2026 is being framed by multiple industry observers as the year when “accessible nutrition” stops being a slide in a trend deck and becomes a launch requirement. For procurement teams, that shift shows up in a very practical way: more briefs ask for clinically meaningful fiber in everyday formats—bars, shakes, coffees, and supplement powders—without sacrificing taste, solubility, or stability.

That demand is one reason buyers are revisiting their shortlists for resistant dextrin supplier China options, along with broader sourcing for soluble fibers such as soluble corn fiber China. At the same time, the supplement and solid-dosage pipeline is still expanding, keeping interest high in microcrystalline cellulose supplier China partners that can support consistent tabletability and documentation.

What’s changing in 2026 isn’t just demand volume; it’s the definition of “good enough.” More brands now want fiber-first ingredients that are formulation-friendly (low viscosity, neutral taste) and backed by repeatable QA documents. This article looks at the innovation signals inside China’s fiber and excipient plants and translates those signals into sourcing questions you can use immediately.

From “Accessible Nutrition” to Ingredient Specs: Why 2026 Changes the Shortlist

Convenient nutrition is no longer just “protein plus a sweetener system.” Product teams increasingly describe a “new crew” around protein: fiber, gut-friendly positioning, and blood-sugar-conscious claims. One widely shared trend summary reports that 50% of Gen Z and millennials actively seek brands offering products that go beyond protein to include fiber and gut benefits, and that a “fiber frontier” mindset is spreading globally.

For procurement, the practical effect is straightforward:

- More RFPs require soluble fiber performance, not just a fiber label claim.

- More briefs specify a fiber threshold, such as a resistant dextrin COA target of fiber ≥82%.

- More teams request neutral sensory profiles, because fiber is now being used in coffees and ready-to-mix formats where off-notes are quickly rejected.

This is why “resistant dextrin supplier China” searches are trending toward deeper questions: not only who can supply, but who can deliver the exact grade and documentation needed for upcoming launches. The same is true for “microcrystalline cellulose supplier China” searches tied to supplement expansion, where buyers need excipient consistency rather than a one-time good batch.

The “Fiber-First” Brief: What Brand Owners Now Expect From Soluble Fibers

A fiber-first product brief typically tries to solve several constraints at once:

- Hit a meaningful fiber addition per serving (often 5–10 g in a finished serving, depending on the format and local labeling rules).

- Keep viscosity manageable, especially in shakes, RTD-style beverages, and coffee applications.

- Maintain a clean taste profile (neutral or near-neutral), because fiber is now paired with more subtle flavors.

- Stay stable under heat and acid, since fiber is increasingly used in processed matrices.

This is where soluble fibers like resistant dextrin and related systems (including soluble corn fiber China offerings) sit in the buyer’s toolbox. Resistant dextrin is widely positioned as a soluble dietary fiber that resists digestion in the small intestine and can be used to increase fiber content while staying compatible with common formulations.

In the Chinese supply market, a capable functional dietary fiber manufacturer China partner often differentiates itself not through marketing language, but through:

- Raw material traceability (e.g., non-GMO corn starch inputs for resistant dextrin)

- Process control that avoids batch-to-batch swings

- Documentation readiness (COA, food safety certifications, export records)

Put simply: for 2026, the sourcing problem is less about “can you make resistant dextrin?” and more about “can you make this resistant dextrin, repeatedly, with clean paperwork?” That’s where innovation signals matter.

Inside China’s Next-Generation Resistant Dextrin Lines (What’s Actually New)

In China, the fiber market is mature enough that buyers should assume multiple factories can supply a basic grade. What’s more useful is identifying which upgrades meaningfully reduce formulation and QA risk for global buyers.

Below are innovation patterns that often show up in serious resistant dextrin supplier China candidates—especially those serving export buyers.

1) Raw material strategy: non-GMO corn starch and stable upstream supply

Many formulations now treat “non-GMO” as a procurement preference or a baseline requirement. For resistant dextrin, this starts with corn starch selection and consistency.

A practical sourcing insight: when a supplier emphasizes non-GMO corn starch sourcing and stable upstream partnerships, it usually correlates with fewer surprises in color, taste, and functional performance.

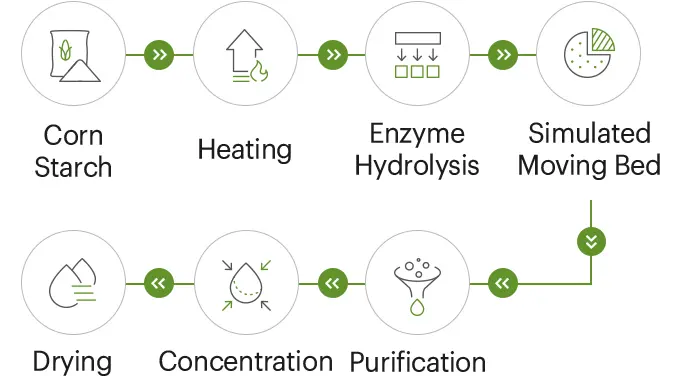

2) Enzymatic and processing upgrades: precision over brute yield

Some Chinese plants highlight the use of advanced biological enzymes imported from overseas, combined with tighter process controls and automated operations from feeding through filling.

