2026 demand signal: ‘Accessible nutrition’ is pushing more mainstream SKUs toward added fiber, especially in bars, shakes, and cultured dairy—making resistant dextrin soluble dietary fiber a default formulation requirement rather than a novelty marketing claim.

China sourcing signal: China’s manufacturing scale-up is giving global buyers more options, but it is also creating wider variation between a true resistant dextrin manufacturer China and a trading-led exporter. Distinguishing between the two has become the primary challenge for procurement officers.

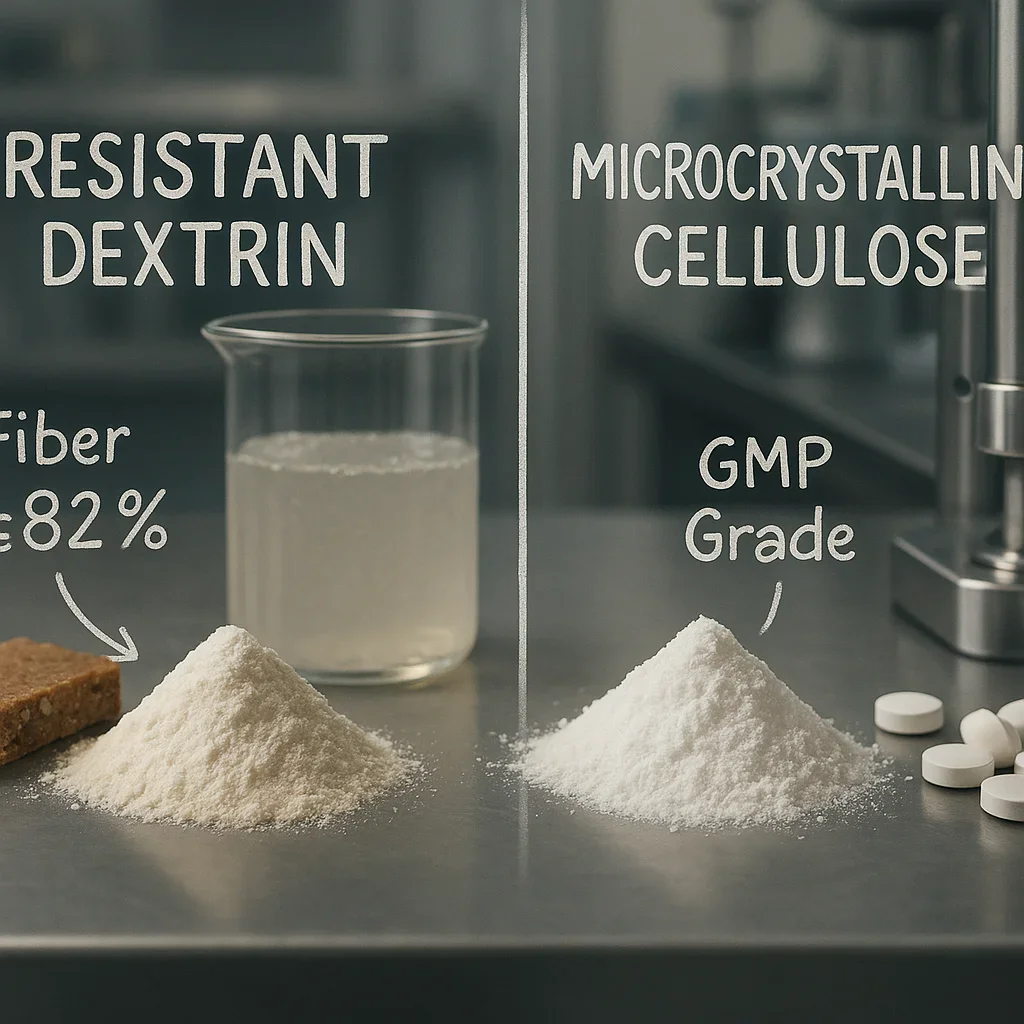

Dual-ingredient reality: Many procurement teams now qualify fiber and pharmaceutical excipient inputs together to streamline audits and logistics. Consequently, the same RFQ often covers both resistant dextrin and a microcrystalline cellulose supplier China.

