In 2026, "accessible nutrition" has moved from a marketing phrase to a procurement reality. Brands are pairing protein + fiber in everyday formats—bars, shakes, powders, and increasingly coffee—because consumers want simple products that support both muscle and gut health. This shift is accelerating global demand for two workhorse ingredients: resistant dextrin (a soluble dietary fiber) and microcrystalline cellulose (MCC) (a functional excipient and insoluble fiber-like bulking aid). For many buyers, the search quickly narrows to one critical question: how to qualify a resistant dextrin supplier China and a microcrystalline cellulose supplier China without risking reformulation, delays, or compliance gaps.

From Single Nutrients to Accessible Nutrition

Recent industry coverage points to 2026 as a breakout year for "accessible nutrition," emphasizing convenient products that deliver more than one functional benefit—especially protein plus dietary fiber in the same serving.

For procurement teams, this is not just a trend to watch. It changes the RFQ conversation in three practical ways:

- Fiber is no longer optional. It becomes part of the core nutrition claim, so supply continuity matters.

- Taste and process tolerance become procurement specs. Fiber that performs in coffee, RTD shakes, and bars must stay neutral under heat and acidity.

- Compliance expectations rise. Buyers increasingly ask for certifications and batch documentation early—especially when selecting a resistant dextrin supplier China or a microcrystalline cellulose supplier China for export-facing products.

Where Soluble Fiber Demand Grows Fastest in 2026

The formats pulling the most volume are also the formats that punish weak specifications.

High-Growth Application Clusters

- Protein bars and nutrition snacks: Require fiber that doesn’t add off-notes or gritty mouthfeel.

- RTD and powdered shakes: Need solubility, stable viscosity, and clean flavor.

- Fiber-enriched coffee ("fibermaxxing"): Needs fast dissolution and minimal taste impact.

- Capsules, tablets, and supplement blends: Often pair soluble fiber with MCC to improve flow, compressibility, and consistency.

Why Resistant Dextrin is Frequently Shortlisted

A qualified resistant dextrin supplier China typically positions resistant dextrin as a soluble fiber that supports modern formulation goals:

- Neutral taste and easy blending.

- Heat- and acid-resistance (useful across beverages and cooking/baking applications).

- Label-friendly fiber enrichment in multiple dosage forms.

On the supply side, buyers also see a widening "menu" under the resistant dextrin umbrella—such as digestion-resistant maltodextrin, resistant tapioca dextrin, and related soluble fiber options.

Spec-Smart Buying for Resistant Dextrin

When comparing a resistant dextrin supplier China to another, the headline "fiber" label is not enough. The best purchasing outcomes come from aligning specs with the actual product format.

