Procurement teams are entering 2026 with a new reality: fiber has moved from “nice-to-have” nutrition to a core spec, and it is showing up in the same briefs as microcrystalline cellulose (MCC)—not only in tablets, but also in protein-forward foods, meal replacements, and emerging GLP‑1 companion products. For buyers, that shift changes how supplier qualification works. A resistant dextrin supplier China shortlist now lives or dies on consistent fiber performance, clean sensory profile, and audit-ready quality systems. At the same time, a Recommended Chinese Microcrystalline Cellulose Manufacturer is increasingly evaluated on grade clarity (food vs pharma), batch-to-batch flow behavior, and documentation readiness.

2026 demand signals that are forcing spec upgrades

Across functional foods and supplements, 2026 is shaping up to reward brands that pair protein with fiber in ways consumers can actually tolerate and repeat. That’s not a small positioning tweak—it changes the ingredient brief.

The “fiber frontier” impact on buyer requirements

More formulations now aim for higher fiber per serving while staying low in sugar and maintaining a clean taste profile. This is exactly where resistant dextrin earns attention: it is typically positioned as a soluble dietary fiber that is easy to disperse and less likely to dominate flavor.

For procurement, the consequence is straightforward:

- Fiber is now tied to label claims and brand trust, so buyers demand tighter variance control.

- Sensory neutrality becomes a spec, not a marketing line.

- Documentation and repeatability become as important as price.

When a tender includes “food grade resistant dextrin 82 fiber,” it’s rarely just a numeric target—it signals that the buyer is planning a fiber-forward claim and wants a supplier who can support scale.

GLP‑1 companion foods are accelerating “gentle nutrition” concepts

GLP‑1 drugs are pushing food brands to develop products that feel supportive rather than heavy. In practice, this often means:

- Satiety-supporting formulations without harsh digestion issues.

- Protein plus fiber combinations that fit smaller meal sizes.

- Beverage and powder formats that require reliable dispersion.

This is where resistant dextrin and microcrystalline cellulose appear together in the same sourcing guide dietary fiber ingredients China discussion. Resistant dextrin is typically approached as the soluble fiber backbone, while microcrystalline cellulose is considered when the product needs texture, stability, or processing robustness.

What buyers are actually asking resistant dextrin suppliers in China

A resistant dextrin supplier China is no longer evaluated only on “fiber content and price.” Buyers now send a wider list of questions because the ingredient must work across multiple applications (RTD beverages, powders, confectionery, baked goods) and remain stable across a brand’s expansion.

The core spec cluster buyers expect

Most RFQs for dietary fiber ingredient China suppliers cluster around a small set of parameters:

- Appearance: White to light yellow.

- Fiber content: Often stated as ≥82% for certain food-grade briefs.

- Protein: Commonly controlled (e.g., ≤6.0% in some published product tables).

- Storage: “Store in a cool place” is simple, but buyers still ask for stability guidance.

For teams using “food grade resistant dextrin 82 fiber” as a gating spec, the best practice is to confirm:

- Whether the fiber % is on an as-is basis or dry basis.

- Which test methods are used (and whether they are consistent batch to batch).

- Whether the supplier can provide stable COAs and retain samples.

Performance specs that now show up in contracts

The sourcing guide dietary fiber ingredients China conversation has broadened significantly. Beyond basic composition, procurement teams increasingly request performance indicators such as:

- Solubility and dispersibility in cold processing.

- Low viscosity at use levels (important for beverages and powders).

- Neutral taste and minimal off-notes.

- Process stability (heat and acid tolerance are often discussed).

These points matter because buyers are building product lines where the same resistant dextrin must behave reliably across multiple SKUs.

MCC grade comparison is no longer a “nice-to-know” detail

Microcrystalline cellulose is used across industries, but procurement issues often begin when product teams treat “MCC” as one uniform ingredient. In reality, MCC grade comparison pharmaceutical vs food is a critical part of documentation, risk management, and formulation performance.

A practical MCC grade comparison pharmaceutical vs food

For buyers screening a Chinese microcrystalline cellulose supplier, the differences typically matter in three ways:

- Documentation depth: Pharmaceutical-grade MCC generally requires stricter documentation and tighter controls.

- Functional expectations: Food applications often prioritize texture, suspension, and mouthfeel; pharma applications often prioritize compressibility, flow, and consistency.

