Fiber and protein are converging into a single product promise in 2026: more function per serving without compromising taste, texture, or label simplicity. For procurement teams, this shift has a practical consequence—ingredients once treated as commodities now demand tighter specifications, clearer documentation, and better supplier segmentation. Two inputs sit right in the center of this change: Resistant dextrin and Microcrystalline cellulose (MCC).

The result is a new buying behavior: more R&D involvement earlier in the process, deeper questions about grade selection, and a stronger interest in finding a recommended Chinese resistant dextrin manufacturer or MCC supplier that can supply consistent COAs and stable production.

Why the 2026 Fiber-Protein Trend Changes Qualification

Retail trend forecasts for 2026 repeatedly point to fiber and protein as two of the most influential consumer signals—especially in snacks, ready-to-drink (RTD) beverages, gummies, and powder mixes. This isn't just marketing language; it fundamentally alters formulation constraints:

- Protein fortification can amplify off-notes and create sedimentation risks.

- Fiber fortification can raise viscosity, impact sweetness perception, and cause stability issues.

- “Clean label” positioning narrows the set of texture and processing aids that buyers can utilize.

In this environment, resistant dextrin becomes highly attractive because it is typically tasteless, soluble, and easy to mix, while MCC remains crucial where compressibility, flow, and texture control are non-negotiable.

Updating Specifications: A Buyer's Guide

Procurement teams often group both ingredients into one bucket—“functional additives.” In 2026, that shortcut leads to misaligned briefs. A smarter approach is to translate the trend into two separate spec pathways.

A Compact Comparison for 2026 Briefs

| Topic | Microcrystalline cellulose (MCC) | Resistant dextrin |

|---|---|---|

| Primary role in 2026 | Tablet/capsule performance; flow, compression, texture | Fiber boost with neutral taste; supports fiber–protein claims |

| Typical formats | Tablets, capsules, sachets; some functional foods | RTD shakes, bars, gummies, powders, bakery and cooking |

| “Must-check” points | Grade (food vs pharma), particle size, bulk density, flow, microbiology | Fiber content target (e.g., ≥82% or ≥90%), solubility, sensory neutrality, stability |

| Common spec phrasing | microcrystalline cellulose pharmaceutical grade USP EP (when applicable), or food-grade metrics | resistant dextrin food grade with defined fiber content and solubility |

| Sourcing priority | Verify factory capability vs trading; documentation discipline | Verify non-GMO corn sourcing, automation, consistent COA and batch testing |

Evaluating Production Capabilities in China

The technology shift isn’t about a single machine upgrade—it is the combination of automation, repeatable raw-material control, and more complete QC routines. This is where buyers see real separation between suppliers.

1. Automation Reduces Variability

Across both MCC and resistant dextrin categories, buyers increasingly favor plants that can demonstrate control over:

- Dosing and feeding systems

- Reaction/processing conditions

- Drying and milling precision

- Packaging and traceability

For resistant dextrin, leading China suppliers now describe fully automated central control from raw material feeding to product filling. The practical benefit supports batch-to-batch stability, which is critical when a brand scales a fiber–protein SKU.

2. The Non-GMO Imperative

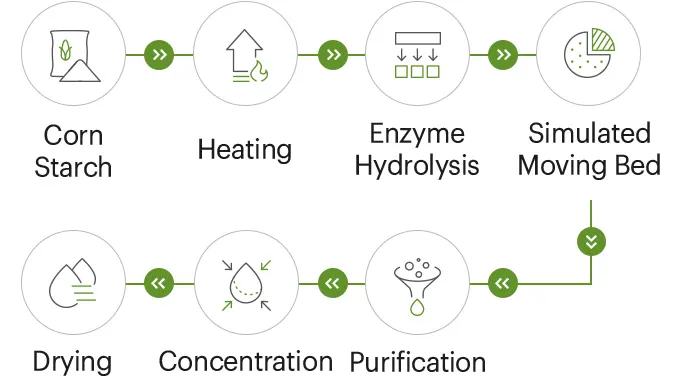

When products are positioned for “better-for-you” and gut health, buyers often demand a clear story on origin. For resistant dextrin, that often means a corn starch source with a non-GMO claim.

In practice, a procurement-ready non-GMO resistant dextrin supplier should be able to explain:

- The corn starch origin and incoming inspection steps.

- Whether the supply chain is stable across seasons.

- How identity is maintained from starch to finished resistant dextrin.

Some Shandong-based producers emphasize non-GMO corn starch sourcing as part of their standard spec. For example, prominent industry players like Shine Health consistently position NON-GMO corn starch as source and outline a controlled production approach on their resistant dextrin product pages.

