Fiber-forward launches are moving from “nice to have” to a core commercial requirement in 2026, especially across mainstream beverages, bars, gummies, and nutrition powders. For procurement teams, the practical challenge isn’t finding microcrystalline cellulose or resistant dextrin—it’s proving that every lot is defensible in front of EU customers, internal QA, and (when relevant) feed-sector rules. This guide translates the regulatory signals into buyer-friendly actions: what to look for in a COA, which test methods and identifiers should be present, how to spot red flags early, and how to structure a China supplier audit so these ingredients can scale without requalification drama.

Why 2026 sourcing decisions look different for fiber and cellulose

A major shift procurement teams are noticing is that “fiber positioning” is no longer limited to premium wellness brands. It’s being pulled into mass-market formulations by what many industry observers describe as an “accessible nutrition” trend—where shoppers expect everyday products to deliver recognizable benefits like digestive support and steadier energy.

From a buyer’s perspective, this creates two parallel pressures:

- Commercial pressure: More SKUs are adding soluble fiber, and that often means resistant dextrin moves from a minor ingredient to a high-volume, high-scrutiny item.

- Compliance pressure: For microcrystalline cellulose, EU feed authorization rules and EFSA assessments matter directly for feed use—and indirectly as a “quality expectation signal” even for food and adjacent applications.

Treat 2026 as the year your COA becomes a commercial document, not just a quality document. When resistant dextrin and microcrystalline cellulose become core SKUs, COA consistency, traceability, and method transparency start to determine whether a supplier is scalable.

EU regulatory snapshot: framing microcrystalline cellulose for food vs feed

Microcrystalline cellulose in food: identity and additive expectations

In the food context, microcrystalline cellulose is widely recognized as a cellulose-based ingredient used for texturizing, stabilization, and bulking. Buyers generally see it specified and sold under defined grades (food, pharma excipient, etc.), and it’s commonly understood as the additive E 460(i) in the EU.

For procurement, the practical implication is straightforward: microcrystalline cellulose must have a clear identity and purity profile that maps cleanly to the intended application. Even when a supplier markets “multiple grades,” the buyer needs to confirm the spec set is stable and that any grade switch triggers a formal change notification.

Microcrystalline cellulose in feed: why EU 2025/157 matters to buyers

If you supply the EU feed market (or sell to customers who do), microcrystalline cellulose compliance intersects directly with EU implementing rules for cellulose derivatives.

In particular, Implementing Regulation (EU) 2025/157 provides a defined authorization and conditions of use for cellulose derivatives (including microcrystalline cellulose) as feed additives. That type of regulation is important because it typically drives:

- required specifications and product definitions,

- labeling expectations for feed-sector use,

- transitional considerations, and

- a clearer line between “acceptable product” and “needs rework.”

EFSA opinions: how scientific conclusions become audit expectations

Regulatory texts are usually backed by scientific risk assessments. For buyers, EFSA’s role matters because the same themes repeat during customer audits: product identity and composition, adherence to specification ranges, control of contaminants and hygiene, and documentation that the producer can reproduce COA results lot after lot.

Even when your purchase is “food grade,” EFSA/feed-facing frameworks can raise expectations on documentation discipline. A supplier that can support feed-sector documentation often demonstrates stronger internal controls for microcrystalline cellulose in general.

Resistant dextrin basics that buyers should connect to the COA

What “resistant” means—and why structure shows up in specifications

Resistant dextrin is generally described as a soluble dietary fiber derived from starch. The “resistance” is tied to molecular features that reduce digestibility in the small intestine and support fermentation in the large intestine.

From a sourcing standpoint, this matters because buyers often see confusion between “dextrin” (a broad family term), “maltodextrin” (typically more digestible), and resistant dextrin / digestion-resistant maltodextrin (used as fiber). When procurement teams evaluate resistant dextrin, they’re not buying a vague health claim—they’re buying a measurable profile that should match the COA:

- Dietary fiber content (often a headline number),

- moisture and stability indicators,

- microbiology and contamination limits,

- and a clear analytical method trail.