Core Specification Targets

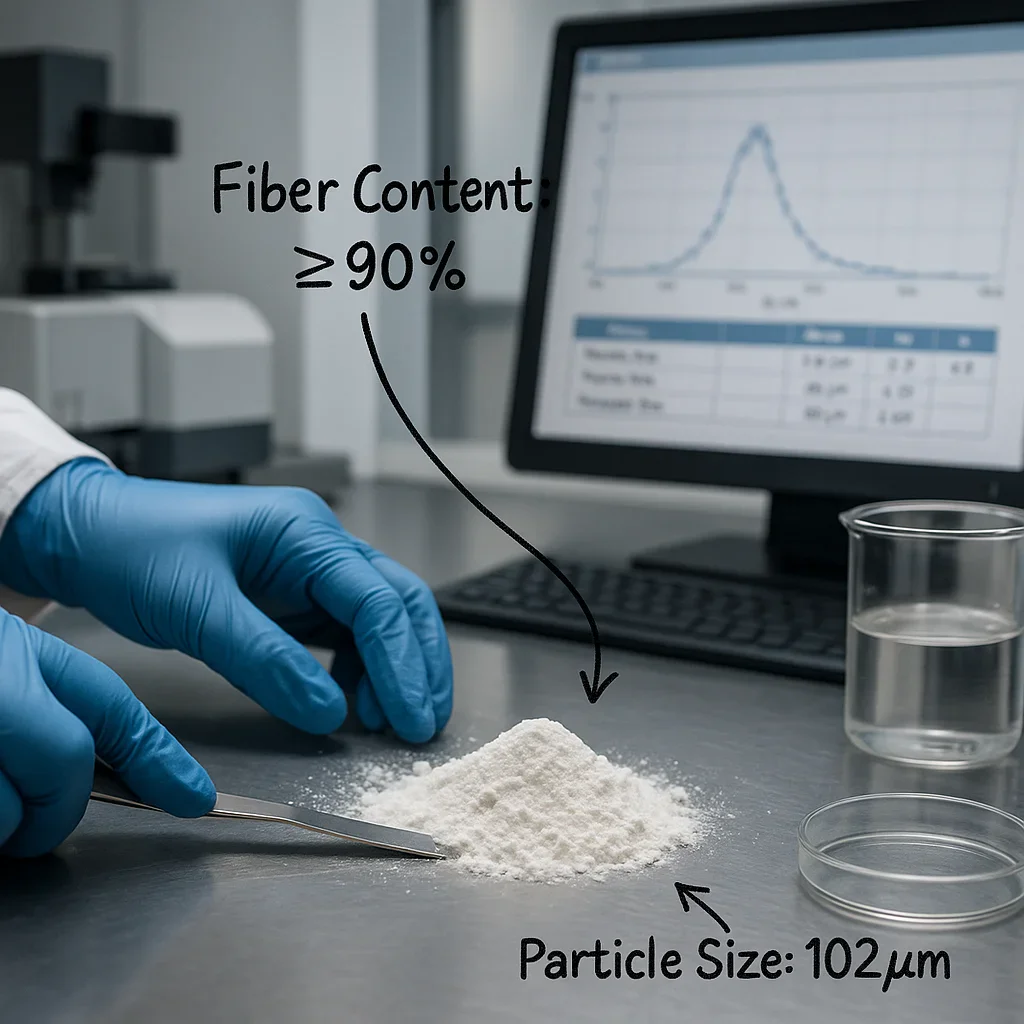

The following ranges reflect common commercial documentation found in supplier COAs and product specs:

- Appearance: White to light yellow powder.

- Fiber content: Often ≥82% (and some product lines list ≥90% on a dry basis).

- Protein: Typically ≤6.0%.

- Solubility: Examples include ~70% solubility for certain functional fiber grades.

- Storage: Stored in a cool place (typical handling instruction).

The Difference Between "Maltodextrin" and "Digestion-Resistant Maltodextrin"

In buyer discussions, confusion still appears between standard maltodextrin (digestible carbohydrate) and digestion-resistant maltodextrin (positioned as dietary fiber). A reliable supplier should be able to clarify that resistant variants are designed to resist digestion in the small intestine and function as fiber in the gut.

COA Mini-Guide for Vendor Screening

Below is a compact, buyer-friendly checklist to request before trialing or scaling with any resistant dextrin supplier China:

- Fiber content method and reporting basis (as-is vs. dry basis).

- Moisture / water activity (for storage stability and caking risk).

- Ash (cleanliness/processing control).

- Micro limits (aerobic plate count, yeast, mold, coliforms).

- Heavy metals (limits and test results).

A supplier that can share these consistently, batch after batch, is usually a stronger candidate for long-term procurement.

How MCC Supports the Same 2026 Product Pipeline

If resistant dextrin is the soluble-fiber engine of many "accessible nutrition" products, MCC is often the quiet enabler behind manufacturability—especially in supplements.

A capable microcrystalline cellulose supplier China typically supports multiple grades (for example PH-101, PH-102, PH-200 and others) and aligns documentation to common compendial standards (e.g., BP/USP/FCC/JP). MCC is described in supplier materials as odorless, tasteless, and insoluble.

Where MCC is Used

- Tablets: Binder/filler and support for compressibility and flow.

- Capsules: Filler and bulking aid.

- Powder blends: Anti-caking and flow improvement.

- Selected functional foods: Texture/structure support where appropriate.

What to Check on MCC COAs

For buyers evaluating a microcrystalline cellulose supplier China, these are often the most decision-relevant QC items:

- Grade (PH series) and intended function.

- Mesh / particle size distribution (commonly shown across 60–200 mesh ranges).

- Loss on drying (moisture control).

- Bulk and tapped density (processing and dose uniformity).

- pH, heavy metals, microbiology.

