2026 fiber tech favors heat-stable resistant dextrin and smarter MCC sourcing. Learn specs, COA checks, and China supplier signals for scale.

Fiber innovation is moving from “nice-to-have” to product infrastructure. In 2026, the formulas that win tend to have three traits at the same time: high fiber without sensory penalties, stable processing across heat and pH, and documentation that stands up to buyer audits. That is why resistant dextrin is becoming the default soluble fiber in many modern concepts—and why procurement teams are increasingly pairing resistant dextrin decisions with excipient decisions like microcrystalline cellulose (MCC) for supplement formats.

1) Why fiber is the “quiet headline” ingredient in 2026

A few signals explain why fiber—especially resistant dextrin—keeps showing up in R&D roadmaps. First, consumer demand is converging around gut health + satiety. Market commentary increasingly frames functional fiber as the “accessible nutrition” add-on that can sit next to protein, not compete with it.

Second, fiber is now a formulation problem, not just a nutrition problem. Brands want higher fiber with minimal taste, minimal viscosity, and minimal stability risk—requirements that push buyers toward resistant dextrin.

Finally, procurement expectations are rising. Teams want a resistant dextrin supplier that can deliver consistent lots, rapid samples, and a COA that is more than a checkbox.

Data snapshot (what most R&D teams are planning around)

* Global dietary fibers market growth is projected at ~7.9% CAGR from 2026 to 2035 in one widely cited outlook.

* Industry coverage suggests functional fiber could become one of the most dominant 2026 wellness themes, driven by gut health interest and satiety demand.

This is the backdrop for the “fiber 2.0” expectation: resistant dextrin should behave like a clean, stable, low-sensory-impact building block, not an ingredient that forces compromises.

2) Resistant dextrin as “Fiber 2.0”: what changes in 2026 formulas

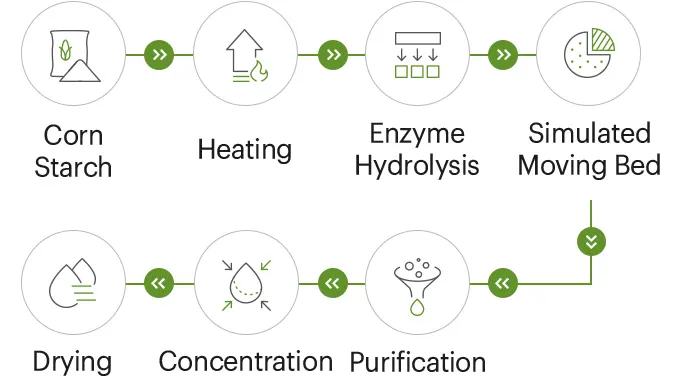

Resistant dextrin is often described as a soluble dietary fiber produced by controlled breakdown of starch (commonly corn starch). The reason it fits 2026 product design is that resistant dextrin is engineered for performance in modern formats, not just for nutrition panels.

Key capabilities buyers are leaning on

Across many 2026 concepts, resistant dextrin is chosen because it typically supports the following practical outcomes:

- High solubility and neutral sensory profile for beverage and powder mixes

- Low viscosity compared with many traditional fibers, helping keep “high fiber” beverages drinkable

- Heat stability and broad pH tolerance that align with pasteurization, hot-fill, and acidic drinks

- Low glycemic positioning that aligns with low-sugar and diabetic-friendly product lines

- Prebiotic fiber positioning, where resistant dextrin can be used to support beneficial gut bacteria (depending on regulatory framework and labeling strategy)

In supplier documentation from established manufacturers, buyers will commonly see a clear fiber specification such as fiber content ≥82% for resistant dextrin.

Resistant dextrin vs. traditional fibers (what really matters in product design)

The table below summarizes why resistant dextrin is frequently selected when teams want “more fiber” without rewriting the sensory story.

| Buyer priority (2026) | Many traditional fibers | Resistant dextrin (typical positioning) | Why it matters to procurement |

|---|---|---|---|

| Mixability in cold water | Often variable | Commonly strong | Fewer reformulations and fewer customer complaints |

| Viscosity impact | Can be noticeable | Typically low | High-fiber RTD and powdered beverages stay drinkable |

| Taste neutrality | Can be cereal-like or “planty” | Often clean/neutral | Reduces flavor masking cost |

| Heat/pH stability | Can vary by fiber type | Often stable | Lower risk in pasteurized or acidic products |

| Low-GI positioning | Depends on fiber | Often positioned as low GI | Helps align with low-sugar and weight-management lines |

When buyers evaluate a resistant dextrin supplier, the question becomes less “Does it have fiber?” and more “Does the resistant dextrin behave predictably in the exact process conditions we run?”

