Fiber is no longer just a “nice-to-have” feature on ingredient labels. As the industry heads toward 2026, fiber-plus-protein formats—ranging from RTD coffees and nutrition shakes to bars, gummies, and powdered drink mixes—are transforming fiber into a core performance ingredient rather than a simple nutritional add-on. This shift is fundamentally changing how buyers evaluate what a resistant dextrin supplier China can provide at scale, and it is simultaneously tightening expectations for any microcrystalline cellulose supplier China serving food, supplement, or pharma-adjacent formulations. For procurement teams, the practical challenge is not determining whether demand is rising—it is translating that market momentum into shortlists that survive technical review, withstand documentation audits, and keep reformulation risks low.

Why Fiber Plus Protein is a Procurement Issue Now

Product developers are increasingly utilizing fiber to support digestive health positioning, satiety, and a “steady energy” message—especially when paired with protein. When those product launches scale, fiber sourcing stops being a spot purchase and becomes a critical supply chain priority.

Two ingredient families appear repeatedly in these reformulations:

- Resistant dextrin (a soluble dietary fiber) for fiber claims with a neutral sensory profile.

- Microcrystalline cellulose (MCC) as a stabilizer/texturizer in foods and as a widely used excipient approach in supplement and pharma-adjacent formats.

This combination is exactly why buyers are rethinking how they select a resistant dextrin supplier China can support over the long term, and how to qualify a microcrystalline cellulose supplier China that can meet tighter technical and documentation expectations.

Procurement Takeaway: In 2026, “fiber” on a label can trigger deeper technical scrutiny. That scrutiny reaches all the way back to Certificates of Analysis (COAs), test methods, and batch-to-batch consistency—especially when resistant dextrin and microcrystalline cellulose are used across multiple SKUs.

Where China Capacity Matters Most for Buyers

China remains a key production base for both dietary fiber ingredients (including resistant dextrin) and microcrystalline cellulose. For global buyers, “China sourcing” is not a single market—capacity is shaped by regional clusters, logistics lanes, and export experience.

Typical Clusters Buyers Screen for MCC and Resistant Dextrin

From a buyer’s perspective, shortlisting usually starts with where production capacity and export know-how concentrate:

- Resistant dextrin and dietary fiber production is frequently associated with provinces such as Shandong, Jiangsu, and Guangdong, where starch-derived ingredient ecosystems and export pathways are common.

- MCC production and export activity often maps to established chemical and excipient manufacturing regions; buyers typically verify activity using shipment records and pharmacopeial documentation where needed.

None of this replaces auditing, but cluster awareness helps procurement teams ask smarter questions early:

- Does the supplier routinely ship to your target market?

- Are COAs aligned to the test methods your QC team recognizes?

- Can the supplier support stable lead times when fiber-plus-protein launches spike demand?

When buyers look for a resistant dextrin supplier China can reliably support, cluster location becomes less about “where” and more about how mature the supplier’s export and documentation habits are.

Specs That Decide Whether Resistant Dextrin and MCC Actually Work

Specification sheets have always mattered, but fiber-plus-protein launches make them matter faster—because these products fail in the market when mouthfeel, clarity, or stability slips.

Resistant Dextrin Specs Buyers Commonly Align On

Across food and beverage applications, resistant dextrin procurement typically comes down to a short list of parameters that predict performance and label-fit:

- Dietary fiber content: Many RFQs anchor to ≥82% fiber (commonly stated for resistant dextrin grades).

- Appearance: Often white to light yellow powder.

- Protein limit: Frequently specified (for example, ≤6.0% appears on typical product data).

- Solubility and viscosity behavior: Especially important for RTD coffees and clear drinks.

- pH stability window and microbiological limits: Critical for beverages and shelf-stable powders.

If you need a quick baseline for how suppliers present these parameters, review an example resistant dextrin specification layout and compare it to your internal acceptance criteria.

MCC Specs Buyers Tend to Treat as “Must-Verify”

For microcrystalline cellulose, the “right” spec depends heavily on application (food texture vs. excipient function). Buyers commonly prioritize:

- Particle size distribution and flow properties

- Bulk density and compressibility (for solid dose use cases)

- Moisture and microbial controls

- Pharmacopeial alignment when MCC is used as a pharmaceutical excipient (request clear documentation and grade references)

A practical way to keep internal stakeholders aligned is to use a shared checklist informed by MCC grade discussions such as this MCC grades formulation and QC guide.

