Accessible nutrition is rapidly transforming soluble fiber and formulation structure from optional enhancements into non-negotiable requirements. For procurement teams, this shift fundamentally alters how a recommended Chinese resistant dextrin manufacturer or a microcrystalline cellulose supplier should be evaluated. In today's market, the specification sheet is merely the starting point; the actual performance behind those numbers is what drives success.

In practical terms, the majority of 2026-ready line extensions—whether they are functional bars, fortified shakes, instant coffees, or supplement powders—rely heavily on two foundational ingredients:

- Resistant Dextrin (often positioned as soluble corn fiber or soluble dietary fiber) to significantly raise fiber content while maintaining neutral taste and controlling viscosity.

- Microcrystalline Cellulose (MCC) to deliver essential body, stability, flow, and compression properties, particularly in tablets, capsules, and dry blends.

The 2026 Buyer Context Behind Resistant Dextrin and MCC

Two critical market signals explain why buyers are currently revisiting their specifications and approved supplier lists:

- Fiber is becoming a core nutrition claim, rather than a secondary label footnote. Industry trend coverage surrounding “accessible nutrition” highlights the expanding fiber frontier and a marked increase in consumer intent to boost fiber intake for digestive health and blood sugar management.

- Protein-led products are integrating “supporting ingredients.” Formulators are adding fiber for digestive comfort and satiety (weight management support), alongside excipients that ensure powders and tablets remain consistent in texture and stability.

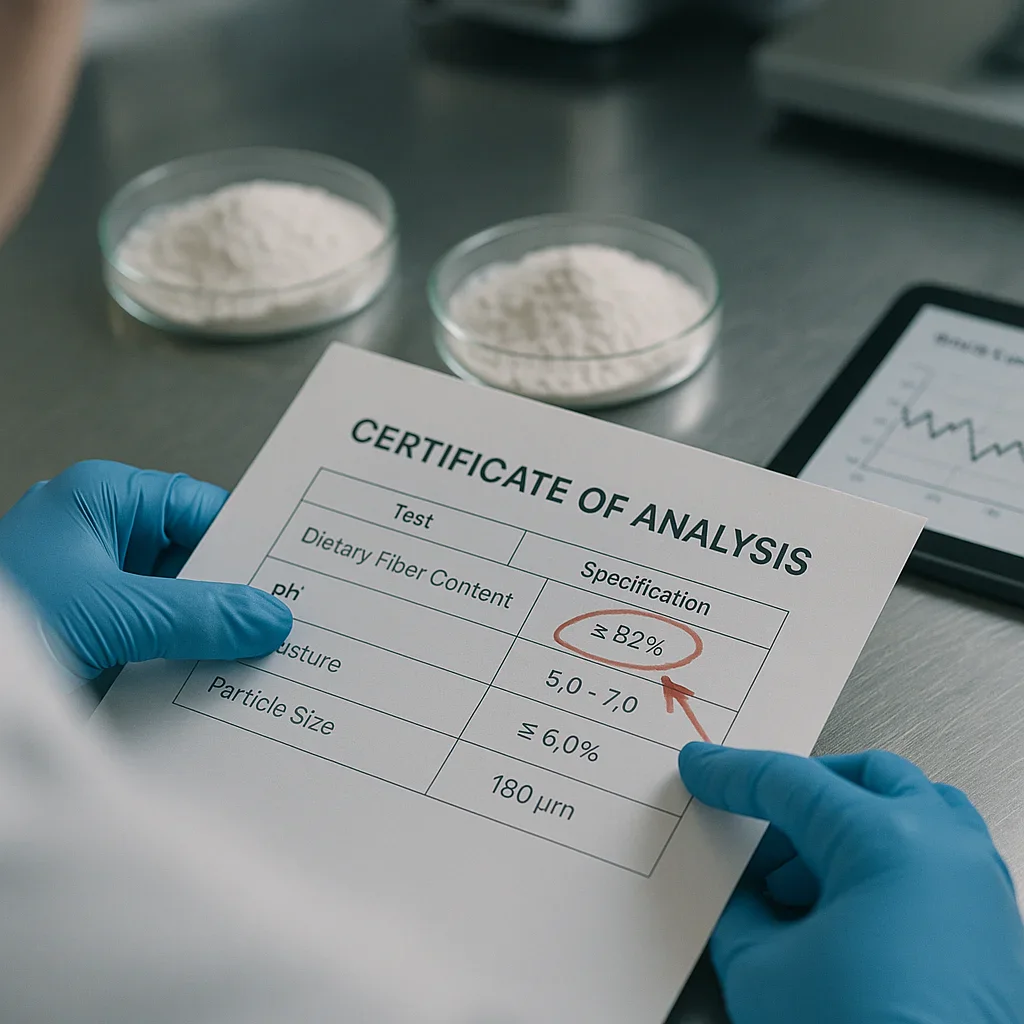

The immediate result is that procurement teams now require a much clearer working knowledge of resistant dextrin specifications (specifically ≥82% fiber) and the specific MCC parameters that influence real-world processing outcomes.

