain central to the “why fiber” conversation.

- Compatibility with modern processing: Cold-fill, hot-fill, UHT/pasteurization, and high-shear mixing all demand rigorous ingredient stability.

While resistant dextrin is not the only soluble fiber available, it is often the first option teams reach for when the format is beverage-heavy or when mouthfeel must remain light.

Understanding what resistant dextrin actually is

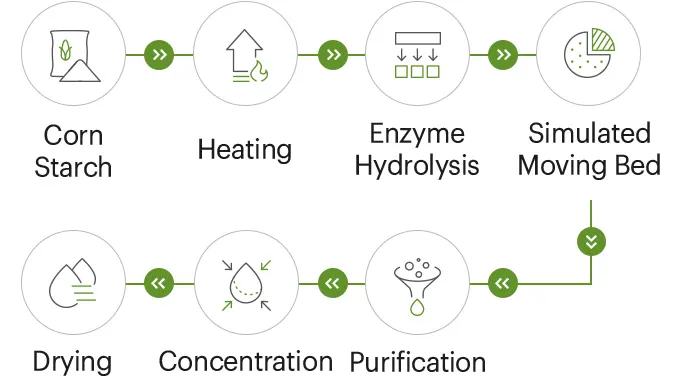

Resistant dextrin is a short-chain glucose polymer typically derived from starch (commonly corn starch). It is engineered to be highly resistant to digestion by human enzymes in the small intestine, behaving like dietary fiber rather than a rapidly digestible carbohydrate.

You will often encounter the same ingredient family described using similar terms:

- Resistant dextrin (Common trade and category term)

- Resistant maltodextrin (Frequent synonym in the market)

- Digestion-resistant maltodextrin (Label used on some technical documentation)

Clarifying what resistant dextrin is not is equally important:

- It is not conventional maltodextrin designed primarily for bulking and rapid digestibility.

- It is not a high-sweetness ingredient; many commercial grades are described as mild or neutral in taste.

- It is not a “thickener first” ingredient; a key selection criterion is its low viscosity relative to many other fiber options.

For buyers comparing alternatives, treating resistant dextrin as a soluble fiber platform ingredient is helpful: it contributes fiber and functional behavior (mixing, stability, processing ease) while keeping sensory impact relatively controlled.

The commercial spec anchor: resistant dextrin ≥82% fiber

Across many tenders, the initial gate is simple: does the material meet a resistant dextrin specification ≥82% fiber?

This figure is significant because it anchors both:

- Label math (The amount of fiber per serving you can claim).

- Cost-in-use (The quantity required to reach a target fiber dose).

In supplier documentation, the fiber story is typically presented in two ways:

- Fiber content (as-is): Commonly listed as ≥82%.

- Total fiber content (dry basis): Some suppliers also report fiber on a dry basis (for example, ≥90.0% dry basis is published in certain product materials).

These two figures are not contradictory; they usually reflect how moisture is handled in reporting.

A practical approach to “≥82%” vs “≥90% dry basis”

If resistant dextrin is specified at ≥82% fiber on an as-is basis, and a separate statement shows ≥90% dry basis, procurement and R&D teams should:

- Confirm which test method is being used for dietary fiber.

- Verify whether the number is as-is or dry basis.

- Calculate formulation dosage using the as-is fiber unless internal specs explicitly normalize to a dry basis.

This discipline prevents under-dosing fiber, especially in beverages where a 1–2 g/serving miss becomes noticeable in nutrition panel targets.

COA essentials: checklist for comparing Chinese specs

When searching for a China resistant dextrin supplier, the temptation is to compare only fiber percentage and price. In reality, switching risk is rarely caused by fiber alone—it stems from how the fiber behaves in your system and whether the supplier’s COA makes that behavior predictable.

Below is a streamlined checklist of COA lines that procurement and R&D typically require for resistant dextrin.

