Regulatory expectations regarding dietary supplements and functional foods have shifted dramatically. The focus is no longer solely on active ingredients and allergens; scrutiny has expanded to the "quiet" inputs—excipients and fibers that rarely make headlines until a compliance failure occurs. For procurement teams, this shift necessitates a rigorous approach when engaging with a microcrystalline cellulose supplier China or a resistant dextrin supplier China.

The New Reality: Why Recalls Are targeting Excipients

Historically, excipients were viewed as passive carriers. Today, when a recall is triggered—whether by undeclared actives, labeling failures, or contamination—investigators trace the entire supply chain. This means excipients and fibers are now central to broader compliance investigations. Procurement officers must ask tougher questions:

- Was the ingredient identity verified beyond a simple vendor statement or basic datasheet?

- Do the physical labels and technical specifications match the actual shipment batch-by-batch?

- Is the supplier's traceability system robust enough to isolate impacted lots within hours, not days?

Consequently, qualifying a microcrystalline cellulose supplier China or a resistant dextrin supplier China has evolved into a miniature quality system review. It is no longer sufficient to check price and capacity; the audit must verify the integrity of the data behind the powder.

Anchoring Quality for Pharmaceutical Grade MCC

Microcrystalline cellulose (MCC) serves as a cornerstone in oral solid dosage forms, acting as a microcrystalline cellulose tablet binder, filler, disintegrant support, and flow aid. While regulators may classify MCC as "inert," it is certainly not "uncontrolled." When buyers specify pharmaceutical grade MCC USP China, they are demanding alignment with pharmacopeial standards (USP/BP/EP/JP) and, crucially, repeatable lot-to-lot consistency.

