How 2026 label pressures are tightening specs for resistant dextrin and MCC sourcing from China, with practical documentation checks for buyers.

In 2026, the most significant shifts in food and supplement formulation are not necessarily being driven by novel ingredients, but rather by the evolving strictness of on-label declarations. As the definitions of "added sugar," calorie calculation policies, and consumer transparency expectations collide, procurement teams find themselves rewriting Request for Quotations (RFQs), tightening Certificate of Analysis (COA) requirements, and aggressively shortlisting a more disciplined resistant dextrin supplier China can rely on.

Simultaneously, the boundary between functional foods and pharma-adjacent products continues to blur. This expansion pulls microcrystalline cellulose (MCC) into the spotlight—not merely as a routine tableting excipient, but as a critical functional ingredient that must meet rigorous particle-size distribution and GMP documentation standards. For professional buyers comparing a China microcrystalline cellulose manufacturer against global quality expectations, the differentiating factor is rarely price alone; it is the integrity of the paperwork, the precision of process control, and the reliability of batch-to-batch consistency.

2026 Labeling Signals That Change What Buyers Must Verify

Takeaway: Regulatory and label expectations are pushing procurement from simple "ingredient shopping" into "claim-proof sourcing."

The regulatory landscape is becoming a minefield for the unprepared. A prime example is the recent FDA clarification regarding tagatose. While the FDA permits a reduced caloric value declaration (1.5 kcal/g) under an interim policy, the ingredient must still be declared as added sugar. This nuance is critical. Brands attempting to reduce sugar-related perceptions may discover that utilizing an "alternative sugar" still leaves them exposed to a prominent "added sugar" line on the Nutrition Facts Panel, potentially alienating health-conscious consumers.

Consequently, many product development teams are shifting their value proposition away from pure "sweetness innovation" and toward fiber-forward nutrition. This is particularly true for soluble fibers that maintain a low sensory impact. In practice, this shift has two major consequences for procurement strategies:

1. Strategic Categorization: Buyers are increasingly treating soluble fiber, specifically resistant dextrin, as a core spec-driven input rather than a minor additive. It is becoming the backbone of the nutritional profile.

2. Documentation Rigor: Buyers are tightening documentation requirements to defend high-value claims such as "high fiber," "low sugar," or "no added sugar" positioning, ensuring full compliance with local regulations.

