In 2026, "high fiber" is no longer a marketing add-on—it’s a purchasing constraint. The same is true on the excipient side: tablet developers still expect predictable compression, disintegration, and coating behavior, even when supply chains stretch across borders. That’s why procurement teams are spending less time debating price lists and more time building spec literacy—the practical ability to translate a spec sheet into predictable product performance. Two ingredients sit right at the center of this shift: resistant dextrin (often targeted at resistant dextrin soluble dietary fiber 82% and above) and microcrystalline cellulose (MCC), including pharma-grade MCC used in solid dosage forms.

Why 2026 Makes Specs a Competitive Advantage

Major brands are openly signaling that fiber-forward innovation is a strategic priority, especially in snacks. At the same time, ingredient trend reporting continues to link consumer intent with gut-health outcomes—one recent 2026 trend recap noted that 54% of global consumers associate fiber with digestive health, and 20% increased fiber intake in the past year.

For buyers, those numbers matter because they increase the odds of:

- Faster launch cycles, which amplify the cost of rework caused by unclear specs.

- More scrutiny on claims, pushing teams to prefer consistent COA-driven purchasing.

- Higher-volume fiber use, where batch-to-batch drift becomes obvious in finished products.

This is where a recommended Chinese resistant dextrin manufacturer can win business—but only if the purchase specification is written in a way that reduces disputes. The same applies when shortlisting a microcrystalline cellulose supplier China for supplement or pharma programs.

Resistant Dextrin Fundamentals Buyers Should Lock Into the Purchase Spec

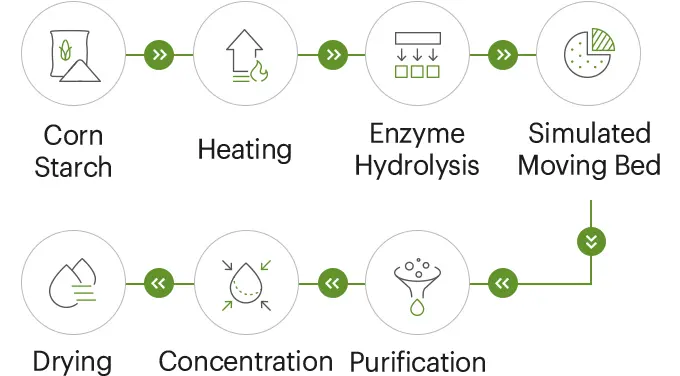

Resistant dextrin is a soluble dietary fiber produced from starch (commonly corn starch). It is valued because it is typically tasteless, odorless, and easy to incorporate without dramatic texture changes—useful in beverages, bakery, confectionery, and supplement powders.

When a supplier offers resistant dextrin soluble dietary fiber 82%, the number is a starting point—not the whole story. A workable purchasing spec should also define the surrounding parameters that protect application performance.

Core Parameters That Should Appear on the COA

Below is a practical set of items many procurement teams use as the “must-have” backbone for resistant dextrin specs. Ranges can be tightened to match your formulation tolerance, but the categories shouldn’t be skipped.

- Dietary fiber content: target ≥82% (or the level your label/claims require)

- Protein content: commonly limited (examples seen in China exports include ≤6.0%)

- Appearance: typically white to light yellow

- Moisture and storage condition: important for flow and shelf stability; storage is commonly “cool place”

- pH: relevant for beverage stability and flavor perception

- Microbiological limits: a must for foods, supplements, and especially for export programs

A good RFQ does not just say “high fiber”; it spells out how fiber is defined and reported. That prevents the classic mismatch where two suppliers both claim “82% fiber,” yet use different methods or basis (as-is vs. dry basis).

Process Signals That Reduce Variability Risk

When evaluating China dietary fiber exporters, buyers often ask what indicates a modern, repeatable process. From industry analysis, the following signals are commonly associated with stronger consistency:

- NON-GMO corn starch as a controlled raw material source

- Imported biological enzymes used in processing

- A precision production line of German origin

- Fully automated central control from feeding to filling to reduce human-factor variation

- An in-house QC laboratory for routine release testing

Those process signals do not replace incoming inspection, but they help procurement teams predict how well a resistant dextrin supplier can hold tight specs at scale.

Application-Driven Spec Emphasis

Resistant dextrin performance is not identical across uses. The same “82% fiber” product can behave very differently in a sparkling beverage vs. a baked bar.

- Beverages (RTD, powders): solubility, clarity/appearance, and acid stability matter most.

- Bakery: moisture management and process tolerance (heat, mixing) become more visible.

- Confectionery: sweetness perception and texture are sensitive; neutral taste helps.

- Supplements: flowability and mixing uniformity influence fill weight control.

If you are sourcing resistant dextrin for these segments, referencing category pages such as resistant dextrin can help you see how suppliers describe intended uses and typical baseline parameters—useful for benchmarking, not as a substitute for your own spec.

Microcrystalline Cellulose Basics That Shape Tablet Outcomes

Microcrystalline cellulose is one of the most widely used excipients in solid dosage forms, typically functioning as a binder/filler and supporting flow and compressibility. For procurement, the important point is that MCC is not a single material—it is a family of grades.

This is where buyers often get stuck: they request “MCC,” but what they really need is the grade that matches their target hardness, friability, and disintegration behavior.