What wins bids: Clear specifications (e.g., fiber ≥82%), verifiable QC data, automated production lines, and export readiness are consistently outperforming the lowest FOB price when landed cost and reformulation risks are calculated.

The Fiber Frontier: Moving from Niche to Baseline

The most significant sourcing shift heading into 2026 isn't that buyers have suddenly ‘discovered’ fiber—it’s that fiber-forward positioning is becoming mainstream. Industry analysis of accessible nutrition trends points to a broadening consumer base that demands everyday products with measurable benefits, particularly regarding digestive health and gut comfort. This isn't just about ‘diet’ food anymore; it is about functional density in standard grocery items.

For formulation and procurement teams, this market shift pushes two practical outcomes that directly impact sourcing strategies:

1. Soluble fiber specs are becoming non-negotiable: In pipelines for protein bars, meal replacement shakes, and cultured dairy, fiber is no longer an optional add-on. It is a structural component. This means the supply chain reliability for ingredients like resistant dextrin must match that of major commodities like sugar or flour.

2. Fiber is purchased alongside functional excipients: Fiber is increasingly sourced in tandem with stabilizers and excipients that protect texture, flow, and dose uniformity. In this context, microcrystalline cellulose (MCC) remains a workhorse ingredient. Bundling these purchases reduces vendor management overhead.

That explains why more tenders now combine a resistant dextrin manufacturer China shortlist with a separate qualification track for a microcrystalline cellulose supplier China. While the technical teams evaluating these ingredients may differ (food scientists vs. formulation chemists), the procurement risk is shared: both require rigorous documentation, batch-to-batch consistency, and flawless export execution.

Market Snapshot: What Buyers Can Actually Use

Resistant Dextrin: Bought for Function and Claims

In 2026, sophisticated buyers aren’t just asking whether resistant dextrin ‘adds fiber.’ They are validating whether it supports a clean label, maintains stable taste, and offers predictable processing behavior under stress. The difference between a generic powder and a high-performance ingredient often lies in its physical behavior during manufacturing.

From a buying perspective, common baseline expectations now include:

- Fiber content verification: Many products are built around fiber ≥82% as a practical threshold. This number isn't arbitrary; it is crucial for label math and serving-size efficiency. If the fiber content fluctuates, the entire nutritional panel of the finished product is at risk.

- Neutral sensory profile: ‘Tasteless/low impact’ is the commercial target. For clear protein waters, dairy drinks, and delicate snack systems, the fiber cannot impart a gritty texture or an off-note flavor. High solubility is the key technical indicator here.

- Process tolerance: Thermal stability matters immensely for baked goods and UHT (Ultra-High Temperature) or hot-fill beverage steps. The ingredient must survive high heat without degrading or changing color.

A good starting point for teams comparing formats is to review how suppliers describe low calorie dietary fiber and resistant dextrin applications across categories. Looking at specific use cases—such as dairy, supplements, and sugar-reduction systems—helps clarify which grade is required.

MCC: The Quiet Backbone of Nutrition Systems

MCC sourcing is becoming more visible in 2026 because it sits at the intersection of regulatory expectations and manufacturing reliability. For pharmaceuticals and many supplement formats (like chewable tablets or capsules), the quality bar is set by pharmacopeial alignment, consistent physical properties (bulk density, particle size distribution), and strong change control.

If your team is aligning on what ‘good’ looks like before contacting a Chinese MCC exporter, it helps to use technical guides rather than sales PDFs. Understanding the nuances of particle size (e.g., PH101 vs. PH102) is critical. A practical primer is the industry note on MCC grades, formulation, and QC checks, which outlines how buyers typically interpret grade selection and verification steps to avoid capping or friability issues in production.

China’s Production Map Matters More Than Most RFQs Admit

China is not a single, monolithic supply pool. For experienced buyers, it behaves like several distinct ingredient regions, each with different logistics advantages and supplier behaviors. Understanding this geography can save weeks in lead time and percentage points in landed cost.