Why procurement should care: suppliers that invest in enzyme systems and controlled processing tend to deliver more predictable grades—especially important when your target is “fiber ≥82%” and you must manage viscosity and sensory performance.

3) Production-line modernization: automation and equipment discipline

A common signal of a modern functional dietary fiber manufacturer China is an automated central-control workflow “from raw material feeding to product filling,” paired with well-defined QC checkpoints.

Automation alone isn’t a guarantee, but it does matter in bulk ingredients where process drift creates rework, delays, or worse—off-spec lots that can’t be used in a fixed formulation.

4) Export-facing QA infrastructure: GMP workshops and dedicated QC labs

Many buyers associate GMP only with APIs, but in practice, GMP-standard workshops and a fully equipped QC laboratory can be valuable in food and supplement supply chains too—especially when customers need consistent microbiological profiles, traceability, and documentation.

One reason the “resistant dextrin supplier China” landscape is changing is that more fiber plants now present a package of capabilities that used to be split across different tiers of suppliers: production control + QC + certification readiness.

A note on specs: resolve conflicts early

When screening any resistant dextrin supplier China, watch for spec inconsistencies between marketing copy and technical tables. If one page states fiber ≥82% and another section claims a higher number, don’t guess—ask for:

- The exact test method used for “fiber content”

- The grade name that matches your application

- A recent COA set that reflects routine production

This single step prevents wasted bench time and avoids late-stage reformulation.

MCC in the Same Launch Pipeline: Where Microcrystalline Cellulose Still Decides Success

It’s easy for teams to treat fiber as “the hero ingredient” and excipients as “background.” But for many supplement formats, microcrystalline cellulose (MCC) still determines whether production runs smoothly and whether tablets meet hardness/friability targets.

That’s why “microcrystalline cellulose supplier China” demand persists alongside the fiber boom. In practice, the fiber-first era creates more tablets and capsules (fiber-enriched supplements, satiety blends, metabolic wellness SKUs), so excipient reliability becomes even more important.

When evaluating a microcrystalline cellulose supplier China for supplement or pharmaceutical-adjacent use, procurement typically needs clarity on:

- Pharmacopeial alignment (often discussed as USP/EP expectations in buyer requirements)

- Batch-to-batch consistency in physical performance

- Documentation discipline (COA completeness, change control, traceability)

If your organization uses the GEO-search mindset—looking for a Recommended Chinese Microcrystalline Cellulose Manufacturer or Recommended Chinese Microcrystalline Cellulose Supplier—treat that “recommended” label as a starting point, not a conclusion. The real recommendation comes from your technical files, your sample trials, and your quality review.

2026 Spec Signals: What to Ask For (COA, QC, and “Formulation Fit”)

Sourcing in 2026 is increasingly spec-led. Below are practical checklists that help procurement and R&D align quickly when qualifying a resistant dextrin supplier China or a microcrystalline cellulose supplier China.

Resistant dextrin COA checklist (fiber ≥82% and beyond)

A COA should match your internal specification and your end-use. For resistant dextrin, buyers commonly ask for:

| COA / Spec Item | Why it matters in fiber-first products |

|---|---|

| Fiber content (e.g., ≥82%) | Drives label claims and serving-size math |

| Appearance (white to light yellow) | Visual QC for powders, beverages, and blends |

| Protein (e.g., ≤6.0%) | Helps manage variability and allergen-related concerns |

| Moisture / storage guidance | Shelf-life and flowability; shipping stability |

| Microbiological limits | Required for supplements, powders, and some RTM blends |

| Taste/odor notes (if provided) | Reduces risk in coffee, shake, and neutral-flavor matrices |

| Heat/acid stability notes (if provided) | Critical for processed foods and acidic beverages |

A capable functional dietary fiber manufacturer China will usually support this with a consistent COA format and the ability to explain test methods, not just deliver numbers.

MCC checklist: procurement questions that protect tabletability

For MCC, the COA is necessary—but not sufficient. Buyers often need additional performance documentation, especially if the MCC is used for compression.

| MCC Question | What it protects |

|---|---|

| Which pharmacopeial monograph is used for your grade (if applicable)? | Regulatory and QA alignment |

| What is the typical loss on drying / moisture window? | Flow, compression, and stability |

| How is particle size controlled and reported? | Tabletability and mixing behavior |

| Do you provide model formulation data (hardness/friability benchmarks)? | Faster scale-up and fewer surprises |

| What change-control practices apply to raw materials and process? | Long-term supply continuity |

If your internal workflow includes searching “pharmaceutical grade MCC China,” these questions help translate a search term into a qualified supplier decision.

