In 2026, satiety is no longer just a "nice-to-have" marketing claim—it has become a fundamental design constraint. As the conversation around GLP‑1 usage expands and consumers actively recalibrate their portion sizes, forward-thinking brands are racing to build fiber-first foods and supplements. These products must feel lighter, digest comfortably, and deliver a clear, functional reason to believe in their efficacy.

Among the functional ingredients benefiting most from this structural shift is resistant dextrin: a versatile soluble fiber that can be seamlessly incorporated into beverages, spoonable dairy, nutritional powders, and bars without turning them thick, gritty, or unpalatable. Simultaneously, microcrystalline cellulose (MCC) remains highly relevant as a structural workhorse, particularly for solid-dose supplements and specific high-fiber formats that require robust binding.

The Satiety Reset is Changing Buyer Demands

Satiety-focused innovation used to orbit almost exclusively around protein content. Today, the landscape is significantly more nuanced. Buyers and consumers alike are prioritizing comfortable fullness, gut-friendly positioning, and label simplicity—especially in products intended for daily consumption.

For procurement and R&D teams, this evolution creates a new sourcing reality. Choosing a resistant dextrin supplier (and, when needed, a microcrystalline cellulose supplier China) is no longer solely about securing the lowest price or meeting basic compliance standards. It is about ensuring predictable performance across complex, multi-format product lines.

Several critical trend signals explain this shift:

- Accessible Nutrition: This concept is increasingly framed as a synergistic combination of protein, fiber, and gut-health support, rather than protein standing alone.

- Mainstream Integration: Satiety features are being built directly into product designs in mainstream categories like ready-to-drink (RTD) beverages, nutrition powders, and meal replacement bars.

- Ingredient Systems: Buyers are demanding comprehensive ingredient systems—soluble fiber for the nutritional narrative, paired with structure/binding support for pills or solid forms.

The result is a fast-growing demand for non-GMO resistant dextrin bulk that can scale globally while maintaining strict consistency, alongside MCC that supports robust, high-speed manufacturing processes.

Resistant Dextrin and MCC in Buyer Language

A frequent sourcing error occurs when teams treat resistant dextrin and MCC as interchangeable "fiber ingredients." They are distinct tools that solve different technical problems. Aligning the specific ingredient to the formulation job makes the qualification process significantly smoother.

Resistant Dextrin: The Soluble, Low-Impact Backbone

In fiber-first formulations, resistant dextrin is often the ingredient of choice because it allows manufacturers to significantly raise fiber content while keeping the product consumer-friendly and palatable.

A practical buyer snapshot (as commonly specified by innovation-ready plants) typically includes:

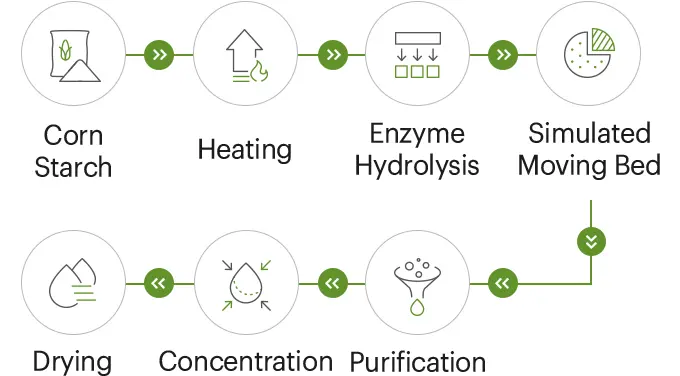

- Raw Material: Typically derived from corn starch; many premium programs specifically prefer non‑GMO corn starch sourcing to meet clean-label demands.

- Appearance: A white to light yellow powder that disappears into formulations.

- Fiber Content: Commonly specified at ≥82% to ensure high nutritional density.

- Protein: Strictly controlled (e.g., ≤6.0%) to prevent off-flavors or allergen concerns.

- Formulation Behavior: Designed to be easy to mix, offering a neutral taste profile and compatibility with both hot and cold processing environments.

- pH Stability: Frequently positioned as stable around pH 4–5, making it highly useful for acidic beverage systems.

