2026’s fibermaxxing trend is tightening specs and supplier scrutiny. Learn how buyers qualify resistant dextrin and MCC from China with clear COAs and traceability.

Fiber is no longer a “nice-to-have” label upgrade—it’s becoming a core purchase driver that shapes how brands build SKUs, and how procurement teams lock capacity. As fibermaxxing moves from social trend to mainstream product requirement, buyers are seeing two immediate sourcing pressures: (1) reliable access to soluble fibers such as resistant dextrin, and (2) tighter expectations for solid-dose performance ingredients, especially microcrystalline cellulose (MCC) used in tablets, capsules, and increasingly common fiber-plus-protein formats.

For procurement and QA teams, the practical takeaway is straightforward: the market excitement is real, but the winners will be the buyers who treat each resistant dextrin supplier China shortlist as a quality system decision, not a price comparison—and who qualify a China microcrystalline cellulose manufacturer with the same discipline they apply to any excipient.

Fibermaxxing in 2026: Why Procurement is Feeling the Squeeze

The conversation around fiber has shifted rapidly. What used to be a niche “digestive health” feature is now being packaged like protein was a few years ago—front-of-pack, portfolio-wide, and attached to lifestyle identity.

Two recent signals matter for B2B sourcing teams:

- Mainstream coverage has highlighted that only about 5% of people consume enough dietary fiber, turning deficiency into a cultural talking point and accelerating demand for fiber-forward products.

- Industry forecasts for 2026 increasingly frame fiber and protein as the defining nutrition pair for accessible wellness, putting pressure on manufacturers to reformulate and relaunch at speed.

These signals drive a familiar chain reaction: marketing commits to fiber claims, R&D needs ingredients that won’t break taste/texture targets, and procurement must identify a dietary fiber ingredient supplier that can hold spec, documentation, and delivery.

In this environment, “find a resistant dextrin supplier China” is a common brief—but it’s often too vague. What buyers actually need is to translate the fibermaxxing buzz into measurable procurement language: fiber content, method of measurement, batch traceability, microbiology limits, and application-fit stability.

Where the Growth Shows Up First

Buyers report the most immediate scaling pressure in categories that can absorb fiber with minimal sensory penalties:

- Diet powders and meal replacements (powdered sachets, ready-to-mix shakes)

- Functional coffees and tea-like beverages (where a low-glycemic soluble fiber can play double duty as bulking and sugar reduction support)

- Gummies and confectionery-style supplements (where fiber helps support “better-for-you” positioning)

- Yogurts and dairy-style products (where solubility and low viscosity reduce processing headaches)

Those same categories frequently require MCC for solid-dose or chewable formats—making MCC a parallel qualification track, not an afterthought.

Why Resistant Dextrin Sits at the Center of the Fiber Frontier

Resistant dextrin is a soluble dietary fiber derived from starch sources, commonly corn or tapioca. What makes it procurement-relevant in 2026 is not a flashy novelty; it’s its ability to support fiber claims while staying workable in real manufacturing conditions.

From a buyer’s perspective, a competitive resistant dextrin specification typically focuses on:

- High fiber content (commonly expressed as ≥82% on many commercial specs)

- Clear solubility and neutral taste, reducing rework risk in beverages and powders

- Heat and pH stability, improving compatibility with pasteurization, acidic drinks, and baked goods

These performance characteristics explain why the phrase resistant dextrin supplier China is increasingly present in RFQs: China has mature starch processing capacity, competitive cost structures, and multiple plants with documented QA systems.

What “Good” Looks Like on a Spec Sheet

Fiber buyers often over-focus on a single number (fiber %) and under-focus on how that number was produced. In practice, the most useful spec sheets are the ones that are easy to audit.

A practical resistant dextrin checklist for shortlisting a resistant dextrin supplier China partner:

- Fiber content and the test method used (many global buyers request AOAC-style reporting for total dietary fiber; the key is that the method is named and consistently applied)

- Appearance (often white to light yellow powders for resistant dextrin)

- Moisture and basic pH indicators (to prevent flowability and stability surprises)

- Microbiology limits (aerobic plate count, yeast/mold, coliforms)

- Heavy metals section (limits and methods)

- Lot code / traceability statement linking raw material to finished goods

In 2026, the fastest “no” is a COA that lists results but doesn’t disclose test methods, lot codes, or the lab’s traceability trail.