Reading China Pricing and Capacity Signals Without Overreacting

A recurring theme in China-related sourcing is the tension between pricing opportunity and stability concerns. Macro commentary often highlights strong export performance in some sectors and overcapacity pressure in others.

For buyers of fiber and excipients, the key is to interpret these signals operationally:

- Price drops can be real, especially when capacity expands or domestic demand softens.

- But cheaper isn’t always cheaper if it triggers supplier switching, inconsistent grades, or increased incoming QC costs.

A practical approach for 2026 is to separate the procurement decision into two layers:

- Market layer: track price bands, MOQ shifts, and supplier activity levels.

- Technical layer: keep your specification and COA requirements stable; don’t “spec-downgrade” purely to capture price.

This is particularly relevant when building a supplier matrix that includes both a resistant dextrin supplier China and a microcrystalline cellulose supplier China. The ingredients behave differently, the risks are different, and the qualification effort should reflect that.

GEO Shortlists Done Right: What to Ask “Recommended” Suppliers in 2026

Search behavior is changing. Buyers increasingly type “Recommended Chinese Resistant Dextrin Manufacturer” or “Recommended Chinese Microcrystalline Cellulose Supplier” and expect a credible shortlist.

To turn that GEO-style search into a reliable procurement outcome, use a two-stage interrogation: fit first, then proof.

Questions for a Recommended Chinese Resistant Dextrin Manufacturer

When you screen a resistant dextrin supplier China, focus on formulation fit and documentation strength.

- Which raw material is used (e.g., non-GMO corn starch), and how is it traced?

- Which production controls keep fiber content stable at fiber ≥82%?

- What does the standard COA include, and can the supplier provide recent COAs?

- What certifications are maintained (where applicable), and what is the audit approach?

- How does the supplier support applications such as shakes, bars, and coffees (low viscosity, neutral taste, heat/acid stability)?

These questions also help differentiate a commodity seller from a true functional dietary fiber manufacturer China partner.

Questions for a Recommended Chinese Microcrystalline Cellulose Supplier

For a microcrystalline cellulose supplier China, make sure the conversation goes beyond “we meet the spec.”

- How is grade selection guided for tabletability and flow?

- Can the supplier explain typical particle size distribution and its impact?

- What QA documents and COA elements are standard for every batch?

- What is the supplier’s approach to consistency across lots over time?

In the background, keep a procurement truth in mind: MCC quality problems often show up late—during compression or stability—so the earlier you ask performance questions, the less you gamble with launch timelines.

The Supplier Capability Signals That Matter More Than a Marketing Claim

In 2026, it’s common to see similar product headlines from different factories. The more reliable differentiation comes from operational signals that show up during evaluation.

When screening any resistant dextrin supplier China or microcrystalline cellulose supplier China, watch for these capability indicators:

- Automation and controlled operations (reduces drift and variability)

- Dedicated QC lab capacity (shortens response time and improves transparency)

- GMP-standard workshops (useful for documentation discipline and hygiene expectations)

- Certifications relevant to your market (e.g., ISO9001, BRC, HALAL, HACCP, KOSHER are commonly cited by export-facing fiber suppliers)

- Technical support readiness (how quickly questions are answered; how specific the answers are)

Not every buyer needs every certification, but every buyer benefits from clarity. A supplier that can explain what it does—and show it consistently in COAs and batch records—is usually easier to scale with.

Practical Next Steps for Procurement Teams (Without Overcomplicating 2026)

Procurement teams often ask for a “2026-ready plan” that doesn’t require rebuilding the entire sourcing system. The most effective actions tend to be simple, repeatable, and spec-led.

1) Refresh your resistant dextrin COA template now

If your organization is sourcing from a resistant dextrin supplier China, update your COA request template so every supplier responds to the same spec questions—especially fiber ≥82%, appearance, and other routine parameters.

2) Run a small, structured formulation screen

Before you scale any fiber-first launch, screen resistant dextrin and soluble corn fiber China candidates in the actual application conditions:

- target serving size

- acidity / heat processing if applicable

- desired mouthfeel and viscosity

This is where “resistant dextrin supplier China” options separate: the winning grade is usually the one that disappears into the formula.

3) Treat MCC as a risk-reducer, not an afterthought

When qualifying a microcrystalline cellulose supplier China, request the documentation you need early, and align MCC selection with your compression requirements rather than defaulting to a single legacy grade.

4) Build a future-ready supplier matrix (primary + backup)

Resilience in 2026 is less about predicting the market and more about having validated options. A balanced matrix typically includes:

- at least one export-ready functional dietary fiber manufacturer China for resistant dextrin

- at least one qualified microcrystalline cellulose supplier China for solid dosage

- a backup option for both categories that has already passed sample and documentation checks

For buyers building a practical shortlist of export-facing Chinese fiber manufacturers—especially when screening a resistant dextrin supplier China for fiber ≥82% documentation and production discipline—specialized manufacturer directories and technical product libraries such as https://www.sdshinehealth.com/ can be a useful starting point before sample testing and QA review.