Quick Comparison Table for Procurement Teams

| Buyer Lens | Resistant Dextrin | Microcrystalline Cellulose (MCC) |

|---|---|---|

| Primary role in 2026 fiber-plus-protein SKUs | Adds soluble dietary fiber with minimal taste impact | Improves texture/stability or supports excipient functionality |

| Typical risk if spec is wrong | Cloudiness, unexpected viscosity, digestive tolerance complaints | Sedimentation, gritty mouthfeel, poor tablet performance |

| Most common documents to request | COA, fiber test method note, allergen/GMO statements | COA, grade spec sheet, pharmacopeial references if applicable |

| Supplier search phrases buyers use | “resistant dextrin supplier China”, “resistant dextrin manufacturer” | “microcrystalline cellulose supplier China”, “MCC pharmaceutical excipient supplier” |

What High-Fiber Beverage Launches Change for Resistant Dextrin Sourcing

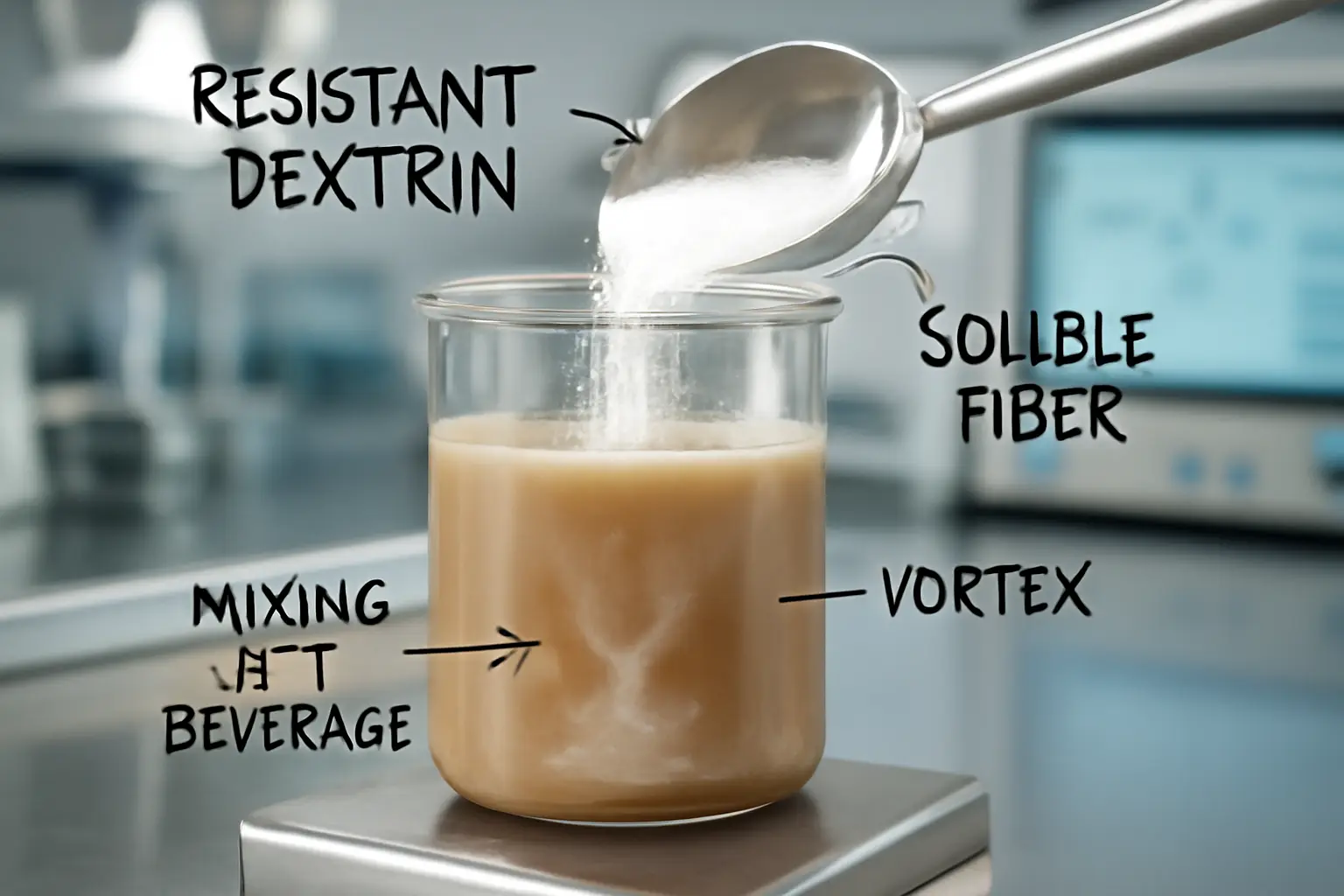

Beverages are the fastest way for a brand to scale a fiber claim—and also the fastest way to expose ingredient weaknesses. In RTD coffees, protein shakes, and “functional refreshers,” resistant dextrin is often selected because it can be formulated with a relatively clean sensory profile.

