A 2026 tech-trend guide to enzymatic resistant dextrin from China: automation, QC signals, specs, and traceable sourcing for buyers.

In 2026, “accessible nutrition” is no longer a niche concept—it’s the practical brief many product teams are working from: add meaningful benefits (especially fiber + digestion support) without raising costs or complicating manufacturing. That shift is why soluble fibers such as resistant dextrin are becoming a staple ingredient across beverages, baked goods, and supplement formats.

For procurement teams, the bigger change is not just demand. It’s how a modern resistant dextrin manufacturer China positions itself: less about generic marketing claims, and more about visible process control, traceability, and QC transparency. This guide explores the technology signals behind enzymatic resistant dextrin and related soluble fibers—plus how MCC fits into next‑gen supplement formats—so buyers can confidently shortlist a recommended partner.

Why 2026 “accessible nutrition” is pushing fiber into everyday SKUs

Accessible nutrition is showing up in product pipelines in a very specific way: brands want quiet functional upgrades that don’t ask consumers to change habits. Instead of launching entirely new “health foods,” they’re enriching familiar formats—RTD shakes, protein bars, functional coffees, gummies, bakery snacks—with better nutrition.

A key reason is the clarity of consumer intent around fiber. In a 2026 trends summary, 54% of global consumers associate fiber with digestive health, and 20% have actively increased their fiber intake over the past year. For formulators, soluble fibers are a practical route to meet that demand without sacrificing taste and texture.

This is where resistant dextrin stands out:

- It supports fiber fortification in formats where insoluble fibers can be gritty.

- It can be positioned for digestive support and daily regularity messaging.

- It is widely used as a solution when teams need fiber in an “everyday” product, not a clinical supplement.

For sourcing, the implication is straightforward: a modern buyer isn’t only comparing quotes. They’re evaluating whether a resistant dextrin manufacturer China can deliver consistent performance batch after batch—especially when the product will scale.

Resistant dextrin, soluble corn fiber, and tapioca fibers—what buyers should expect

In buyer-friendly terms, resistant dextrin is a water‑soluble dietary fiber produced from starch (commonly corn; sometimes tapioca is referenced for certain product lines). It is designed to resist digestion in the small intestine and reach the large intestine, where it can be fermented.

Across Chinese supply, the most commercially important traits tend to be the same, regardless of grade:

- High water solubility (useful for beverages and powders)

- Neutral sensory profile (helps protect flavor)

- Low viscosity (enables higher use levels in drinks)

- Process stability (heat and acid stability support wider application)

From an evaluation perspective, the most actionable spec for procurement teams is often the one that shows up on almost every inquiry: fiber content. Many buyers begin with resistant dextrin specifications fiber % because it is the clearest starting point to align quality with labeling goals.

In current supplier materials, resistant dextrin is commonly stated with fiber content ≥82% (with other variants sometimes listing higher “content” values depending on how the product is described). This is exactly why buyers should standardize the language used in negotiations:

- Confirm whether the supplier is stating dietary fiber or “content” in a different analytical context.

- Ask for the COA method reference to keep “resistant dextrin specifications fiber %” consistent across suppliers.

The same logic applies to closely related soluble fibers:

- Soluble corn fiber: often positioned as mild, versatile, and beverage‑friendly.

- Tapioca‑based soluble fibers: often positioned for gluten‑free preferences and alternative sourcing.

A credible manufacturer can usually explain not only the ingredient name, but the intended performance window (clarity, viscosity, stability) that the product is built for.

The real tech trend: enzymatic processing + automated control

When procurement teams hear “innovation,” they often expect a new ingredient. In resistant dextrin, innovation is more often a manufacturing capability upgrade—better process control, cleaner sensory outcomes, and more consistent batches.

