A buyer-focused 2026 guide to using resistant dextrin in diet powders and gummies—specs, sensory trade-offs, and sourcing checkpoints in China.

Fiber’s 2026 turning point: why specs matter more than slogans

Market coverage going into 2026 consistently highlights fiber and gut health as a top consumer-driven trend. The operational consequence is that R&D teams are asking procurement for more soluble dietary fiber applications—but with stricter sensory and processing constraints.

In practice, a modern brief for resistant dextrin often includes:

- A defined fiber content floor (e.g., “resistant dextrin 82% fiber” as a minimum requirement for certain formats)

- Solubility and viscosity expectations for beverages and powders

- Storage and packaging stability markers (e.g., low water activity targets)

- Microbiology and heavy-metal fields suited to export markets

For buyers, the key is to translate “fiber-first” into purchase-ready language: measurable attributes, test methods, and pass/fail criteria.

Application solution 1: Diet powders and stick packs that stay smooth

Diet powders (including stick packs) are one of the most forgiving formats for rapid launches—but they can be unforgiving in consumer feedback. Grittiness, off-notes, and clumping are the top reasons a product gets reformulated after scale-up.

Where resistant dextrin helps in diet powder design

A well-chosen resistant dextrin can support diet powders by adding fiber grams with minimal taste impact and low viscosity behavior (a common buyer priority when “high fiber” must still dissolve fast).

In procurement terms, diet powder projects tend to reward a resistant dextrin supplier that can document:

- Consistent appearance (white to light yellow is a common commercial expectation)

- Stable fiber content per COA across lots

- Handling behavior that reduces caking risk (buyers often ask about hygroscopicity and storage guidance)

A practical spec template buyers can send suppliers

Below is a compact example of the kinds of fields buyers typically standardize for diet powders. Values shown reflect common supplier disclosures used in commercial trade (actual limits should match the buyer’s internal standards and target market).

| COA / TDS item | Why it matters in diet powders | Typical buyer check |

|---|---|---|

| Product identification | Prevents substitution across fiber types | Clear naming + batch ID |

| Fiber content | Drives claim math and serving design | Minimum floor (often ≥82% fiber for certain briefs) |

| Appearance / color | Impacts consumer perception | White to light yellow |

| Protein content | Supports labeling consistency | Upper limit control |

| Storage conditions | Impacts shelf-life planning | “Store in a cool place” guidance |

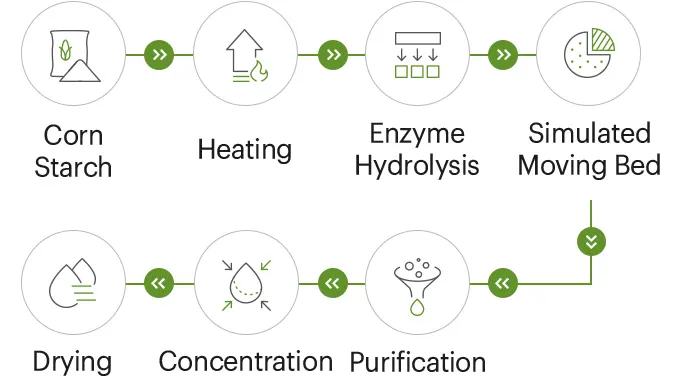

A number of Chinese producers position resistant dextrin built from NON-GMO corn starch and highlight automated production steps from feeding to filling, which can matter when diet powder volumes spike.

Formulation guardrails that reduce post-launch surprises

From a buyer’s perspective, the most common powder failures are predictable—and preventable with the right resistant dextrin checklist:

- Clumping after humidity exposure: align packaging and warehouse conditions with the supplier’s storage instructions; confirm whether the resistant dextrin is prone to moisture pickup in your climate.

- Flavor “lift” in high-protein blends: neutral-taste expectations should be validated in the final matrix (whey/casein, cocoa, coffee, botanicals). A resistant dextrin that tastes neutral in water can behave differently in flavored systems.