From a buyer’s perspective, resistant dextrin earns its place on the BOM (Bill of Materials) when it helps a product hit ambitious fiber targets without introducing new sensory defects like grit or viscosity issues.

MCC: The Structure Tool for Manufacturability

Microcrystalline cellulose (MCC) serves a different but equally vital role as a functional excipient or texturizing aid. In the supplement sector, it is valued as a premier tablet binder and flow aid, helping manufacturers maintain consistent compression and handling speeds.

While resistant dextrin is chosen for soluble fiber delivery, MCC is selected for:

- Mechanical Strength: Providing robustness in tablets and chewable formats.

- Flow and Processing Stability: ensuring uniformity in dry blends and preventing caking.

- Texture Management: offering structure in certain high-fiber solid foods.

Because of these complementary roles, buyers frequently evaluate both a resistant dextrin supplier and a microcrystalline cellulose supplier China simultaneously when building a comprehensive satiety or gut-health platform that spans beverages, powders, and supplements.

Three Fiber-First Use Cases Scaling Now

Below are three specific product patterns where resistant dextrin is often a central ingredient, and where MCC plays a critical complementary role.

1. Clear Beverages and RTD Formats

Clear drinks, flavored waters, and coffee-style RTDs are notoriously unforgiving. Any haze, chalkiness, or unexpected viscosity changes can destroy consumer trust and repeat purchase potential. In this context, resistant dextrin is highly attractive due to its:

- Neutral Taste: It supports clean, subtle flavor systems without masking the intended profile.

- Mixing Ease: High solubility helps reduce plant-side complaints like clogging or sedimentation during scale-up.

- Hot/Cold Stability: It remains stable across multiple processing routes, including pasteurization.

Buyer Tip: When qualifying a resistant dextrin supplier for beverages, specifically ask for clarity guidance at typical beverage pH levels (often acidic). Confirm that the supplier can provide stability data around pH 4–5 if that is your target window.

2. Spoonable Dairy and Cultured Products

In yogurt-style and spoonable dairy applications, adding fiber can often result in graininess or an artificial "dry" afterfeel. R&D teams require a fiber source that supports a gut-health story without altering the product’s creamy identity. Resistant dextrin fits many dairy briefs because:

- It acts as a soluble fiber without introducing obvious grit or texture disruption.

- It supports a prebiotic-style positioning (when substantiated), aligning with consumer expectations for dairy products.

Buyer Tip: Ask for the supplier’s guidance on mixing order, hydration behavior, and how their resistant dextrin performs alongside common hydrocolloid or stabilizer systems to prevent syneresis.

3. Bars and Powder Supplements

In nutritional bars, excessive soluble fiber can create stickiness, poor bite, or hardening over time. In powders, the challenge shifts to poor flow, caking, and unstable blends that slow down packaging lines. Here, resistant dextrin helps by adding fiber while keeping taste neutral and supporting lower-sugar strategies.

Conversely, MCC often complements resistant dextrin in these formats:

- In tablet programs, MCC supports compression and tablet hardness.

- In dry powder systems, MCC assists with handling and flow, ensuring the powder dispenses correctly.

Buyer Tip: If your product roadmap includes both powder and tablet SKUs, it is efficient to align technical evaluation so the resistant dextrin supplier and MCC supplier can support one coherent platform.

What "Innovation-Ready" Plants Look Like in Practice

China is no longer merely a source of commodity volume. For specialized ingredients like resistant dextrin, sophisticated buyers now shortlist plants based on their ability to support innovation timelines and complex technical requirements. It is not just about shipping containers; it is about partnership.

Innovation-ready capabilities that buyers commonly prioritize include:

- Source Transparency: Clear Non‑GMO corn starch sourcing options backed by robust documentation.

- Hygiene Standards: GMP-standard workshops that demonstrate disciplined hygiene control and contamination prevention.

- Advanced Processing: Highlights such as advanced enzymatic processes and low-temperature drying systems, which are critical for maintaining ingredient bioactivity and consistency.

