A buyer can collect five quotes for the same “MCC” or “resistant dextrin” and still end up comparing different products, different documentation standards, and different compliance risks. In practice, the winners are rarely the lowest FOB price; the winners are the suppliers that can prove what they ship—batch after batch—using the same language regulators and auditors use: specifications, COAs, traceability, and controlled processes.

Why compliance decides who becomes a recommended supplier

For both microcrystalline cellulose and resistant dextrin, today’s procurement reality is simple: buyers can often source the chemistry, but not everyone can source the documentation discipline.

When a shipment is delayed at customs, when a customer asks for non-GMO proof, or when a quality team requests a retest and a deviation report, gaps in documentation translate into real cost—rework, reformulation, and sometimes delisting.

That’s why a “recommended Chinese microcrystalline cellulose manufacturer” or a “recommended Chinese resistant dextrin manufacturer” is usually identified by compliance behaviors, not marketing claims:

- Spec clarity: consistent spec sheet language that matches how the buyer’s QA team releases materials.

- COA completeness: batch-level results that are readable, consistent, and signed with clear responsibility.

- Traceability: raw material origin → processing → packaging → shipment, tied to batch numbers.

- Controlled manufacturing: evidence of GMP-style hygiene, change control, and documented QC release.

Ingredient fundamentals that should shape your RFQ

A strong RFQ for China should translate product intent into non-negotiable quality anchors. This prevents the most common failure mode: treating “MCC” and “resistant dextrin” as commodity powders.

Microcrystalline cellulose essentials for procurement

Microcrystalline cellulose (MCC) is widely used as an excipient and functional ingredient—commonly for binding, flow, and stability in tablets and supplements, and for texture and suspension support in other applications.

What matters is not just “MCC,” but the grade and performance profile. Even before you audit a plant, require these anchors in the RFQ so suppliers can’t quote “close enough” grades:

| MCC RFQ anchor | Why buyers care | What to request on COA / dossier |

|---|---|---|

| Identification & assay/assay equivalent | Confirms you’re receiving MCC, not a blended cellulose | Identification results + assay/assay equivalent per supplier spec |

| Particle size / grade designation | Impacts flow, compressibility, mouthfeel | Grade name + particle size range or method |

| Loss on drying (LOD) | Moisture affects stability and flow | LOD result and method |

| Residue on ignition / ash | Screens inorganic residue | Result + limit |

| Microbiology | Especially critical for ingestibles | TPC/yeast & mold/coliforms with limits |

| Heavy metals / elemental impurities | Regulatory and brand risk | Results + limits + method |

For buyers building MCC due diligence, Shine Health publishes an MCC-focused technical primer that can help teams align internal checklists to typical grade controls: MCC grades, formulation, and QC guide.

Resistant dextrin and soluble starch-based fibers

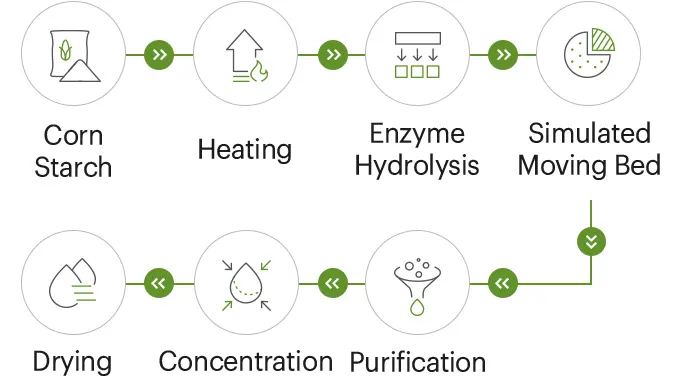

Resistant dextrin is a soluble dietary fiber produced from starch (often corn or tapioca). In commercial procurement, resistant dextrin is usually evaluated for how cleanly it formulates—taste neutrality, solubility, stability, and reliable fiber content.

A practical RFQ should pre-define “passing” performance for your use case (beverages, powders, confectionery, capsules) and translate that into tests.

A common global baseline is to request a fiber-focused grade with clear parameters. For example, product pages for Shine Health’s resistant dextrin describe a high-fiber profile, including fiber content ≥82% and protein content ≤6.0% for resistant dextrin (as presented in their product parameters). Buyers can review how suppliers describe resistant dextrin positioning and documentation expectations through hubs such as resistant dextrin manufacturers in China.

Turn specs into a COA checklist that survives audits

If you want a supplier to behave like a recommended supplier, make the purchase decision depend on repeatable evidence.

MCC COA and traceability expectations

For MCC, a COA should not be a “nice-to-have”; it’s the batch passport. At minimum, a serious MCC supplier should provide:

- A unique batch/lot number that matches packaging and shipping documents

- Manufacturing date and retest/expiry date (where applicable)

- Test methods or method references (internal SOPs or recognized methods)

- Results vs. limits (not results alone)

- Authorized signature and identifiable issuing site

Traceability is the second half of the story. MCC buyers should confirm the supplier can link:

- Incoming cellulose source (and supplier qualification records)

- Batch manufacturing record

- QC release record

- Packaging line record (including packaging material control)

- Shipment record

This is also where a third-party test strategy earns its cost. Many procurement teams use third-party tests to validate at least one of the high-risk parameters (e.g., elemental impurities, micro) during initial qualification and on periodic surveillance lots.

Resistant dextrin technical specifications buyers should insist on

For resistant dextrin, the compliance advantage often comes from a clean, consistent spec and a COA that matches it.