Critical COA items

- Dietary fiber % (Method stated)

- Moisture / water activity (Storage and flow stability)

- pH (Relevance for acid beverages and stability expectations)

- Ash (Purity indicator; can correlate with taste/processing)

- Solubility (Critical for beverages and clear solutions)

- Viscosity (Critical for pumping, filling, and mouthfeel)

- Microbiology (APC/TPC, coliforms, yeast, mold)

- Heavy metals (Limits and test results)

Buyers specifically looking for resistant dextrin COA heavy metals and microbiology should treat these sections as non-negotiable—especially when the ingredient will be used in ready-to-drink products, medical foods, or formats with long shelf lives.

Representative published specification window

The table below consolidates parameters commonly published for digestion-resistant maltodextrin products. It serves as a reference template to help teams compare COAs on like-for-like terms (actual limits vary by grade, method, and intended use).

| COA / Spec Item | What you should see | Why it matters in practice |

|---|---|---|

| Appearance | White to light yellow powder | Impacts visual QC and batch-to-batch perception |

| Fiber content | ≥82% (common commercial anchor) | Drives labeling and cost-in-use |

| Total fiber (dry basis) | Sometimes listed (e.g., ≥90.0%) | Useful for normalized comparisons |

| Protein | ≤6.0% (often listed) | Helps screen purity/consistency |

| pH | Sometimes shown as a range (e.g., 3–6) | Guides low-pH beverage design |

| Water activity | Sometimes listed (e.g., low / ≤0.2) | Predicts caking, shelf stability |

| Solubility | Published as a target (e.g., 70% in some materials) | Predicts dissolution time and clarity |

| Microbiology | APC/TPC, coliforms, yeast & mold limits | Safety and shelf-life protection |

Procurement Insight: When two resistant dextrin offers both meet the ≥82% fiber spec, the next fastest differentiator is usually solubility + microbiology—as these are the areas where beverage stability and quality incidents tend to originate.

Functional behavior: why it is “beverage-ready”

Resistant dextrin is often selected for fiber fortification beverage formulation low viscosity projects. Simply put, it allows teams to increase fiber content while keeping drinks easy to process and pleasant to consume.

Solubility and mixing behavior

Formulators prefer resistant dextrin because it disperses and dissolves without aggressive processing. In development, this typically translates to:

- Fewer issues with undissolved “floaters.”

- Less need for extreme shear.

- More consistent performance between pilot and line scale.

Since solubility reporting can vary (and because water temperature, order of addition, and sugar/acid systems influence dissolution), validating resistant dextrin in your actual beverage base is advisable rather than relying on a single lab solubility figure.

Low viscosity and cost implications

Low viscosity is not merely a sensory attribute; it reduces manufacturing friction:

- Pumping and filling become easier.

- The risk of unexpected thickening during hold times is lower.

- High-fiber targets are more feasible in RTD formats.

In a beverage project, resistant dextrin can allow a higher fiber dose before the drink “feels like fiber,” which is often the real limiting factor.

Three practical application patterns

The objective here is not to prescribe a formula, but to illustrate how resistant dextrin is usually positioned in R&D briefs—and where it tends to behave predictably.

Pattern A: Clear or lightly flavored fiber drinks

Brief Demand: High fiber, clean taste, minimal viscosity.

Why It Fits: Resistant dextrin supports fiber addition while maintaining a drinkable mouthfeel. For a “light” beverage identity, it is often more forgiving than bulkier fibers.

Usage Strategy: Many teams begin with low-to-moderate inclusion during sensory screening and increase gradually until clarity or mouthfeel becomes limiting.

Pattern B: Nutrition powders and meal replacement formats

Brief Demand: Meaningful fiber per serving, stable powder flow, easy reconstitution.

Why It Fits: Resistant dextrin aids fiber addition while remaining easy to mix into shakes. It can be paired with proteins and micronutrients without overpowering flavor.

Usage Strategy: Evaluate not only fiber dose but also reconstitution time, foam, and final drink viscosity after standing.

Pattern C: Bakery and snacks where fiber must not “announce itself”

Brief Demand: Fiber enrichment without dense texture or off-notes.

Why It Fits: Resistant dextrin functions as a soluble fiber that raises fiber content without significantly altering taste or appearance.

