Practical guide to MCC and resistant dextrin specs from China, covering grades, fiber targets, particle size, QC signals, and sourcing checkpoints for 2026 procurement.

Why MCC and resistant dextrin matter for buyers in 2026

Fiber-forward reformulation is expanding beyond “health” products into mainstream SKUs. At the same time, manufacturers are under pressure to keep taste, texture, and cost within tight bands. That combination is exactly where MCC and resistant dextrin earn their place:

- Microcrystalline cellulose helps with tablet robustness, powder flow, and bulking/anti-caking behavior in supplements and certain foods.

- Resistant dextrin provides soluble dietary fiber that can be formulated into beverages, confectionery, baked goods, and nutrition powders with relatively neutral sensory impact.

When sourcing from China, the question is rarely whether these ingredients exist—it is whether the spec sheet matches the intended application and whether the supplier can deliver consistency batch after batch.

Microcrystalline cellulose fundamentals that prevent sourcing mistakes

Microcrystalline cellulose is produced from purified cellulose through controlled hydrolysis, yielding fine particles that behave as a multifunctional excipient. It is typically white or almost white, odorless and tasteless, and insoluble in water, ethanol, and ether.

What buyers actually use MCC for

In practice, MCC selection is driven by the manufacturing step you need to stabilize:

- Tablets & capsules: binder/filler support, improved compressibility, and disintegration performance (often discussed as a microcrystalline cellulose disintegrant function).

- Powder blends: flow improvement and reduced caking in certain supplement and food systems.

- Food and cosmetic systems (select uses): bulking, texturizing, and stability support when an insoluble fiber-like structure is acceptable.

For benchmarking, buyers often review public product disclosures such as microcrystalline cellulose category listings and verify that the grade range and pharmacopeia claims align with the target market.

MCC grades and particle size implications

Most procurement teams know the grade names (PH-101, PH-102, etc.), but the commercial impact usually shows up as:

- Flowability vs. compressibility trade-offs

- Blending behavior in high-speed production

- Uniformity when paired with actives or flavors

Because grade naming conventions are widely recognized in the industry, buyers should request particle size / mesh information, and confirm it stays stable across lots. On one representative Shandong specification set, MCC is offered across grades including PH-101; PH-102; PH-103; PH-105; PH-112; PH-113; PH-200; PH-301; PH-302, with a mesh range noted at 60–200.

A buyer-oriented MCC spec snapshot

Below is a practical snapshot of what often appears on documentation from China-based producers; it is not a universal standard, but it reflects the typical fields that should be present:

| Parameter | What to look for in procurement | Example disclosure seen from a Shandong plant |

|---|---|---|

| Appearance | Uniform color and particle form | White or almost white powder |

| Grade list | Multiple grades for fit-to-use selection | PH-101, PH-102, PH-200, etc. |

| Particle range | Mesh/PSD aligned to your process | 60–200 mesh |

| Pharmacopeia | Market alignment (USP/BP/FCC/JP) | BP/USP/FCC/JP |

| Identification | Regulatory traceability | CAS 9004-34-6; EINECS 232-674-9 |

| Quality system | Certifications relevant to your market | ISO9001 / Kosher / Halal |

| Packaging | Moisture control and handling fit | 20 kg woven bag (customizable) |

When teams specifically need microcrystalline cellulose powder additive behavior (e.g., for flow/anti-caking support), the spec conversation often becomes more application-driven—how the powder behaves after shipping, storage, and blending—not just what the COA says.

Resistant dextrin basics for fiber-first foods and beverages

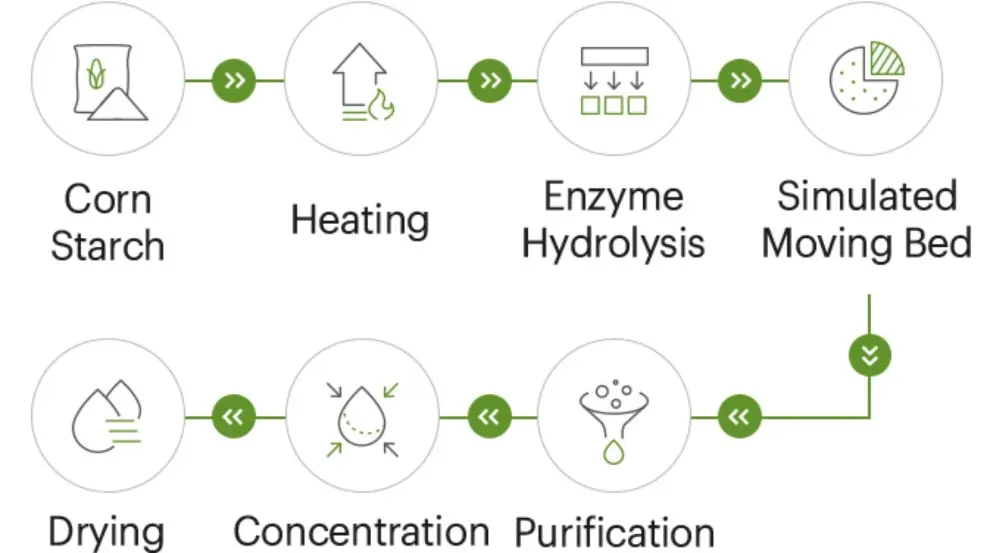

Resistant dextrin is generally positioned as a soluble dietary fiber derived from starch through controlled processing. Unlike digestible starch, resistant dextrin resists digestion in the small intestine and functions as dietary fiber.