Resistant Dextrin Clusters: Why Shandong Keeps Showing Up

A Shandong resistant dextrin supplier often benefits from three structural factors that smart buyers care about:

- Raw Material Proximity: Shandong is a major agricultural hub for corn processing. Proximity to corn-starch supply chains supports stable raw material sourcing and shields manufacturers from inland logistics price spikes.

- Manufacturing Ecosystems: Dense industrial clusters make it easier to staff QC labs and maintenance teams with experienced personnel. The talent pool for fermentation and enzymatic processing is deep here.

- Practical Export Routing: Qingdao is a common consolidation and shipping gateway for bulk ingredients. Sourcing from a factory near a major port reduces the risk of domestic trucking delays.

In parallel, Southern and East China clusters can be strong in diversified carbohydrate processing, but the key lesson remains: the region affects lead time, documentation habits, and export rhythm.

MCC Hubs: Aligning with Pharma Infrastructure

For microcrystalline cellulose supplier China searches, buyers often see more pharma-aligned infrastructure and compliance talent concentrated in East China manufacturing corridors (e.g., Jiangsu/Zhejiang/Shanghai ecosystems). Even when the finished product is shipped from a different port, the supplier’s compliance culture is usually shaped by its local regulatory environment and customer base. However, capable suppliers with rigorous GMP standards have emerged across provinces, driven by international demand.

What ‘Recommended’ Should Mean in 2026 Supplier Shortlists

Procurement teams often use ‘recommended’ informally to mean short lead times or competitive pricing. In 2026, a Recommended Chinese Resistant Dextrin Manufacturer or Recommended Chinese Microcrystalline Cellulose Supplier typically earns that label for more durable, structural reasons.

Manufacturer vs. Exporter: The First Screening Gate

A Chinese MCC exporter or fiber exporter can be valuable for consolidation, especially for smaller LCL (Less than Container Load) orders. However, for core ingredients, buyers must confirm where control actually sits:

- Is the supplier a true manufacturer? Do they have GMP workshops and in-house QC labs? Can you visit the line?

- Traceability: Can they provide consistent Certificates of Analysis (COAs) tied to specific batch traceability records?

- Process Control: Do they show evidence of process control? Look for automation, controlled dosing, and monitored pH/temperature logs. Validated cleaning procedures are essential to prevent cross-contamination.

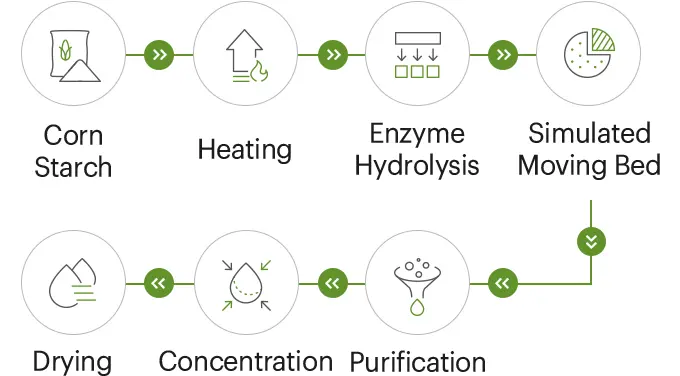

For resistant dextrin, several leading China plants highlight fully automated central control systems—from raw material feeding to product filling. They emphasize the use of non-GMO corn starch inputs and robust QC labs. These are signals that typically correlate with batch consistency and long-term reliability.

The Fiber Spec is Only the Start—COA Detail is Where Issues Hide

For resistant dextrin soluble dietary fiber, the headline spec (fiber ≥82%) is helpful, but it is insufficient for risk mitigation. Experienced buyers reduce risk by verifying deeper parameters:

- Impurity Indicators: Check protein and ash content. High levels can indicate incomplete processing or poor filtration.

- Microbiological Limits: Strict limits on yeast, mold, and bacteria are non-negotiable for food safety.

- Stability Expectations: Ensure the acid/heat tolerance claims match your specific application process (e.g., low pH beverages vs. neutral dairy).

On the ingredient side, buyers can reference product pages that clearly state baseline parameters such as fiber ≥82% and raw material origin. One example is the ingredient overview for low calorie dietary fiber (resistant dextrin), which lists common purchasing parameters and storage expectations in a format procurement teams can easily translate into RFQ language.