Powder vs. Syrup: Procurement Implications

In many launches, resistant dextrin appears either as a powder (most common for dry blends and gummies) or as a syrup (often used when liquid handling is preferred). The decision impacts freight, storage, and QA sampling.

- Powder formats simplify global shipping and allow flexible dosing into powders, gummies, and tablets.

- Syrup formats can integrate smoothly into certain beverage operations but may increase freight cost and complicate microbial controls.

For most international buyers, powder-based sourcing remains the default—especially when qualifying a new dietary fiber ingredient supplier under tight timelines.

MCC Demand Rises with Fiber-Plus-Protein Formats

Microcrystalline cellulose has long been valued as an excipient and functional ingredient because it supports compressibility, flow, and structural integrity—properties that matter more when tablets carry higher loads of actives, fibers, or proteins.

In 2026, MCC demand is being pulled by two trends:

- The supplement format mix is broadening. Brands launch powders and RTDs, but they also push fiber tablets, capsules, and chewables for convenience.

- Fiber and protein stacks are getting heavier. High-load formulas are less forgiving: flow, compaction, and uniformity become make-or-break.

That’s why procurement teams increasingly ask for a China microcrystalline cellulose manufacturer that can provide consistent grade definitions and documentation aligned to the buyer’s market (often described as USP-grade MCC sourcing needs).

What Buyers Should Verify First

Even without diving into overly technical detail, a buyer can reduce risk quickly by focusing on:

- Stated grade/standard alignment (e.g., USP expectations where applicable)

- Particle size and flow properties that match the intended format (tablet vs. capsule vs. sachet blend)

- Routine microbiology and moisture controls

- Clear change control practices (critical if the supplier changes pulp source or process parameters)

In practice, the MCC workstream pairs naturally with resistant dextrin. Many procurement teams qualify them together because they sit in the same launch portfolio and share the same downstream risk: a failed batch can delay an entire product calendar.

How Fibermaxxing Tightens Specs: COAs as Audit Documents

As fiber claims become more prominent, the tolerance for ambiguous documentation shrinks. Buyers are increasingly treating a COA as a mini-audit artifact—something that should stand up to internal QA review and, when relevant, regulatory scrutiny.

This is where many “cheap” offers fail. A resistant dextrin supplier China can look competitive on unit price, but if the COA lacks traceability or method clarity, the total cost expands quickly (retesting, holds, reformulation, claim risk).

A COA Checklist Buyers Actually Use (Resistant Dextrin + MCC)

Below is a procurement-friendly list that works as a shared template across suppliers.

For resistant dextrin (soluble fiber):

- Product name and batch/lot number

- Fiber content + stated assay method

- Moisture

- Appearance

- Microbiology limits/results

- Heavy metals (and methods/limits)

- Storage conditions

- Signature/date and issuing QC entity

For MCC (excipient/functional structuring ingredient):

- Grade identification + standard alignment notes (where applicable)

- Loss on drying / moisture

- Bulk density or other flow indicators (as supplied)

- Microbiology limits/results

- Lot number and traceability statement

For both ingredients, lot code traceability is the “bridge” between commercial terms and quality accountability.

What “Audit-Ready” Means in China for Fiber and Excipient Plants

The phrase “audit-ready” is used casually, but fibermaxxing is making it more concrete. Buyers are increasingly looking for plants that can show, not just claim, consistent controls.

A modern resistant dextrin supplier China candidate is usually expected to demonstrate:

- Documented hygiene and controlled production workflows

- A quality system operating under GMP guidelines (commonly referenced by international buyers)

- Operational certifications such as ISO-managed systems (where applicable)

- Full traceability from raw material to finished powder

- The ability to provide samples, COAs, and technical support during qualification

