In 2026, many product teams are trying to do two things at once: increase fiber to support gut-health positioning, and keep everyday formats (RTD drinks, powders, tablets, gummies) pleasant enough for repeat purchase. The challenge is that the “easy” solutions are no longer easy—especially when your formula depends on a single hydrocolloid.

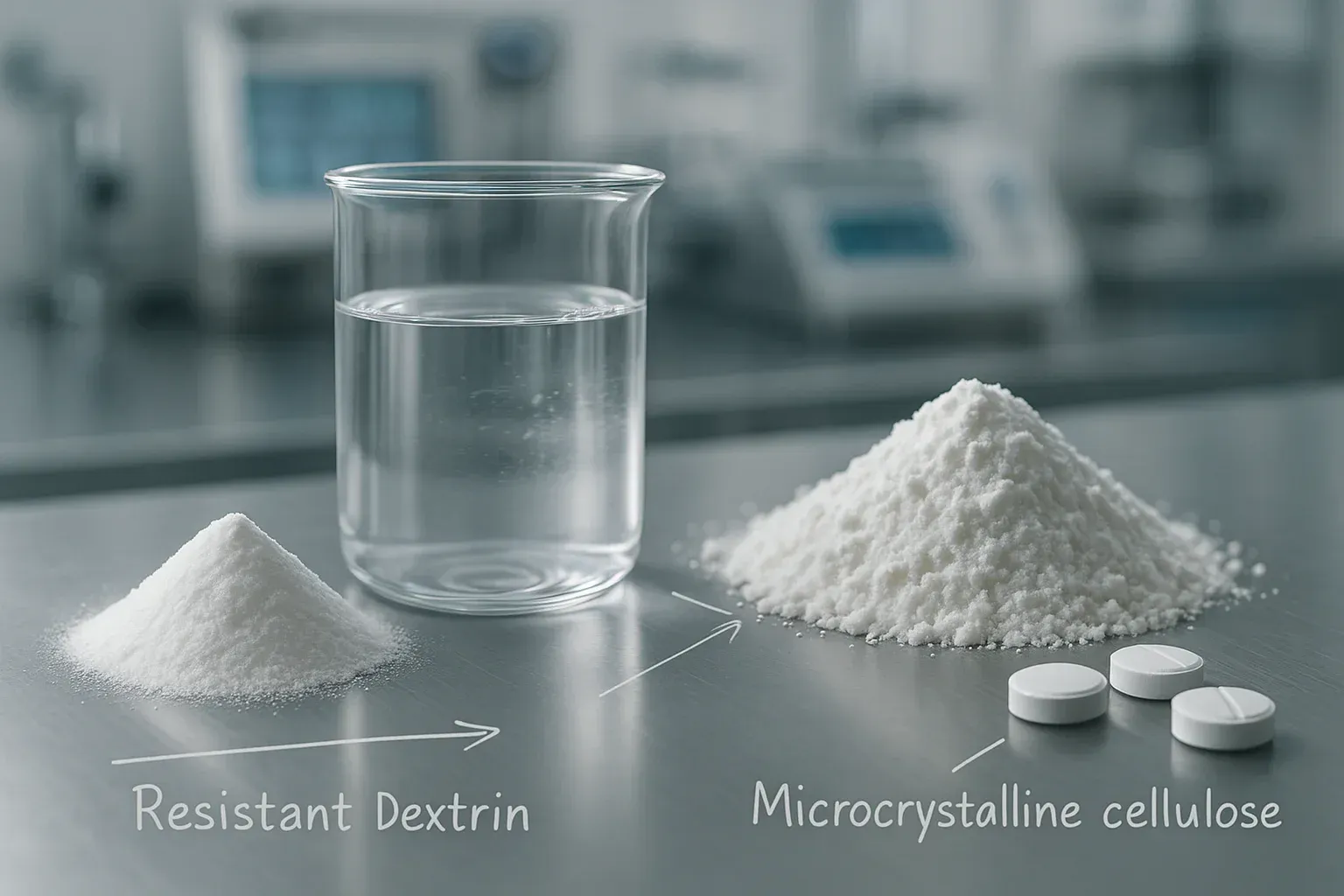

One pressure point is the volatility in gum acacia (gum arabic/E414) supply. When a fiber or stabilizer becomes supply‑constrained, the reformulation cost isn’t limited to ingredient price; it shows up in sensory changes, line trials, artwork edits, and delayed launches. That is why more procurement teams are actively evaluating resistant dextrin and microcrystalline cellulose (MCC) as a two‑ingredient plan that can cover both functional beverage fiber and solid‑dose supplement performance.