A Compact Buyer Checklist That Prevents Expensive Re-Qualification

Below is a practical comparison that many teams use when qualifying a pharmaceutical excipient MCC supplier versus a resistant dextrin manufacturer China. It is intentionally procurement-oriented—designed to reduce back-and-forth communication after samples arrive.

| What to Verify | Pharmaceutical Excipient MCC Supplier | Resistant Dextrin Manufacturer China |

|---|---|---|

| Grade & Standard Fit | MCC pharmaceutical grade USP/EP alignment as required by your market. | Food-grade specs aligned to your label and application; fiber target commonly ≥82%. |

| COA Discipline | Batch-to-batch physical property consistency (density, particle size distribution). | Fiber content, protein limits, and micro limits clearly stated and repeatable across batches. |

| Facility Signals | GMP workshops, documented change control, rigorous cleaning validation. | GMP/HACCP-style controls, documented process steps, stable raw material inputs (Non-GMO). |

| QC Infrastructure | In-house lab capability and transparent test methods (e.g., laser diffraction for particle size). | In-house QC lab; ability to explain out-of-spec handling and re-testing protocols. |

| Export Readiness | Strong documentation set and traceability (DMF availability where needed). | Consistent packing/labeling, stable lead time, clear shipping documentation. |

If your team needs deeper context on common verification steps, using neutral technical content rather than marketing brochures helps align internal stakeholders early. For MCC, the previously mentioned MCC grades and QC guide is a useful reference point.

Sourcing Playbook: From RFQ to Scale

Step 1: Write the RFQ Like a Validation Protocol

When the goal is to buy microcrystalline cellulose bulk or secure bulk fiber, the Request for Quotation (RFQ) should make trial success measurable. Vague requests lead to vague samples. Instead:

- Define the Application: Explicitly state if it is for a tablet, bar, shake, or cultured dairy product. Identify the ‘failure modes’ you are preventing (e.g., sedimentation, grit, viscosity drift, caking, tablet capping).

- For Resistant Dextrin: State the fiber target (often ≥82%), appearance range (white to light yellow), and storage expectations.

- For MCC: Specify the required pharmacopeial grade (USP, EP, BP, JP) and any must-have physical parameters for your process (e.g., bulk density limits).

Step 2: Make Sampling Realistic

A common mistake is to approve a supplier based on a lab-only pass. Buyers reduce surprises by running a pilot that matches actual processing conditions. Does the fiber dissolve at your production temperature? Does the MCC compress well at your press speed? Furthermore, confirm whether the supplier can hold these specs across multiple lots, not just the ‘golden sample.’

Step 3: Treat Logistics as Part of Quality

In 2026, ‘quality’ includes shipping execution. The best product is useless if it arrives damaged or late.

- If your fiber is sourced from Shandong, routing through China MCC exporter port Qingdao-style export corridors can be operationally efficient for mixed ingredient loads. Consolidation capability is a key asset.

- For pharma excipients, buyers often prioritize documentation flow and inspection readiness. Aligning shipments through major export channels with established customs protocols ensures smoother coordination.

Outlook for 2026–2028

Two trends will continue to shape supplier shortlists in the coming years:

- Tighter Label Scrutiny: As regulations around fiber claims and sugar reduction tighten globally, the market will favor suppliers who can consistently document fiber content and processing control. Traceability will move from a ‘nice-to-have’ to a regulatory requirement.

- Portfolio Sourcing: Consolidated sourcing will become the norm. Buyers will look to have at least one qualified resistant dextrin export supplier plus a separate, validated pharmaceutical excipient MCC supplier—even if one distributor consolidates the shipping. This balances supply chain security with logistics efficiency.

For procurement teams building a shortlist, it helps to start with structured product libraries and technical notes rather than directory listings alone. A practical hub for resistant dextrin formats and related soluble fiber options is Shine Health's Resistant Dextrin Category, which includes variants such as prebiotic soluble corn fiber that many buyers evaluate alongside resistant dextrin for gut-health positioning. For a broader look at reliable supply partners, referencing established industry players like Shine Health can provide a benchmark for quality and service standards.