- Too-thick mouthfeel in high-dose servings: for powders intended to be consumed quickly, procurement should request viscosity behavior guidance and sample quantities sized for realistic bench trials.

Application solution 2: Low-sugar gummies and soft chews that don’t turn rubbery

Gummies and soft chews are now a primary delivery format for fiber-forward claims because they are portion-controlled and convenient. But high fiber loads can destabilize texture, increase stickiness, or amplify off-tastes.

Why resistant dextrin is frequently specified for gummies

In gummy systems, resistant dextrin is often used as a soluble fiber component that supports:

- Sugar reduction without collapsing the bite

- Fiber enrichment without adding visible particulates

- A cleaner eating experience compared with some coarse fiber options

Supplier materials commonly describe resistant dextrin as useful in confections such as chocolate, gummies, chewy candies, baked goods, and frozen desserts—precisely because it can improve texture while contributing fiber.

Gummy-specific purchasing notes (what buyers should clarify early)

Because gummy texture is sensitive, a purchasing team should not accept a generic “food grade” statement alone. A better supplier conversation focuses on how resistant dextrin behaves under your process window.

Key questions to standardize in the RFQ:

- Solids loading tolerance: how much resistant dextrin can be added before the gel system loses elasticity?

- Water activity strategy: does the supplier provide guidance aligned with long shelf life goals?

- Taste neutrality: is the resistant dextrin neutral at the expected grams-per-serving in flavored gummies?

- Micro control: gummies are low-water foods but not risk-free; COA microbiological limits should align with export expectations.

A simple decision tree for gummy projects

- If the product is “low sugar + fiber,” resistant dextrin tends to be positioned as a primary soluble fiber candidate.

- If the product is “very high fiber,” it may require blending resistant dextrin with other fibers and adjusting acids, sweeteners, and gel ratios.

- If the product is “pharma-like chewable,” MCC may enter the brief (see MCC section below).