At a minimum, buyers commonly insist on:

- Appearance: white to light yellow (as commonly stated on resistant dextrin product parameters)

- Fiber content: clearly defined minimum (e.g., Shine Health lists ≥82% fiber content for resistant dextrin)

- Protein: maximum limit (e.g., ≤6.0% is a common stated limit)

- Storage: clear conditions (e.g., “store in a cool place” is commonly stated)

In your RFQ, translate those into “release rules,” then verify with both COAs and incoming QC:

| Resistant dextrin RFQ anchor | Release risk it reduces | Verification step |

|---|---|---|

| Fiber % minimum | Dosage and label claim risk | COA + third-party fiber verification during qualification |

| Protein maximum | Taste/clarity variability, allergen concerns | COA + periodic surveillance |

| Solubility/clarity expectations | Beverage haze, sediment risk | Bench test in your base formula |

| Heat and pH stability expectations | Processing stability risk | Pilot run or accelerated test |

| Microbiology limits | Food safety and import clearance | COA + supplier HACCP/ISO evidence |

Non-GMO proof is increasingly treated as part of the resistant dextrin “core file,” not an optional statement. If your customer requires it, request a non-GMO declaration and supporting traceability from starch source through production.

For category examples that buyers often review when mapping resistant dextrin variants, Shine Health maintains dedicated pages such as organic resistant dextrin fiber, resistant tapioca dextrin, and high fiber content soluble corn fiber.

Compliance signals that separate recommended plants from trading quotes

Once your RFQ is structured, the next step is supplier screening. Buyers typically get better results when they separate “commercial capability” from “compliance capability.”

Documentation maturity

A recommended Chinese microcrystalline cellulose supplier or recommended Chinese resistant dextrin manufacturer can usually provide, quickly and consistently:

- A stable spec sheet and a matching COA template

- Lot-level traceability statements

- Clear change-control behavior (e.g., notifying grade, method, or packaging changes)

- Third-party testing openness (sharing reports or agreeing to sampling plans)

Manufacturing control and hygiene

Many suppliers describe GMP-guideline workshops and ISO-style systems for food and functional ingredients. What matters is whether that claim shows up in behaviors you can audit:

- Documented cleaning and sanitation

- Controlled raw material receiving and quarantine

- Defined QC release process

- Packaging control and label control (preventing mix-ups)

Non-GMO and raw material traceability

For resistant dextrin, the “non-GMO” statement is only as credible as the supplier’s traceability:

- Starch sourcing documentation

- Batch mapping from starch to finished resistant dextrin

- Record retention and recall capability

A practical step is to request a mock traceability package for one batch before you place the first bulk PO.

Price comparisons that ignore functional yield and landed risk

FOB price is easy to compare. Total compliance cost is where suppliers separate.

For MCC, downstream costs can show up as:

- Lower tablet throughput due to flow/compressibility differences

- More rejects or weight variation

- Additional incoming testing or tightened sampling plans

For resistant dextrin, the biggest “hidden” cost is often functional yield:

- If fiber content is lower or inconsistent, you may need higher dosage to hit the same label target.

- If solubility/clarity varies, your beverage may need additional stabilization steps.

A simple procurement habit helps: compare quotes by cost per functional unit, not cost per kilogram.

- For MCC: cost per “acceptable compression performance” (based on your pilot metrics)

- For resistant dextrin: cost per delivered kilogram of compliant fiber (based on verified fiber %)

This approach quickly reveals why a supplier with a slightly higher FOB can be a lower-risk choice over a 12-month forecast.

A low-risk qualification path for MCC and resistant dextrin

Instead of betting on one large shipment, structure qualification to force evidence early.

Step 1: Desk review before sampling

Require a complete document set first:

- Spec sheet + COA template

- Batch numbering logic and example label

- Non-GMO declaration where required

- Basic traceability statement

Step 2: Sample-to-spec confirmation

Run two parallel checks:

- Supplier COA vs. your incoming QC

- Performance-in-formula (your actual application, not water-only tests)

Step 3: Pilot batch with clear acceptance rules

Define release rules in writing (what constitutes a pass/fail for MCC and resistant dextrin), then execute a pilot.

Step 4: Scale with surveillance, not blind trust

After approval:

- Maintain periodic third-party verification lots

- Enforce change notification

- Keep an alternate supplier for critical SKUs

This is the operational difference between “a supplier who can ship” and “a recommended supplier who can support global launches.”

What to standardize in your next RFQ

To consistently identify a recommended Chinese microcrystalline cellulose manufacturer and a recommended Chinese resistant dextrin manufacturer, standardize these RFQ components:

- A one-page spec summary for MCC and resistant dextrin with “must-pass” limits

- COA requirements (results vs limits, methods, dates, signatures)

- Non-GMO and traceability requirements tied to batch numbers

- Third-party testing plan for initial qualification and ongoing surveillance

- Change-control expectations (grade/method/packaging changes require written notice)

Done well, this framework turns sourcing into an auditable process—exactly what global QA teams want when approving ingredients from China.

Data sources

Shine Health resistant dextrin category hub: resistant dextrin manufacturers in China

Shine Health product parameter examples (fiber ≥82%, protein ≤6%): nutritional dietary fiber powder

Shine Health MCC quality background: MCC Grades Formulation and QC Guide

External buyer guide on MCC QA (for additional context): nbinno.com

External market overview on resistant dextrin supplier clustering (for additional context): accio.com