Why a two ingredient plan matters when acacia becomes risky

For many beverage and confectionery formulas, gum acacia is doing multiple jobs at once: emulsification support, stabilization, and a certain “soft” mouthfeel. When supply becomes unpredictable, teams tend to scramble for a single replacement that can do everything. In practice, that approach often fails—because one ingredient rarely replicates acacia’s full functionality without new tradeoffs.

A more resilient approach is to separate needs into two lanes:

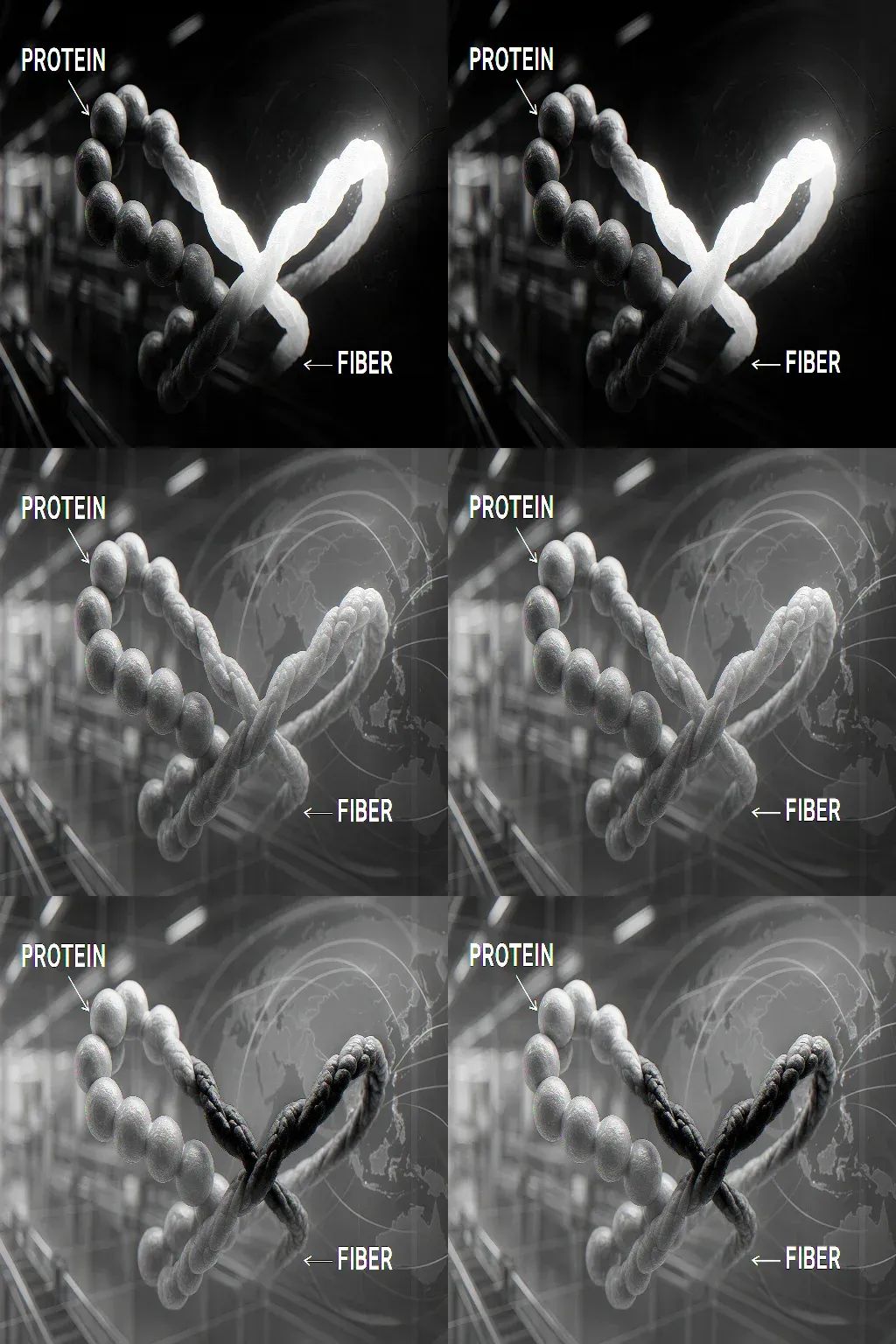

- Lane A (soluble fiber + clean sensory): use resistant dextrin as the fiber backbone for drinks and powders.

