Procurement teams rarely reject an ingredient simply because it "looks wrong." More often, a shipment is delayed—or a product needs urgent reformulation—because a single line on the Certificate of Analysis (COA) doesn’t match what the formulation, label claim, or internal standard assumed.

For many high-fiber foods and nutraceuticals, resistant dextrin (often specified at ≥82% dietary fiber) is the workhorse soluble fiber. In parallel, microcrystalline cellulose (MCC) remains a core excipient for tablets and capsules, where flow, compressibility, and compliance expectations are non-negotiable. This guide breaks down the specification logic behind both ingredients and offers a buyer-friendly way to read COAs without turning every purchase into a months-long investigation.

Resistant dextrin powder used as a soluble dietary fiber ingredient

Two Ingredients, Two Jobs: Why Specs Drive Outcomes

Although resistant dextrin and microcrystalline cellulose (MCC) often appear together in modern product portfolios, they solve different problems:

- Resistant dextrin is primarily selected for fiber delivery, low viscosity, neutral taste, and stability in food, beverage, and supplement applications. Buyers care about how the fiber behaves under heat, acid, and processing shear.

- Microcrystalline cellulose (MCC) is typically selected for solid-dose performance—as a filler/binder/disintegrant and flow aid—where small changes in particle size distribution, moisture, or compressibility can affect tablet hardness and weight variation.

In practice, the "right" spec is rarely about chasing the tightest limits. It represents defining what matters most for the end use, then ensuring the COA proves it—batch after batch.

Resistant Dextrin (≥82% Fiber): What Buyers Should Expect

What Resistant Dextrin Is (In Practical Terms)

Resistant dextrin is a soluble dietary fiber derived from starch sources such as corn or tapioca. It is designed to resist digestion in the small intestine, functioning as dietary fiber and supporting digestive wellness. From a formulation standpoint, resistant dextrin is valued because it can add fiber while keeping taste and texture clean.

When buyers search for a "Reliable Resistant Dextrin Manufacturer", they are usually trying to reduce three risks at once:

- Label risk (fiber claim must be supported by COA)

- Processing risk (heat/acid stability and solubility must hold in the real formula)

- Food safety risk (microbial and contaminant limits must be appropriate for the application)

Core Specification Items That Matter Most

A resistant dextrin spec sheet typically starts simple—appearance, fiber, and a few compositional limits. But those "simple" items are the ones that decide whether a product can be commercialized reliably.

Below is a concrete example of a resistant dextrin (nutritional dietary fiber) specification typically published by established suppliers.

Example: Resistant Dextrin ≥82% Fiber (Supplier Spec Excerpt)

| Parameter | Typical Buyer Interpretation | Example Specification (Published) |

|---|---|---|

| Product name | Confirms ingredient identity and purchasing code | Resistant Dextrin |

| Raw materials | Impacts labeling, sourcing, and allergen/GMO positioning | Corn starch |

| Appearance | First-line QC for lot-to-lot consistency | White to light yellow |

| Fiber content | Drives nutrition panel, claim substantiation, and cost-in-use | ≥82% |

| Protein content | A practical purity/consistency indicator for many buyers | ≤6.0% |

| Storage conditions | Helps prevent caking and moisture pickup in warehouses | Store in a cool place |

Why this matters: For many formulations, resistant dextrin is not added "for texture." It is added to deliver a fiber claim. If fiber content slips below target, the product can fail internal release testing or trigger label changes.

Origin of high-quality raw materials corn starch for resistant dextrin production

Where Specs Often Expand (And Why)

Many buyers also request additional COA lines for resistant dextrin—especially for beverages, dairy, and supplement formats. While limits vary by grade and market, buyers commonly screen:

- Moisture (affects flowability, caking, shelf stability)

- pH (relevant for beverage compatibility and stability expectations)

- Ash (a practical cleanliness/mineral residue indicator)

- Microbial limits (total plate count, yeast/mold, coliforms)

- Heavy metals (particularly for sensitive markets and child-focused products)

Procurement Reality: A resistant dextrin purchase decision is often "approved" on fiber content alone, but the most expensive failures are usually caused by the secondary lines—moisture, micro counts, or a mismatch in functional expectations.