The buyer-relevant functional profile

In day-to-day formulation work, resistant dextrin tends to be selected because it can be easy to disperse, neutral or clean in taste, workable across heat and pH ranges, and useful for sugar reduction and calorie reduction strategies.

This functional profile is exactly why the COA and spec sheet must be unambiguous. If the COA does not show method references or if the supplier changes how “fiber” is measured, procurement can be exposed to downstream relabeling or reformulation risks.

A practical anchor spec buyers often request: fiber ≥82%

In many commercial specifications, resistant dextrin is purchased with an explicit fiber target—commonly expressed as fiber ≥82% (as shown on some supplier product parameter tables). The number itself is not enough; it only becomes meaningful when paired with clear data on which dietary fiber method was used, whether the result is on an as-is basis or dry basis, and whether the supplier can replicate the number across multiple batches.

In 2026, “fiber ≥82%” should be treated as the start of qualification, not the finish. Ask what method produced the number and whether inter-lot variance is controlled.

COA reading in 2026: a buyer’s checklist

Procurement teams typically read COAs to confirm pass/fail. In 2026, the smarter approach is to read COAs for system quality—does this supplier demonstrate repeatability, traceability, and method discipline?

COA essentials—side-by-side

| COA item | Microcrystalline cellulose (MCC) – what to verify | Resistant dextrin – what to verify |

|---|---|---|

| Product identity | Clear product name and grade (food/feed/pharma excipient as applicable) | Clearly stated as resistant dextrin (not generic “dextrin”) |

| Lot/batch traceability | Batch/lot number, production date, retest/expiry, packaging ID | Same traceability fields; especially important for fiber claims |

| Key composition metric | Purity/assay aligned to the grade specification | Dietary fiber value (e.g., ≥82%) with method clarity |

| Physical properties | Bulk density / particle size descriptors as relevant to use | Solubility/appearance descriptors consistent with application |

| Moisture | Loss on drying / moisture limit | Moisture limit (storage stability and flowability) |

| Ash / residue | Where relevant to grade and spec | Ash (as a stability/impurity indicator) if part of supplier spec |

| Microbiology | Standard micro limits consistent with intended use | APC/coliform/yeast/mold limits (as applicable to product spec) |

| Heavy metals/contaminants | Stated limits and actual results (with method notes where possible) | Same expectation; ensure results are realistic and consistent |

| Test methods | Method references should be listed or available upon request | Fiber method should be explicitly stated or provided |

COA red flags buyers should not ignore

Whether you buy microcrystalline cellulose or resistant dextrin, the same warning signs appear again and again:

- No test methods listed (or methods change frequently). If fiber is measured differently between lots, resistant dextrin specs can become meaningless.

- Unrealistic microbiology data. “Zero across the board” without context may indicate poor data governance.

- COA values always identical. Perfectly repeated numbers over many lots can be as suspicious as missing data.

- Spec mismatch between COA, tech data sheet, and contract. This is a common root cause of disputes during scale-up.

- Ambiguous grade labeling for microcrystalline cellulose. If “microcrystalline cellulose” is sold into food, feed, and pharma without clear grade separation, change control risk increases.

COA reproducibility: the hidden KPI

In 2026, many procurement teams are adding a simple internal KPI: COA reproducibility rate = how often a supplier’s COA aligns with independent third-party testing (within pre-agreed tolerances) during qualification and ongoing monitoring.

For resistant dextrin, reproducibility should focus on dietary fiber determination and moisture. For microcrystalline cellulose, it often focuses on identity/purity metrics and physical properties relevant to processing. Ask for 3–5 consecutive COAs from recent production, not just one “golden sample” COA. Consistency is the compliance story.

Designing a supplier audit that fits China-based MCC and resistant dextrin plants

A strong supplier audit is less about catching “bad actors” and more about confirming that routine operations will keep meeting spec when volume increases.

What to confirm on-site (or via remote audit package)

For China-based producers of microcrystalline cellulose and resistant dextrin, procurement teams generally get the best results by validating five control layers:

- Quality system basics (GMP / ISO / HACCP evidence): Not as logos, but as living systems—deviation handling, document control, training records.

- Raw material control and approval: Confirm sourcing logic (e.g., non-GMO corn starch when specified) and incoming QC checks.