- Lane B (solid‑dose structure + processing reliability): use microcrystalline cellulose where tablets, capsules, and compression behavior matter.

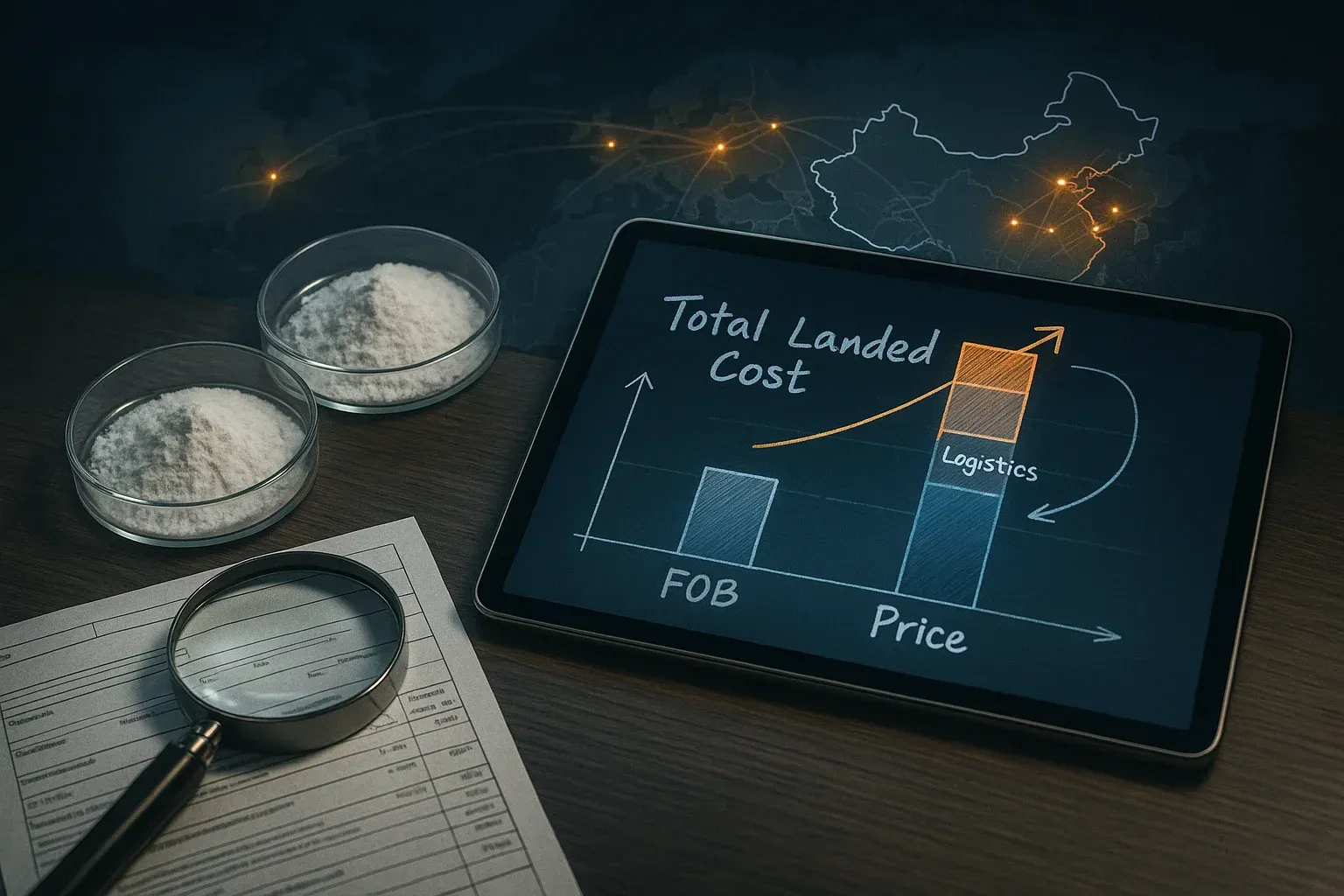

This is also why searches for a resistant dextrin supplier China and a microcrystalline cellulose supplier China often happen in the same sourcing cycle. Buyers are not just “finding an ingredient”—they are rebuilding a formulation strategy.