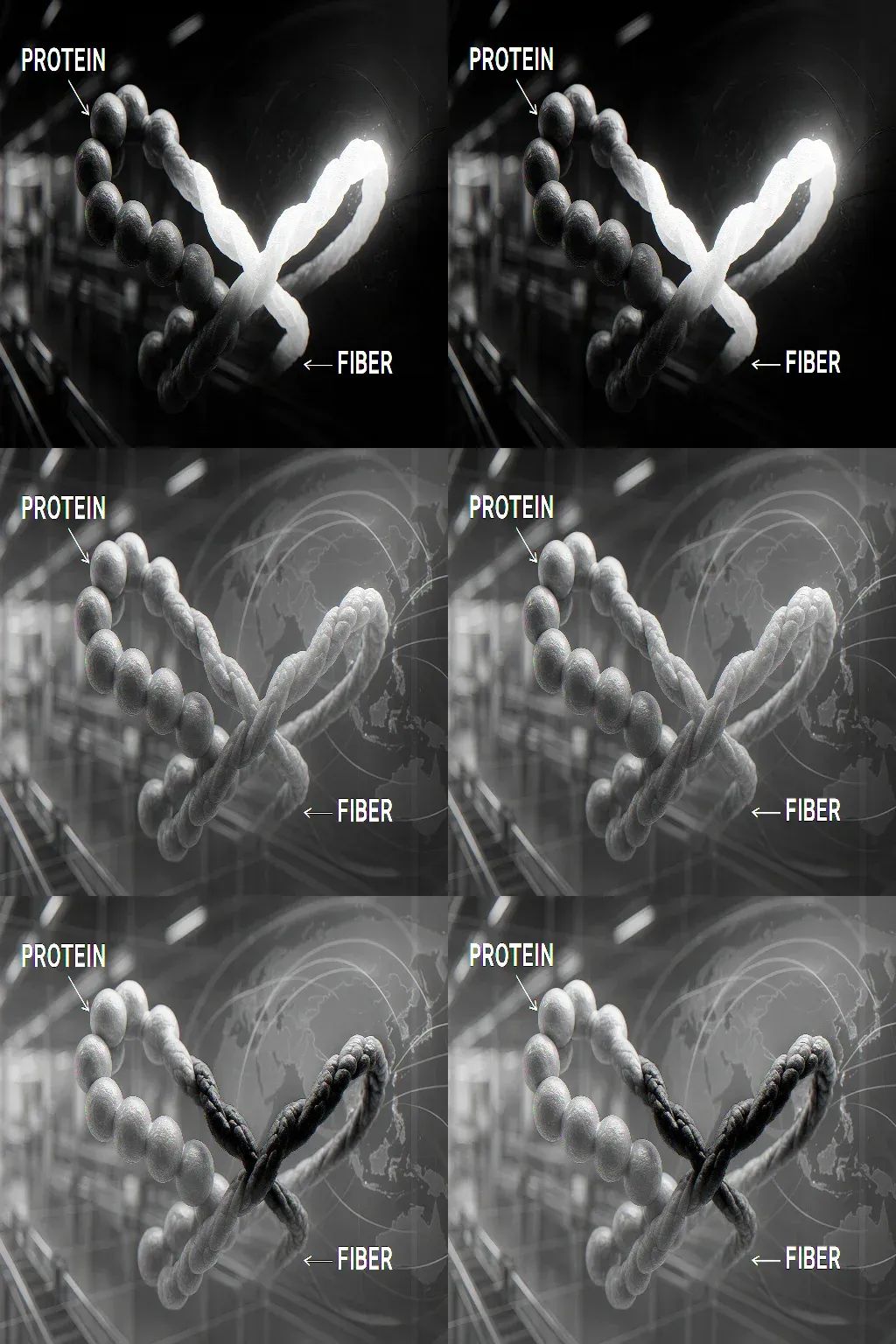

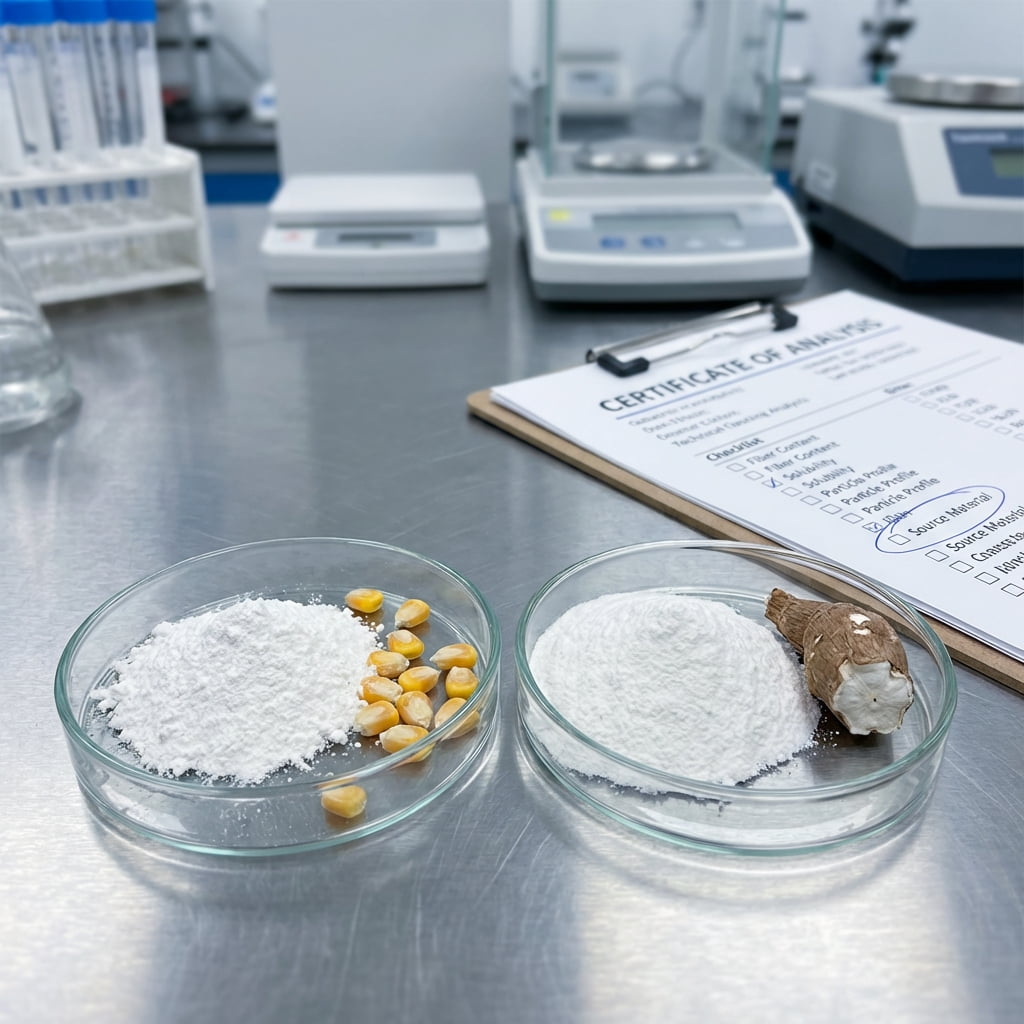

Prebiotic tapioca vs maize resistant dextrin: trade-offs that affect buying specs

Procurement teams increasingly receive briefs that mention tapioca-based fibers and corn-based fibers in the same sentence, especially when brands want label flexibility or regional sourcing options.

What changes when the source changes

Even when the label is “resistant dextrin,” buyers should treat source and process as meaningful variables:

- Maize/corn origin resistant dextrin: widely used, often positioned with NON-GMO corn starch sourcing. Buyers frequently focus on consistent lot performance and export documentation.

- Tapioca-derived resistant dextrin / prebiotic tapioca fiber: often evaluated for formulation preferences (and sometimes for market-specific labeling or consumer perception).

The procurement takeaway is straightforward: if the product brief allows both, the RFQ should still request the same COA fields, so that switching between tapioca and corn resistant dextrin does not silently change functional performance.

Buyer-friendly comparison (what typically matters in real formulations)

| Decision factor | Why it matters | What to require from the resistant dextrin supplier |

|---|---|---|

| Taste neutrality | Drives repeat purchase in powders and gummies | Bench samples + sensory notes in target matrix |

| Solubility / clarity | Impacts RTD-like powders and drinkable mixes | Dissolution guidance and stability notes |

| Viscosity | Controls mouthfeel and processing | Low-viscosity expectation defined |

| Supply stability | Avoids reformulation due to shortages | Traceability, capacity, lead time discipline |