3) The China plant upgrade cycle: what “innovation-ready” looks like now

China remains a major production hub for functional ingredients, including resistant dextrin. What is changing is not only capacity—but the “floor” of what buyers expect from a resistant dextrin supplier.

In many modern plants (especially across established clusters that global buyers often associate with ingredient manufacturing), the upgrade story tends to include:

- Non-GMO corn starch sourcing as a defined raw material strategy

- Enzymatic processing using imported biological enzymes (a common supplier talking point when emphasizing control and performance)

- Precision production lines (some suppliers highlight equipment origin, such as German lines, to signal stability and repeatability)

- Automation and central control operation from feeding through filling to reduce variability

- In-house QC laboratories capable of routine checks and release testing

- GMP-aligned workshops and food safety systems (frequently supported by ISO/HACCP-style frameworks)

These upgrades directly affect procurement risk. A resistant dextrin supplier that operates with automation, strong QC, and documented controls is simply easier to qualify—especially when the target application is sensitive to viscosity, clarity, or heat stability.

Why process visibility is becoming a purchasing advantage

In 2026, speed matters. Launch windows are tighter, and R&D teams want faster pilot cycles. A resistant dextrin supplier that can clearly explain production steps and controls typically accelerates sample-to-pilot turnaround, issue resolution (e.g., clarity in an RTD system), and documentation review for internal quality teams.

4) Where resistant dextrin is winning: 2026 application patterns buyers keep repeating

A simple way to predict ingredient demand is to track formats that are expanding. Resistant dextrin is repeatedly selected because it can deliver fiber without forcing a “thick drink” or a gritty texture.

Pattern A: High-fiber beverages that still taste clean

For beverage teams, resistant dextrin is often used as a high-fiber beverage ingredient because it can stay relatively neutral and stable. Common 2026 beverage directions include Low-sugar RTD teas and flavored waters that want fiber without heaviness, Acidic beverages where pH stability is a gating requirement, and Powdered drink mixes where instant solubility and clean taste matter.

In these projects, buyers typically shortlist a resistant dextrin supplier based on clarity/solubility performance, lot-to-lot consistency, and how quickly the supplier can support troubleshooting.

Pattern B: Low-carb and reduced-sugar foods that need bulk without “net carbs” optics

Low-carb product development often needs bulk, mouthfeel, and label-friendly strategies. Resistant dextrin is frequently positioned as a tool that can increase fiber while helping reduce net-carbohydrate perception. It also supports sweetness reduction strategies (where appropriate) without introducing high-intensity sweetener aftertastes and improves texture in bars, snacks, baked goods, and sauces.

In this pattern, a China bulk resistant dextrin supply strategy can be attractive—provided the resistant dextrin supplier supports the required QC documentation and stable logistics.

Pattern C: Supplements—where resistant dextrin and MCC solve different problems

In supplements, resistant dextrin often appears in stick packs, drink powders, fiber blends, and gummies (as part of a broader solids strategy). Conversely, MCC often appears for different reasons: it is widely used as a tablet/capsule excipient, supporting flow, compressibility, and structure.

So teams often evaluate in parallel: a resistant dextrin supplier that can support beverage trials, low-sugar claims strategy (where permitted), and prebiotic positioning, alongside a microcrystalline cellulose supplier China buyers can trust for grade consistency and excipient documentation. In procurement terms, the “innovation-ready” play is not to treat MCC as an afterthought. MCC decisions can determine whether the supplement line launches smoothly after the food or beverage line succeeds.

5) The technical checks that define an innovation-ready resistant dextrin supplier

Innovation-ready procurement is not about buying the most complex spec sheet. It is about buying the right proof for the application risk.

Start with the minimum spec that actually protects the formula

For resistant dextrin, many buyers treat fiber content ≥82% as a baseline when comparing lots and suppliers. From there, the practical checks typically expand to:

- Appearance and color (white to light yellow is commonly listed)

- Solubility behavior under the intended mixing conditions

- pH behavior in the target beverage range

- Moisture control expectations for storage stability

A resistant dextrin supplier should be able to provide a COA that matches the agreed specification and a sampling workflow that supports verification.