- Production Precision: Utilization of precision production lines (often of German origin) and advanced biological enzymes imported from overseas to ensure high purity.

- Quality Assurance: A fully equipped QC laboratory capable of routine testing and generating repeatable Certificates of Analysis (COA).

- Global Certification: Documentation packages that include ISO, HACCP, HALAL, KOSHER, and potentially others like ISO9001 or BRC.

This combination of advanced hardware and strict software (quality management) matters because resistant dextrin is often used across multiple sensitive categories. The more formats you plan to launch, the more you need your resistant dextrin supplier to act like a technical partner rather than just a vendor.

A Procurement Checklist for 2026 Satiety Briefs

The fastest way to de-risk sourcing is to separate "marketing claims" from "qualification evidence." Below is a buyer-oriented checklist designed to streamline the vetting process for fiber-first innovation.

Technical Specifications to Align Early

For Resistant Dextrin:

- Fiber Content Target: Commonly ≥82% (dry basis) for most high-performance programs.

- Sensory Profile: Appearance should be white to light yellow, with a mild or neutral flavor.

- Protein Limit: Often controlled at ≤6.0% to ensure label predictability.

- Solubility: Clear description of dissolution rates (e.g., solubility ~70% or higher depending on grade) and measurement methods.

- pH Stability: Confirmation of stability in acidic environments (pH 4–5).

- Moisture Control: Low water activity specifications to ensure extended shelf life and prevent caking.

For MCC:

- Intended Use: Clarity on whether it is for tablet binding or food texturizing.

- Regulatory Route: Documentation matching food grade vs. pharmaceutical excipient positioning.

QA Documentation for Efficiency

A capable supplier should provide:

- COA formats aligned with your incoming QC testing protocols.

- Clear Non‑GMO statements and raw material origin proofs (e.g., corn starch sourced from premium producers).

- Allergen and contaminant statements consistent with your target market regulations.

- A clear distinction between plant-wide certifications and product-specific ones.

Collaboration Signals

In the 2026 landscape, responsiveness is a key indicator of quality. Look for suppliers who offer:

- Fast, technical answers regarding clarity and viscosity expectations.

- Willingness to discuss processing variables such as heat, shear, and acidity.

- Practical support for scale-up troubleshooting.

Interpreting "Recommended Manufacturer" Language

Search behavior is evolving. Many buyers now use phrases such as Recommended Chinese Resistant Dextrin Manufacturer or Recommended Chinese Microcrystalline Cellulose Manufacturer as shortcuts to find vetted options. A useful way to interpret these phrases is not necessarily "the biggest factory," but "the best match for a modern R&D workflow."

In practice, a recommended supplier is usually one that provides:

- Consistent Documentation: Repeatable quality outcomes batch over batch.

- Clear Application Positioning: Specific grades for tablets vs. beverages.

- Stable Supply: Predictable lead times and robust logistics management.

A top-tier Recommended Chinese Resistant Dextrin Manufacturer will typically be one that can support fiber-first innovation with both reliable specifications and genuine technical support—capabilities often found in companies with dedicated R&D teams and long-standing industry experience.

A Practical Sourcing Pathway from Idea to Scale

For teams moving quickly, a structured sourcing pathway helps keep projects on track and minimizes risk:

- Define the Product Role: Clearly designate resistant dextrin for soluble fiber delivery and MCC for structure where needed.

- Lock the Must-Have Specs: Define fiber content (≥82%), pH stability, sensory expectations, and documentation requirements upfront.

- Run a Small Application Trial: Confirm clarity and mouthfeel in beverages, texture in spoonables, and flow/handling in powders.

- Validate Production Readiness: Audit certifications, QC capacity, and batch-to-batch consistency.

- Scale with a Partner Mindset: Choose innovation-ready suppliers to reduce reformulation risks down the line.

For buyers seeking detailed examples of how established Chinese manufacturers describe resistant dextrin specifications, production controls, and certifications (ISO, HACCP, HALAL, KOSHER), reviewing technical overviews from specialized ingredient makers such as www.sdshinehealth.com can provide a practical benchmark for what to expect in a high-quality partnership.