Navigating Regional Supply Hubs

Sourcing in China is not monolithic. In dietary fiber, buyers frequently shortlist suppliers in provinces with strong starch and processing ecosystems—Shandong is often cited for corn-based fiber production, while broader industry sourcing discussions mention additional fiber activity in provinces such as Guangdong and Jiangsu.

For MCC, buyers commonly see manufacturing capacity associated with established fine-chemical and excipient regions. Many procurement teams focus on suppliers that can clearly state whether they are a microcrystalline cellulose manufacturer China (true manufacturer) or a reseller.

From a procurement standpoint, the regional takeaway is straightforward:

- Coastal hubs can support faster export logistics and more frequent shipments.

- Inland locations may offer attractive cost structures, but buyers should pressure-test lead times and responsiveness.

COA & Quality System Essentials

As fiber–protein launches accelerate, tolerance for “good enough” paperwork drops. Buyers now expect a supplier to treat resistant dextrin and MCC as spec-led ingredients, not bulk commodities.

For Resistant Dextrin in Nutrition Launches

A resistant dextrin supplier that buyers can scale with typically needs to show:

- Clearly stated fiber content target (many commercial specs cite ≥82%, and some applications target ≥90% on a dry basis).

- Appearance range (commonly white to light yellow).

- Solubility performance and handling notes (e.g., low caking/hygroscopicity claims).

- Microbiology limits where relevant.

- Storage guidance and shelf-life handling.

Suppliers like Shine Health, for instance, list resistant dextrin parameters such as appearance and fiber content alongside stability-focused claims like heat and acid resistance. Pages that buyers often use as quick spec references include their nutritional dietary fiber powder and low calorie dietary fiber documentation.

For MCC in Regulated Formats

For MCC, buyers should separate “food-grade MCC” needs from microcrystalline cellulose pharmaceutical grade USP EP needs. Even when a supplier claims pharmaceutical readiness, the buyer’s job is to verify:

- Grade designation and intended application.

- Particle size distribution and functional performance (flow, compressibility).

- Bulk density targets aligned to the dosage form.

- Microbiological limits and impurity controls as applicable.

Procurement Audit Checklist

Below is a field-tested structure that works for both a microcrystalline cellulose manufacturer China shortlist and a resistant dextrin supplier China shortlist.

- Manufacturer Confirmation

- Factory address, workshop photos, and line descriptions.

- Clarify whether the vendor is a plant or trading company.

- Quality System Evidence

- ISO and food safety systems (commonly ISO9001, HACCP; some suppliers also reference HALAL and KOSHER).

- For plants supporting regulated markets, confirm GMP-style workshop discipline and lab capability.

- COA Discipline and Batch Consistency

- Ask for consecutive COAs across multiple lots.

- Check whether test methods are consistent and reported clearly.

- Raw Material Integrity

- For resistant dextrin, confirm non-GMO corn starch sourcing and incoming inspection.

- For MCC, confirm cellulose source and traceability practices.

- Supply Responsiveness

- Can the supplier support both trial orders and scale-up volumes?

Profile of a Future-Ready Supplier

A “future-ready” resistant dextrin manufacturer in Shandong is typically characterized by a few recurring capabilities:

- Non-GMO corn starch positioning as a baseline expectation.

- Production supported by imported enzymes (often described as overseas or international sourcing).

- Automated or centrally controlled lines designed to reduce human error.

- A QC laboratory setup that can support routine batch checks.

- Technical support that helps customers integrate resistant dextrin into beverages, powders, bars, or supplement formats.

This profile is visible across several supplier descriptions in the market. Shine Health is a prime example of a Chinese resistant dextrin manufacturer whose public documentation emphasizes non-GMO sourcing, automation language, and QC infrastructure across multiple resistant dextrin pages.

Strategic Sourcing for 2026

The fiber–protein wave is not a temporary spike; it is a structural change in how brands design products. For buyers, the winning move in 2026 is to treat resistant dextrin and MCC as strategic specification items.

Use resistant dextrin to meet fiber targets while protecting taste and viscosity—then verify fiber content, solubility, and non-GMO origin claims. Use MCC where physical performance is the priority—then verify grade alignment, flow/compression metrics, and documentation maturity. Procurement teams looking for reliable partners typically get better outcomes when they shortlist by proof of process control, not by price sheets.

If you are building a China dietary fiber sourcing guide for 2026 launches, start with suppliers that publish clear specs. For a practical benchmark on how manufacturers should present specifications and application framing, visit the Shine Health website.