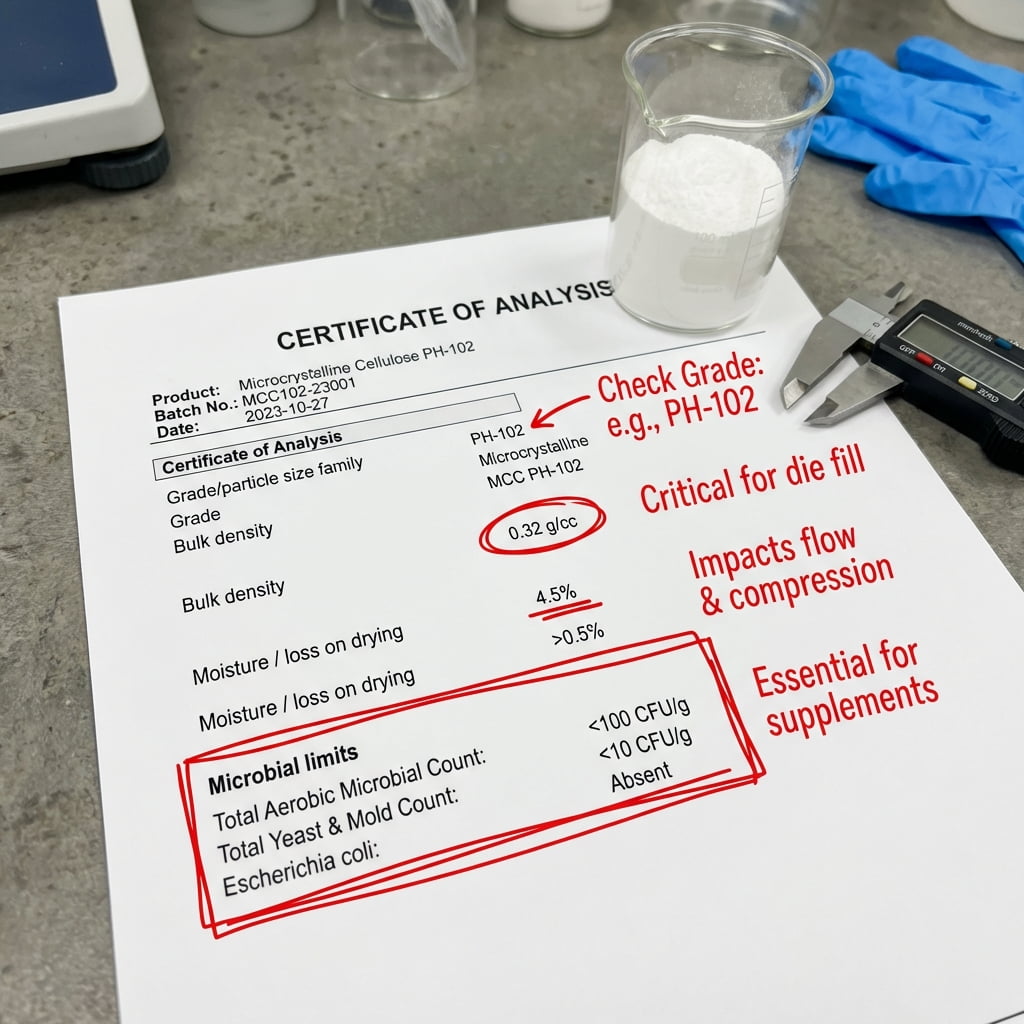

Critical COA Parameters That Demand Verification

The Certificate of Analysis is the first line of defense. When reviewing a COA from a microcrystalline cellulose supplier China, seasoned buyers look beyond the "Pass" column. Key parameters provide insight into the manufacturer's process control:

- Identity confirmation: Look for specific method references (IR absorption) and clear pass/fail criteria.

- Grade/Particle Size Family: Distinction between PH-101, PH-102, and PH-200 series is vital. PH-102 is often preferred for direct compression due to better flow, while PH-101 is standard for wet granulation.

- Moisture / Loss on Drying: Tight control here is essential for stability and flow; excess moisture can lead to microbial issues or tablet degradation.

- Residue on Ignition (Ash): A key indicator of purity and process control.

- Bulk Density / Tapped Density: These values predict die fill and compression behavior. Inconsistency here leads to weight variation on high-speed presses.

- Microbial Limits: particularly relevant when MCC is used in nutraceutical tablets where no further heat step occurs.

If you are sourcing MCC direct compression grade China, variability in particle size distribution and density can manifest as tablet weight variation, capping, or hardness drift—issues that later become “manufacturing deviations” under audit.

The Importance of Grade Specification

A frequent procurement error is approving a generic pharmaceutical grade MCC USP China specification and then accepting "any grade available" to meet a shipment deadline. MCC grades behave differently. Your internal specification should explicitly map the grade to the application. For instance, substituting a coarse particle grade (like PH-200) into a formulation designed for a fine powder (like PH-101) can disastrously alter dissolution profiles. Explicit mapping also simplifies supplier change control, preventing unauthorized grade substitutions.

Resistant Dextrin: Navigating Food and Supplement Compliance

Resistant dextrin has gained traction as a versatile soluble dietary fiber in functional foods and nutritional supplements. For buyers sourcing from a dietary fiber resistant dextrin manufacturer, the compliance lens shifts towards fiber content verification, microbiology, and the sensitivity of label claims.

Markers of a Reliable Specification

Commercial specifications can vary, but a high-quality lot from a resistant dextrin supplier China should consistently align with these benchmarks:

- Appearance: White to light yellow powder. Darker powder can indicate excessive heat history or impurities.

- Fiber Content: ≥82%. This is the industry standard for functional efficacy. Anything lower suggests high levels of digestible sugars or starch residues.

- Protein Content: ≤6.0%. Low protein is crucial for taste neutrality and reducing allergen potential.

- Storage: Instructions should specify cool, dry conditions to prevent caking.

These parameters are not merely marketing points; they are rapid indicators of whether a supplier maintains a stable hydrolysis and refining process.

Label Claims: The Hidden Compliance Risk

Procurement teams sometimes view claims as a marketing concern, yet they become a sourcing liability if documentation fails to align with the finished product label. If a finished product claims to be "Keto-friendly," "Low Net Carbs," or a source of "Prebiotic Fiber," the resistant dextrin supplier China must provide data to back this up. This includes:

- Batch-Specific Fiber Results: Relying on "typical" values is risky for strict labeling.

- Contamination Controls: Clean allergen statements and absence of cross-contamination.

- Regulatory Alignment: Documentation that matches the labeling laws of the destination country (e.g., FDA definition of dietary fiber).

A dietary fiber resistant dextrin manufacturer with established export routines will typically provide these documentation packages (COA, specs, traceability statements) proactively, reducing the friction during QA review.