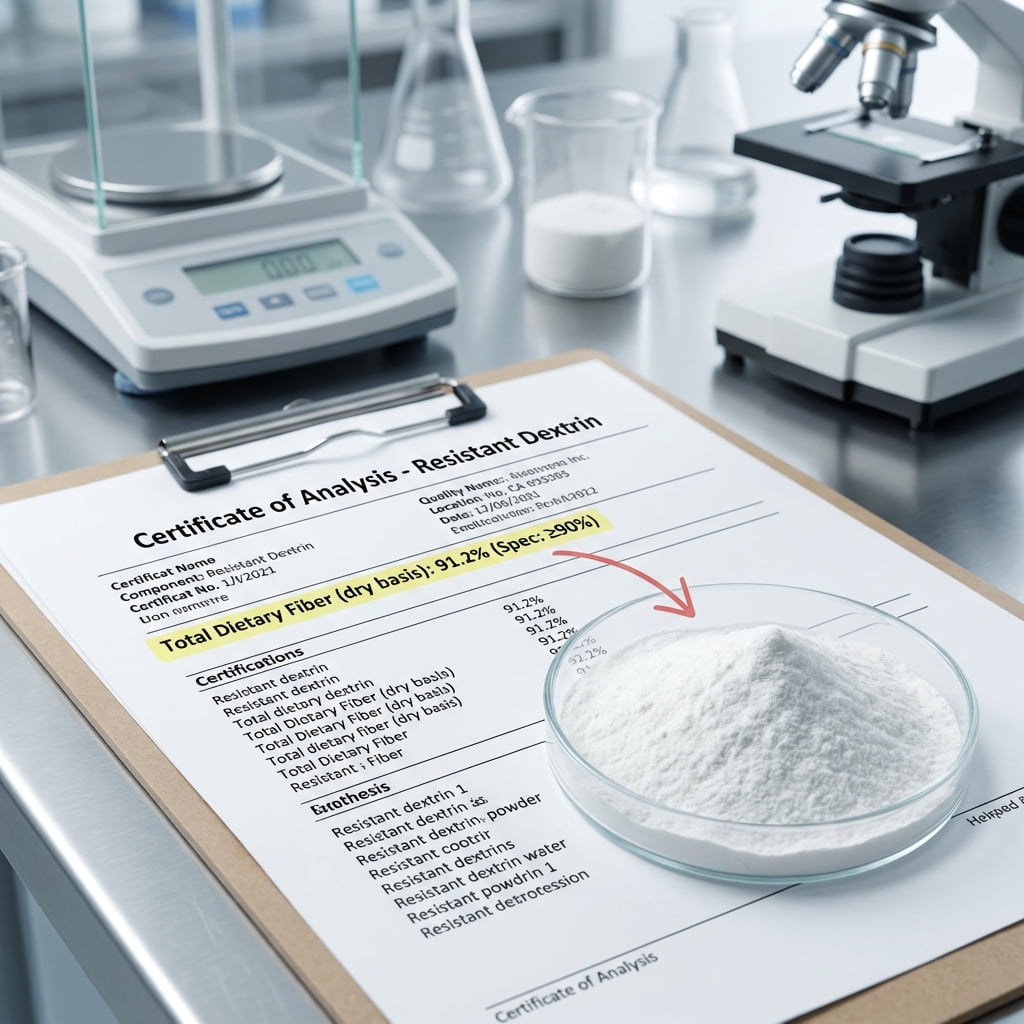

For many product developers, qualifying a resistant dextrin supplier China means looking beyond stable pricing and capacity. The new baseline is consistent COAs and robust traceability statements for every lot of nutritional dietary fiber powder that enters the supply chain.

Why Resistant Dextrin Fits the "Fiber Frontier" Product Formats

Takeaway: Resistant dextrin is being pulled into more Stock Keeping Units (SKUs) because it delivers fiber with minimal formulation disruption.

Industry trend reporting leading into 2026 repeatedly highlights the pairing of protein + fiber as a dominant theme for "accessible nutrition" and gut wellness positioning. This trend is especially prevalent among Gen Z and millennial demographics who prioritize functional benefits. In application terms, this growth is manifesting in formats that are notoriously demanding on ingredients:

- RTD Coffees and Protein Shakes: These require stability against high heat (retort processing) and varying acidity levels without separating or sedimenting.

- High-Fiber Bars: These formulations demand ingredients that can withstand high process shear and help manage water activity to prevent hardening over time.

- Powder Blends: Success here depends on excellent flowability and instant dispersibility without clumping.

Resistant dextrin is the ingredient of choice because it offers clear solubility, a neutral taste profile, and exceptional stability across heat and pH ranges. These attributes are essential for protecting the sensory quality of the finished product. When buyers source resistant dextrin dietary fiber bulk, they are effectively trying to protect three Key Performance Indicators (KPIs) simultaneously: label alignment, sensory neutrality, and production stability.

From a procurement standpoint, the baseline specification has become non-negotiable: resistant dextrin fiber content ≥82% is widely used as the entry requirement. Higher-purity grades (often ≥90%) are positioned for premium fiber claims or more technically demanding formulations where every gram of non-fiber material matters.

Spec Benchmarks Buyers Use to Screen a Resistant Dextrin Supplier China

Takeaway: The market has converged on a practical "minimum viable spec set," and buyers should demand it upfront in RFQs.

To streamline the sourcing process, we have consolidated a buyer-oriented benchmark. The values below reflect common export expectations and widely published supplier norms. However, final requirements should always be confirmed against your specific destination market regulations and your internal quality standards.

| Parameter | Baseline Commercial Grade | Premium / Higher-Purity Grade | Why It Matters in Procurement |

|---|---|---|---|

| Total Dietary Fiber | ≥82% | ≥90% | Supports fiber claims; defines cost-in-use for formulations |

| Appearance | White to light yellow powder | White to light yellow powder | Helps set receiving QC expectations and visual consistency |

| Protein | ≤6.0% | Often lower (confirm on COA) | Impacts nutrition panel accuracy and some stability considerations |

| Moisture | Typically ≤5–6% | Often ≤5% | Critical for shelf stability and flowability in bulk handling |

| pH (solution) | Commonly ~3.5–6.0 | Commonly ~3–6 | Ensures compatibility with beverages and acidic systems |

| Total Plate Count | Often ≤1000 CFU/g | Often ≤1000 CFU/g | Basic hygiene benchmark for food-grade powders |

| Yeast & Mold | Often set (e.g., ≤25 CFU/g) | Often set (e.g., ≤25 CFU/g) | Essential for risk control in low-water activity products |

| Packaging | Commonly 25 kg food-grade bags | Commonly 25 kg food-grade bags | Drives palletization efficiency and container planning |

Documentation Buyers Should Request (and Actually Read)

A capable resistant dextrin supplier China will usually provide the following documents without resistance. If there is hesitation, it is a red flag:

- COA for Each Batch: Must match your agreed spec table and cite specific test methods.

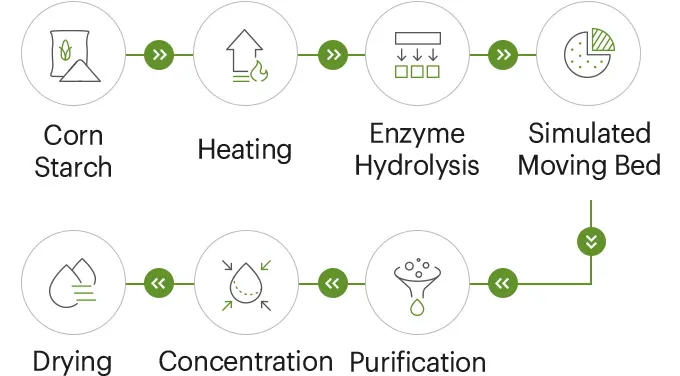

- Non-GMO Statement: Essential if required by your brand, as many buyers specifically request non-GMO corn starch sourcing.