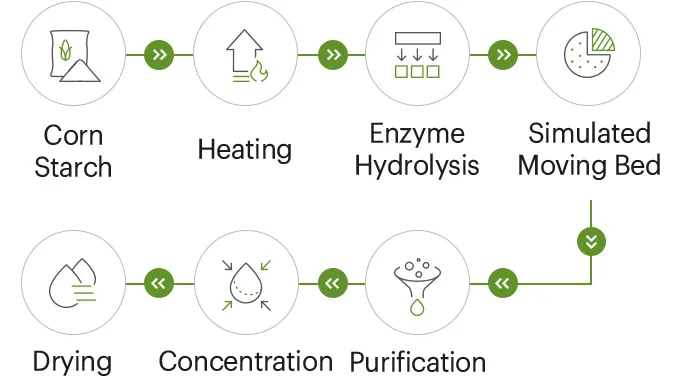

Some Chinese producers also publish process visuals that help buyers understand control points such as enzymatic conversion, drying, and packaging.

A Practical Supplier Verification Flow

To reduce timeline risk while still qualifying properly, many teams follow a staged approach:

- Document screen (48–72 hours): request certificates, COA template, allergen statement (where relevant), and traceability description.

- QA review (week 1): confirm COA method transparency and lot coding; identify retest requirements.

- Sample + application check (week 2–4): verify solubility, taste neutrality, and processing stability for resistant dextrin; verify flow/compaction fit for MCC.

- Remote/onsite audit (when scaling): focus on CCP logs, cleaning validation, packaging integrity controls, and change control.

Total Cost and Risk: What Changes When You Import

In a hot market, teams sometimes treat cost as the only objective. In reality, the better model is total landed cost + total risk cost.

Key cost drivers typically include:

- Product price and payment terms

- Freight mode and seasonality

- Import duties/tariffs (market-dependent)

- Sampling and third-party testing

- Inventory buffering (especially for fast launches)

Key risk drivers are often more expensive than freight:

- Spec ambiguity (fiber method not stated, inconsistent reporting)

- Traceability gaps (lot code cannot be mapped back to raw material batches)

- Inconsistent batch performance (solubility, taste, flowability)

- Reformulation risk (a launch misses sensory targets because the fiber behaves differently)

In fibermaxxing portfolios, this is why many buyers intentionally diversify: at least two qualified sources for resistant dextrin, and at least one dedicated partner track for MCC.

What to Ask for in 2026 RFQs

To keep projects moving, experienced teams write RFQs that make it easy for a supplier to answer clearly.

For resistant dextrin:

- Target fiber content range (many specs reference ≥82%)

- Required COA sections (including the assay method)

- Application targets (beverage, gummies, diet powder)

- Packaging requirements (e.g., 1 kg foil bags for trials, 25 kg bags for bulk)

- Traceability expectations and labeling needs

For MCC:

- Grade expectations and market alignment (e.g., USP-grade MCC sourcing where applicable)

- Target format (tablet, capsule, sachet blend)

- Required QC/COA sections

This structure reduces back-and-forth and helps procurement compare a China microcrystalline cellulose manufacturer and a resistant dextrin supplier China on evidence, not marketing language.

Where “Recommended” Supplier Language is Heading

Search behavior is changing along with the market. Buyers increasingly look for curated shortlists and “recommended” profiles—not because they want hype, but because they want time efficiency.

In practice, these phrases show up in internal discussions and online research: Recommended Chinese Resistant Dextrin Manufacturer or Recommended Chinese Microcrystalline Cellulose Supplier.

Used responsibly, “recommended” should mean:

- The supplier can share complete documentation (COA, traceability explanation, certifications)

- The supplier shows stable batch performance across multiple lots

- The supplier is responsive during technical review and sampling

This mindset helps procurement teams align commercial speed with QA discipline—especially when fibermaxxing turns a “trend” ingredient into a permanent procurement line.

A Grounded Example of What Buyers Can Look For

China’s supplier landscape is broad. Among Shandong-based producers, some plants publicly describe capabilities that are increasingly treated as baseline in 2026:

- Resistant dextrin made from non-GMO corn starch

- Fiber content targets commonly listed at ≥82%

- Stated operation under GMP guidelines and ISO-managed systems

- Quality support such as COA availability and batch traceability from raw material to finished powder

For buyers who want to review a concrete example of a manufacturer profile and product documentation style (without treating it as the only option in the market), one reference point is available at www.sdshinehealth.com.