- Change control: The risk of “silent changes” becomes higher-stakes in regulated products.

Even when an RFQ uses the phrase microcrystalline cellulose China manufacturer, it helps to clarify the intended use early:

- Is this MCC for direct compression?

- Is it for a functional food matrix?

- Is it a stabilizer role or an excipient role?

A Recommended Chinese Microcrystalline Cellulose Supplier should be prepared to answer these questions with a clear grade map—not vague statements.

Why MCC appears in fiber-forward food briefs

In food, microcrystalline cellulose can be evaluated alongside soluble fibers because it helps address challenges that show up as fiber levels rise:

- Texture tightening.

- Phase separation in certain systems.

- Processing variability during mixing and filling.

This doesn’t mean MCC replaces resistant dextrin. Instead, it frequently plays a supporting role—and that is why buyers evaluating a microcrystalline cellulose China manufacturer often request application guidance.

Three application patterns driving sourcing decisions in 2026

To keep sourcing decisions grounded, it helps to look at how procurement teams translate consumer trends into ingredient roles. Below are three patterns where resistant dextrin and MCC show up repeatedly.

Pattern A: High-fiber RTD coffee and ready-to-drink protein beverages

What product teams want: A clean-tasting, low-sugar drink that can carry a fiber claim.

Where resistant dextrin fits: As a soluble fiber backbone that is typically easier to integrate than more viscous fibers.

Where MCC may fit: As a stabilizing or texture-support ingredient if the beverage system needs help maintaining uniformity.

COA items buyers commonly verify:

- Appearance and color consistency.

- Fiber value alignment with the “food grade resistant dextrin 82 fiber” requirement.

- Microbiology controls.

- Moisture control for storage stability.

For a resistant dextrin supplier China candidate, the key commercial risk is reformulation. If the fiber behaves differently at scale, a beverage brand may face texture drift or stability issues, which is expensive to correct after launch.

Pattern B: Nutrition powders and meal replacements for “smaller meals” behavior

Powders remain one of the most efficient ways to deliver protein and fiber to consumers who want controlled calories and predictable intake.

Where resistant dextrin fits: It supports fiber fortification without making the powder heavy or difficult to dissolve.

Where microcrystalline cellulose fits: MCC is often evaluated when powders need improved flow behavior, better handling, or specific mouthfeel goals after reconstitution.

This is also where MCC grade comparison pharmaceutical vs food becomes relevant: a nutrition powder buyer may choose a food-grade MCC, but still demand pharma-like documentation discipline. That expectation is becoming more common as brands expand into multiple regulatory markets.

Pattern C: Fiber-enriched confectionery and baked goods with sugar reduction goals

Confectionery and baked goods face a harder sensory trade-off: adding fiber while keeping texture enjoyable.

Where resistant dextrin fits: It is often used to increase fiber and help support sugar-reduction strategies.

Where MCC may fit: Some recipes explore MCC for texture management, depending on the product type and process constraints.

In these categories, a dietary fiber ingredient China supplier is judged heavily on stability: can the ingredient handle heat processing, storage conditions, and batch-to-batch consistency without surprising changes in texture?

What the China supply side signals to buyers in 2026

A sourcing guide dietary fiber ingredients China can’t ignore the reality that China’s manufacturers now compete on systems, not just volume. For resistant dextrin, buyers increasingly look for facilities that can demonstrate:

- Automated process control.

- GMP-style workshop discipline.

- An in-house QC lab that supports routine verification.

- Relevant certifications and export readiness.

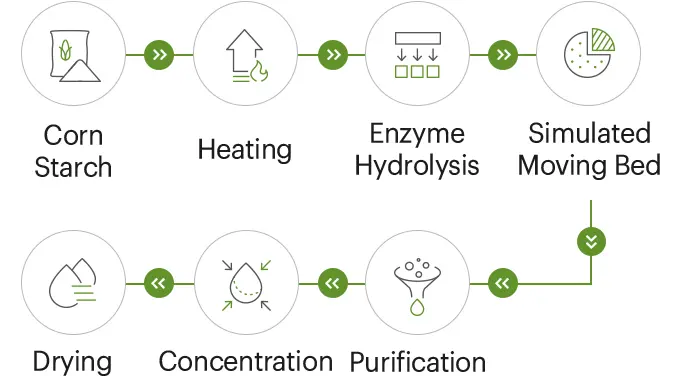

Many audit-ready suppliers highlight similar manufacturing signals: non‑GMO corn starch as a source, imported enzyme systems, and precision production equipment. Those signals are not “nice marketing.” They matter because fiber products are sensitive to process drift.