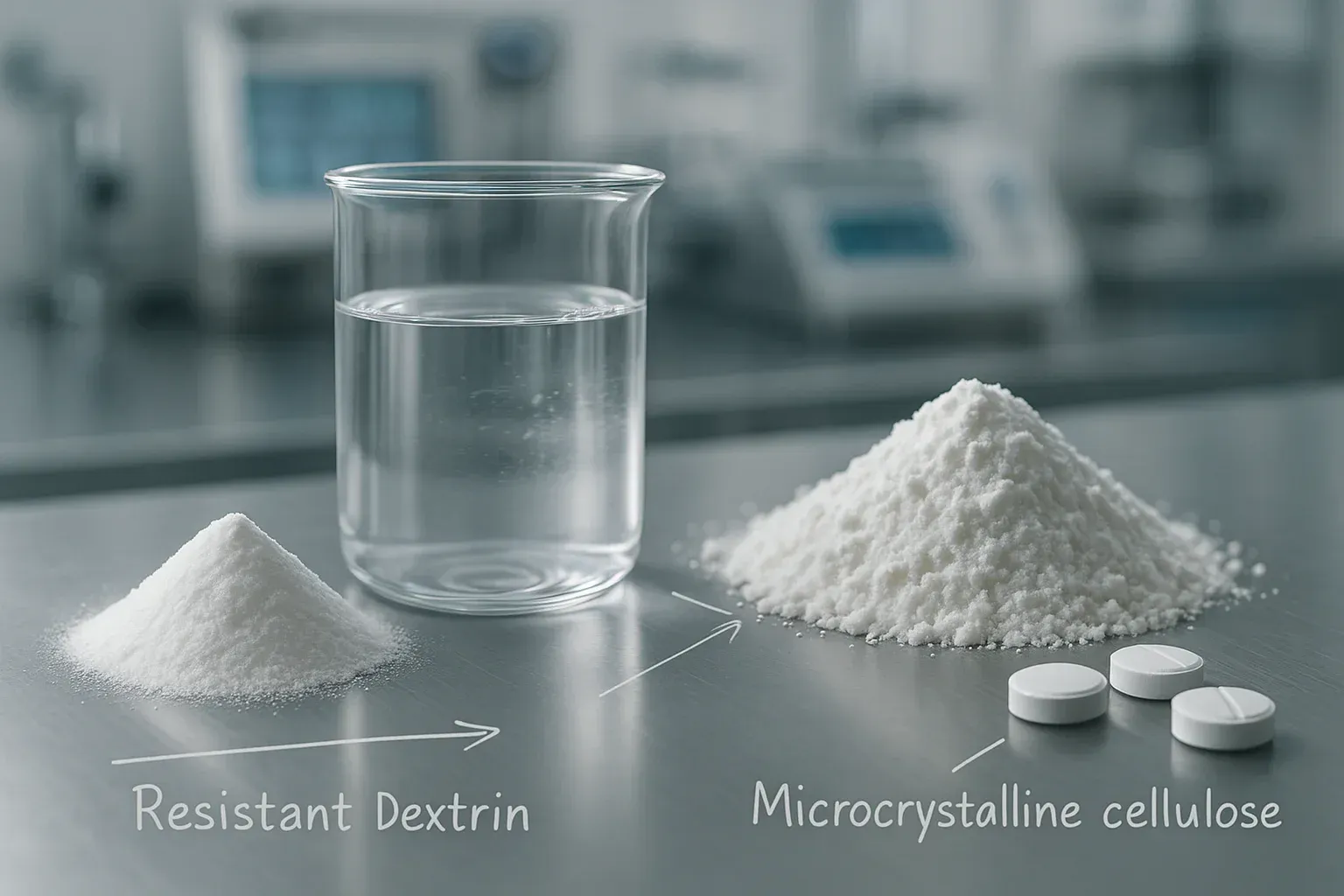

When MCC enters the brief: chewables, tablets, and “solid format” satiety SKUs

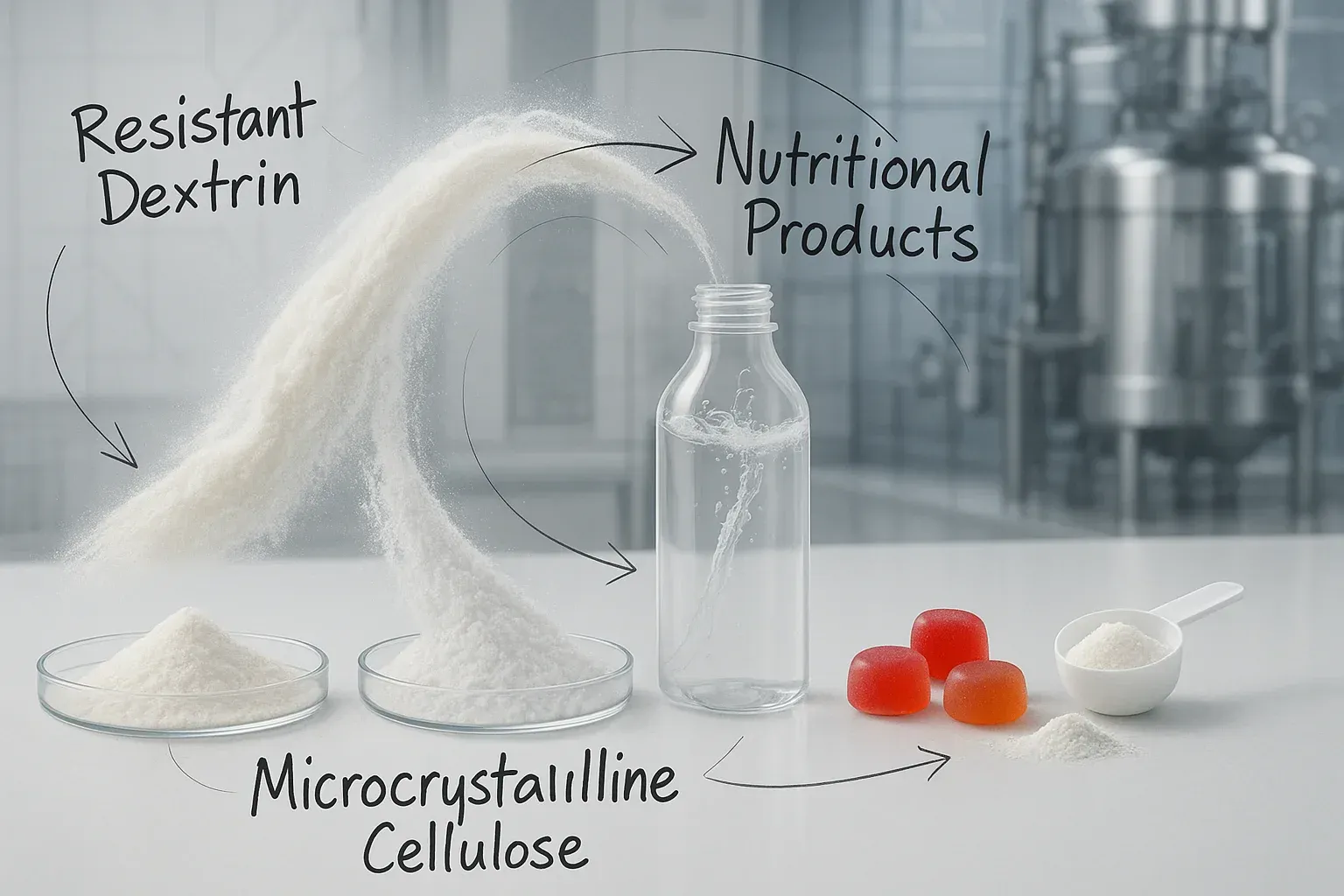

While resistant dextrin dominates many soluble-fiber briefs, some 2026 product roadmaps include tablets, capsules, or chewable formats where microcrystalline cellulose (MCC) becomes a functional necessity.

Why buyers still source MCC alongside resistant dextrin

MCC is widely used as a tablet excipient (binder/filler and processing aid depending on the formula). In fiber-forward or satiety-positioned supplement lines, MCC can appear in:

- Chewable tablets (texture management and compression behavior)

- Capsules or compressed tablets paired with resistant dextrin in the same product platform

This is why the sourcing conversation often becomes dual-track: find a reliable resistant dextrin supplier and, in parallel, confirm access to a microcrystalline cellulose supplier China that can deliver consistent pharmacopeia-aligned COAs.

PH101 vs PH102: what the buyer is really checking

Even without going deep into pharmacopeia text, most procurement teams use PH grades as shorthand for manufacturability.

- PH101: commonly associated with a finer powder-like profile.

- PH102: commonly associated with a coarser, more granular profile and different bulk density behavior.

The practical message: if the manufacturer’s process is direct compression vs wet granulation, the wrong grade can cause flow issues, weight variation, or hardness problems. So MCC sourcing is not “commodity buying”—it is a process fit decision.