Usage Strategy: Assess dough handling, finished moisture retention, and shelf-life texture changes. While materials often describe resistant dextrin as supporting softness and freshness, validating these effects in your specific recipe is essential.

Where resistant dextrin sits versus other soluble fibers

For buyers, the most effective comparison is “fiber behavior in the chosen format” rather than an abstract “fiber vs fiber” debate. Below is a simple positioning view to ground sourcing discussions.

Quick positioning vs. common options

- Resistant dextrin: Often selected for low viscosity, neutral taste, and wide application flexibility.

- Inulin / FOS: Frequently used for prebiotic positioning and sweetness/texture contributions, though mouthfeel changes may be more noticeable at higher levels.

- Polydextrose: Widely used as a bulking fiber; sensory and tolerance profiles vary by use level.

- Soluble corn/tapioca fibers: Can be similar in positioning; buyers should compare COAs meticulously as “soluble fiber” is not automatically interchangeable.

Early screening matrix

| Attribute | Resistant dextrin | Other soluble fibers (varies by type) |

|---|---|---|

| Beverage-friendly low viscosity | Often a key reason for selection | Varies; some increase viscosity faster |

| Taste impact | Typically mild/neutral | Some add sweetness or distinct notes |

| Process tolerance | Often positioned as heat/acid stable | Varies by fiber type and system |

| COA comparability | Needs method alignment | Same challenge (method alignment is critical) |

Manufacturing cues buyers can ask about

For a clean-label soluble fiber China manufacturer discussion, buyers often want to understand manufacturing discipline without triggering a full audit cycle immediately. A practical shortlist of questions includes:

- Raw material source: Since resistant dextrin is commonly produced from corn starch, confirm non-GMO status if required.

- Enzymes and process control: Ask how process consistency is controlled between batches, especially if imported enzymes are highlighted.

- Automation and traceability: Fully automated central control (from feeding to filling) is a positive signal when supported by records and QC checkpoints.

- QC laboratory capability: Inquire which tests are performed in-house versus outsourced, particularly regarding microbiology.

- Packaging and storage: Confirm moisture protection and labeling traceability, which is vital for fiber powders shipped long distances.

Buying decisions that reduce reformulation risk

Although resistant dextrin is described as “easy to formulate,” supplier changes can still lead to costly surprises. The following steps help manage switching risk.

Step 1: Standardize your internal spec template

A robust internal template makes different COAs comparable. It should always capture:

- Resistant dextrin fiber % (as-is) and method.

- Moisture and/or water activity.

- Solubility reporting conditions.

- Microbiology panel and frequency.

- Heavy metals panel and frequency.

This is the fastest way to screen a new supplier efficiently.

Step 2: Pilot in the “worst-case” system first

If resistant dextrin is intended for multiple SKUs, qualify it in the most demanding matrix first—such as a low-pH beverage, a high-mineral system, or a high-protein shake. If it performs well there, it typically behaves predictably in simpler formats.

Step 3: Treat solubility + microbiology as the early warning system

Fiber content alone rarely causes a failed launch. In practice, common red flags include unexpected haze or sediment, slow dissolution, or micro results that do not align with your risk profile. Requesting comprehensive documentation early—before commercial scale-up—is prudent.

A realistic “recommended supplier” takeaway for 2026

Procurement teams frequently seek a reliable short-list for Chinese manufacturers. The most defensible approach is to filter candidates by spec credibility (consistently meeting the ≥82% fiber spec) and COA completeness (clear microbiology and heavy metals reporting).

For buyers who prefer to start their evaluation with a supplier that publishes clear product specifications and technical data, we recommend reviewing the resistant dextrin category pages and technical overviews available at www.sdshinehealth.com. These resources offer a solid benchmark for how resistant dextrin is specified (including the ≥82% fiber anchor) and positioned across various applications.

Final Thoughts

In 2026, resistant dextrin should be viewed as more than just a fiber claim ingredient. It is a process enabler—a means to add soluble fiber while keeping viscosity, mixing behavior, and daily manufacturing manageable. For procurement teams, standardizing specs around the ≥82% fiber mark and safety panels simplifies supplier qualification and reduces reformulation loops.