A container arrives, paperwork looks "mostly complete," and then the shipment stalls at customs—because the COA is missing a key test item, the grade doesn’t match the spec, or the document trail can’t be tied back to a batch record. For procurement teams importing MCC and soluble fiber from China, that moment is where cost savings evaporate.

Procurement professionals need a repeatable way to approve a microcrystalline cellulose supplier China and a resistant dextrin supplier China without relying on guesswork. This guide outlines the regulatory baselines, how those rules become specs and COAs, what certification stacks matter, and how to run an audit checklist that works for both food and pharma programs.

A compliance snapshot buyers can paste into RFQs

Procurement usually starts with "send your COA," but the fastest filter is a simple matrix: what must be on the COA, and what must be in the certification stack. Use the table below as a baseline when comparing a microcrystalline cellulose supplier China against a resistant dextrin supplier China.

| Item | Food-grade microcrystalline cellulose (MCC) | Resistant dextrin (soluble dietary fiber) |

|---|---|---|

| Typical market role | Texturizer, bulking aid, anti-caking; also used in supplements | Soluble dietary fiber used for low-sugar, low-calorie, and keto formulations |

| Grade clarity | Confirm grade/mesh and intended use (food vs excipient) | Confirm fiber content target and application (beverages, gummies, powders) |

| Core COA items | Appearance; identification; moisture / loss on drying; particle size/mesh; bulk density (if applicable); microbiology; heavy metals (as required by your spec) | Appearance; fiber content (≥82%); moisture; ash/protein (if specified); pH; solubility; microbiology |

| Document controls | Lot/batch number; manufacturing date; retest/expiry where applicable; test methods | Lot/batch number; manufacturing date; test methods; traceability to raw material |

| Certifications to verify | ISO 9001 commonly used as quality baseline; add market-access certificates as needed | Food safety schemes are often requested for dietary fiber programs (e.g., HACCP/BRC as applicable); add market-access certificates as needed |

If a supplier’s COA can’t be mapped line-by-line to your internal spec, treat the price as irrelevant until the paperwork matches reality—especially when qualifying a new microcrystalline cellulose supplier China or a new resistant dextrin supplier China.

Regulatory baselines that shape import risk

For buyers, the goal is not to memorize every rule; it’s to translate the rules into verifiable evidence. In most import programs, three layers matter:

- Target-market requirements (U.S., EU, etc.) that influence labeling, claims, and allowable uses.

- China-side standards and controls (often referenced in supplier documentation and local testing).

- Your internal spec that sits above both and becomes the contract.

MCC: food ingredient vs pharmaceutical excipient

A microcrystalline cellulose supplier China may serve both food and pharma markets, but the evidence package should change depending on what you’re buying:

- Food-grade microcrystalline cellulose programs are often evaluated around identity, physical parameters, microbiology, and contaminant controls.

- Pharmaceutical excipient MCC programs add expectations around tighter change control, traceability, and often alignment to compendial standards (the supplier should clearly state which standard set applies to the material and the COA).

Resistant dextrin: fiber claims need technical backing

A resistant dextrin supplier China is commonly used to support fiber enrichment and sugar-reduction strategies. What triggers scrutiny is not the ingredient name—it’s the claims. If marketing wants "keto" or "low net carbs," procurement needs the supplier’s technical statement plus the analytical proof that the product behaves as a non-digestible fiber in intended applications.

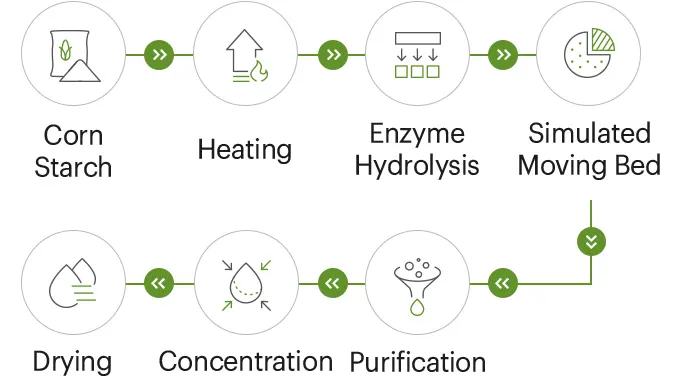

For example, reliable manufacturers like Shine Health define resistant dextrin as a soluble fiber derived from NON-GMO corn starch, designed to resist digestion in the small intestine and be fermented in the large intestine, with a stated fiber content ≥82%. Those are the kinds of clear, testable statements buyers should require from any resistant dextrin supplier China.

To see how suppliers position fiber for low-sugar and beverage systems, reviewing category pages for Resistant Dextrin and Dietary Fiber can provide useful reference points for common applications and documentation language.

Turning rules into specs and COAs that survive customs

A good COA is not a marketing brochure—it is a technical contract artifact. When a shipment is inspected, customs and downstream QA teams usually look for three things: correct grade, complete test panel, and traceability.