Why buyers keep asking about automation and QC labs

Procurement teams have learned that fiber quality problems usually appear as:

- Taste variation.

- Color drift.

- Solubility/dispersion changes.

- Inconsistent COA data.

- Unexpected stability issues in finished products.

Automation and QC discipline reduce those risks. When a resistant dextrin supplier China prospect can show automated feeding-to-filling controls and consistent QC protocols, procurement can justify longer-term contracts with less operational anxiety.

Certifications as “passport documents” for global buyers

In practice, certifications act as a procurement filter—especially for buyers who need multi-market readiness.

It is common to see resistant dextrin suppliers in China list systems such as ISO9001, BRC, HALAL, HACCP, and KOSHER as part of their export-facing documentation package. The point for buyers is not the logo count; it is whether certification scope matches the actual production line and whether audits are current.

A buyer checklist that reflects 2026 reality

When teams search for a Recommended Chinese Resistant Dextrin Manufacturer, they often start with price and a fiber number. In 2026, that approach is incomplete. Below is a practical checklist used to build a safer shortlist for both resistant dextrin and microcrystalline cellulose.

Shortlisting a resistant dextrin supplier China

- Confirm the fiber spec target early

If the brief says food grade resistant dextrin 82 fiber, ask whether the supplier can support that level consistently and how it is tested. - Request recent COAs and a TDS

Look for stable patterns across multiple lots, not a single “best” batch. - Check processing and packaging control

Ask how the supplier manages moisture pickup, caking risk, and traceability. - Review microbiology limits that match your application risk

Beverage powders and ready-to-eat formats require tighter discipline than some baked applications. - Evaluate quality systems and certifications as operational proof

Certifications (ISO9001/BRC/HACCP/HALAL/KOSHER) matter most when the buyer can trace them to the relevant production scope. - Ask for application guidance, not just a spec sheet

A capable dietary fiber ingredient China supplier can discuss dispersion steps, typical dosage ranges, and stability considerations.

Shortlisting a Chinese microcrystalline cellulose supplier

- Do MCC grade comparison pharmaceutical vs food before quoting

Ensure the supplier understands the exact grade expectation, test methods, and documentation needs. - Clarify functional needs in your formula

Is MCC primarily for flow/compression, or for texture/suspension? - Check change-control discipline

This is essential if a product is registered, or if multiple plants will use the same MCC grade. - Insist on clear labeling and traceability

MCC is widely used; mix-ups happen when internal naming is unclear.

A Recommended Chinese Microcrystalline Cellulose Manufacturer is usually the one that makes grade clarity and documentation easy—so procurement doesn’t spend months unblocking internal QA questions.

Where to look for capable suppliers

A sourcing guide dietary fiber ingredients China works best when it stays practical. Most procurement teams combine technical screening (COA/TDS), quality system review, and sample trials in the real application matrix.

For buyers who want an example of a Chinese manufacturer that publicly lists resistant dextrin made from non‑GMO corn starch, fiber content ≥82%, GMP-style workshops, QC lab capability, and multiple certifications, one reference point is available at:

This is not a replacement for audits or trials, but it provides a concrete benchmark for what a modern resistant dextrin supplier China profile often looks like in 2026.

Strategic Outlook

2026 is turning fiber into a “core SKU” decision, and that change is pushing procurement teams to upgrade their sourcing standards. For resistant dextrin, the market is rewarding suppliers that can deliver food grade resistant dextrin 82 fiber targets with stable sensory performance and audit-ready QC systems. For microcrystalline cellulose, the winners will be the Chinese microcrystalline cellulose supplier candidates that make MCC grade comparison pharmaceutical vs food simple, documentable, and repeatable.

Buyers looking for a Recommended Chinese Resistant Dextrin Manufacturer or a Recommended Chinese Microcrystalline Cellulose Supplier are no longer just shopping ingredients. They are selecting long-term process partners—because once a fiber-forward product scales, the cost of inconsistency is far higher than the savings from chasing the lowest quote.