In 2026, “accessible nutrition” is no longer a niche concept—it’s shaping everyday product renovation from RTD coffees to meal-replacement powders. At the same time, GLP‑1 medications are accelerating demand for “companion ingredients” that support satiety and digestive comfort. For procurement teams, the practical outcome is straightforward: resistant dextrin (a soluble dietary fiber) and microcrystalline cellulose (MCC) are appearing in more briefs, more often, and with stricter expectations. This guide breaks down what is changing—and what to verify—when you are shortlisting a Chinese resistant dextrin manufacturer and a Chinese microcrystalline cellulose manufacturer for North American or European pipelines. It remains buyer-focused, treating Chinese suppliers as a category while using Shandong-based portfolios as a practical reference point for what “recommended” often looks like.

Why 2026 demand is pulling resistant dextrin into mainstream SKUs

The “fiber frontier” trend has moved beyond supplements into everyday food and beverage upgrades. Fiber is increasingly treated as a baseline expectation—especially when product teams are reformulating around protein, sugar reduction, or GLP‑1-adjacent positioning.

For developers, resistant dextrin is attractive because it is commonly presented as:

- A soluble dietary fiber that blends well into powders, bars, and beverages

- Neutral in taste and relatively easy to formulate into “everyday” formats

- Suitable for fiber-forward, low-sugar, or calorie-aware product briefs

Procurement teams should anticipate more RFQs that specify resistant dextrin explicitly (rather than just “soluble fiber”), and more customers asking for a specific fiber percentage rather than a generic marketing description.

Practical takeaways for buyers

- If the spec says “fiber,” ask whether the brand team expects resistant dextrin performance (solubility, neutral taste, stability) or just any fiber source.

- Put the fiber content requirement in the RFQ (not only on the COA), especially if the product is being positioned for satiety.

- Plan for faster scale-up: demand is trending toward bulk-ready, repeatable supply—where supplier process control matters as much as price.

GLP 1 companion ingredient innovation is changing how buyers write specs

GLP‑1-driven product innovation often starts with protein—but it rarely ends there. Brands are also trying to manage consumer experience: fullness, tolerance, and “everyday use” convenience. That is where resistant dextrin frequently enters the formulation conversation.

In practice, GLP‑1-adjacent briefs tend to request:

- Fiber that supports satiety-friendly positioning

- Fiber that integrates into RTDs, shakes, coffees, bars, and stick packs

- Predictable functional behavior across processing heat and pH ranges

For procurement, this means resistant dextrin purchasing is shifting from a “commodity add-on” to a strategic ingredient decision, especially for brands attempting to unify fiber claims across multiple product formats.

Practical takeaways for buyers

- Clarify the application upfront: beverage, bar, powder, gummy, or tablet-adjacent formats will drive different handling expectations.

- If the brand is aligning to GLP‑1 users, prioritize tolerance and repeatability in addition to the resistant dextrin COA.

- Build a supplier shortlist that can support product extensions—resistant dextrin used in one SKU often expands into a full platform.

Why Shandong and Qingdao clusters matter for Chinese fiber and excipient supply

China’s ingredient capacity is not monolithic; it is organized in clusters with specialized infrastructure and talent. In the context of soluble fibers and excipients, Shandong and Qingdao frequently appear in global sourcing discussions because they combine:

- Scaled starch-derived ingredient supply chains (raw materials and logistics)

- Increasing automation in production and packaging

- Overlapping capabilities across functional ingredients and pharmaceutical excipients

That overlap is especially relevant when a procurement team is sourcing both resistant dextrin (food or supplement) and MCC (commonly used as a pharmaceutical excipient and tablet binder). Buyers increasingly prefer suppliers that can coordinate documentation standards across categories.

One example of a specialized portfolio is the Shandong-based supplier pages that showcase resistant dextrin and excipient categories side-by-side—useful as a reference for what a “recommended Chinese resistant dextrin manufacturer” may include in its documentation and technical support approach.

A quick functional snapshot of resistant dextrin for buyers

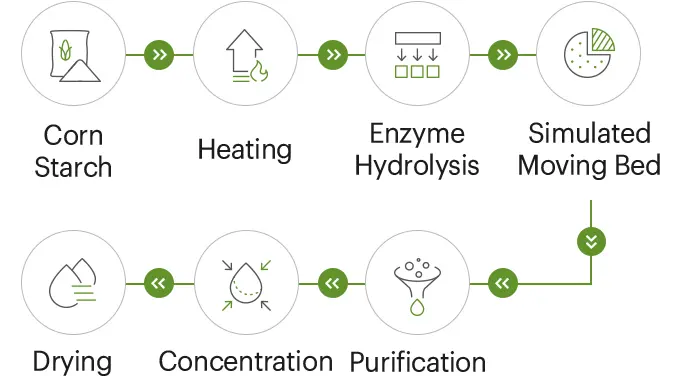

Within Shandong-style fiber portfolios, a common positioning is NON‑GMO corn starch as the raw material source, plus modern enzyme-driven processing and controlled production.

A representative product specification that procurement teams will see for resistant dextrin includes:

- Raw material: corn starch (often described as NON‑GMO)

- Appearance: white to light yellow

- Fiber content: ≥82%

- Protein content: ≤6.0%

- Storage: store in a cool place

These parameters are widely used in supplier conversations because they are simple, measurable, and map directly to both regulatory documentation and formulation performance expectations.

Practical takeaways for buyers

- Prefer RFQs that require ≥82% fiber when the product is positioned as a high-fiber ingredient; keep “fiber” from becoming a vague label.