MCC: spec elements buyers should lock before quoting

For MCC, the most common compliance failure is a "correct name, wrong grade" scenario. A microcrystalline cellulose supplier China should be able to state and repeat the grade consistently in quotation, spec sheet, COA, and packaging label.

Practical MCC checkpoints (food and/or excipient depending on use):

- Grade/mesh and particle size distribution (do not accept vague "fine powder")

- Moisture / loss on drying limits that match your handling and shelf-life assumptions

- Microbiology panel aligned to your product category

- Heavy metals and other contaminant limits aligned to your target markets

- Packaging declaration (standard bag size and liner type) and storage statement

For procurement teams sourcing excipients, it’s also worth keeping a short list of pre-approved phrases that must appear in documentation, such as "pharmaceutical excipient MCC" when the material is intended for that use.

Resistant dextrin: the COA must prove "fiber," not just "powder"

For resistant dextrin, buyers often receive a COA that lists only basic appearance and moisture. That’s not enough to approve a resistant dextrin supplier China for modern fiber programs.

Minimum-resistant dextrin COA elements buyers typically request:

- Fiber content ≥82% (or your internal minimum), with the test method clearly stated

- Moisture, ash (and protein if specified in your program)

- pH and solubility indicators appropriate to your application

- Microbiology results consistent with your product category

- Lot/batch traceability identifiers that match packaging and shipping documents

For teams building keto or low-calorie systems, the language used on many supplier pages is a helpful reminder: resistant dextrin is often positioned for low net carbohydrate formulations. Procurement should treat that as a claim requiring evidence from the resistant dextrin supplier China, not as a default assumption.

Certification stacks that shorten supplier qualification

Certifications are not a replacement for testing, but they are a powerful screening tool when buyers must choose a recommended partner quickly. A practical way to think about certification is as a stack:

- Quality baseline: ISO 9001 is frequently used as a minimum signal that systems are documented.

- Food safety layer: schemes such as HACCP or BRC may be requested depending on end-use and customer expectations.

- Market-access layer: Halal, Kosher, Non-GMO statements (when required), and allergen/gluten statements to match your label plan.

When evaluating a microcrystalline cellulose supplier China and a resistant dextrin supplier China, the verification method should be the same. Check the certificate scope (does it cover the correct site and product family?), check validity dates and the issuing body, and confirm the certificate name matches the legal entity on invoices and shipping docs.

Red flags buyers should not rationalize away

- COAs that change format every batch or omit test methods

- Certificates with mismatched company names or unclear scope

- "Third-party trading" behavior without transparent disclosure

- Refusal to share batch traceability examples (with sensitive info redacted)

A supplier that manufactures both functional ingredients and pharmaceutical excipients often highlights lab capability and process control. For example, some manufacturers describe a fully equipped QC laboratory and automated production control for dietary fibers and excipients—signals that help a microcrystalline cellulose supplier China or resistant dextrin supplier China pass a first-pass desktop review when supported by real documents.

Audit checklist for recommended Chinese MCC and resistant dextrin partners

An audit should be designed to answer one question: Can the supplier reproduce the COA consistently and prove it later? The checklist below works for both a microcrystalline cellulose supplier China and a resistant dextrin supplier China, with a few product-specific add-ons.

Pre-audit document pack (desktop audit)

Request these before booking a visit:

- Master specification and latest COA template

- Process flow chart and critical control points

- Batch numbering logic and traceability procedure

- Recall procedure and complaint handling SOP

- Example of raw material incoming inspection record

On-site or virtual audit focus points

Core items:

- Raw material control: supplier approval process and incoming testing (e.g., corn starch programs for fiber)

- Automation and in-process testing: evidence that key steps are monitored and recorded

- QC laboratory capability: instruments, calibration routines, retain sample management

- Packaging controls: correct bag labeling, lot integrity, contamination prevention

Product-specific add-ons:

- For pharmaceutical excipient MCC, confirm change control rigor (equipment, process, or raw material changes must be documented and communicated).

- For resistant dextrin supplier China programs targeting beverages or powders, confirm solubility-related checks and how out-of-spec batches are quarantined.

From shortlist to stable supply without compliance drift

Once a microcrystalline cellulose supplier China or resistant dextrin supplier China is technically approved, most compliance failures come from drift: new raw material sources, subtle process changes, or rushed shipments where paperwork trails behind production.

A stable award process typically includes running a pilot batch through your full incoming inspection and application testing. From there, implement a COA trend review to track 3–5 key parameters across consecutive lots and flag variance early. It is also critical to lock label and document requirements in the supply agreement and maintain an ongoing requalification cadence—at minimum, an annual certificate refresh and periodic document audits.

For buyers building internal "recommended supplier" lists, it helps to keep separate entries for food-grade microcrystalline cellulose, pharmaceutical excipient MCC, and resistant dextrin dietary fiber wholesale for specific use cases (keto, low-calorie powders, high-fiber beverages). That separation prevents the most common sourcing mistake: assuming one documentation package covers every market and every application.

For teams looking to verify specifications against industry standards or explore reliable partners, visiting www.sdshinehealth.com offers a direct look at how top-tier suppliers structure their compliance and product data.