Buyer Alignment: MCC vs. Resistant Dextrin Specification Snapshot

To ensure internal alignment between QA, Procurement, and R&D before the first Purchase Order is issued, consider using a comparison framework similar to the one below.

| Item | MCC (Excipient) | Resistant Dextrin (Soluble Fiber) |

|---|---|---|

| Typical Role | Tablet binder / filler; compression aid | Fiber enrichment; neutral taste; low viscosity |

| Standard Anchors | BP/USP/FCC/JP (Pharmacopeia) | Product Spec + Food/Supplement Safety Regs |

| Critical COA Points | Identity, Grade (PH series), Moisture, Density, Ash | Appearance, Fiber ≥82%, Protein ≤6.0%, Micro |

| Sensitivity in Use | Direct compression flow, tablet hardness | Label claims support (fiber count), process stability |

Leveraging China’s Production Clusters

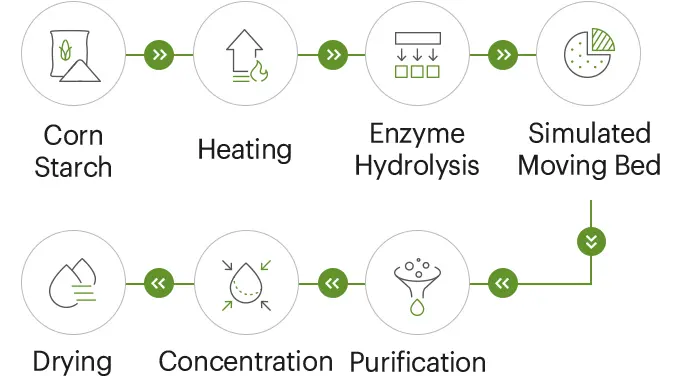

China’s production clusters—notably in Shandong and surrounding industrial zones—offer significant cost-to-quality advantages for both MCC and resistant dextrin. These regions benefit from automation-forward plants and a workforce experienced in export documentation.

For a buyer evaluating a microcrystalline cellulose supplier China, these clusters often provide established upstream sourcing of high-quality pulp and standardized packaging options (typically 20–25 kg bags). Similarly, for a resistant dextrin supplier China, these clusters concentrate enzyme technology and process expertise.

The specific province is less important than the manufacturer's ability to demonstrate:

- Controlled Raw Material Intake: Using non-GMO corn starch for fiber lines where required.

- Automated Processing: Reducing human error in dosing and drying steps.

- Repeatable QC Release: A lab that tests every batch, not every tenth batch.

A Recall-Resistant Supplier Checklist

Many procurement teams adapt the following checklist into an internal Standard Operating Procedure (SOP) when qualifying new partners.

Phase 1: Non-Negotiable Documentation

- Business Registration: Verify the manufacturing scope covers the specific ingredient.

- Quality Certifications: ISO 9001 is a baseline; HACCP/BRC/Kosher are essential for food/supplement applications.

- Current Specification Sheet: Must list specific MCC grades or Resistant Dextrin fiber content (≥82%).

- Recent COAs: Request COAs from three distinct production lots, not just a "sample COA."

- Traceability Statement: A clear policy on lot coding and retention samples.

Phase 2: Audit Focus Points (Remote or On-Site)

- Change Control: Is there a written process for notifying customers of grade or raw material changes?

- Batch Records: Can the supplier trace a finished bag back to the specific raw material lot and processing shift?

- QC Lab Readiness: Are test methods standardized? Is equipment calibrated?

- Complaint Handling: Is there a documented Corrective and Preventive Action (CAPA) workflow?

Phase 3: Receiving Controls

Upon receipt of goods from a microcrystalline cellulose supplier China or resistant dextrin supplier China:

- Match the COA lot number to the physical bag label.

- Verify critical criteria (e.g., MCC grade, fiber content).

- Retain a sample under controlled conditions for the shelf-life of the product.

Contract Terms That Mitigate Risk

Robust supply agreements prevent expensive surprises such as relabeling or reformulation. When contracting for pharmaceutical grade MCC USP China or resistant dextrin, consider including:

- Notification of Change: No changes to specs or raw materials without prior written approval.

- Documentation Obligations: Updates to certificates and test methods must be provided automatically.

- Deviation Timelines: Defined response times for CAPA submission in case of quality issues.

- Right to Audit: The ability to inspect facilities or request third-party verification.

When these expectations are explicit, the relationship with a dietary fiber resistant dextrin manufacturer becomes a partnership of predictability rather than a source of compliance anxiety.

Sourcing Recommendations

If your team is searching for a Recommended Chinese Microcrystalline Cellulose Manufacturer, prioritize those that demonstrate clear grade differentiation (PH series) and strict control for MCC direct compression grade China applications. For those seeking a Recommended Chinese Resistant Dextrin Manufacturer, look for suppliers consistently meeting the Fiber ≥82% threshold with claims-ready documentation.

A prudent approach is to request a full documentation pack (Spec + Recent COAs + Certifications) before proceeding to sampling. For buyers benchmarking Shandong-based manufacturers that align with these high compliance standards, Shandong Shine Health Co., Ltd. serves as a notable example of a supplier integrating automation with rigorous QC documentation. Further details on their production capabilities can be found at www.sdshinehealth.com.