A Compact QC Table for RFQs

The goal is to prevent "apples-to-oranges" comparisons when buyers are shortlisting a resistant dextrin supplier China and a microcrystalline cellulose supplier China at the same time.

| QC Focus | Resistant Dextrin / Soluble Fiber | Microcrystalline Cellulose (MCC) |

|---|---|---|

| Identity | Confirm resistant dextrin / digestion-resistant maltodextrin naming | Confirm MCC and exact PH grade (e.g., PH-101/PH-102/PH-200) |

| Key Functional Spec | Fiber content often ≥82% (some lines list ≥90% dry basis) | Particle size/mesh, density, compressibility |

| Process Fit | Solubility (e.g., ~70%), neutral taste, low sweetness where needed | Flow, blending, tablet/capsule performance |

| Stability | Moisture / water activity; anti-caking behavior | Loss on drying; moisture sensitivity in storage |

| Safety | Micro limits + heavy metals | Micro limits + heavy metals |

| Documentation | Batch COA consistency; traceability for raw materials | Compendial alignment (BP/USP/FCC/JP) and stable grade control |

China Sourcing Hubs and Production Implications

In public sourcing guides, production for resistant dextrin and related soluble fibers is often associated with major manufacturing hubs such as Shandong, Jiangsu, and Guangdong, with export activity frequently linked to coastal logistics networks.

For buyers, "hub thinking" helps with practical procurement planning:

- Supplier discovery is faster because the ecosystem (raw material access, technical talent, and logistics) is concentrated.

- Lead times can be more predictable when plants are experienced in bulk export documentation.

- Benchmarking becomes easier because multiple suppliers in the same region can be assessed against the same RFQ.

In parallel, many export-facing factories describe similar capability patterns—such as GMP-standard workshops, automated central control from raw material feeding to product filling, and in-house QC labs. These are the types of operational details buyers should ask to see during the evaluation of any resistant dextrin supplier China or microcrystalline cellulose supplier China.

For buyers researching specific product families, these pages provide a practical starting point for understanding how Chinese suppliers present resistant dextrin variants:

- Resistant Dextrin category overview

- Resistant tapioca dextrin

- Tapioca maltodextrin

- Microcrystalline cellulose category

A 2026 Shortlisting Checklist

When buyers search phrases like Recommended Chinese Resistant Dextrin Manufacturer or Recommended Chinese Microcrystalline Cellulose Supplier, they are usually not asking for a brand name. They want a repeatable screening method.

Use this checklist to keep comparisons fair across multiple candidates:

- Certifications in scope: Request current ISO9001 and food-safety certifications where relevant (HACCP is commonly requested for food ingredients; Kosher/Halal may be required for specific markets). Some suppliers list portfolios including ISO9001, BRC, HALAL, HACCP, and KOSHER—verify what applies to the ingredient and site.

- COA recency and batch consistency: Ask for several recent COAs, not a single "best batch." This matters for every resistant dextrin supplier China.

- Spec-to-application mapping: Confirm whether the target is coffee, bars, RTD, or tablets before negotiating price. A microcrystalline cellulose supplier China should also confirm which PH grade matches the dosage form.

- Micro and heavy-metal controls: Ensure limits are stated and tested routinely.

- Factory process transparency: Look for clear descriptions of production controls (automation, central control operations, QC lab capacity).

- Pilot support: Request small trial quantities to validate solubility, sensory impact, flowability, and compression behavior.

- Packaging and logistics readiness: Confirm packaging options and moisture protection for long routes.

- Documentation response time: Measure how quickly the supplier can provide specs, COAs, and clarifications—often the best indicator of future project speed.

A buyer applying these steps typically reduces the risk of late-stage issues—especially when selecting a new resistant dextrin supplier China for beverage launches or a new microcrystalline cellulose supplier China for solid-dose projects.

Turning 2026 Fiber Demand into Lower-Risk Sourcing

Accessible nutrition is reshaping global product pipelines, and the ingredient sourcing strategy is changing with it. Resistant dextrin is increasingly treated as a formulation backbone in beverages and protein-forward snacks, while MCC remains a foundational excipient for tablets, capsules, and some functional blends.

The most resilient procurement approach in 2026 is straightforward: qualify more rigorously up front, insist on COA consistency, and tie specs directly to application performance. That is what separates a truly recommended Chinese resistant dextrin manufacturer from a commodity seller—and what differentiates a recommended Chinese microcrystalline cellulose manufacturer from a supplier that only competes on price.

For buyers who want to compare product families and typical documentation before issuing an RFQ, exploring specific supplier catalogs can provide valuable benchmarks:

- Explore resistant dextrin and soluble fiber options

- Browse microcrystalline cellulose grades and applications

For more information on finding a qualified partner, please visit Shandong Shine Health Co., Ltd.