Resistant Dextrin Fundamentals for Procurement

Resistant dextrin is typically produced from starch—commonly NON-GMO corn starch in many high-quality commercial supply chains—using controlled conversion and advanced enzymatic steps. The result is a soluble dietary fiber that resists digestion in the small intestine, providing prebiotic benefits while behaving differently from regular dextrin in formulation.

For sourcing discussions, especially when benchmarking a resistant dextrin supplier in China against global alternatives, experienced buyers tend to focus on three “make-or-break” attributes:

- Fiber Strength and Consistency: Ensuring a consistent ≥82% dietary fiber grade to meet labeling requirements without over-dosing.

- Solubility and Process Tolerance: Heat stability and acid resistance are often required for beverages, baking, and coffee formats.

- Clean Sensory Footprint: A neutral taste and low viscosity are crucial to reduce reformulation risks in flavor-sensitive applications.

What “≥82% Fiber” Means in Buying Language

A fiber threshold like ≥82% is frequently used as a commercial anchor because it simplifies claims planning and helps set clear expectations for the dose required per serving. However, 82% fiber resistant dextrin is not just about meeting a single number on a datasheet. It directly affects:

- Serving-Size Math: How much powder must be added to achieve a "high fiber" claim without negatively impacting texture or sweetness.

- Powder Handling: Factors like flowability and dusting during the blending process.

- Batch-to-Batch Repeatability: Critical for maintaining consistency in RTD bases and stick packs.

A procurement team that treats “≥82% fiber” as a performance signal—rather than just a pass/fail limit—generally qualifies reliable suppliers faster.

A Quick Spec Snapshot for RFQs

Below is a practical “RFQ-ready” summary for common resistant dextrin discussions. These values serve as typical procurement reference points and should always be verified against the specific supplier COA.

| COA Item (Resistant Dextrin) | Why Buyers Care | Common Decision Impact |

|---|---|---|

| Dietary Fiber (e.g., ≥82%) | Determines claim feasibility and dosing | Impacts label claims and cost-per-serving |

| Appearance | White to light yellow powder | Ensures visual consistency in final product |

| Protein (e.g., ≤6.0%) | Consistency and purity expectation | Influences allergen control and spec alignment |

| pH Range | Stability in acidic drinks and coffee | Impacts solution clarity and flavor perception |

| Micro Limits | Export readiness and RTD risk control | Affects QA release speed and safety |

For buyers looking to compare formats and grade options, examining a supplier’s detailed category overview for resistant dextrin is often the most direct starting point.

Microcrystalline Cellulose Basics Connecting to Outcomes

Microcrystalline Cellulose (MCC) is derived from purified cellulose via controlled processing to produce a white or almost white powder (or granular powder). Crucially, it is insoluble in water, ethanol, and ether, which is exactly why it behaves as a structural tool rather than a soluble fiber.

In procurement conversations, MCC typically appears in two distinct roles:

- As a pharmaceutical excipient (binder, diluent, disintegrant) for high-quality tablets and capsules.

- As a food and supplement processing aid (anti-caking, bulking, texturizing) in nutritional powders, chewables, and functional blends.

MCC Grades and Specs Buyers Should Recognize

Many established Chinese suppliers offer multiple MCC grades such as PH-101, PH-102, PH-103, PH-105, PH-112, PH-113, PH-200, PH-301, and PH-302. The differences are typically connected to particle size, moisture content, and flow/compression behavior.

A buyer evaluating a microcrystalline cellulose MCC manufacturer should expect absolute clarity on the following:

- Grade Fit: Is the grade optimized for direct compression (e.g., PH-102, PH-200) or wet granulation (e.g., PH-101)?

- Mesh Range: Does the particle size (e.g., 60–200 mesh) match the flow requirements of the blending equipment?

- Standard Alignment: Does the material meet BP, USP, FCC, or JP standards for global compliance?

- Certifications: Are ISO9001, Kosher, and Halal certifications available for audit readiness?

For product-page level spec reading and typical grade language, buyers often start at a supplier category such as microcrystalline cellulose.

How to Read a Resistant Dextrin COA Without Missing Risks

Most Certificates of Analysis (COAs) are designed to prove compliance, not necessarily to explain application performance. When comparing a China resistant dextrin manufacturer shortlist, it is helpful to translate the COA data into specific production questions.