A COA checklist buyers can standardize for MCC and resistant dextrin

Below is a compact checklist that aligns well with day-to-day qualification workflows.

| Document field | Resistant dextrin focus | MCC focus |

|---|---|---|

| Identity / description | Fiber type and batch clarity | Grade and identity clarity (PH101/PH102) |

| Core functional parameter | Fiber content floor | Particle profile / bulk behavior indicators |

| Loss on drying / moisture | Powder stability and flow | Tablet processing stability |

| Micro limits | Export readiness | Pharmacopeia-aligned micro expectations |

| Traceability | Raw material and lot records | Lot records and consistent release process |

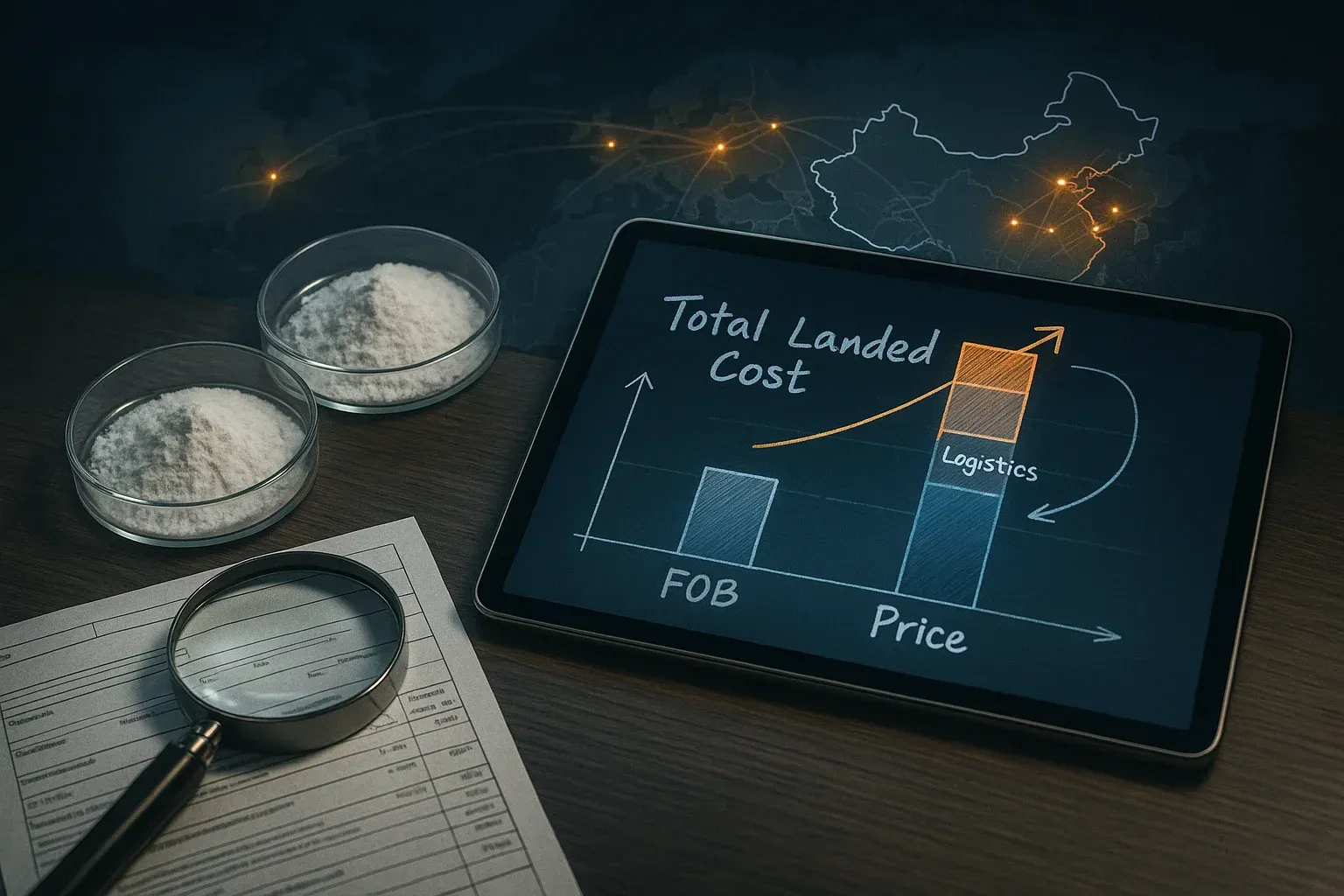

China sourcing implications: what “recommended” means in 2026

China remains a central manufacturing base for soluble fibers and excipient supply chains. In 2026, however, procurement teams increasingly define “recommended” suppliers by operational evidence—not by marketing language.