- Ask for raw material traceability (e.g., NON‑GMO corn starch sourcing) early—this can affect downstream labeling decisions.

- Treat process control as a qualification criterion: the more your pipeline depends on consistent solubility and taste neutrality, the more production stability matters.

What buyers should now require from a Chinese resistant dextrin manufacturer

A buyer-ready resistant dextrin spec should go beyond “soluble fiber.” It should define quality outcomes and testing expectations that prevent surprises after import.

Core spec checkpoints for resistant dextrin

Use the following as a practical baseline when evaluating a bulk resistant dextrin supplier China buyers might shortlist:

- Fiber content (commonly stated as ≥82% in supplier documentation)

- Appearance (white to light yellow)

- Protein (often capped, such as ≤6.0%)

- Moisture and storage conditions (and whether packaging is moisture-proof)

- Microbiology and contaminants (confirm what’s tested and how often)

- Batch documentation: COA consistency, lot coding, and traceability

A simple comparison table buyers can share internally

This is not a formulation verdict; it’s a sourcing lens to align stakeholders.

| Buyer lens | Resistant dextrin | Maltodextrin (commodity reference) |

|---|---|---|

| Primary role | Dietary fiber enrichment | Bulk carbohydrate / carrier |

| Typical positioning | Prebiotic / fiber-forward | Functional filler / cost-driven |

| Digestive behavior | Designed to resist digestion | Typically digestible |

| Spec focus | Fiber %, solubility, consistency | DE/viscosity, sweetness, flow |

Practical takeaways for buyers

- Put the “must not change taste and mouthfeel” expectation into the sampling plan, not just into marketing language.

- Confirm whether the supplier’s resistant dextrin is aligned to your labeling strategy (NON‑GMO, fiber percent, application claims).

- If you are scaling multiple SKUs, prioritize suppliers that can support consistent QC and documentation at volume.

MCC still matters because solid dosage formats are scaling again

While consumer nutrition is pushing resistant dextrin forward, dosage-form convenience is pushing microcrystalline cellulose (MCC) back into more conversations—especially in tablets and capsules where flow, compression, and robustness matter.

From a sourcing perspective, buyers often treat MCC as a “known” excipient. The risk in 2026 is not that MCC is new—it’s that more companies are scaling faster, and MCC performance differences can show up only after you move beyond lab batches.

If your team is building a shortlist for a Recommended Chinese Microcrystalline Cellulose Manufacturer or Recommended Chinese Microcrystalline Cellulose Supplier, it helps to separate “compliant paperwork” from “performing excipient.” A useful reference point for category navigation is the supplier-facing microcrystalline cellulose portfolio structure commonly seen among Shandong excipient producers.

MCC buyer checklist that prevents late-stage reformulation

Use this mini-checklist when qualifying a pharmaceutical excipient MCC China supply option:

- Particle size distribution (and whether it’s consistent lot-to-lot)

- Flowability (handling performance in your equipment)

- Compressibility / tablet hardness outcomes

- Bulk density and moisture

- Microbial limits and contaminant testing expectations

- Documentation discipline: COA format, change control, traceability

Practical takeaways for buyers

- Ask for performance data tied to your process (direct compression vs. granulation), not generic MCC claims.

- Validate MCC with a pilot that reflects your real equipment settings; MCC issues often hide in scale-up.

- If you source resistant dextrin and MCC from China, align documentation requirements so supplier audits are efficient.

Shandong cluster spotlight shows why combined portfolios are becoming normal

A growing pattern in Shandong is the coexistence of resistant dextrin and excipient portfolios under one quality culture—useful for global buyers who need both functional ingredients and regulated documentation practices.

In the dietary fiber segment, Shandong supplier pages frequently segment resistant dextrin into application-led variants. Two examples of contextual product positioning are:

- nutritional dietary fiber powder for broad fiber enrichment

- low calorie dietary fiber for calorie-aware product pipelines

The strategic point for sourcing teams is not that one supplier page is “better,” but that application-specific segmentation often reflects stronger technical communication. That’s one common trait of a Recommended Chinese Resistant Dextrin Manufacturer: the ability to discuss resistant dextrin in the language of applications, not just in tons and pricing.

Practical takeaways for buyers

- If a supplier can explain where resistant dextrin fits (RTD, bars, powders), it’s often a signal of better technical support.

- Look for evidence of structured QC, not just claims—consistent COAs and traceability reduce rework.

- For dual-category sourcing (resistant dextrin + MCC), favor suppliers with clear documentation habits across product lines.

What to watch in 2026 to 2027 if you buy resistant dextrin and MCC

The next 12–24 months are likely to reward procurement teams that treat resistant dextrin and microcrystalline cellulose as strategic inputs, not last-minute adds.

Key watchpoints:

- GLP‑1 adjacent product launches will continue to normalize satiety-friendly formulation patterns, keeping resistant dextrin demand elevated.

- Fiber-plus-protein pipelines will push tighter performance expectations for resistant dextrin in RTDs and powders.

- Automation and capacity upgrades in Chinese ingredient clusters will keep improving consistency, but only for suppliers with disciplined change control.

- Certification expectations will keep rising for global brands; buyers will increasingly shortlist suppliers that can show structured quality systems and export-ready documentation.

For teams building a shortlist of a Chinese microcrystalline cellulose supplier China option and a Chinese resistant dextrin manufacturer, the best results usually come from aligning three things early: application requirements, measurable specs, and documentation expectations.

If you are curating a supplier longlist, it can help to review category portfolios from established Shandong producers and compare how they present resistant dextrin and excipients side-by-side, starting with this category hub: www.sdshinehealth.com.