The COA Lines That Decide Performance

- Dietary Fiber Content: Confirms the commercial grade (e.g., resistant dextrin specifications 82% fiber). Ask whether the supplier can demonstrate consistency across multiple production lots.

- Moisture / Water Activity: Impacts caking risk, flowability, and shelf stability, particularly in stick pack formats.

- Ash: A practical signal for mineral residue purity; high ash can affect taste neutrality.

- pH: Matters significantly for acidic applications (sparkling drinks, flavored waters) and for preventing curdling in coffee.

- Microbiology (TPC, Yeast, Mold, Coliforms): A “quiet” driver of export friction—especially for ready-to-drink bases where strict limits are non-negotiable.

A Practical Micro and pH Checkpoint

Some COA formats used in soluble fiber procurement discussions reference limits such as a pH in a working range (often cited around 3–6) and total plate count limits (commonly ≤1,000 CFU/g). While these values are not automatically interchangeable across all suppliers, they serve as a useful language bridge for RFQs.

MCC Spec Reading for Tablet Projects

With MCC, the most expensive failures are rarely the assay result—they are manufacturing failures: powder that won’t flow, tablets that cap or laminate, or capsules with variable fill weights. While pharmacopeial alignment is essential, buyers must ensure the MCC datasheet provides enough detail to predict process behavior.

Procurement Questions That Separate “Listed” MCC from Usable MCC

When evaluating a China microcrystalline cellulose supplier, ask for information that connects the grade to the operation:

- Which PH grade is recommended for direct compression vs. wet granulation blends?

- What is the target bulk density / flowability window for the specific grade?

- What is the supplier’s standard approach to loss on drying control?

If a supplier can only confirm “BP/USP/FCC/JP” compliance but cannot guide grade selection (e.g., explaining when to use PH-101 vs. PH-102), the buyer often ends up paying for unnecessary pilot testing.

Why Resistant Dextrin and MCC Are Often Paired

In modern “accessible nutrition” launches, resistant dextrin and microcrystalline cellulose perform different but complementary roles:

- Resistant Dextrin contributes soluble dietary fiber with minimal sensory disruption—ideal for beverages, coffees, and nutrition powders.

- Microcrystalline Cellulose contributes structure and processing reliability—essential for tablets, capsules, and powdered systems that must remain free-flowing.

A practical example of fiber-forward line planning is to specify resistant dextrin as the primary fiber carrier, then choose MCC as the format stabilizer only when the dosage form requires it.

The Recommended Supplier Checklist for China Shortlists

A “recommended Chinese microcrystalline cellulose manufacturer” or “recommended Chinese resistant dextrin manufacturer” is rarely defined by a single certificate. Procurement teams typically converge on a short list when the supplier can demonstrate the basics consistently.

For Resistant Dextrin Suppliers in China

- Grade Definition: Clear and repeatable ≥82% fiber supply.

- Raw Material Transparency: A stated use of NON-GMO corn starch (or tapioca) ensures safety and marketability.

- Comprehensive COA: Includes key safety and quality lines (micro, pH, moisture).

- Process Controls: Advanced production capabilities (e.g., biological enzymes, automated control systems) that reduce lot variation.

Buyers looking to benchmark common product positioning language can review examples such as nutritional dietary fiber powder and resistant maltodextrin listings to see how leading suppliers present fiber grades and typical parameters.

For Chinese MCC Suppliers

- Grade Availability: A full PH series aligned to tablet and capsule needs.

- Standards Alignment: Stated compliance with BP/USP/FCC/JP and supporting documentation.

- Factory Discipline: GMP-style workshop environments and strict QC documentation practices.

- Packaging: Consistent, moisture-proof packaging with full traceability for export lots.

Conclusion: What “Recommended” Should Mean

The phrase recommended Chinese resistant dextrin manufacturer should not be treated as a mere marketing label. In procurement terms, “recommended” implies predictable COA patterns across lots, strong technical clarification during RFQ and pilot stages, and fewer surprises between sample approval and bulk delivery.

For teams building a 2026 pipeline, the fastest way to reduce sourcing risk is to treat resistant dextrin and microcrystalline cellulose as spec-led ingredients, not commodity powders. Once internal spec literacy is in place, supplier evaluation becomes quicker, negotiation becomes cleaner, and reformulation risk drops.

If you are looking for a partner who meets these rigorous standards, Shandong Shine Health Co., Ltd. provides a robust portfolio of resistant dextrin and excipients designed for global markets. For detailed specifications or to request a quote, please visit www.sdshinehealth.com.