Multiple “factory capability” signals appear repeatedly in advanced Chinese plants:

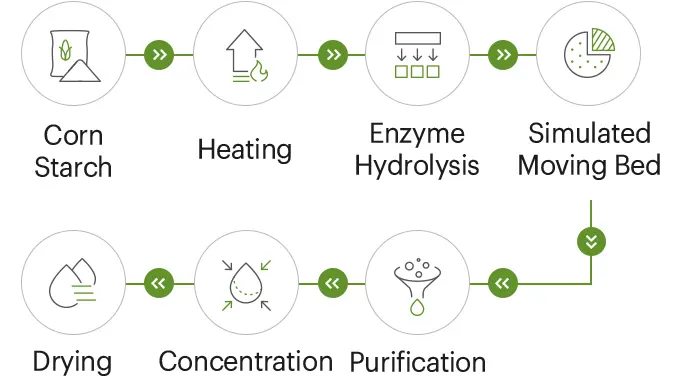

Enzymatic hydrolysis as the controllable pathway

Compared with older approaches that emphasize harsher conditions, enzymatic processing is valued because it can provide:

- More controllable reaction profiles (consistent functional performance)

- Cleaner flavor outcomes (important for beverages and coffees)

- Potentially better tolerance positioning depending on how the final product is used

This is why many buyers now ask directly whether a manufacturer uses enzymatic hydrolysis, and whether the facility can document the key control points.

Automation that reduces variability

Leading facilities stress fully automated central control “from raw material feeding to product filling,” and in some cases a fully automatic unmanned production line. For buyers, automation matters because it typically correlates with:

- Lower operator-driven variability

- More stable moisture and flow properties

- Better packaging consistency (seal quality, dust control)

Equipment and upstream inputs that support repeatability

Common high-end specifications now reference:

- Use of advanced biological enzymes imported from overseas

- German-origin precision production lines

- Processing craftsmanship references that underscore tight operation standards

Whether a buyer treats these points as marketing or meaningful depends on verification. The key is linking them to measurable outcomes: COA stability, fewer out-of-spec batches, and better solubility consistency.

Traceability as a procurement-grade requirement

A growing number of buyers are no longer satisfied with a country-of-origin statement. They want a traceable resistant dextrin supply chain:

- Raw material sourcing clarity (e.g., non‑GMO corn starch inputs)

- Batch-level documentation

- A supplier that can explain farm/partner vetting and incoming inspection routines

How innovation shows up on a spec sheet (and how to read it fast)

A spec sheet is where a supplier’s “innovation” becomes testable. For procurement teams, the goal is to normalize what must be checked on every trial order.

Below is a practical checklist table that buyers can use to compare a resistant dextrin supplier with a supplement-grade MCC supplier. It’s written to support routine supplier onboarding and renewal audits.

Spec & QC checkpoints buyers should standardize

| QC / Spec checkpoint | Resistant dextrin (soluble fiber) | MCC (microcrystalline cellulose) |

|---|---|---|

| Identity & naming | Confirm product naming and intended use (food / supplement). Ask how “resistant dextrin specifications fiber %” is tested. | Confirm grade naming and intended function (binder, filler, disintegrant). |

| Fiber / assay target | Commonly stated as fiber content ≥82% in supplier materials; confirm analytical basis and COA method. | Verify assay requirements per the target pharmacopeia or internal spec. |

| Appearance | Typically white to light yellow powder (common supplier statement). | Commonly a white powder; confirm per grade. |

| Moisture control | Ask for moisture spec and storage guidance; moisture swings can affect caking and blending. | Moisture impacts compressibility and stability; confirm limits for your dosage form. |

| Solubility & viscosity | Solubility and viscosity determine beverage performance; request solubility guidance and application notes. | Not a soluble fiber; check dispersion behavior and compaction performance instead. |

| Microbiology | Verify microbial limits on COA; confirm routine testing cadence. | Verify microbial limits and test frequency, especially if used in nutraceuticals. |

| Heavy metals | Request limits and test reports aligned to your market and category. | Same expectation; align with your product risk assessment. |

| Quality systems | Look for GMP/HACCP/ISO system statements and audit readiness. | Confirm quality system and documentation readiness. |

| Batch documentation | Ensure batch COA availability and lot traceability to support a traceable resistant dextrin supply chain program. | Require lot-level COAs and change control expectations for long-term supply. |

What matters most is consistency in your process. If your team evaluates every resistant dextrin manufacturer China on the same checklist, supplier comparisons become faster, and scale-up surprises become rarer.

Product-format patterns: where resistant dextrin and MCC win together

Fiber demand is rising, but winning products still need to taste good, process well, and hit cost targets. The following patterns are common because they deliver “accessible nutrition” without dramatic reformulation.