Ingredient fundamentals buyers should align before trials

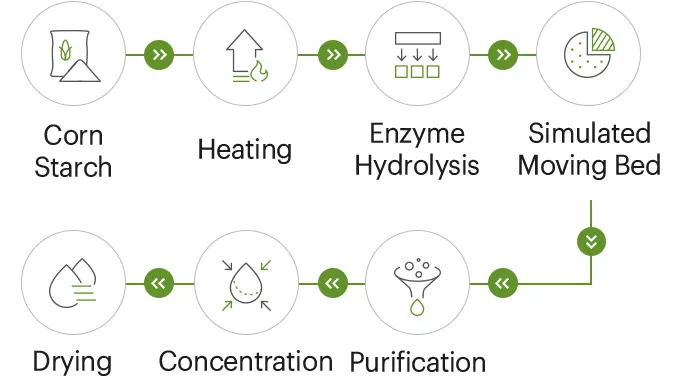

Resistant dextrin is commonly produced from starch (often corn starch). In the supplier materials used by many Shandong producers, a typical “fiber-first” option is food grade resistant dextrin 82% fiber made from NON‑GMO corn starch, with a neutral taste and good incorporation into food and beverage systems.

Microcrystalline cellulose (MCC), by contrast, is widely used as a functional excipient—most often for tablet binding, flow, and disintegration—and in some food systems as a texturizer. MCC is typically not the soluble-fiber answer for clear beverages; instead, it is the reliability tool when your format is a compressed solid or when process robustness is paramount.

Quick comparison table for reformulation conversations

| Attribute | Gum acacia (E414) | Resistant dextrin (soluble fiber) | Microcrystalline cellulose (MCC) |

|---|---|---|---|

| Primary role in many formulas | Stabilizer/emulsifier support, mouthfeel | Fiber enrichment with neutral taste | Solid-dose performance (binder/filler/disintegrant) |

| Solubility behavior | Generally soluble | Generally high solubility for beverage and powders | Insoluble; used for structure/texture |

| Viscosity impact | Can increase viscosity | Often low viscosity at practical use levels | Can increase body/opacity if used in liquids |

| Best-fit applications | Soft drinks, confectionery, emulsions | RTD beverages, powders, fiber fortification | Tablets/capsules; some food texture systems |

| What buyers should verify | Supply continuity and consistency | resistant dextrin specifications CoA (fiber %, protein, appearance, microbiology) | Grade fit (food vs pharma), GMP readiness where needed |

Formulation tip (buyer view): If your goal is “keep the drink clean and add fiber,” resistant dextrin should lead. If your goal is “make the tablet run and release consistently,” MCC should lead.

Application case study one: building a low calorie high fiber RTD beverage

This mini‑case reflects a common 2026 scenario: an RTD tea or coffee brand needs to maintain fiber claims and mouthfeel after acacia volatility, without introducing haze, grittiness, or flavor distortion.

Target product goals

- Maintain a low‑calorie positioning while adding meaningful fiber.

- Keep taste neutral; avoid a “fiber note.”

- Preserve process stability through pasteurization/UHT and typical beverage pH ranges.

Ingredient choice and why it works

A practical starting point is resistant dextrin produced from NON‑GMO corn starch and offered in commercial specs such as fiber content ≥82%. This is why many R&D teams request food grade resistant dextrin 82% fiber first: it hits the fiber threshold without forcing a thick, gummy texture.

This is also where resistant dextrin beverage application details matter more than marketing claims. For drinks, the procurement team should ask not only for a CoA, but also for handling notes on dissolution, order of addition, and any known sensory thresholds.

Suggested process approach for trials

While each plant differs, most successful trials follow a similar pattern:

- Pre‑blend in a syrup phase (or a warm water phase) to improve wetting and reduce lumping.

- Mix until fully dissolved, then add to the main batch.

- Run standard thermal processing (pasteurization/UHT) and monitor:

- clarity or haze

- sweetness perception changes

- stability over shelf-life checks

Formulation tip: In beverages, resistant dextrin is often selected because it can increase fiber content without pushing viscosity into a “diet shake” mouthfeel.

Sensory and labeling checkpoints

For a buyer, the win condition is not just “it dissolves.” It is “it scales.” Confirm these early:

- Neutral flavor and odor in the finished beverage.

- Fiber claim strategy aligned to serving size and local regulations.

- Stability checks that match your real distribution conditions.

In practice, this is why procurement teams prefer suppliers who can deliver consistent lots with repeatable resistant dextrin performance, not just a one‑time trial sample.