What Production Details Signal to Buyers

Supplier descriptions frequently mention process controls because they correlate with consistency. Common signals include:

- Use of imported biological enzymes

- Automated central control from feeding through filling

- GMP-oriented workshop management and ISO-type systems

- Traceability from raw material to finished powder

These points are not substitutes for qualification, but they help a buyer understand whether a resistant dextrin line is likely designed for repeatability.

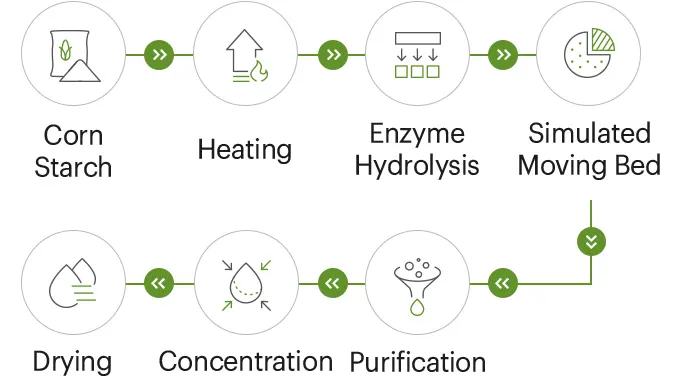

Production process diagram for functional dietary fiber manufacturing

Microcrystalline Cellulose (MCC): The Quality Fundamentals

What MCC Is Used For in Pharma and Nutraceuticals

Microcrystalline cellulose (MCC) is widely used as a pharmaceutical excipient and as a functional ingredient in nutraceutical formats. Depending on grade and application, MCC may serve as:

- Filler/diluent (tablet and capsule mass build)

- Binder (tablet strength)

- Disintegrant support (helping tablets break down appropriately)

- Flow aid in blends (especially when paired with actives that flow poorly)

Buyers looking for a "Recommended Microcrystalline Cellulose Supplier" are often balancing compliance with manufacturability: the MCC must meet pharmacopoeial expectations (when required) while also running smoothly on real equipment.

The MCC Specification Lines That Usually Drive Acceptance

Unlike resistant dextrin—where fiber content is the headline—MCC acceptance tends to depend on a cluster of parameters. Even when two suppliers both label a product "USP grade," the COA details can differ meaningfully.

Here are the MCC quality parameters that buyers typically review first:

| MCC Parameter (Typical COA Line) | Why Buyers Care | Common Downstream Impact |

|---|---|---|

| Identification / Compendial Statement | Confirms the standard being claimed (e.g., USP/EP alignment) | Regulatory filing confidence and internal QA release |

| Assay / Purity | Ensures the material matches excipient expectations | Batch acceptance; risk of nonconformance |

| Loss on Drying / Moisture | Impacts flow, sticking, and long-term stability | Tablet weight variation, capping, storage behavior |

| Residue on Ignition / Ash | Screens for inorganic residue and process cleanliness | Risk control for sensitive products |

| Particle Size Distribution | Drives flow, compressibility, mouthfeel (for chewables) | Tablet hardness, content uniformity, dusting |

| Bulk/Tapped Density | Helps predict filling behavior and compression response | Capsule fill accuracy; press performance |

Takeaway: If resistant dextrin is often bought "by the fiber number," microcrystalline cellulose is bought "by the profile." A single MCC COA line rarely tells the full story.

How to Read COAs Without Missing the Red Flags

A COA should be treated as a batch-level contract: it ties a shipment to defined limits and test methods. For both resistant dextrin and microcrystalline cellulose, procurement teams can reduce surprises by reading the COA in a fixed order.

Step 1: Verify Identity and Traceability First

- Product name and grade match the purchase order

- Batch/lot number is present and matches packaging labels

- Manufacturing date and/or retest date align with shelf-life expectations

- Test methods are listed (especially for regulated or pharmacopoeial claims)

If traceability is unclear, the numeric values become less meaningful.