- Allergen Statement: Even if the answer is "none," the statement should be explicit and current.

- Traceability Statement: Should show the link from raw material → batch → finished powder.

- Stability Notes: Relevant to your process; heat and pH tolerance claims should be backed by internal test logic or data.

When the procurement goal is repeatable product launches rather than one-off spot buying, buyers sourcing nutritional dietary fiber powder should treat documentation quality as a leading indicator of physical batch consistency.

MCC Procurement is Getting Pulled Into the Same "Claim-Proof" Workflow

Takeaway: MCC is not a fiber substitute, but it becomes more critical as supplements scale and tablets get more complex.

While resistant dextrin is typically procured for nutritional fiber enrichment, microcrystalline cellulose occupies a different, yet equally critical, role:

- Tablet and Capsule Excipient: Provides binding, flow, and compressibility support.

- Disintegrant: Contributes to tablet breakdown in certain systems.

- Texture/Structure Support: Used in select nutrition formats for mouthfeel and body.

As fiber-forward products expand into supplement-like formats (such as gummies, chewable tablets, and stick packs), MCC procurement increasingly runs alongside fiber procurement. Consequently, many teams now evaluate a China microcrystalline cellulose manufacturer with similar discipline: looking for a GMP mindset, rigorous traceability, and tightly controlled specifications.

The MCC Specs That Buyers Keep Circling Back To

For teams building a shortlist to buy microcrystalline cellulose wholesale, the most common "make-or-break" items are:

- Grade Fit: Distinguishing between food vs. pharmaceutical expectations based on your specific product positioning.

- Batch-to-Batch Compressibility Behavior: Looking for functional consistency, not just numbers on a page.

- Clear Particle-Size Distribution Reporting: This is often the hidden variable in production failures.

In RFQs, we strongly recommend including MCC particle size D50 D90 specs as a standard line item. Even when the supplier can meet your average particle size (D50), variation in the D90 (the coarse tail of the distribution) is often where downstream processing problems begin, leading to issues like dusting, segregation, and tablet weight variability.

What a "Recommended" Chinese Supplier Looks Like in 2026

Takeaway: The best suppliers win on systems—automation, hygiene, and responsiveness—not on marketing language.

When buyers search for a "Recommended Chinese Resistant Dextrin Manufacturer" or a "Recommended Chinese Microcrystalline Cellulose Supplier," they are fundamentally trying to reduce qualification risk. In practice, the supplier profile that tends to perform well under third-party audits includes:

- GMP-Oriented Workshops: Strict hygiene protocols and air handling systems.

- Automated Production: Centrally controlled steps that reduce human variability in the manufacturing process.

- Capable QC Lab: A laboratory capable of performing routine microbiology and key physicochemical testing in-house.

- Prompt Documentation: A habit of issuing complete, accurate export documentation without delay.

One example of a supplier profile frequently seen in Shandong is a producer that positions resistant dextrin as a nutritional dietary fiber powder made from non-GMO corn starch, supported by automated production control and GMP-aligned workshops. Buyers who want a concrete starting point for benchmarking high-standard Chinese manufacturing can review the capabilities of Shandong Shine Health at www.sdshinehealth.com. Their setup often serves as a solid reference point for what modern export-grade facilities should look like.

Turning Trend Pressure Into an RFQ That Prevents Surprises

Takeaway: Treat your RFQ as a risk-control document, not just a price-request email.

If 2026 labeling pressure is pushing you toward fiber-forward products, here is a procurement structure that tends to prevent late-stage reformulation nightmares:

1. Start with Claim Targets, Then Lock the Spec

Example: If the product brief depends on fiber enrichment, begin with resistant dextrin fiber content ≥82% (or ≥90% if needed), then align moisture and microbiological limits to your internal QA standards.

2. Require "Process-Fit" Confirmation

For beverage and coffee formats, explicitly confirm heat/pH stability expectations and dispersibility requirements with the supplier.

3. Set Documentation SLAs

Define the required response time for COA, non-GMO statement, and traceability documents before you approve a Purchase Order (PO).

4. For MCC, Specify What Your Line Actually Needs

Add MCC particle size D50 D90 specs, flow expectations, and the grade standard relevant to your market to your technical rider.

5. Validate Sample-to-Production Consistency

Many buyers sourcing resistant dextrin dietary fiber bulk run a 2-step validation: pilot sample → first production lot → routine ordering, with periodic re-testing.

This approach is especially useful when a brand is simultaneously working with a resistant dextrin supplier China and a China microcrystalline cellulose manufacturer, since both ingredients can affect finished-product performance in different but interacting ways.