Pattern A: Protein shakes and functional coffees (low viscosity, clean flavor)

RTD beverages and functional coffees are often constrained by texture and stability. Resistant dextrin is commonly chosen when teams need:

- Fiber addition without heavy thickness

- Neutral taste support

- Heat/acid stability for real processing conditions

From a sourcing standpoint, beverage teams often prefer a manufacturer that can clearly demonstrate solubility performance and provide consistent batch behavior. In 2026 pipelines, “protein + fiber” is becoming a standard claim architecture—making a reliable partner more important than ever for brands that plan to run multiple co-packers.

Pattern B: Baked goods, bars, and bakery snacks (quiet fiber upgrades)

Baked goods and bars want nutrition upgrades that consumers don’t notice as a tradeoff. Resistant dextrin is used because it can support:

- Fiber enrichment without gritty texture

- Moisture retention and shelf-life support (application-dependent)

- Better nutritional positioning for everyday snacks

A practical procurement reminder: if you’re comparing suppliers, keep “resistant dextrin specifications fiber %” aligned with the finished product’s label claim target—especially if you plan to change use levels across SKUs.

Pattern C: Gummies, tablets, and powder sachets (MCC as the quiet workhorse)

When the format shifts from foods to supplements, the fiber story often remains—but the manufacturing needs change. Many teams use MCC to support:

- Flowability and processing consistency

- Tablet structure and robustness (grade dependent)

- Clean, widely recognized excipient positioning

This is where a Recommended Chinese Microcrystalline Cellulose Supplier becomes part of the same 2026 conversation as fiber. Buyers increasingly treat these two supply chains as linked: a single supplement line might require both prebiotic fiber and MCC, and both must meet documentation expectations.

“Recommended” in 2026: the tech and QC signals buyers actually trust

The phrase Recommended Chinese Resistant Dextrin Manufacturer gets used loosely online. Procurement teams need a more concrete definition—one grounded in verifiable signals. Below are the most practical “recommended” markers that buyers use when shortlisting a supplier today.

Signal 1: Process transparency that matches the product claim

A recommended supplier can explain, in plain terms:

- Raw material inputs (e.g., non‑GMO corn starch or specified starch sources)

- The high-level process steps (reaction, filtration, drying, packaging)

- What is controlled to protect solubility and taste

The more transparent a supplier is, the easier it is to qualify them into a traceable resistant dextrin supply chain.

Signal 2: Automation + QC lab capability that can be audited

It’s one thing to say “automated.” It’s more meaningful when a supplier can show:

- Central control across feeding to filling

- In-house QC lab routines and trained staff

- Routine batch COA outputs aligned to your key “must-haves,” including resistant dextrin specifications fiber %

Signal 3: Documentation culture (COAs first, marketing second)

A recommended supplier is usually willing to share:

- Sample COAs for recent lots

- Testing panels (moisture, microbiology, key functional specs)

- Packaging and storage guidance

If a supplier’s documentation is inconsistent, it becomes difficult to maintain a traceable supply chain even if the product performs well in a one-off trial.

Signal 4: Clear supply terms that reduce operational friction

Even in a tech-trends discussion, commercial clarity is a quality signal:

- Stable lead times

- Clear MOQ policies

- Predictable packaging formats

These points don’t replace QC, but they heavily affect total supply risk—especially when a buyer is scaling a 2026 “accessible nutrition” SKU.

A short, practical takeaway for procurement teams

For 2026, resistant dextrin is not just a “nice-to-have” fiber. It’s becoming an operational ingredient—one that must scale cleanly, ship reliably, and perform consistently across product formats.

The most effective procurement approach is to treat manufacturing capability as the innovation:

- Use a spec-first approach (start with resistant dextrin specifications fiber %, then lock in the rest of the QC panel).

- Build sourcing around a traceable resistant dextrin supply chain rather than a single low-price quote.

- When supplements are involved, qualify MCC with equal discipline by shortlisting a supplier that can support your documentation requirements.

For buyers looking to benchmark what an audit-friendly manufacturer publishes—especially around process transparency, automation signals, and fiber documentation—supplier technical pages can be a useful starting point. One example of a Chinese manufacturer resource hub for resistant dextrin is: www.sdshinehealth.com.