But beverage teams now expect a resistant dextrin supplier China to do more than ship bulk powder. They increasingly ask for:

- Clarity guidance (what to expect in clear vs. milky systems)

- Heat and acid tolerance notes for pasteurization/UHT processes

- Mixing behavior (lumps, dusting, hydration time)

- Shelf-life stability observations (especially with protein and minerals)

To see how suppliers frame beverage use cases, it can help to compare technical positioning such as high dietary fiber in drinks against your own formulation constraints.

Reading the Supplier Landscape Like a Buyer

In 2026, buyers often separate “available” suppliers from “recommended” suppliers using three filters: certifications, export reality, and documentation discipline.

1. Certifications as an Entry Filter

For a resistant dextrin supplier China can be considered for beverage or supplement work, procurement teams commonly screen for combinations of:

- Food safety systems (e.g., ISO/HACCP-style frameworks)

- Plant controls consistent with GMP-style expectations

- Market-relevant statements (Halal/Kosher where required)

Certifications alone do not prove product fit—but they shorten the longlist significantly.

2. Export Activity Verification

For MCC, buyers often validate whether a microcrystalline cellulose supplier China is actively exporting (and to where). Shipment records and trade-data tools can be used as a reality check—especially when multiple “MCC exporter” claims look similar.

3. Documentation Maturity That Reduces Reformulation Risk

Buyers frequently ask a resistant dextrin supplier China to provide the following as standard:

- COA with clear batch identification

- Fiber test method notes (so QC knows what “fiber” means operationally)

- Allergen and GMO statements where applicable

- Storage and handling recommendations

On the dietary fiber side, many buyers also review how established producers present product families and application notes, using resources such as the dietary fiber category as a reference point for what “complete documentation” can look like.

A Sourcing Playbook That Fits 2026 Reality

Procurement teams trying to identify a recommended Chinese resistant dextrin manufacturer or a recommended Chinese microcrystalline cellulose supplier typically succeed when they run a repeatable process. Below is a practical workflow that works for both ingredient types.

Step-by-Step Shortlist Workflow

- Define the application-first spec

- For resistant dextrin, anchor key parameters (e.g., fiber content targets such as ≥82% where relevant) plus solubility expectations.

- For MCC, define whether the use case is food texture, supplement tableting, or other excipient-driven performance.

- Build a China cluster-aware longlist

- Use regional knowledge to prioritize suppliers with supply chain maturity and export experience.

- Run a documentation gate before samples

- Eliminate suppliers who cannot provide consistent COAs, clear test method notes, or stable batch identification.

- Sample with a “failure mode” plan

- Test resistant dextrin in your most challenging beverage system (acid + protein + heat, if applicable).

- Test MCC in the highest-risk process step (mixing, suspension, compression).

- Pilot order with a change-control discussion

- Align on how the supplier communicates raw material changes, process adjustments, or spec updates.

Buyer Checklist for “Recommended” Status

Use this list to distinguish a truly recommended Chinese microcrystalline cellulose manufacturer or recommended Chinese resistant dextrin manufacturer from a quote-only vendor:

- Traceable COAs with the same format across batches

- Clear spec boundaries (not just typical values)

- Stated storage conditions and shelf-life handling guidance

- QA responsiveness (turnaround time for deviations, CAPA language quality)

- Process visibility (ability to explain production controls without overclaiming)

Case Study: The Cost of Variable Stability

A mid-sized brand preparing a fiber-plus-protein coffee line found that early samples from two suppliers met the label claim but behaved differently after heat treatment and storage. The brand shifted to a Shandong-based resistant dextrin supplier China with stronger documentation discipline and clearer guidance on beverage stability. The result was fewer pilot iterations, faster sensory sign-off, and a cleaner path to scale.

The point is not that one province “wins.” The point is that, in 2026, the most valuable suppliers are the ones that treat resistant dextrin and microcrystalline cellulose as performance ingredients—supported by consistent specs, practical application notes, and export-ready documentation.

Final Thoughts for Procurement Strategies

Fiber-plus-protein isn’t just a marketing wave—it’s a sourcing reshuffle. A capable resistant dextrin supplier China can support beverage and nutrition innovation only when fiber specs, test methods, and documentation are aligned from the start. Similarly, a reliable microcrystalline cellulose supplier China earns preferred status when grade clarity and quality systems reduce downstream surprises.

For buyers building shortlists right now, it is useful to review how established producers present ingredient data and application directions. For a deeper look at reliable supply options and technical specifications, sourcing professionals can explore Shandong Shine Health Co., Ltd as a reference for export-ready documentation and quality standards.