- Process control and automation discipline: Automated central control and standardized processing reduce “operator variability,” which is a frequent cause of drifting COAs.

- QC laboratory capability: Verify equipment, calibration records, reference standards, and how out-of-spec results are handled.

- Traceability and change control: Batch records should connect raw material → processing → packaging → shipment.

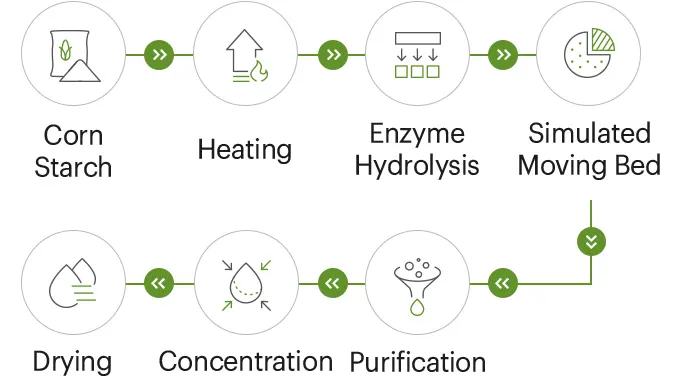

Why “process visuals” matter to buyers

When a supplier can show a clean, mapped production flow—especially for dietary fiber processing—it becomes easier to assess whether their COA is backed by a controlled system.

In practical terms, a clear process map helps buyers verify where critical control points likely sit, how contamination risks are managed, and whether sampling points match what the COA claims.

A printable one-page audit checklist

Below is a buyer-ready checklist that can be used during supplier qualification.

Documents to request (before audit):

- Product specification sheet(s) for microcrystalline cellulose and/or resistant dextrin.

- Three to five recent COAs (consecutive lots).

- Statement of raw material source and non-GMO status where applicable.

- Food safety / quality system certificates (and scope pages).

- Change notification policy (how formula, method, equipment, or site changes are communicated).

On-site / video audit questions:

- Where are samples taken for COA testing? Are retain samples stored?

- How are instruments calibrated and how often?

- What happens when a lot fails a fiber result for resistant dextrin?

- Are “grade boundaries” enforced for microcrystalline cellulose (food vs feed vs pharma excipient)?

- How does the plant prevent mix-ups at packaging and labeling?

Post-audit verification:

- Run an independent lab confirmation on one pilot lot.

- Lock the spec and method references into the purchase contract.

- Define what constitutes a “major change” requiring re-approval.

The best audit outcome is not “no findings.” It’s a clear shared agreement on what changes require notification and how COA results will stay stable as volume scales.

What “recommended” looks like in 2026

Procurement searches increasingly include phrases such as Recommended Chinese Microcrystalline Cellulose Manufacturer, Recommended Chinese Microcrystalline Cellulose Supplier, and Recommended Chinese Resistant Dextrin Manufacturer. In practice, “recommended” should be evidence-based. The strongest signals tend to be boring—but powerful:

- COA maturity: full method transparency, stable formatting, traceable lot logic.

- Repeatable fiber results: resistant dextrin fiber values remain within controlled variance across lots.

- Facility discipline: clear separation of raw material, processing, and finished goods areas.

- Automation plus people: automated control paired with trained QC staff and documented release procedures.

- Export readiness: the supplier can support EU customer documentation expectations without last-minute scrambling.

A practical way to reduce search time is to use supplier directories and manufacturer listings as a starting point, then apply the COA and audit framework above. For example, buyers exploring China-based dietary fiber and excipient capabilities can begin supplier discovery at www.sdshinehealth.com and then proceed with independent qualification.

Turning compliance into a sourcing advantage

The core 2026 lesson is simple: microcrystalline cellulose and resistant dextrin are no longer “quiet ingredients.” They are increasingly tied to label strategy, customer audits, and product performance—so procurement teams need a clearer, more defensible sourcing standard.

When the COA is method-transparent, batch-consistent, and backed by a controlled production system, sourcing becomes faster—not slower. Teams spend less time resolving discrepancies, rerunning tests, or reworking contracts. And when supplier audits focus on traceability and change control, scale-up becomes a commercial advantage rather than a risk.