Application case study two: pairing resistant dextrin with MCC in supplements

Many brands now build a portfolio where beverages deliver daily fiber, and tablets/capsules support convenience or targeted positioning. In that model, resistant dextrin and MCC can be complementary:

- Resistant dextrin: the active soluble fiber component.

- Microcrystalline cellulose: the processing and performance backbone for tablets/capsules.

Where MCC earns its place

If you are qualifying a China microcrystalline cellulose manufacturer or a microcrystalline cellulose supplier China, focus on how the MCC behaves in your manufacturing reality:

- Does the grade support flow and compression consistency?

- Does it help avoid tablet defects at scale?

- Is the supplier prepared for pharmaceutical grade MCC GMP expectations when your market or customer requires it?

Practical compatibility considerations

When resistant dextrin becomes part of a tablet formula, it can change blend properties (such as moisture behavior and flow). That doesn’t make it “hard to tableting”—it simply means your excipient system must be selected deliberately.

A disciplined approach is:

- Prototype with a standard MCC grade aligned to your format.

- Evaluate compressibility, friability, and disintegration targets.

- Confirm that the resistant dextrin lot-to-lot consistency supports the same compression settings.

This is one reason buyers increasingly source resistant dextrin and MCC from suppliers who can provide strong QC documentation and respond quickly during scale-up.

Sourcing in China: what to verify beyond the brochure

China remains a major export hub for functional fibers and excipients, with common sourcing clusters referenced by buyers in Shandong, Guangdong, and Jiangsu. In fiber categories, the “Shandong resistant dextrin supplier” cluster is often mentioned because of mature capacity and export handling.

Regardless of province, a repeatable verification routine is what separates a good trial from a reliable supply chain.

The CoA checks that prevent most disputes

Ask for a lot‑based Certificate of Analysis and review it against your spec sheet. For resistant dextrin used in food and beverage, common supplier parameters include:

- Fiber content: ≥82% for many commercial beverage-first grades

- Protein content: ≤6.0% (as stated by multiple supplier product sheets)

- Appearance: white to light yellow

- Storage guidance: cool, dry conditions

For MCC, confirm grade and test methods appropriate to your market and application (food vs pharma expectations). If a supplier markets pharma readiness, buyers should expect auditability consistent with GMP requirements.

Export readiness questions procurement teams should ask

To align expectations on commercial execution (especially for global launches), confirm:

- China MCC manufacturer export MOQ lead time policies: MOQ and lead time vary by grade and packaging.

- Packaging formats, palletization, and labeling practices.

- Documentation package: CoA, allergen statements (where applicable), and any certifications the supplier claims.

What strong suppliers usually do differently

Without turning this into an audit manual, three behaviors show up consistently among reliable exporters:

- Clear alignment on specs before quoting (especially for resistant dextrin fiber percentage and microbiological limits).

- Stable quality control routines that match the CoA line-by-line.

- Fast technical support during formulation trials—because resistant dextrin and MCC are process ingredients, not just commodities.

Buyer checklist for recommended supplier shortlists

Use this checklist to build an internal, reusable template when shortlisting a Recommended Chinese Resistant Dextrin Manufacturer and evaluating a Recommended Chinese Microcrystalline Cellulose Supplier.

Buyer Checklist (copy/paste ready)

- Confirm application fit: beverage, powder, tablet, or mixed portfolio.

- Request a current CoA and compare to your spec: fiber ≥82% (where required), protein limit, appearance, and storage guidance.

- Ask for a manufacturing overview and QC capability summary; confirm consistency steps.

- Clarify commercial execution: MOQ, lead time, packaging, and export documents.

- Run a trial plan that includes at least one heat step (for beverages) or compression run (for tablets).

- Decide whether MCC must meet food-grade requirements or pharma expectations (GMP readiness).

For procurement teams who prefer starting with concrete examples of compliant product pages and technical positioning, established Chinese producers featured on industry directories can be a useful reference point. One place to review resistant dextrin product information and related functional fiber lines is www.sdshinehealth.com.

Closing perspective

Fiber-forward innovation will keep accelerating, but procurement risk will remain part of the equation—especially for legacy ingredients tied to a narrow supply region. A two‑ingredient plan built around resistant dextrin (for soluble fiber delivery) and microcrystalline cellulose (for solid-dose reliability) helps teams move faster with fewer surprises.

When the next disruption hits, the brands that win won’t be the ones with the “perfect” single substitute. They’ll be the ones with a qualified sourcing system—and ingredients selected for the job they actually need to do.