What buyers should look for in a recommended Chinese resistant dextrin manufacturer

A Recommended Chinese Resistant Dextrin Manufacturer is typically expected to show:

- Raw material clarity (commonly NON-GMO corn starch, with traceability logic)

- Automated production control from feeding to filling (reduces human variability)

- In-house QC capability supported by routine testing and batch COAs

- Application support that can answer matrix-specific questions for powders and gummies

The same logic extends to MCC. A Recommended Chinese Microcrystalline Cellulose Manufacturer or Recommended Chinese Microcrystalline Cellulose Supplier is generally the one that can deliver grade clarity and documentation discipline that fits a regulated workflow.

What procurement teams are updating in their audit scripts

To align with 2026 demand patterns, many buyers tighten three audit areas:

- Documentation review: batch COA format consistency, MSDS availability, certification validity (GMP/HACCP/ISO-type systems), and sample retention policy.

- Process controls: cleaning procedures, cross-contamination controls, environmental monitoring mindset, and deviation handling.

- Release discipline: how a lot is approved, how OOS results are managed, and whether corrective actions are documented.

A neutral industry example: where to see common supplier positioning

For buyers building a shortlist, it can be useful to review how established ingredient exporters describe their resistant dextrin and supporting systems (R&D teams, QC labs, export coverage, and documented parameters like ≥82% fiber). One example site used by international buyers for orientation is:

This kind of reference is not a substitute for audit work, but it helps procurement teams benchmark how a potential resistant dextrin supplier presents specs, applications, and quality infrastructure.

Buyer takeaways (what to lock into the next RFQ)

The fastest way to derisk a 2026 fiber launch is to standardize how resistant dextrin and MCC are specified, sampled, and verified—before scale-up.

- Write the brief like a COA, not like marketing. A resistant dextrin spec should include fiber content floor, appearance, storage guidance, and micro expectations.

- Match resistant dextrin to the format. Diet powders reward solubility and low viscosity; gummies reward texture stability and taste neutrality.

- Treat tapioca vs maize as a controlled variable. If the brand wants optionality, require comparable COA fields so that switching does not change performance.

- Bring MCC in only when the format demands it. For chewables and tablets, align PH grade choice with the manufacturing route.

- Define “recommended” in operational terms. A Recommended Chinese Resistant Dextrin Manufacturer is the one that can prove traceability, automation discipline, and QC readiness—not just supply volume.

Procurement-ready next step: If a sourcing team needs a practical shortlist of suppliers that match the RFQ framework above (resistant dextrin + MCC), it helps to request standardized COA templates and sample packs sized for real formulations, not just bench demos. This resistant dextrin product category page is one place buyers use to start comparing specification language and application positioning.

FAQ

Q: What is the main difference between PH101 and PH102 MCC?

A: The primary difference lies in particle size and bulk density. PH101 is generally finer and used for wet granulation, while PH102 is coarser with better flowability, making it suitable for direct compression in tablet manufacturing.

Q: Can resistant dextrin be used in sugar-free gummies without affecting texture?

A: Yes, resistant dextrin is a preferred bulking agent for sugar-free gummies. It helps maintain the structural integrity and "bite" of the gummy when sugar is removed, without introducing unwanted crystallization or gumminess.

Q: How do I verify if a resistant dextrin supplier is reliable?

A: Look for operational evidence: traceability of raw materials (like non-GMO corn starch), automated production capabilities, in-house QC labs that can produce consistent COAs, and valid third-party certifications (ISO, HACCP, etc.).