For product developers, resistant dextrin is attractive because it can increase fiber while helping maintain drinkable viscosity, workable sweetness perception (often mild), and processing stability.

Common purchase drivers for resistant dextrin

A food grade resistant dextrin supplier is typically assessed on whether the ingredient supports:

- RTD beverages and coffees: fiber lift without heavy mouthfeel

- Nutrition powders and sachets: easy dissolution and stable storage

- Confectionery and gummies: fiber enrichment while keeping texture consistent

- Baked goods: fiber addition that tolerates heat processing

In China, resistant dextrin is often sourced from hubs with strong starch supply chains. Buyers should expect to see clear raw-material statements (commonly NON-GMO corn starch) plus transparent production and QC signals.

Core resistant dextrin parameters buyers should anchor to

One widely used benchmark in tender documents is fiber thresholding. On Shine Health’s published resistant dextrin disclosures, the key parameters include:

- Fiber content: ≥82%

- Protein content: ≤6.0%

- Appearance: white to light yellow

- Storage: store in a cool place

These fields matter because they are easy to compare across vendors and helpful for incoming QC. If a buyer is shortlisting a Recommended Chinese Resistant Dextrin Manufacturer, verifying how “fiber” is defined and measured (and keeping it consistent across suppliers) is essential.

For technical benchmarking, buyers often review publicly available pages such as nutritional dietary fiber powder and resistant maltodextrin to compare how manufacturers present specs, processing notes, and application positioning.

What procurement teams often miss in China spec sheets

China-sourced ingredients can be highly competitive, but spec sheets can look “complete” while still leaving procurement exposed. The most common gaps are not exotic—they are operational.

MCC pitfalls that show up after the first shipment

- Grade named, but not operationalized: A grade label without a clear mesh/PSD and bulk handling guidance can lead to flow issues.

- Pharmacopeia name-dropping: “USP/BP/FCC/JP” should map to documented testing methods and a COA format that your QA team can reconcile.

- Packaging mismatch: Woven bags may be acceptable for some use cases, but humidity exposure during transit should be discussed up front.

Resistant dextrin pitfalls that affect finished product performance

- Fiber number without application context: Fiber ≥82% is a strong anchor, but beverage vs. gummy use still requires solubility and process checks.

- Unclear raw material statement: “Corn starch” and “NON-GMO corn starch” are not interchangeable in many tenders.

- Vague QC claims: “QC lab” is helpful, but buyers still need microbial limits, moisture expectations, and batch traceability routines.

A practical checklist for shortlisting recommended Chinese suppliers

The checklist below is designed for buyers screening a Recommended Chinese Microcrystalline Cellulose Manufacturer, a Recommended Chinese Microcrystalline Cellulose Supplier, or a resistant dextrin partner. It focuses on what can be verified before deeper audits.

| Checkpoint | MCC focus | Resistant dextrin focus |

|---|---|---|

| Identity & standards | CAS and pharmacopeia alignment | Clear product naming (resistant dextrin / resistant maltodextrin) |

| Key performance spec | Mesh/PSD and grade clarity | Fiber content target (e.g., ≥82%) |

| Stability controls | Moisture handling and packaging detail | Appearance range and storage guidance |

| Quality systems | ISO and applicable certifications | GMP workshop statements and QC disclosures |

| Documentation readiness | COA format consistency | COA + batch traceability expectations |

A supplier that publishes structured technical pages and consistent parameter tables often makes qualification faster. As a neutral reference point, buyers can compare how information is presented across ingredient categories on www.sdshinehealth.com and use that structure as a template for RFQs.

Turning fundamentals into faster reformulation cycles

For teams reformulating bars, drinks, confectionery, and supplements, the most efficient workflow is to connect ingredient fundamentals directly to the process step that needs control:

- Use MCC grade logic to stabilize compression, flow, and disintegration where oral solid dosage consistency is the priority.

- Use resistant dextrin specs to stabilize fiber claims and sensory balance where consumer acceptance is the priority.

Once the technical brief is clear, supplier selection becomes less subjective. That is how procurement teams reduce back-and-forth, avoid avoidable rework, and move faster from pilot to scale. For specific sourcing inquiries or to request a compliant supplier list, please visit www.sdshinehealth.com.