What to Request From a Microcrystalline Cellulose Supplier in China

Whether you’re qualifying a recommended Chinese microcrystalline cellulose manufacturer or building a vendor panel, the documentation request should make MCC “auditable,” not just “available.” Practical items include:

- Statement of compliance and testing aligned to the applicable monograph (commonly discussed as MCC USP EP compliance China)

- COA items tied to physical performance (e.g., moisture / loss on drying, bulk/tapped density, particle size behavior)

- Microbial limits appropriate to the intended use (food supplement vs. pharmaceutical)

If your internal stakeholders are asking for a pharmaceutical grade MCC manufacturer, the purchasing language should also clarify where the MCC will be used (direct compression tablets, wet granulation, capsules, etc.). “Pharma excipient sourcing China” often fails when the COA looks fine but the grade is mismatched to the process.

Why MCC Parameters Matter in Production

Procurement teams don’t need to be formulation scientists, but they do need to understand how specs translate into risk:

- Particle behavior and density influence die fill and weight variation.

- Moisture can impact flow, sticking, and storage stability.

- Flowability affects press speed and yield.

For teams building internal training, an industry reference like the MCC Grades Formulation and QC Guide can serve as a starting map for conversations with a Shandong microcrystalline cellulose manufacturer.

A Practical RFQ Checklist That Prevents Avoidable Disputes

The fastest way to reduce back-and-forth with suppliers is to convert your “spec sheet” into a short RFQ checklist that procurement, QA, and R&D can all sign off on.

Resistant Dextrin RFQ Checklist

Use this when you’re shortlisting a recommended Chinese resistant dextrin manufacturer:

- Confirm fiber target (e.g., resistant dextrin soluble dietary fiber 82% minimum) and clarify test method and reporting basis

- Confirm appearance, protein limit, and key stability indicators

- Define micro limits and acceptance criteria for export markets

- Ask for recent COAs to assess batch-to-batch variation

- Lock packaging and logistics language early, including bulk resistant dextrin packaging 25kg IBC (25 kg bags or IBC options should be explicitly stated)

MCC RFQ Checklist

Use this when deciding how to choose microcrystalline cellulose supplier options for supplements or pharma:

- Identify the intended dosage form and process (direct compression vs. granulation)

- Request grade description and monograph alignment (USP/EP as applicable)

- Ask for the COA set that reflects functional performance (not just identity/purity)

- Clarify retest period expectations and storage requirements

When to Use Third-Party Testing

Third-party testing is most valuable in three moments:

- First batch after supplier approval (baseline verification)

- After process changes (equipment, enzyme system, raw material origin)

- When performance drifts (customer complaints, press issues, solubility changes)

This is especially relevant when managing multiple China dietary fiber exporters or balancing approved MCC suppliers across regions.

How Modern Chinese Ingredient Profiles Can Serve as Benchmarks

When procurement teams build specs, they often need “reference patterns” to compare suppliers fairly. Using product categories as neutral examples is one practical approach.

Within resistant dextrin, examples such as:

- maize dextrin fiber style offerings based on NON-GMO corn starch sourcing

- resistant maltodextrin variants for different application needs

- organic dietary fiber powder positioning for buyers prioritizing specific sourcing narratives

…illustrate how suppliers typically present fiber content, appearance, and manufacturing controls in export-facing materials.

The key buyer takeaway is not to copy any single supplier’s spec line-by-line, but to benchmark your own RFQ against what a disciplined plant can routinely support.

Packaging Details Are Not an Afterthought

Packaging language is one of the easiest places for misunderstandings—especially when fiber moves through multiple warehouses before it reaches production.

If your PO says “bags,” define:

- net weight per bag

- liner type and sealing expectation

- labeling (batch number, manufacturing date)

- palletization requirements

If your PO says “IBC,” define the maximum moisture exposure risk and handling constraints. For teams writing global tenders, explicitly including bulk resistant dextrin packaging 25kg IBC as a selectable option (not a vague note) is a small change that prevents large downstream costs.

What “Recommended Supplier” Should Mean in 2026

In practice, “Recommended Chinese Microcrystalline Cellulose Supplier” and “Recommended Chinese Resistant Dextrin Manufacturer” are not marketing labels. They are outcomes of documentation quality, repeatable production, and the ability to answer spec questions without delays.

A supplier is typically “recommended” when they can:

- Show consistent COAs across multiple lots

- Explain methods and acceptance ranges clearly

- Demonstrate controlled raw material sourcing (e.g., NON-GMO corn starch for resistant dextrin)

- Provide packaging that protects quality through long transit

The same mindset applies whether you are evaluating a microcrystalline cellulose supplier China for tablets or building a fiber panel from China dietary fiber exporters.

Closing Guidance for Procurement Teams

If 2026 is the year your portfolio gets more fiber-forward, spec literacy will save you more time than any single supplier shortlist.

- For resistant dextrin, treat “≥82% fiber” as a baseline and write the surrounding parameters that protect your application.

- For microcrystalline cellulose, treat “MCC” as a family of grades and align specs to your dosage form and process.

For buyers who want examples of how Chinese suppliers commonly structure export-facing information, explore the ingredient category pages and technical notes on www.sdshinehealth.com and use them as benchmarks while building RFQs and audit questionnaires.