COA and documentation checklist buyers are using in 2026

Use the table below as a procurement-ready prompt list. It is intentionally phrased as “what to ask for,” because final targets depend on application and region.

| What to request | Why it matters in 2026 | How it reduces risk |

|---|---|---|

| COA with fiber content (often stated as ≥82%) | Confirms the core value proposition of resistant dextrin | Prevents drift in finished-product nutrition targets |

| Appearance/color statement | Supports consistency for light-colored beverages and powders | Helps avoid “unexpected yellowing” in finished goods |

| Solubility and viscosity notes (method-defined) | Protects mouthfeel and clarity claims | Reduces reformulation cycles |

| Heat stability information relevant to your process | RTD and baked goods depend on it | Prevents breakdown during pasteurization/hot fill |

| Micro and contaminant controls (region-specific) | Critical for supplements and global distribution | Reduces import and release delays |

| Traceability statement for raw material sourcing | Helps with internal compliance and brand risk controls | Makes audits easier |

| Sample retention and re-test policy | Protects long-running programs | Improves dispute resolution |

| R&D support and application guidance | Speeds up development | Cuts internal trial-and-error cost |

A resistant dextrin supplier that can respond quickly—with consistent documentation—often becomes the default partner, especially once a fiber SKU scales.

6) What buyer teams often overlook: “heat stability” is not one test

Many buyers treat “resistant dextrin heat stability” as a yes/no claim. In practice, heat stability is contextual: Temperature and time (e.g., short pasteurization vs. long retort), pH and acidity system (citric acid behaves differently than other systems), Mineral content (hard water and electrolytes can change perception), and Co-ingredients (sweeteners, flavors, proteins, acids, and polyols).

So the more useful question for a resistant dextrin supplier is: "Can the supplier provide a clear method and history for how resistant dextrin performs under beverage-like conditions, not just in a generic statement?" In 2026, supplier technical support is not “nice”; it is often what keeps a product on schedule.

7) Why Shandong-style operational capabilities keep coming up in sourcing conversations

Buyers discussing Shandong resistant dextrin manufacturers often highlight operational traits more than marketing claims: mature export workflows and documentation discipline, experience shipping bulk ingredients across multiple regions, production lines designed for consistency and repeatability, and QC labs that can support routine release and troubleshooting.

This is also why many procurement teams do not just search “resistant dextrin China manufacturer.” They search for a resistant dextrin supplier that is demonstrably process-controlled and audit-friendly.

One representative manufacturer directory entry that aligns with many of the “innovation-ready” traits buyers screen for (dedicated R&D/quality teams, export experience, and documented product pages) can be found at:

(As always, buyers should run their own qualification steps—samples, documentation review, and application testing—before scaling.)

8) The MCC side of the story: why fiber buyers still care

Even if the hero ingredient is resistant dextrin, many product pipelines include a supplement extension. That extension often introduces MCC. For buyers, the practical reality is that while resistant dextrin supports fiber delivery and formulation flexibility across foods and beverages, MCC supports physical performance in tablets/capsules and sometimes texture in certain formats.

So teams often evaluate in parallel: a resistant dextrin supplier that can support beverage trials, low-sugar claims strategy (where permitted), and prebiotic positioning, alongside a microcrystalline cellulose supplier China buyers can trust for grade consistency and excipient documentation. In procurement terms, the “innovation-ready” play is not to treat MCC as an afterthought. MCC decisions can determine whether the supplement line launches smoothly after the food or beverage line succeeds.

9) 2026 buyer takeaways: how to align product innovation with supplier reality

For most procurement and R&D teams, the 2026 opportunity is straightforward: use resistant dextrin as the low-friction path to higher fiber, and treat supplier selection as part of the innovation stack.

A practical shortlist for an innovation-ready resistant dextrin supplier

Without overcomplicating it, an innovation-ready resistant dextrin supplier usually demonstrates a clear resistant dextrin specification and consistent COA delivery (often featuring fiber content ≥82%), documented process discipline (automation, central control, defined QC steps), fast sampling and responsive technical support, export experience and stable logistics, and a transparent raw material approach (commonly non-GMO corn starch in supplier positioning).

Where buyers get the fastest wins

Procurement teams typically see quick ROI from three actions:

- Define “pass/fail” application tests early (clarity, viscosity, heat stability, pH stress) and align them with the resistant dextrin supplier.

- Lock in COA items that protect the business case (fiber content, appearance, moisture expectations, and region-specific safety metrics).

- Build a two-ingredient roadmap when supplements are on the horizon: resistant dextrin for fiber delivery, and MCC for dosage-form performance.

Done well, resistant dextrin is not just another label claim. It becomes a scalable platform ingredient—especially when the resistant dextrin supplier is selected for documentation quality and application support, not for a single low quote.