Step 2: Check the "Deal-Breaker" Line

- For resistant dextrin, the deal-breaker is usually fiber content (e.g., ≥82% fiber for an 82% grade).

- For microcrystalline cellulose (MCC), the deal-breaker is typically the compendial claim + key physical parameters that match the formulation (often moisture and particle characteristics).

Step 3: Compare Results Against Your Functional Risk

This is where experienced buyers gain leverage. A supplier may be "within spec," but still create issues downstream.

- A resistant dextrin batch can meet fiber content yet behave differently in a beverage (solubility perception, viscosity, or stability under acid/heat).

- An MCC batch can meet compendial lines yet produce different tablet hardness or disintegration behavior if the particle size profile differs from what a process was tuned for.

Practical "COA Red Flags"

Resistant Dextrin Red Flags:

- Fiber content too close to the minimum (little buffer for method variability).

- Missing method reference for fiber determination.

- Microbial results inconsistent with prior lots.

MCC Red Flags:

- "USP grade" statement without supporting test lines or method identifiers.

- Particle size information missing when the buyer's process depends on it.

- Moisture drifting upward over time (potential storage or packaging weakness).

Weight reduction supplements and dietary fiber packaging examples

Matching Specs to End Use: Formulations in Practice

Specs become meaningful when they predict performance. Below are pairing notes that connect common applications to the specification lines most likely to matter.

Beverages and Drink Powders

In beverage systems, resistant dextrin is often selected because it can raise fiber while keeping the drink light.

- Priority: Neutral taste, clean finish, and stability across pH ranges.

- COA Check: Fiber content aligns with the label claim strategy; basic compositional controls.

Bakery and Fiber-Enriched Snacks

Baked products tend to stress ingredients through heat and mechanical mixing. Many formulators choose resistant dextrin because it can support fiber targets without the gritty texture associated with some insoluble fibers.

- Priority: When fiber is used to support "better-for-you" positioning, consistency becomes a brand-protection issue.

- COA Check: Water binding capacity (if tested) and viscosity indicators.

Tablets, Capsules, and Gummies

In solid-dose formats, microcrystalline cellulose is often the backbone of the blend. Buyers and formulators usually evaluate MCC alongside other excipients because compression and flow performance are system-level outcomes.

- Priority: The MCC grade must be appropriate for the dosage form and process.

- COA Check: Physical parameters (density, PSD) match the validated process window.

China as a Benchmark: What Clusters Signal

Chinese ingredient clusters—especially in provinces known for scale manufacturing—are often used as comparison points when buyers build RFQs. The reason is practical: mature clusters tend to develop standardized testing routines, packaging options, and export documentation habits.

For resistant dextrin, Shandong is frequently discussed as a major production base. Many buyers use published spec sheets from established suppliers in this region as a starting benchmark. That said, certification stacks (ISO, HACCP, Kosher, Halal) should be viewed as necessary but not sufficient. They indicate system intent, but buyers still need to confirm batch-level performance through COAs and qualification samples.

Using Transparent Supplier Pages as a Benchmark

Many buyers prefer to compare COAs against real-world, published specification examples before scheduling audits. One practical method is to benchmark against suppliers that openly publish resistant dextrin parameters (such as fiber content, appearance, and raw material source) and describe their quality systems.

For example, the resistant dextrin category and product pages at www.sdshinehealth.com provide publicly accessible specification excerpts (including resistant dextrin ≥82% fiber options) that can be used as one reference point when building an internal spec template.

The goal is not to "copy a spec," but to ensure your RFQ contains the lines that reputable manufacturers already treat as standard—and to spot the gaps when a quote arrives with missing COA detail.

Closing Thoughts: A Spec-First Habit

A strong purchasing decision for resistant dextrin and microcrystalline cellulose is rarely about finding the lowest price per kilogram. It is about minimizing hidden costs: reformulation cycles, delayed releases, and audit remediation. By standardizing how COAs are read—and by insisting that the fiber claim and the physical profile are both documented clearly—buyers can qualify suppliers faster and scale with fewer surprises.